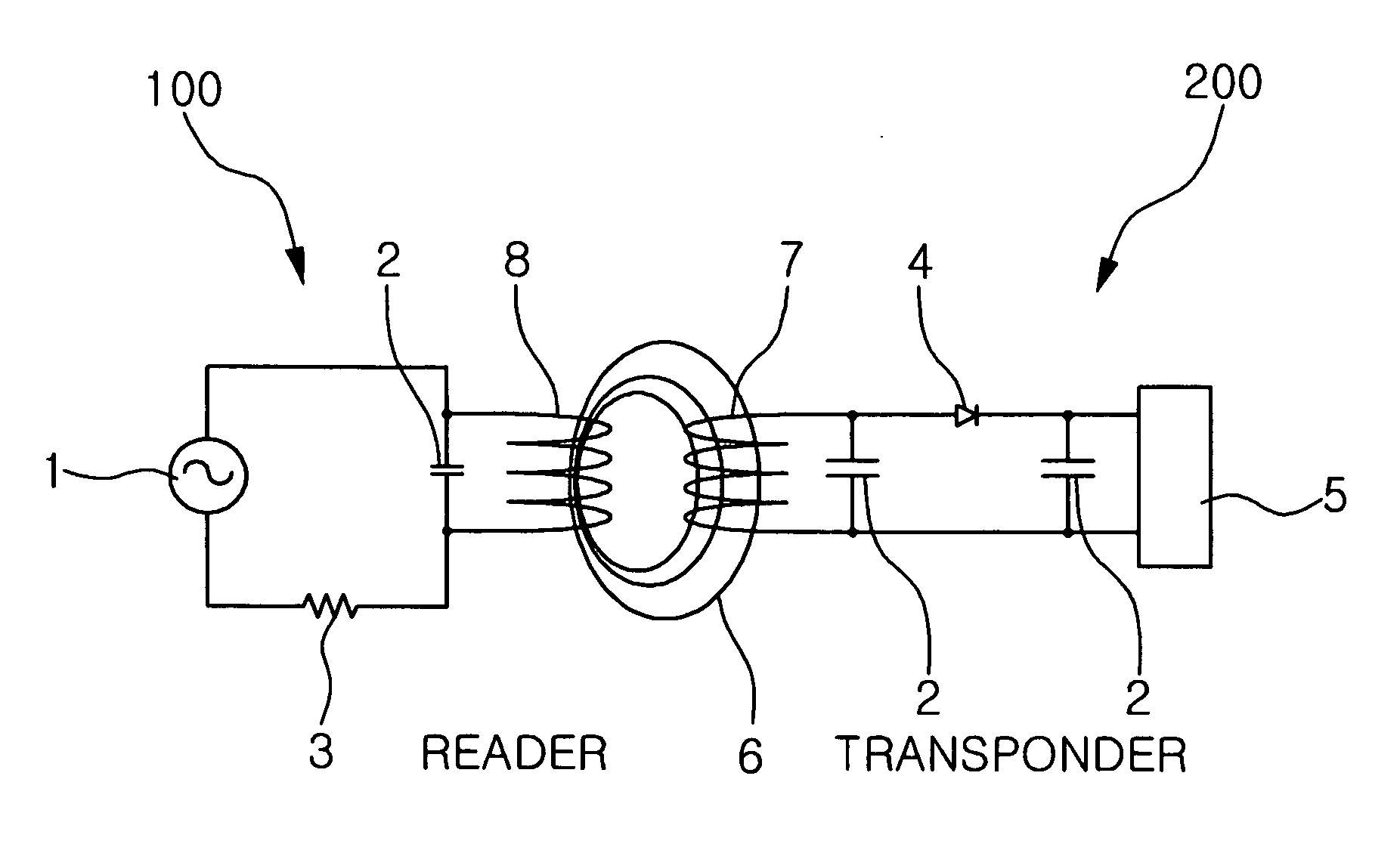

Magnetic sheet for radio frequency identification antenna, method of manufacturing the same, and radio frequency identification antenna using the same

a radio frequency identification and antenna technology, applied in the direction of antennas, magnetic bodies, magnetic materials, etc., can solve the problems of high inferiority ratio, difficult to tune the lc resonance circuit, increased data communication distance,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

