Weathering steel and manufacturing method thereof

A technology of weathering steel and controlled rolling, which is applied in the field of weathering steel and its manufacturing, can solve the problems of slow solidification cooling speed, macro cracks, high production cost, etc., achieve sustainable development, improve corrosion resistance, and promote recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

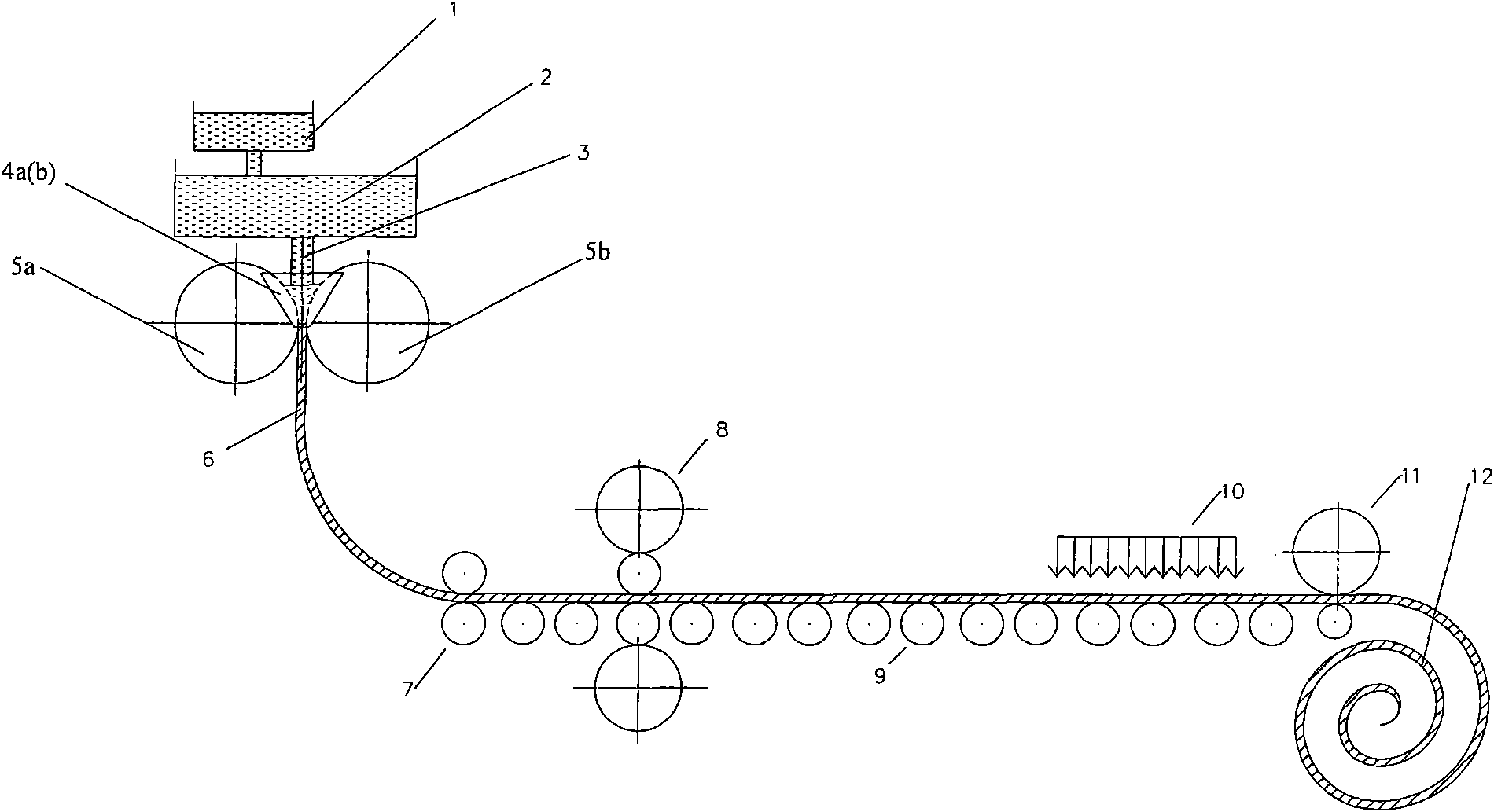

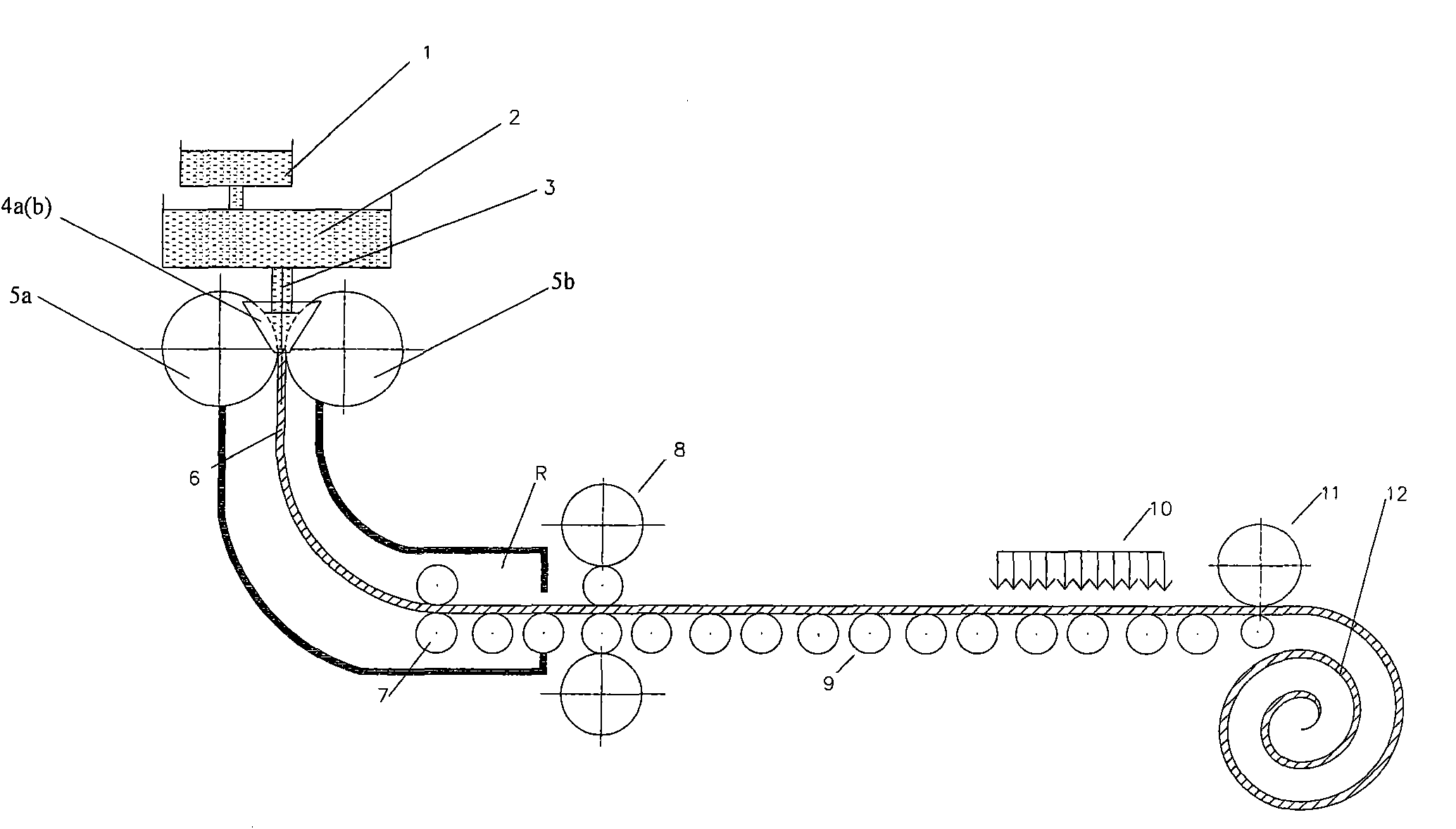

Method used

Image

Examples

Embodiment 1

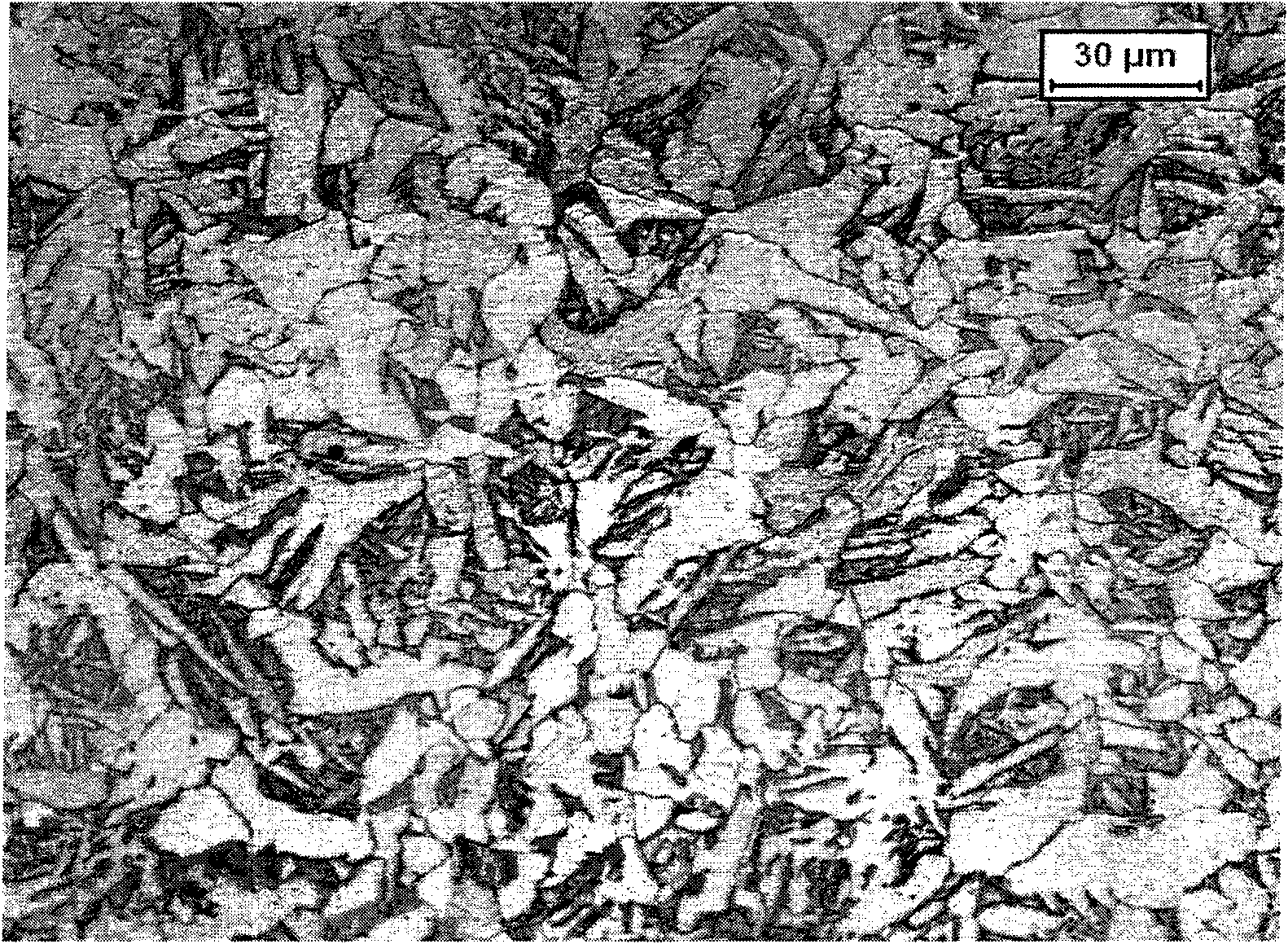

[0060] 1. Manufacture of steel in this embodiment: through deep desulfurization of molten iron, top-bottom compound blowing of converter, RH vacuum cycle degassing process, calcium treatment, twin-roll continuous casting, passing through closed space R, controlled rolling, controlled cooling and Coiled to obtain finished steel with the chemical composition shown in Table 2 below, wherein the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7. image 3 It is the typical microstructure morphology of the steel in this example. It can be seen from the microstructure that the structure type of the steel in the present invention is mainly acicular ferrite.

