Drill-following reamer

A reamer and drilling-while-drilling technology, which is applied to drill bits, drilling equipment, earth-moving drilling and mining, etc., can solve the problems of small blade flare angle, large wellbore enlargement rate, and inability to reach it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

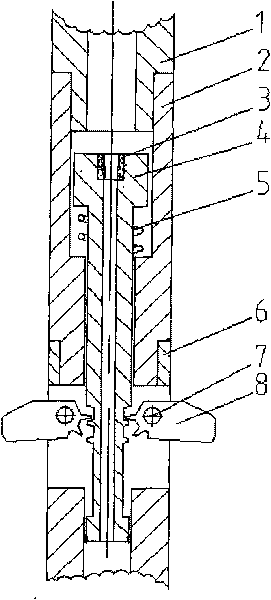

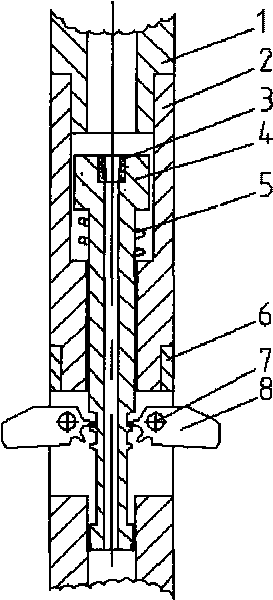

[0008] The present invention will be further described now in conjunction with the accompanying drawings of the description.

[0009] When the present invention is used for reaming while drilling, the upper joint 1 is connected to the drilling tool, the threaded thread at the bottom of the reamer body is connected to the drill bit, and the upper joint 1, reamer body 2, piston nozzle 3, The tool string that piston 4, compression spring 5, limit block 6, bearing pin 7 and knife wing 8 and drill bit form is sent to the bottom of the well. At the wellhead, the circulation system starts to circulate the pump, and the fluid produces a pressure drop at the piston nozzle 3, which generates a thrust on the large end surface of the piston 4, overcomes the reaction force of the compression spring 5, and makes the piston 4 move downward, due to the gear structure on the blade 8 Engage with the groove on the piston 4, so the blade 8 rotates outwards with the pin shaft 7 as the axis. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com