Method of producing and painting stone similar paint for flexible flat surface

A production method and technology of imitation stone paint, applied to the device and coating of the surface coating liquid, can solve the problems of heavy quality of plane imitation stone products, large load-bearing burden of the wall, and violation of environmental protection requirements, etc. The effect of clean surface, lifelike shape and color, not easy to accumulate dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

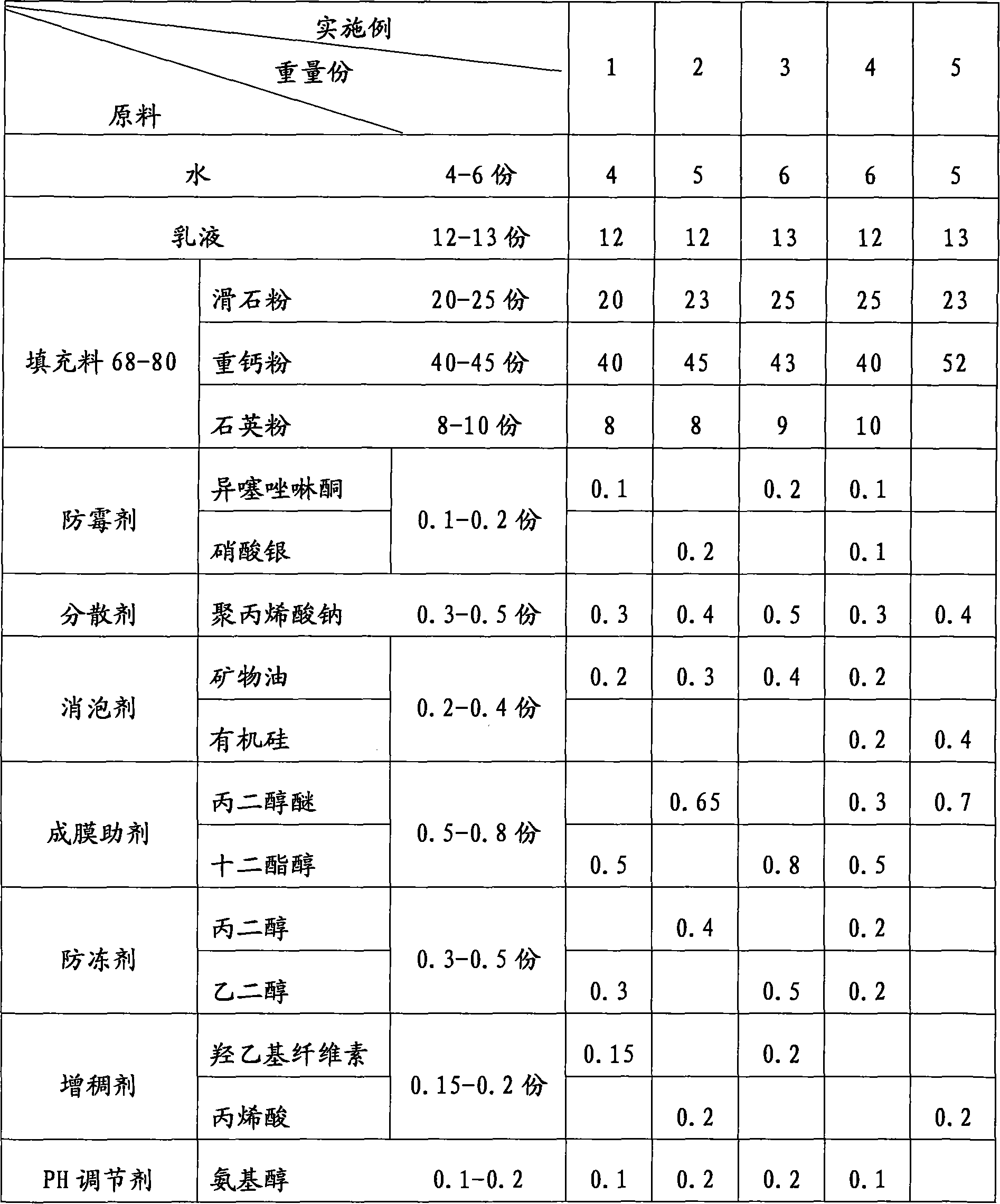

[0021] Embodiment 1 (corresponding raw material and parts by weight data of embodiment 1 in the comparison table):

[0022] With 4 parts by weight (the same below) of water, 12 parts of water-based pure acrylic emulsion (referred to as emulsion), 20 parts of talcum powder, 40 parts of heavy calcium carbonate powder (referred to as heavy calcium), 8 parts of quartz powder, 0.1 part of isothiazoline Ketone, 0.3 parts of sodium polyacrylate as a dispersant, 0.2 parts of mineral oil defoamer, 0.5 parts of lauryl alcohol as a coalescent, 0.3 parts of ethylene glycol as an antifreeze, 0.15 parts of Hydroxyethyl cellulose, 0.1 part of amino alcohol represented by 2-amino-2-methyl-1-propanol as a pH regulator, first put water, emulsion, and various additives at room temperature and pressure at high speed Adjust the disperser to medium speed, disperse at medium speed for 5-10 minutes, add fillers such as talcum powder, and disperse at low speed for 20-30 minutes. Add 0.1 part when dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com