Intelligent surface construction method capable of achieving wettability conversion and device therefor

A construction method and wettability technology, applied in the field of intelligent surface manufacturing, can solve the problems of complex preparation methods and chemical dependence, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

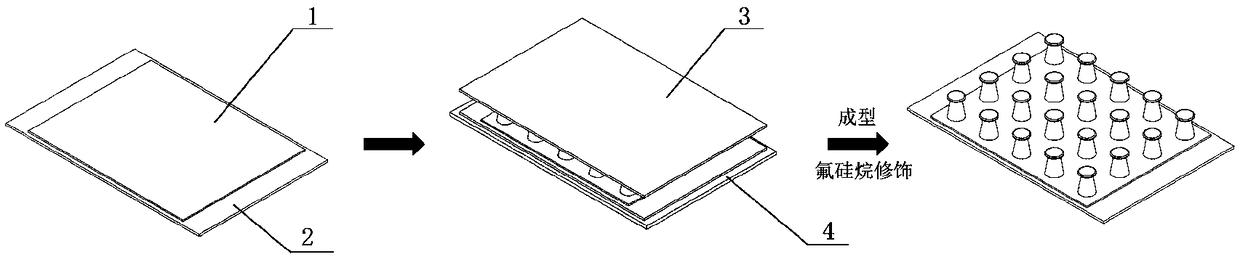

[0025] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the device used in the method includes a substrate 2, an anti-adhesive flat plate 3, a magnet 4 and a liquid rubber and magnetic particle mixture 1, the substrate 2 is placed on the magnet 4, the anti-adhesive flat plate 3 is located above the substrate 2, and the substrate 2 is coated with There is a mixture 1 of liquid rubber and magnetic particles, and the mixture 1 of liquid rubber and magnetic particles is located between the substrate 2 and the anti-adhesive plate 3 .

[0026] 1) After mixing polydimethylsiloxane (PDMS) prepolymer (the mass ratio of main agent and curing agent is 20:1) and magnetic carbonyl iron particles with a particle size of 1-10 μm in a mass ratio of 1:0.6, The mixture 1 of liquid rubber and magnetic particles is formed, and the mixture 1 of liquid rubber and magnetic particles is scraped on a glass slide to form a film with a thickness of 70 μm.

[0027] 2) Fi...

Embodiment 2

[0030] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the device used in the method includes a substrate 2, an anti-adhesive flat plate 3, a magnet 4 and a liquid rubber and magnetic particle mixture 1, the substrate 2 is placed on the magnet 4, the anti-adhesive flat plate 3 is located above the substrate 2, and the substrate 2 is coated with There is a mixture 1 of liquid rubber and magnetic particles, and the mixture 1 of liquid rubber and magnetic particles is located between the substrate 2 and the anti-adhesive plate 3 .

[0031] 1) After mixing polydimethylsiloxane (PDMS) prepolymer (the mass ratio of main agent and curing agent is 20:1) and magnetic carbonyl iron particles with a particle size of 1-10 μm in a mass ratio of 1:0.8, The mixture 1 of liquid rubber and magnetic particles is formed, and the mixture 1 of liquid rubber and magnetic particles is scraped on a glass slide to form a film with a thickness of 80 μm.

[0032] 2) Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com