Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118 results about "Electrolytic iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrolytic Iron. Electrolytic Iron could be considered as the purest form of iron and is derived from the chemical electrolysis of the solution containing iron compound like ferrous sulphate. The purity of this type of iron makes it suitable for various purposes in manufacturing, chemicals, and food & pharmacy industry.

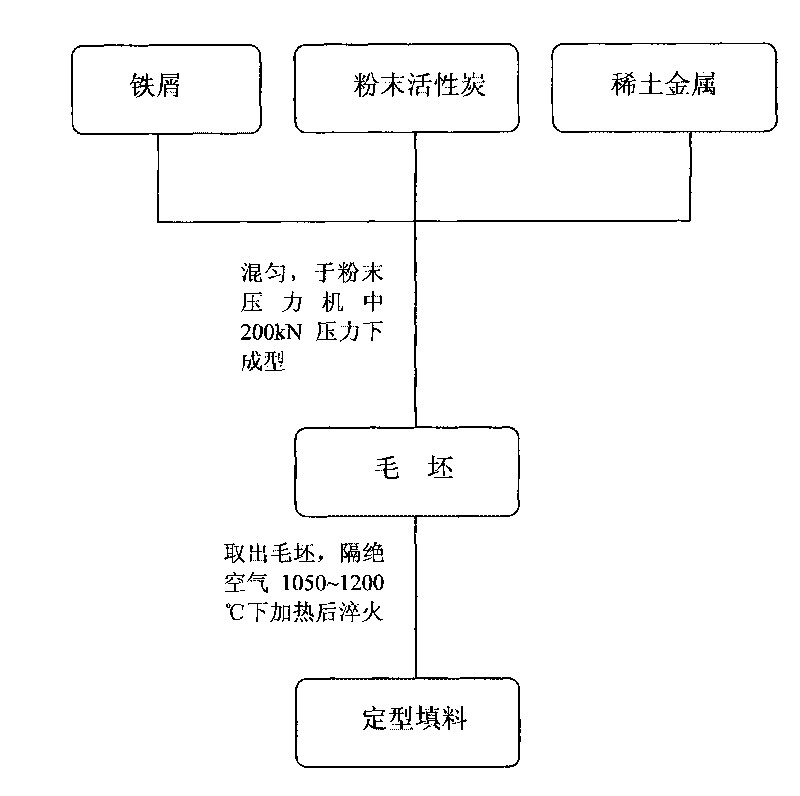

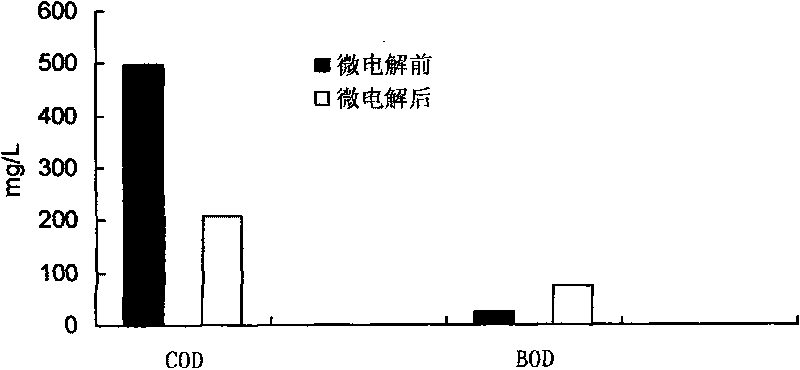

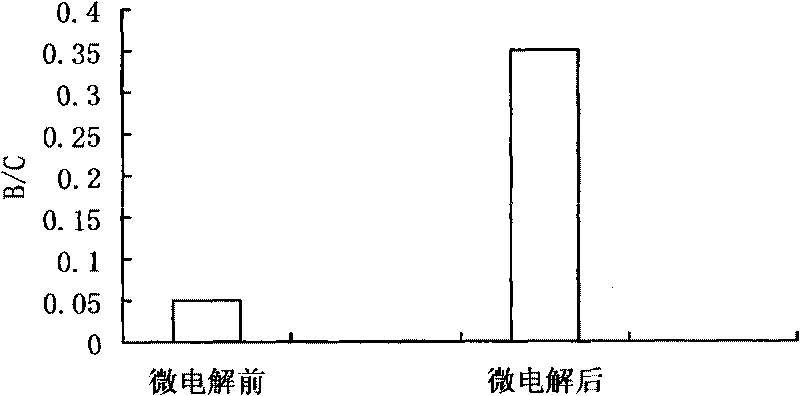

Preparation method of iron-carbon micro-electrolytic filler

InactiveCN101704565ALarge specific surface areaImprove responseWater contaminantsWater/sewage treatmentActivated carbonPowder mixture

