Nylon alloy composite micro-powder for selective laser sintering, and preparation method thereof

A laser sintering and selective technology, applied in the field of polymer materials, can solve the problems of low low temperature impact performance, poor environmental stress resistance, and high water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 40g of nylon 6 and 10g of nylon 12 into 350ml of formic acid and heat to 100°C, stir for 2 hours to fully dissolve the materials. Then add 450ml of ethanol solution containing 100g of PVP-K30 and stir to precipitate powder, filter, wash and dry to obtain nylon alloy micropowder;

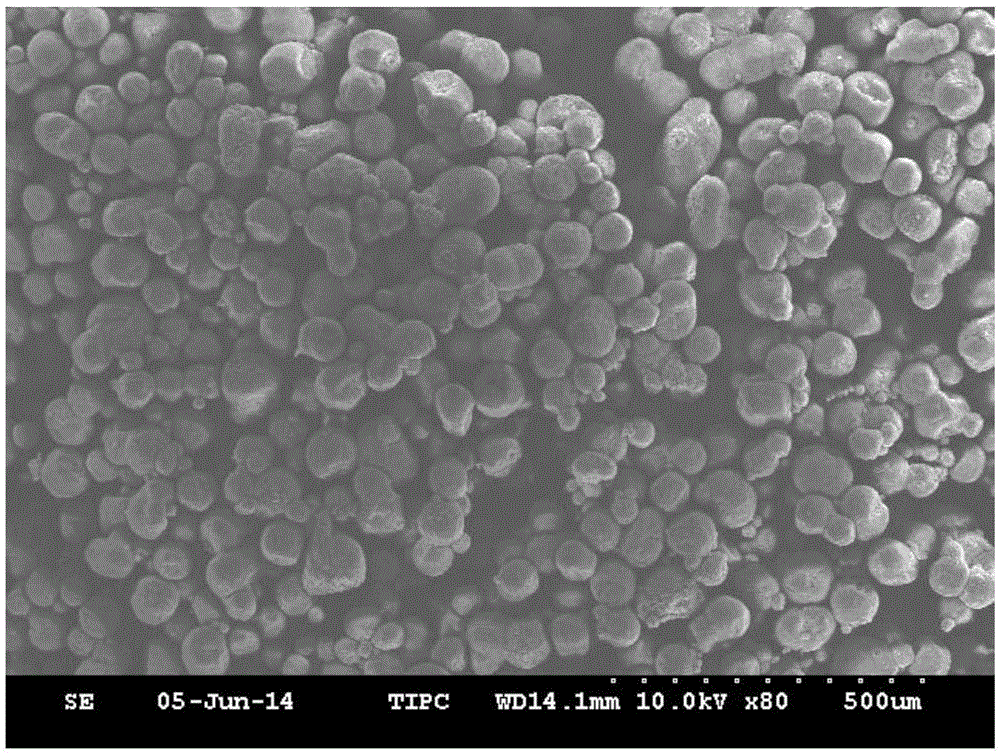

[0033] Get above-mentioned gained nylon alloy micropowder 50g, and flow aid nano silicon dioxide 0.1g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol) 0.1g, in stand Stir and mix in a type agitator for 1 hour, and pass through a 150-mesh sieve after the materials are evenly mixed to obtain nylon micropowder for selective laser sintering. figure 1 For the scanning electron micrograph of the nylon alloy micropowder prepared in Example 1, its average particle diameter is 80 microns. Figure 6 It is the DSC curve chart of the nylon alloy micropowder prepared in embodiment 1. There are melting peaks at 172.7°C, 178.5°C, 217.8°C, and 207.9°C, and crystallization peaks at 159.4°C a...

Embodiment 2

[0035] Add 25g of nylon 6 pellets and 25g of nylon 12 pellets into 350ml of formic acid and heat to 100°C, stir for 2 hours to fully dissolve the materials. Then add 450ml of ethanol solution containing 100g of PVP-K30 and stir to precipitate powder, filter, wash and dry to obtain nylon alloy micropowder;

