Chemical mechanical fine polishing liquid for silicon wafer

A chemical-mechanical, fine-polishing technology, applied in the direction of polishing compositions containing abrasives, to reduce scratches, increase polishing rate, and increase friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

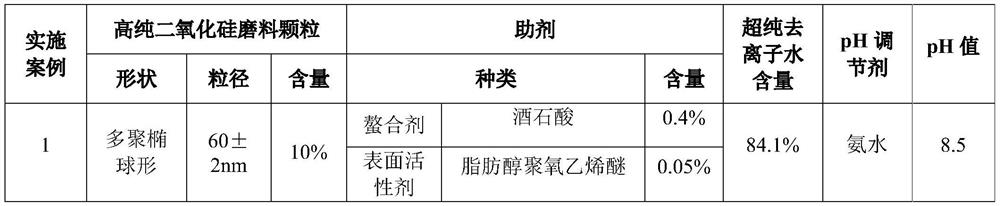

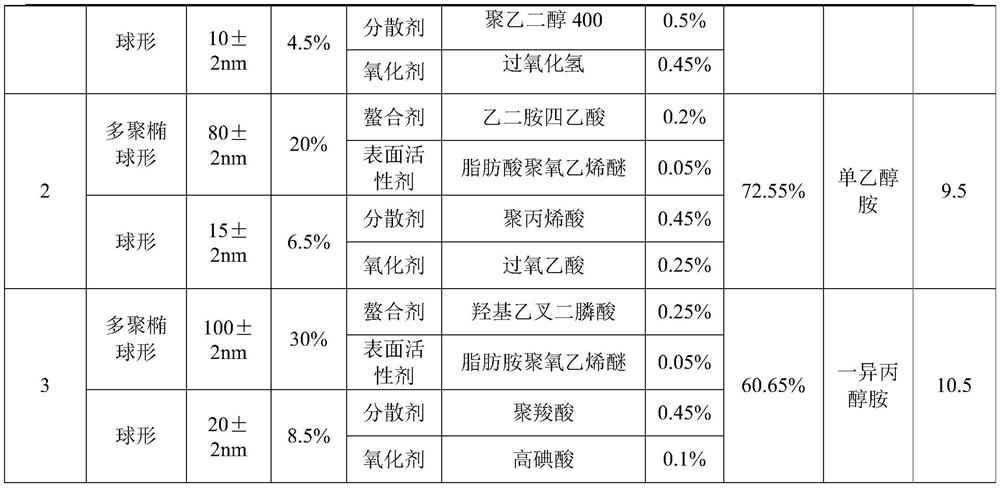

[0023] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0024] Table 1 is the formula of the implementation cases 1 to 3 of the chemical mechanical fine polishing liquid of the present invention. According to the components listed in Table 1 and their mass percentages, they are uniformly mixed in a fluorine-coated reactor, and then the fine polishing is adjusted with a pH regulator. Liquid to the corresponding pH value, that is, silicon wafer chemical mechanical fine polishing liquid.

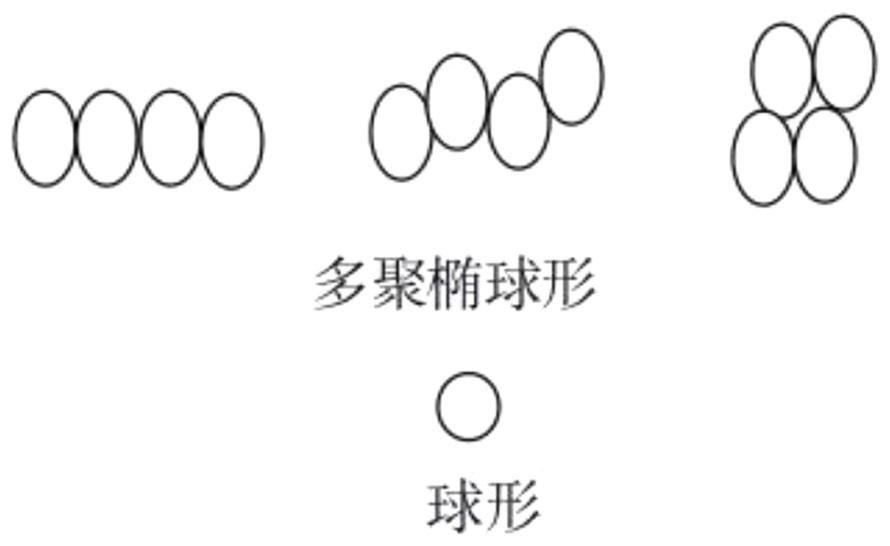

[0025] Wherein, the preparation method of polyellipsoidal silicon dioxide abrasive particle is, add analytical pure catalyst tartaric acid and ultrapure deionized water to the mixed alcohol solvent of analytical pure ethanol and isopropanol, stir, be mixed with solution A; Add analytically pure organic silicon source to solution A on time and in quantit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com