A preparation method of iron-carbon micro-electrolytic filler relates to a preparation method of the micro-electrolytic filler for treating wastewater, comprising the following steps: using scrap iron with grain diameter of less than 60 meshes, active carbon powder with grain diameter of less than 100 meshes and rare-earth metal powder as raw materials; using hydrochloric acid solution with mass percentage of 5% for acid washing the scrap iron to activate the scrap iron; mixing the scrap iron with the active carbon powder and the rare-earth metal powder on mass percent of 85%: (14.91-14.00)%: (0.01-0.09)%; using a press machine to add the powder mixture to a Bauer ring-shaped mould for molding at 200 kN; demolding to obtain rough product; heating the rough product for 90-100 min at 1050-1200 DEG C in the absence of air; and then annealing to obtain the iron-carbon micro-electrolytic filler. The iron-carbon micro-electrolytic filler has good specific surface, excellent micro-electrolytic effect and simple technique, and is capable of effectively preventing passivation of the filler surface and hardening of the filler; moreover, the preparation method is easy to promote and suitable for industrial production.

Owner:TONGJI UNIV

Production method of electrolytic manganese metal

The invention discloses a production method of electrolytic manganese metal, which sequentially comprises the following steps: (1) simultaneously adding mixed ore powder of manganese dioxide ores, sulfurous iron ores and manganese carbonate ores and sulfuric acid into a leaching combination tank, heating to 90-95 DEG C, performing leaching combination reaction for 4-6 hours, and performing solid-liquid separation to obtain a rough manganese sulfate solution; (2) performing two-stage purification on the rough manganese sulfate solution to remove impurities, wherein in the primary purification process, SDD or BaS is added for impurity removal, and then aluminum sulfate is added for purification; and in the secondary purification process, 10-30% of deep impurity removal agent is added, and then ammonium sulfide is added for zinc removal; reacting for 1-2 hours, checking and regulating the pH value to 6.0-8.0, performing pressure filtration, then transferring into a standing tank, and standing; and (3) injecting the purified manganese sulfate solution into an electrolytic tank, controlling the pH value of an electrolytic tank solution to be 7.0-8.0, and electrolyzing for at least 24 hours to obtain the electrolytic manganese metal product. According to the method disclosed by the invention, manganese ore resources are reasonably utilized, and the production cost is lowered.

