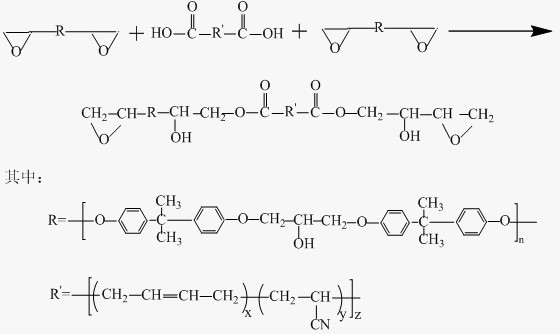

High-performance thermosetting epoxy asphalt binder and preparation method thereof

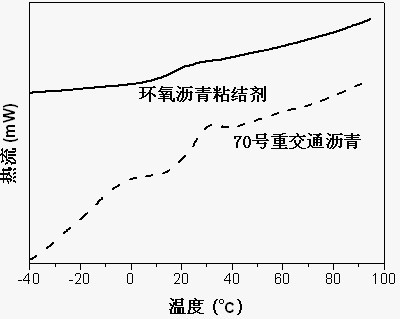

An epoxy asphalt and thermosetting technology, which is applied in the direction of asphalt material adhesives, adhesives, epoxy resin glue, etc., can solve the problems of easy softening and decreased adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Take by weighing 100 parts of bisphenol A type glycidyl ether epoxy resin (E51) (provided by Wuxi Resin Factory), add respectively 20 parts of liquid carboxylated nitrile rubber (CTBN) (provided by China Petroleum Lanzhou Petrochemical Company) and 0.5 Parts of triphenylphosphine (TPP) (Suzhou Jinyuan Fine Chemical Co., Ltd.), start stirring, and gradually increase the temperature to 130 ° C, react for 2 hours and cool to room temperature, add 8 parts of allyl glycidyl ether (USA provided by Huntsman Company) to obtain a rubber-toughened modified epoxy resin (component A).

Embodiment 2

[0030] Embodiment 2: take by weighing 100 parts of bisphenol A type glycidyl ether epoxy resins (E51), add 35 parts of liquid carboxyl nitrile rubbers (CTBN) and 2 parts of triphenylphosphine (TPP) respectively, start to stir, and gradually Raise the temperature to 160°C, react for 5 hours, then cool to room temperature, and add 20 parts of allyl glycidyl ether to obtain a rubber-toughened and modified epoxy resin, which is component A of the epoxy asphalt binder.

[0031] The preparation method of component B of high-performance epoxy asphalt binder is as follows:

Embodiment 3

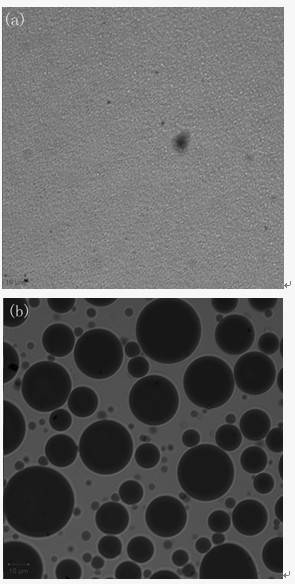

[0032] Example 3: Weigh 300 parts of No. 70 heavy traffic asphalt (provided by Zhonghai Asphalt (Taizhou) Co., Ltd.), 150 parts of hexadecenyl succinic anhydride (HDSA) (provided by Dixie Chemical Company of the United States), 10 parts of nonylphenol (NP) (provided by Huntsman, USA), 2 parts of sodium petroleum sulfonate (provided by Sinopec Anqing Petrochemical Plant) and 100 parts of rubber extender oil (provided by Shandong Xinli Petrochemical Co., Ltd.), heated to 130 ° C and mixed , and then transfer the mixture to a colloid mill for high-speed shear dispersion, the mixing time is 10min, and the mixture is cooled to room temperature to obtain the B component of the epoxy asphalt binder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com