[0061] Chemical composition (wt%) of steel of table 2 embodiment 1

[0062]

[0063] 2. Atmospheric corrosion resistance test: Taking ordinary carbon steel Q345B and high-strength weathering steel Q450NQR1 as comparison samples, a 72h periodic infiltration cyclic corrosion test was car...

Embodiment 2

[0065] 1. Manufacture of steel in this embodiment: through deep desulfurization of molten iron, top-bottom compound blowing of converter, RH vacuum cycle degassing process, calcium treatment, twin-roll continuous casting, passing through closed space R, controlled rolling, controlled cooling, Coiled to obtain finished steel with the chemical composition shown in Table 3 below, wherein the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7. The structure type of the steel in this example is mainly acicular ferrite type.

[0066] Chemical composition (wt%) of steel of table 3 embodiment 2

[0067]

[0068] 2. Atmospheric corrosion resistance test: Taking ordinary carbon steel Q345B and high-strength weathering steel Q450NQR1 as comparison samples, a 72h periodic infiltration cyclic corrosion test was carried out according to the weathering steel periodic infiltration corrosion test method (TB / T2375-93). The average corrosion rate is o...

Embodiment 3

[0070] 1. Manufacture of steel in this embodiment: through deep desulfurization of molten iron, top-bottom compound blowing of converter, RH vacuum cycle degassing process, calcium treatment, twin-roll continuous casting, passing through closed space R, controlled rolling, controlled cooling, Coiled to obtain finished steel with the chemical composition shown in Table 4 below, wherein the process parameters are shown in Table 6, and the mechanical properties are shown in Table 7. The structure type of the steel in this example is mainly acicular ferrite type.

[0071] The chemical composition (wt%) of table 4 embodiment 3 steels

[0072]

[0073] 2. Atmospheric corrosion resistance test: Taking ordinary carbon steel Q345B and high-strength weathering steel Q450NQR1 as comparison samples, a 72h periodic infiltration cyclic corrosion test was carried out according to the weathering steel periodic infiltration corrosion test method (TB / T2375-93). The average corrosion rate is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com