Polyhydroxy polybutadiene liquid rubber and controllable preparation method thereof

A technology of polyhydroxy polybutadiene and aldehyde-terminated polybutadiene, which is applied in the field of polyhydroxy polybutadiene liquid rubber and its controllable preparation, can solve the problem of no industrialization prospect, complex process, and difficulty in realizing large quantities Production and other issues, to achieve a wide range of industrial application prospects, the effect of simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

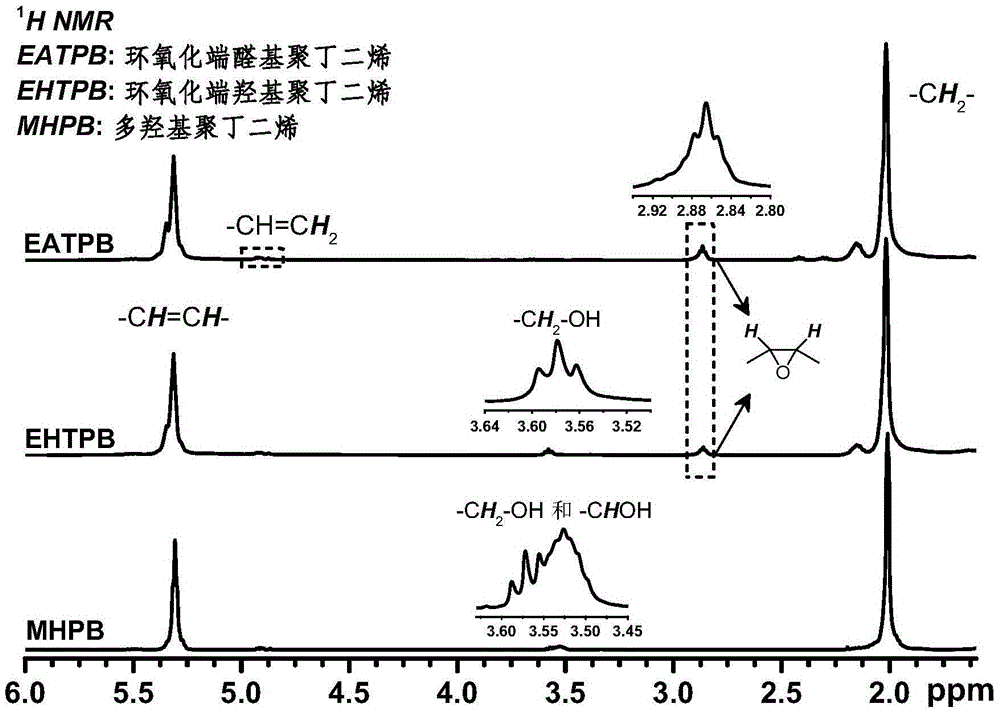

[0054] Take 5.00g of nickel-based butadiene rubber (BR9000), dissolve it completely in 100mL of tetrahydrofuran, the rubber concentration is 50g / L, keep the temperature at 30°C, add m-chloroperoxybenzoic acid under vigorous stirring, the amount of m-chloroperoxybenzoic acid is 2% of the butadiene structural unit in nickel-based butadiene rubber (BR9000), the reaction time is 6 hours, and the product is precipitated with a large amount of ethanol and dried in vacuum. product by 1 HNMR showed that the epoxy rate was 2.0%.

[0055] Take 4.00g of the above-mentioned epoxidized butadiene rubber, completely dissolve it in 100mL of tetrahydrofuran, the rubber concentration is 40g / L, keep the temperature at 30°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group is 1 :2, reacted for 30 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized terminal aldehyde polybutadiene liquid rubber, and the product is passed through...

Embodiment 2

[0058] Take 5.00g of cobalt-based butadiene rubber (Taipol), dissolve it completely in 200mL of cyclohexane, the rubber concentration is 25g / L, keep the temperature at 50°C, add m-chloroperoxybenzoic acid and m-chloroperoxybenzoic acid under vigorous stirring The dosage is 4% of the butadiene structural unit in cobalt-based butadiene rubber (Taipol), the reaction time is 4 hours, and the product is precipitated with a large amount of ethanol and dried in vacuum. product by 1 HNMR showed that the epoxy rate was 4.0%.

[0059] Take 4.00g of the above-mentioned epoxidized butadiene rubber, completely dissolve it in 100mL of dichloromethane, the rubber concentration is 40g / L, keep the temperature at 10°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group The ratio is 1:4, and the reaction time is 40 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized aldehyde-terminated polybutadiene liquid rubber, and the epoxy...

Embodiment 3

[0062] Take 5.00g of neodymium-based butadiene rubber (BR9100), dissolve it completely in 100mL of toluene, the rubber concentration is 50g / L, keep the temperature at 70°C, and add (1S,2S)-(+)-[1,2- Cyclohexanediamine nitrogen-N,N'-bis(3,5-di-tert-butyl salicylidene)] manganese(III) chloride 0.005g, the amount of sodium hypochlorite is butyl in neodymium-based butadiene rubber (BR9100) 8% of the diene structural unit, the reaction time is 2 hours, the product is precipitated with a large amount of ethanol and dried in vacuo. product by 1 HNMR showed that the epoxy rate was 8.0%.

[0063] Take 4.00g of the above epoxidized butadiene rubber, completely dissolve it in 100mL of toluene, the rubber concentration is 40g / L, keep the temperature at 50°C, add periodic acid under vigorous stirring, the molar ratio of periodic acid to epoxy group is 1 :8, reacted in 50 minutes. The product can be filtered to obtain high cis-1,4 content epoxidized aldehyde-terminated polybutadiene liqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com