Regulatable hydraulic machine with up and down both double moving

A hydraulic press, adjustable technology, applied to the driving device of stamping press, press, forging press, etc., can solve the problems of increasing the structural complexity and manufacturing cost of the hydraulic press, and the compound forming that cannot perform reverse blanking at the same time, to achieve Save manufacturing raw materials and special hydraulic components, good application prospects and market prospects, and improve the effect of energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

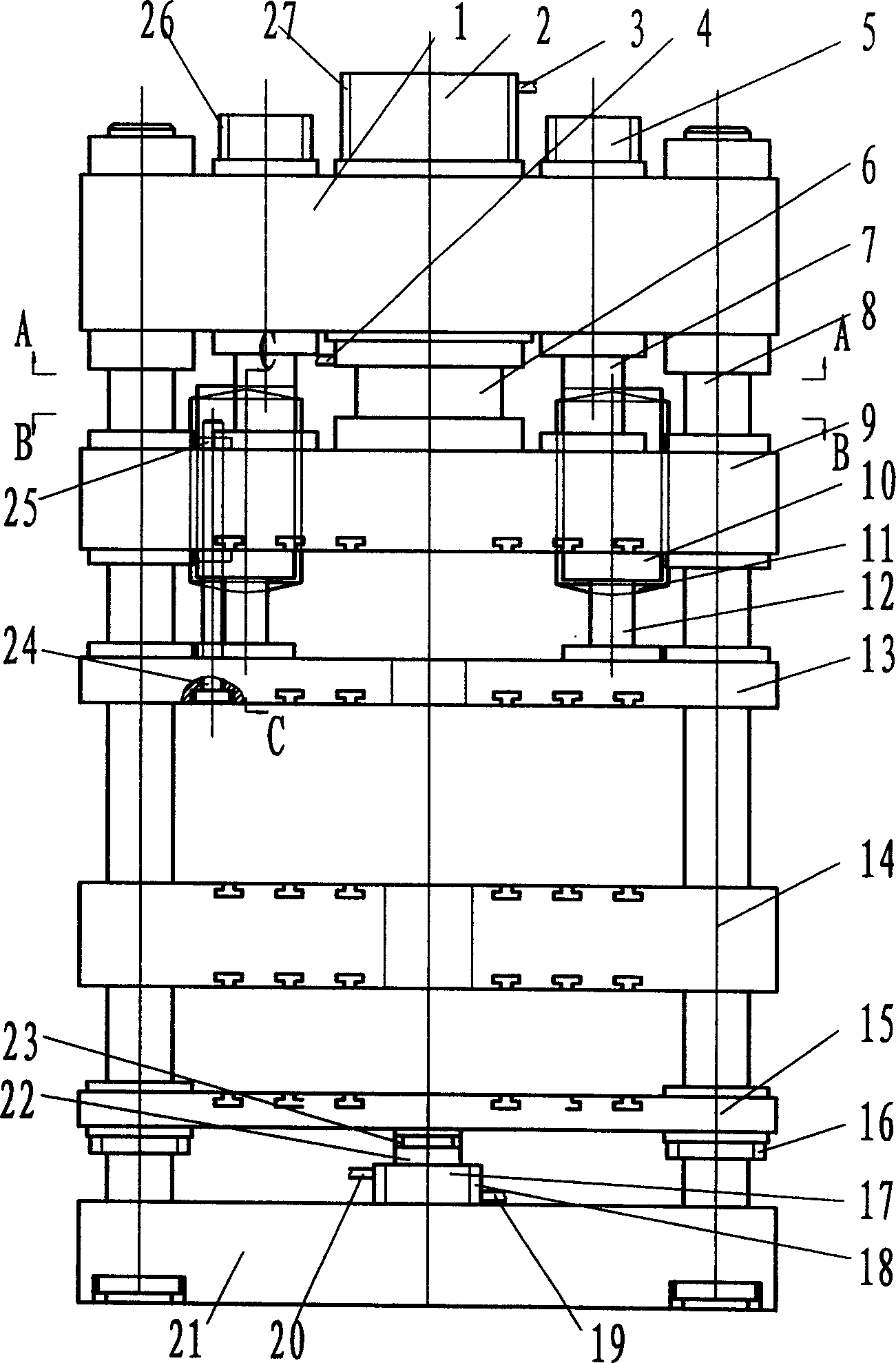

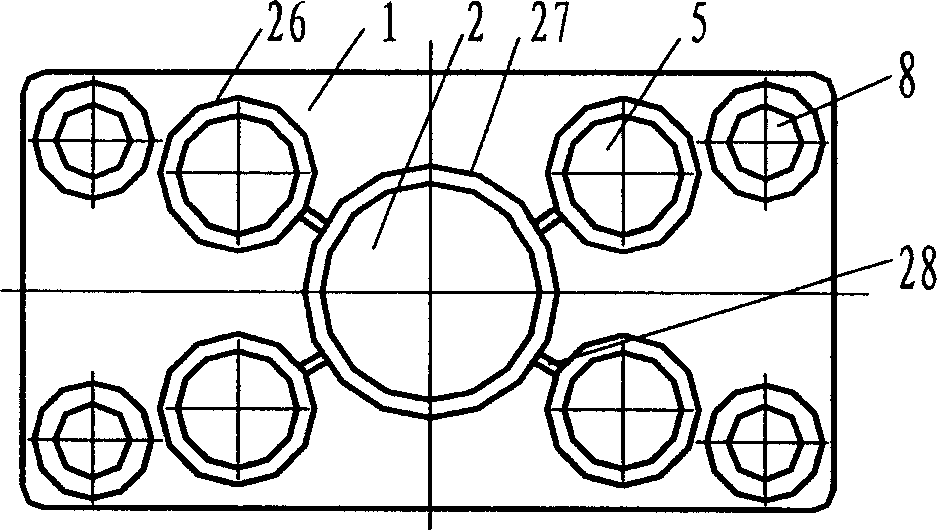

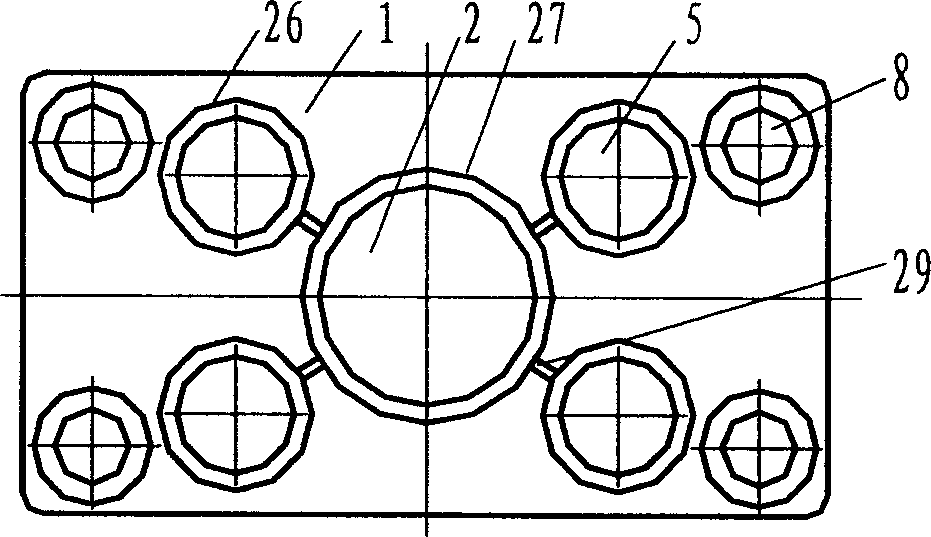

[0038] The specific structure of the present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

[0039] refer to Figures 1 to 4 , the four-column adjustable hydraulic press is double-moving up and down, the upper beam 1, the main slider 9, the edge slider 13, the workbench 14, the floating workbench 15 and the lower beam 21 are mounted on the four columns 8, The upper beam 1, the workbench 14, the lower beam 21 and the column 8 are all fastened with nuts, and the strength and rigidity of the overall structure of the hydraulic press must be ensured. Between 14, it is a sliding fit with the column 4, and to ensure good fit accuracy and wear resistance, the floating workbench 15 is installed between the workbench 14 and the lower beam 21, and it is also a sliding fit with the column 8, and the floating work The table limit nut 16 can limit the floating table 15 to a predetermined height, and a T-shaped fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com