Wood-plastic composite for walls and preparation method thereof

A wood-plastic composite material and wood-plastic material technology, which is applied in the field of polymer processing, can solve the problems of low moisture absorption rate, weather resistance, and large amount of wood-plastic materials, and achieves low moisture absorption rate, good processing performance, and improved processing performance and mechanics. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1. Preparation of wood-plastic material 1

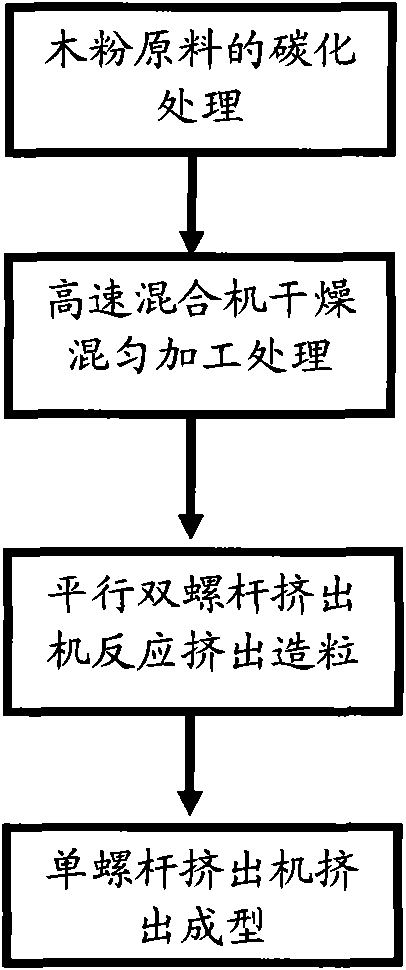

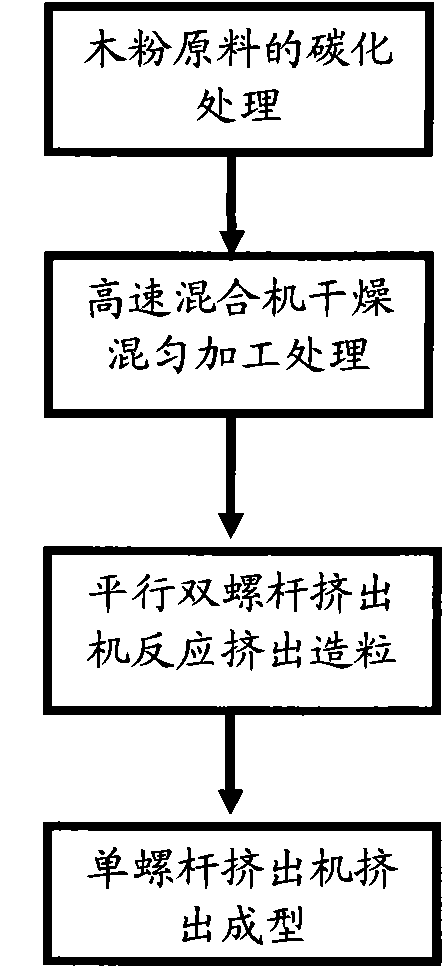

[0033] like figure 1 As shown, the preparation method of the wood-plastic material of the present invention includes pretreatment of wood powder raw materials, drying and mixing processing with a high-speed mixer, reaction extrusion granulation with a parallel twin-screw extruder, and extrusion molding with a single-screw extruder. The components and parts by weight of the wood-plastic material are as follows:

[0034] Component and content (parts by mass) of the wood-plastic material of embodiment 1

[0035] 78 pieces of wood flour

[0036] PE plastic 20 parts

[0037] Maleic anhydride grafted polyethylene 2 parts

[0038] Tris[2.4-di-tert-butylphenyl]phosphite 0.1 part

[0039] Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyl

[0040] 0.05 parts

[0041] Phenyl) propionate] pentaerythritol ester

[0042] Light calcium carbonate-simethicone 2 parts

[0043] In light cal...

Embodiment 2

[0062] Embodiment 2. Preparation 2 of wood-plastic material

[0063] The preparation method of the wood-plastic material in this embodiment is the same, the difference lies in the composition and content of the prepared wood-plastic material.

[0064] Component and content (parts by mass) of the wood-plastic material of embodiment 2

[0065] 68 pieces of wood flour

[0066] PE plastic 24 parts

[0067] Silane coupling agent 1 part

[0068] Maleic anhydride grafted polyethylene 2 parts

[0069] Tris[2.4-di-tert-butylphenyl]phosphite 0.1 parts

[0070] Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyl

[0071] 0.1 part

[0072] Phenyl) propionate] pentaerythritol ester

[0073] Light calcium carbonate-simethicone 3 parts

[0074] Wherein, the mass ratio of light calcium carbonate to simethicone oil is 1:3.

[0075] With reference to GB / T17657-1999; GB / T24137-2009, the physical indicators and mechanical strength of the products prepared in t...

Embodiment 3

[0084] Embodiment 3. Preparation of wood-plastic material 3

[0085] The preparation method of the wood-plastic material in this embodiment is the same, the difference lies in the composition and content of the prepared wood-plastic material.

[0086] Component and content (parts by mass) of the wood-plastic material of embodiment 3

[0087] 75 parts wood flour

[0088] PE plastic 22 parts

[0089] Silane coupling agent 1 part

[0090] Maleic anhydride grafted polyethylene 3 parts

[0091] Tris[2.4-di-tert-butylphenyl]phosphite 0.05 part

[0092] Tetrakis[methyl-β-(3,5-di-tert-butyl-4-hydroxyl

[0093] 0.1 part

[0094] Phenyl) propionate] pentaerythritol ester

[0095] Light calcium carbonate-simethicone 5 parts

[0096] Wherein, the mass ratio of light calcium carbonate and simethicone oil is 2:1.

[0097] In this example, the amount of PE plastic accounts for about 20% of the total formulation amount, which is lower than the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com