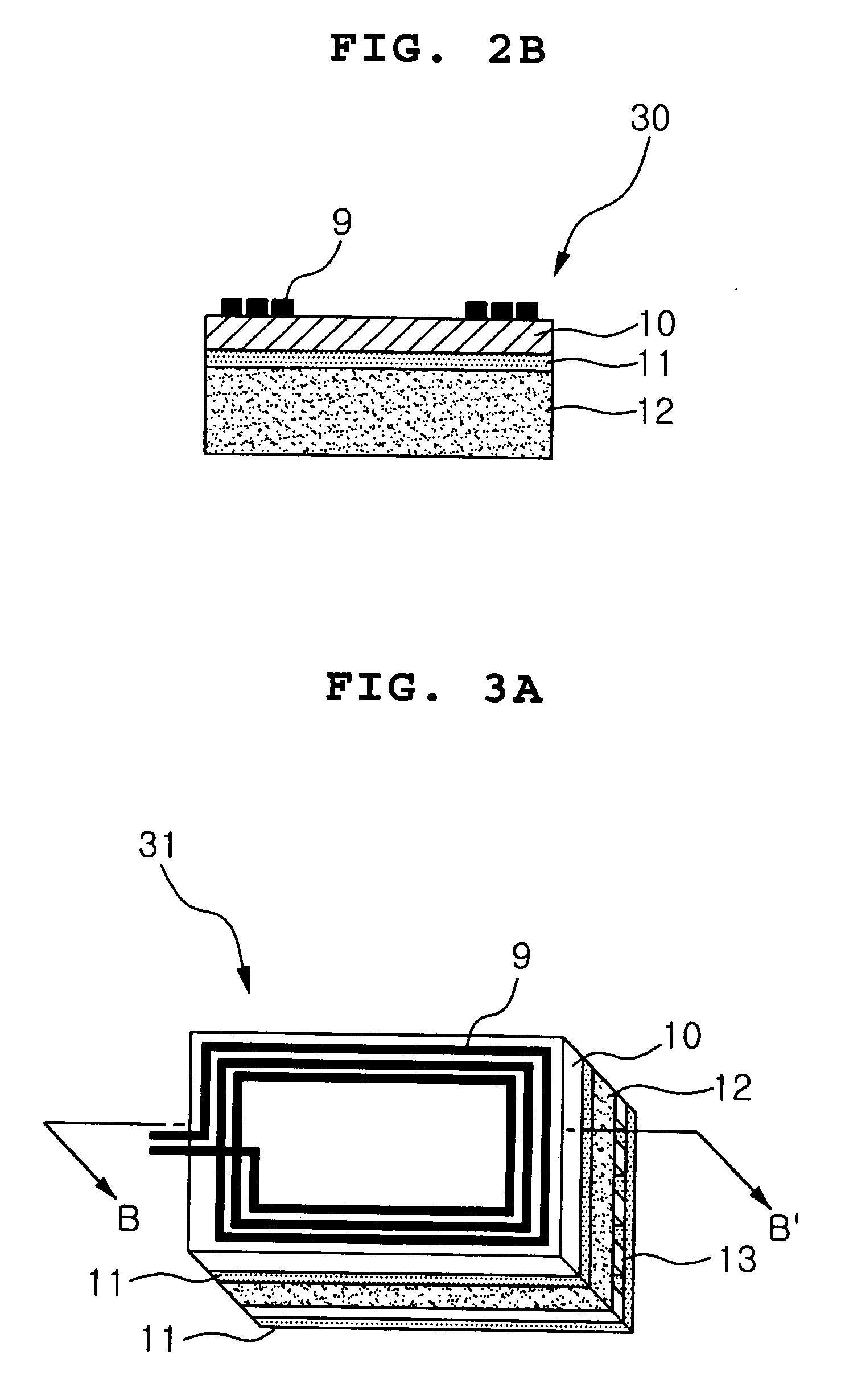

third and fourth embodiments

[0124] As an alloy for a magnetic sheet according to third and fourth embodiments, an amorphous alloy of a composition of Fe73.5Cu1Nb3Si13.5B9 being FINEMET (registered trademark) of the Japanese Hitach corporation or Vvitroperm (registered trademark) of the German Vacuumschmelze corporation was used. Except that the magnetic sheet was made of 0.20 mm thick (third embodiment) or 0.25 mm thick (fourth embodiment), the RFID antenna was manufactured in the same method as that of the first embodiment.

fifth embodiment

[0125] Fe—B was used as a starting material in manufacturing an alloy for a magnetic sheet. In order to fit for a composition ratio, electrolytic iron (Fe) and Zr were added to manufacture an amorphous alloy of a composition of Fe90Zr7B3 Except that the magnetic sheet was made of 0.25 mm thick, the RFID antenna was manufactured in the same method as that of the first embodiment.

sixth embodiment

[0126] Co—B was used as a starting material in manufacturing an alloy for a magnetic sheet. In order to fit for a composition ratio, elements of Co, Si, Fe, Ni and Cr were added to manufacture an amorphous alloy of a composition of Co76(Si, B)15Fe4 (Cr, Ni)5. Except that the magnetic sheet was made of 0.40 mm thick, the RFID antenna was manufactured in the same method as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com