Wood plastic plank stuff production technology and equipment thereof

A technology of board production and production technology, which is applied in the field of wood-plastic board production technology and its equipment, can solve the problems of high cost, poor strength, easy corrosion, etc., achieve improved crystal form and surface shape, good physical and mechanical properties, and reduce environmental pollution. pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

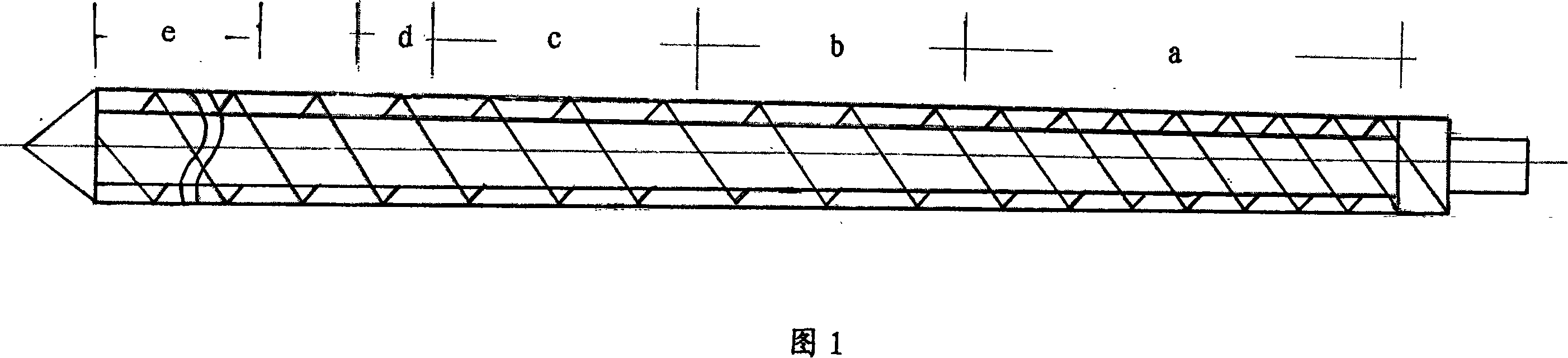

Image

Examples

Embodiment Construction

[0017] Production technology of the present invention is as follows:

[0018] (1) Collect plastic bags and similar wastes to be crushed evenly by special equipment, with a particle size of 10-30 mesh, and sawdust or plant straw powder or mixed with it indefinitely, with a particle size of 10-30 mesh, for later use;

[0019] (2) Inclusive treatment is carried out on the surface of sawdust or plant straw powder: add 0.3% of coupling agent, 0.2% of toughening agent, 4% of phase solvent, 1.5% of chlorinated paraffin, and 5% of mixing oil to wood powder by weight percentage , and then mixed in a low speed mixer for 5 minutes, set aside:

[0020] (3) Modification of recycled plastic PE crushed flakes: add 2% PE wax, 1.2% stearic acid, 0.8% stearic acid octyl, and 1% basic lead phosphite to the plastic flakes by weight percentage, and put them into high-speed Mix in a mixer for 5 minutes and set aside;

[0021] (4) Mixing treatment: put the above two raw materials into a large-scal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com