Method for preparing water-expandable polyurethane elastomer

A polyurethane elastomer, water-swelling technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of large mass loss due to hydrostatic swelling, less repeatable expansion times, and low expansion rate, etc. The effect of high repeated expansion times and high expansion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

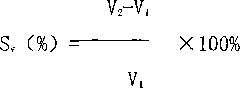

Method used

Image

Examples

example 1-4

[0017] The process method of this embodiment is as follows: First, weigh all the raw materials of each embodiment separately according to parts by weight, as shown in Table 1, add polyether polyol, plasticizer, and nano-filler with temperature control and adjustable speed stirring In a four-necked flask with a nitrogen port and a nitrogen port, heat up to 100℃~130℃, start the vacuum pump to control the vacuum degree at -0.1MPa for 30min~120min, then cool the raw materials to below 60℃, add isocyanate, at 80± Heat and react at 2°C for 2 to 4 hours, then degas at -0.1MPa for 30min to 60min to prepare polyurethane prepolymer; then put a certain quality of prepolymer at 60℃~80℃ and 100℃~130℃,- 0.1MPa vacuum dehydrated chain extender (crosslinking) mixture, add catalyst, vulcanize at 80℃~130℃ for 0.5~2 hours, or vulcanize at room temperature for 12~24 hours, then at 100℃~130℃ twice After vulcanizing for 8-24 hours, a high-performance water-swellable polyurethane elastomer is prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com