Low-yield ratio and high-strength steel for bridges and manufacturing method thereof

A low yield ratio, bridge steel technology, applied in the field of high-performance structural steel and its manufacturing, can solve the problems of low strength, can not meet the high yield ratio of high-performance bridge engineering steel, achieve short production cycle, The structure and properties are uniform, and the effect of enhancing the toughness and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

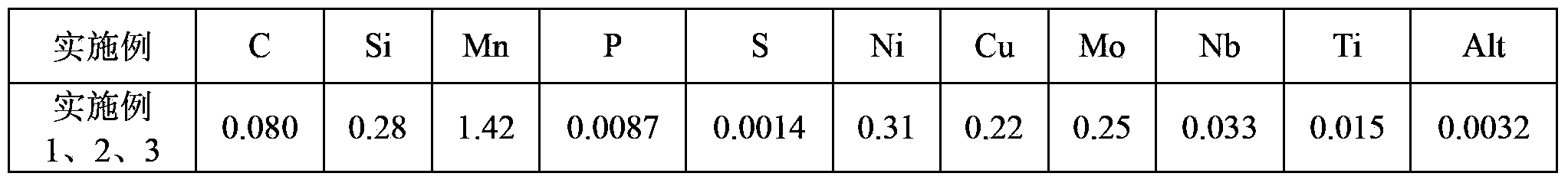

[0029] The main chemical composition (wt%) of a low yield ratio high-strength bridge steel provided in Examples 1-3 is shown in Table 1; Table 1 The main chemical composition (wt%) of the embodiment of the present invention

[0030]

[0031] The two-stage controlled rolling technology of the austenite recrystallization zone and the austenite non-recrystallization zone is adopted. The rough rolling uses a large reduction in the pass to break the austenite grains, and the rough rolling, finish rolling control and post-rolling control are carried out in sequence. Cooling, turning red, finally air cooling; the rough rolling finish rolling temperature of embodiment 1-3, finishing rolling control opening temperature and turning red temperature are as shown in table 2;

[0032] Table 2 Rolling cooling process parameter table

[0033] Example

Thickness mm

Rough rolling finish temperature ℃

Finish rolling start temperature ℃

Finishing temperature ℃

Retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com