Method for preparing Al-Si-Fe alloy by using high-ferrum and high-silicon bauxite

A technology of high-silicon bauxite and ferroalloy, which is applied in the field of preparing aluminum-silicon-ferroalloy from high-iron and high-silicon bauxite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

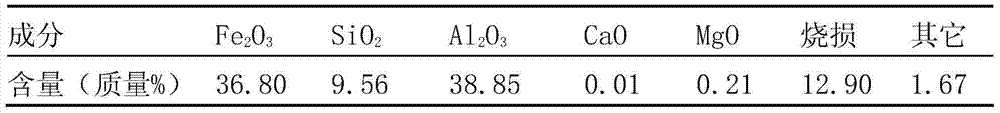

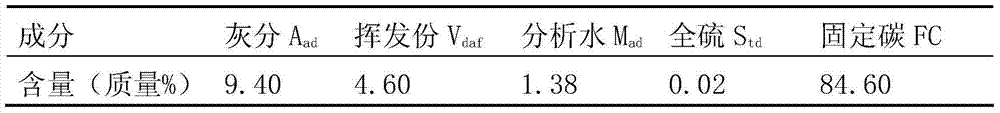

[0017] A high-iron high-silicon bauxite Fe 2 o 3 The content is 36.80%, SiO 2 The content of Al is 9.56%, Al 2 o 3 The content of carbon dioxide is 38.85%, the reducing agent is blue carbon, and its fixed carbon content is 84.60%. The components of high-iron and high-silicon bauxite and semi-coke are listed in Table 1 and Table 2, respectively.

[0018] Table 1 Chemical composition of a certain high-iron and high-silicon bauxite

[0019]

[0020] Table 2 industrial analysis of the chemical composition of semi-coke for reduction

[0021]

[0022] The implementation steps are as follows:

[0023] (1) Crushing the high-iron and high-silicon bauxite raw ore, silica, and semi-coke with a crusher so that the particle size is not greater than 0.015mm;

[0024] (2) Mix the high-iron and high-silicon bauxite powder, silica powder, and semi-coke powder in a ratio of 100:20:30, and add 4% of the total mass of the material as a binder and 8% of the total mass of the material ...

Embodiment 2

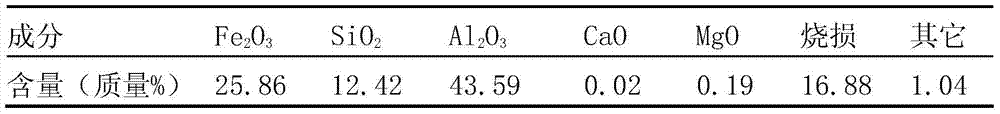

[0030] Select a high-iron and high-silicon bauxite Fe 2 o 3 The content is 25.86%, SiO 2 The content of Al is 12.42%, Al 2 o 3 The content of carbon is 43.59%, the reducing agent is coke, and its fixed carbon content is 86.74%. The high-iron and high-silicon bauxite and coke components are listed in Table 3 and Table 4, respectively.

[0031] Table 3 Chemical composition of a certain high-iron and high-silicon bauxite

[0032]

[0033] Table 4 Industrial Analysis of Chemical Composition of Coke for Reduction

[0034]

[0035] The implementation steps are as follows:

[0036] (1) Crushing the high-iron and high-silicon bauxite raw ore, silica, and coke with a crusher so that the particle size is not greater than 0.015mm;

[0037] (2) Mix high-iron and high-silicon bauxite powder, silica powder, and coke powder in a ratio of 100:10:30, and add 4% binder and 9% water to the mixed material , perform secondary mixing, and stew the mixed material for 40 minutes to make...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com