Modified urea formaldehyde resin and preparation method thereof

A urea-formaldehyde resin and a modification technology, applied in the field of modified urea-formaldehyde resin and its preparation, can solve the problems of poor weather resistance and heat resistance, poor dimensional stability, poor thermal stability, etc., and achieve a good degree of modification and thermal stability. Improved, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

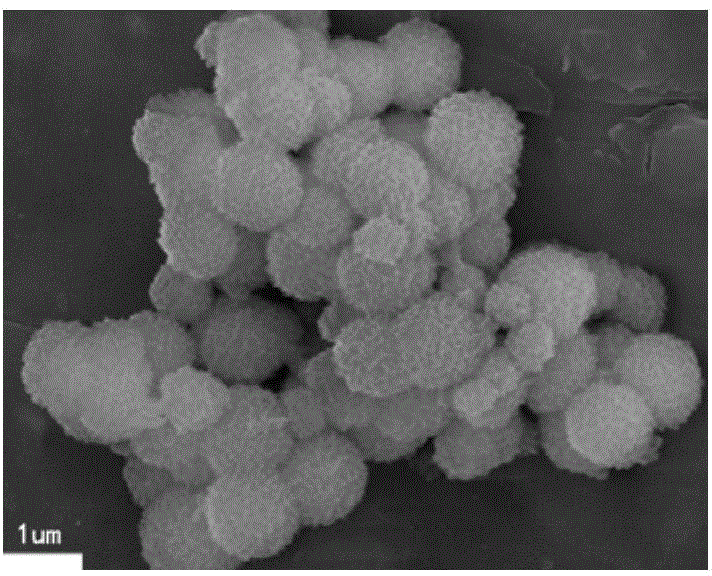

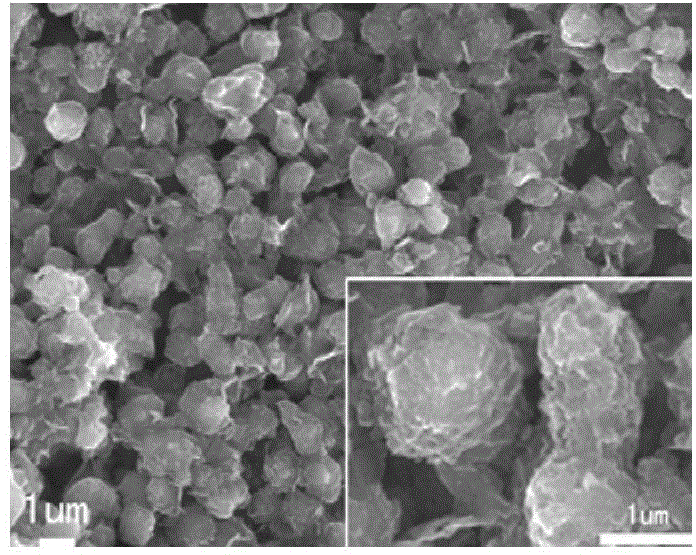

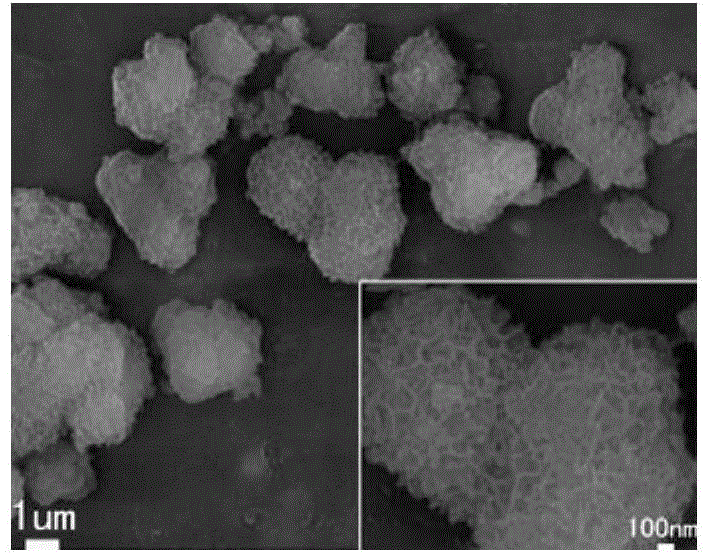

Image

Examples

Embodiment 1

[0062] A modified urea-formaldehyde resin, prepared by the following method:

[0063] (1) Kaolin modification steps:

[0064] ①Short-chain modifier modification: 2.0g of dry kaolin was activated at 500°C for 4h, dispersed into 50.0mL of ethanol, and ball-milled for 2h; then the mixture of kaolin and ethanol was transferred to 250mL of 10.0mL of ammonia In a three-necked flask, raise the temperature to 60°C, heat for 1h, then add 5.0mL of TEOS, and continue to stir for 6h; filter the obtained slurry, wash with ethanol for 3 times, and finally obtain short-chain modifier-modified kaolin filter cake;

[0065] ②Preparation of long-chain coupling agent hydrolyzate: add 2.0mL of γ-aminopropyltriethoxysilane to a mixture of 0.5mL of water and 10.0mL of ethanol for 1h, adjust the pH to 4 with anhydrous acetic acid, and stir for 1h , to obtain the hydrolyzate of γ-aminopropyltriethoxysilane;

[0066] ③Long-chain coupling agent modification: redisperse the kaolin filter cake modified...

Embodiment 2

[0073] A modified urea-formaldehyde resin, prepared by the following method:

[0074] (1) Kaolin modification steps:

[0075] ①Short-chain modifier modification: 6.0g of dry kaolin was activated at 800°C for 5h, dispersed into 50.0mL of ethanol, and ball-milled for 4h; then the mixture of kaolin and ethanol was transferred to 250mL of 16.0mL of ammonia In a three-neck flask, raise the temperature to 60°C, heat for 1h, then add 16.0mL of TEOS, and continue to stir for 6h; filter the obtained slurry, wash with ethanol for 3 times, and finally obtain short-chain modifier-modified kaolin filter cake;

[0076] ②Preparation of long-chain coupling agent hydrolyzate: Add 6.0mL of γ-aminopropyltriethoxysilane to a mixture of 1.5mL of water and 12.0mL of ethanol for 1h, adjust the pH to 4 with anhydrous acetic acid, and stir for 1h , to obtain the hydrolyzate of γ-aminopropyltriethoxysilane;

[0077] ③Long-chain coupling agent modification: redisperse the kaolin filter cake modified ...

Embodiment 3

[0083] A modified urea-formaldehyde resin, prepared by the following method:

[0084] (1) Kaolin modification steps:

[0085] ①Short-chain modifier modification: 10.0g of dry kaolin was activated at 1000°C for 8h, dispersed into 150.0mL of ethanol, and ball-milled for 8h; the mixture was transferred to a 250mL three-necked flask filled with 20.0mL of ammonia water, Raise the temperature to 60°C, heat for 1 h, then add 20.0 mL of TEOS, and continue to stir for 6 h; filter the obtained slurry, wash with ethanol for 3 times, and finally obtain a kaolin filter cake modified by a short-chain modifier;

[0086] ②Preparation of long-chain coupling agent hydrolyzate: Add 8.0mL of γ-aminopropyltriethoxysilane to a mixture of 2.0mL of water and 15.0mL of ethanol for 1h, adjust the pH to 4 with anhydrous acetic acid, and stir for 1h , to obtain the hydrolyzate of γ-aminopropyltriethoxysilane;

[0087] ③Long-chain coupling agent modification: redisperse the kaolin filter cake modified b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com