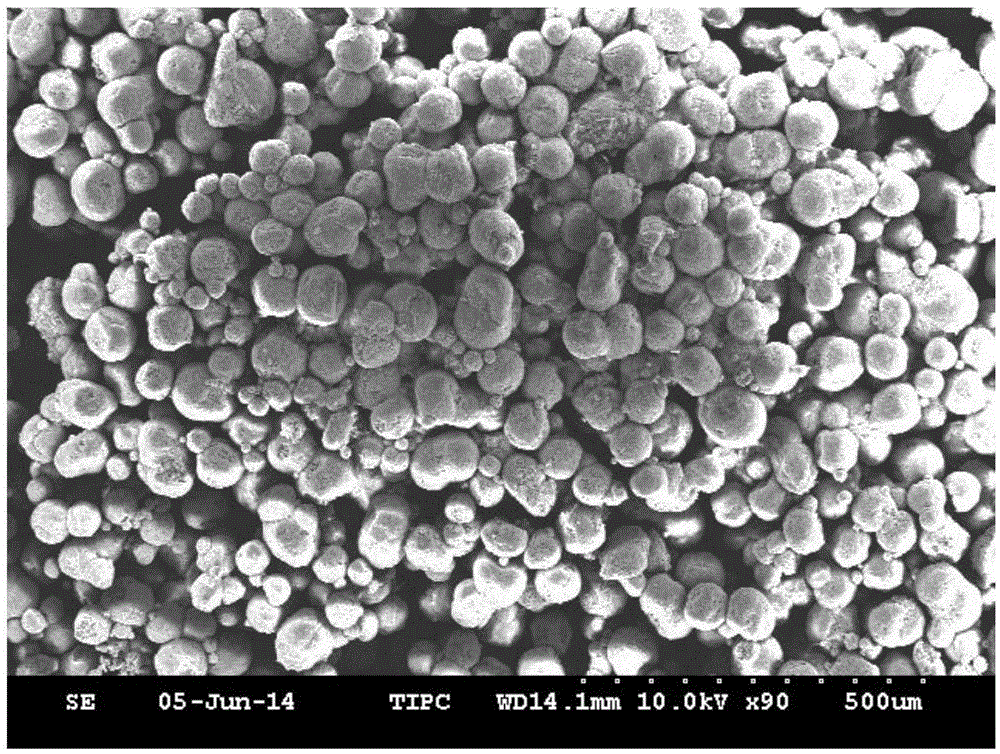

[0036] Get above-mentioned gained nylon alloy micropowder 50g, and flow aid nano silicon dioxide 0.1g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol) 0.1g, in stand Stir and mix in a type agitator for 1 hour, and pass through a 150-mesh sieve after the materials are evenly mixed to obtain nylon micropowder for selective laser sintering. figure 2 For the scanning electron micrograph of the nylon alloy micropowder prepared in embodiment 2, its average particle diameter is 75 microns. Figure 5 The DSC curve of the nylon alloy powder prepared in Example 2 has melting peaks at 178.1°C, 207.8°C, and 217.3°C, respectively, and crystallization peaks at 159.4°C and ...

Embodiment 3

[0038] Add 10g of nylon 6 pellets and 40g of nylon 12 pellets into 350ml of formic acid and heat to 100°C, stir for 2 hours to fully dissolve the materials. Then add 450ml of ethanol solution containing 100g of PVP-K30 and stir to precipitate powder, filter, wash and dry to obtain nylon alloy micropowder;

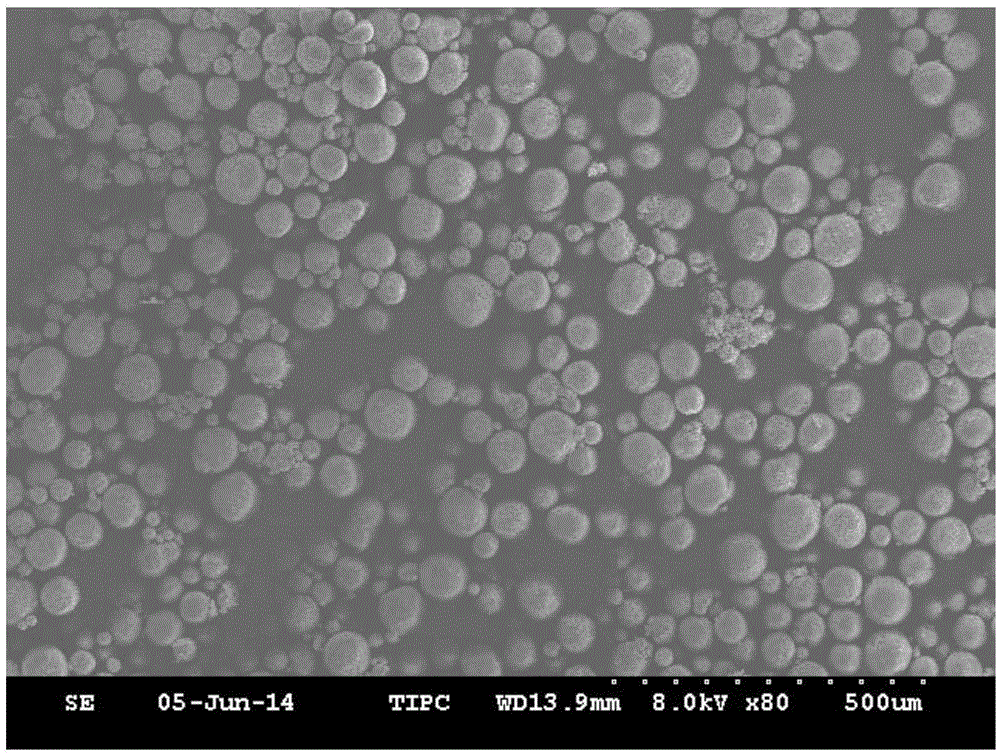

[0039] Get above-mentioned gained nylon alloy micropowder 50g, and flow aid nano silicon dioxide 0.1g, antioxidant 2,2'-methylene bis-(4-methyl-6-tert-butylphenol) 0.1g, in stand Stir and mix in a type agitator for 1 hour, and pass through a 150-mesh sieve after the materials are evenly mixed to obtain nylon micropowder for selective laser sintering. image 3For the scanning electron micrograph of the nylon alloy micropowder prepared in Example 3, its average particle diameter is 60 microns. Figure 6 It is the DSC curve chart of the nylon alloy micropowder prepared in embodiment 3. There are melting peaks at 178.7°C, 206.1°C, and 217.3°C, and crystallization peaks at 158...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com