Owner:GUANGXI NON FERROUS METALS GROUP HUIYUANMENGYE

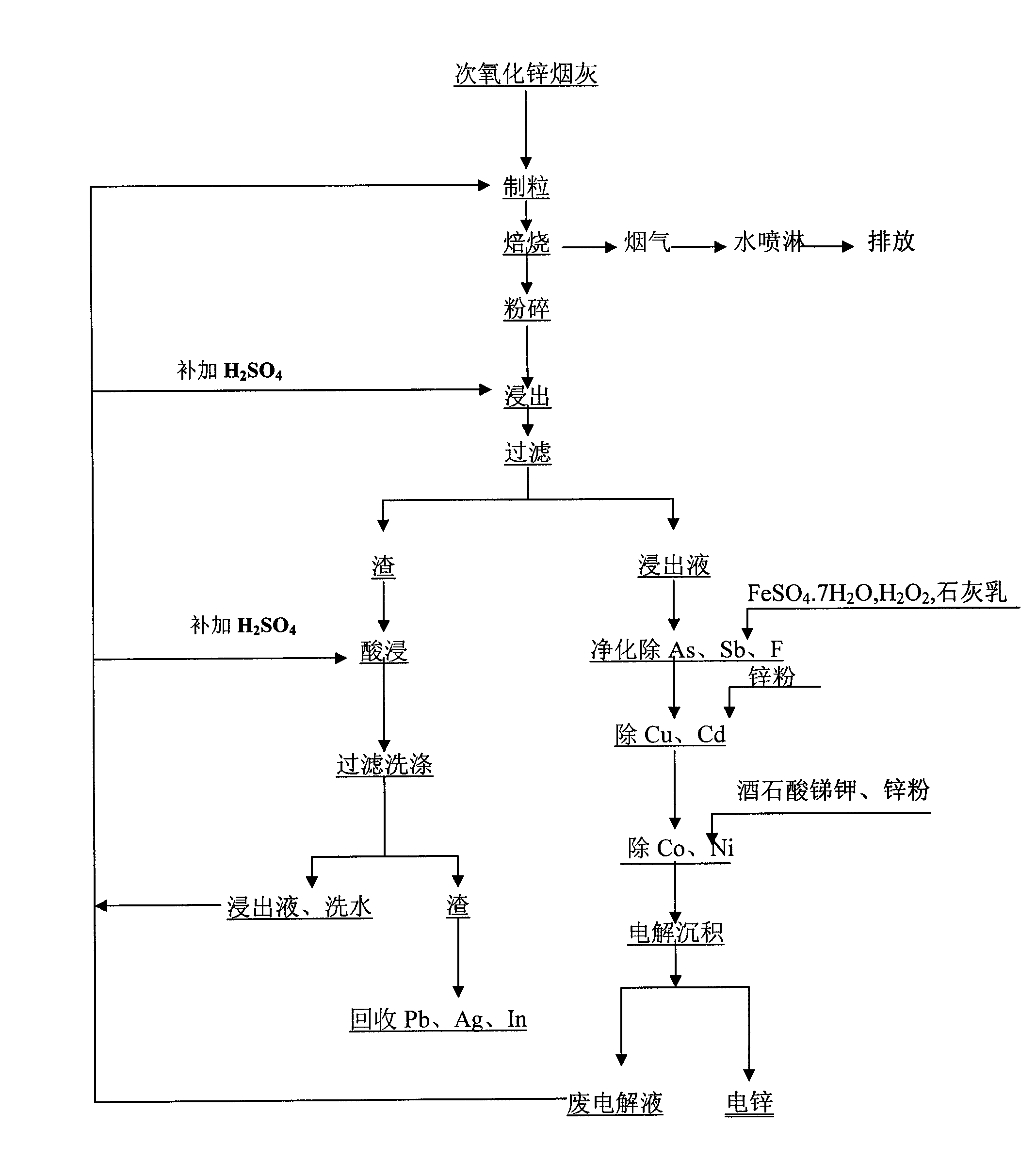

Methods of removing F and Cl in secondary zinc oxide dust effectively and producing electrolytic zinc

InactiveCN101649396AEfficient removalImprove qualityPhotography auxillary processesProcess efficiency improvementPregnant leach solutionElectrolysis

The invention provides a method of removing F and Cl in secondary zinc oxide dust effectively. The method comprises the following steps: adding dilute sulphuric acid solution in secondary zinc oxide dust to acidize, granulating, roasting to remove F and Cl effectively, using sintered powder for neutral leaching while controlling the pH of the end point to 3-3.5, detecting the end point contents ofAs, Sb and F in the obtained leaching solution, adding FeSO4-7H2O in the leaching solution, then adding hydrogen peroxide to perform oxidation and neutralization and remove As and Sb and finally adding lime milk to ensure that no Fe<2+>, As, Sb or F is detected in end point detection. The invention also provides a method of producing electrolytic zinc with secondary zinc oxide dust. The method comprises the following steps: treating secondary zinc oxide dust with the above method, removing Cu, Cd, Ni, Co and other impurities by the traditional method and electrodepositing to obtain the electrolytic zinc. In the methods of the invention, the removal rate of F and Cl can reach 96%-98% which is increased by 10-20 percentage points compared with the traditional process so as to increase the quality of fresh electrolyte and improve the quality of electrolytic zinc and the electrolytic operation environment.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Comprehensive recovering process of multimetal sulfide mineral

ActiveCN100999782AHigh recovery rateImprove resource utilizationPhotography auxillary processesMagnetic separationResource utilizationHydrometallurgy

The present invention discloses one kind of comprehensive polymetal sulfide mineral recovering process. The recovering process combines a roasting process after adding proper amount of lime and potassium chloride into raw mineral and a wet metallurgical process to recover Cu, Zn, Co, S, Fe, etc from the polymetal sulfide mineral. It can obtain electrolytic copper, electrolytic zinc, electrolytic cobalt, potassium sulfate, iron ore concentrate and other products, and has Cu and Zn recovering rate over 94 % and 92 % separately, simplified production process, raised comprehensive metal recovering rate and high resource utilization rate.

Owner:ZIJIN MINING GROUP

Sleeve-friendly wear-resistant strip flux-cored wire

InactiveCN101524789AImprove the safety of useHigh hardnessWelding/cutting media/materialsSoldering mediaElectrolysisIron powder

A sleeve-friendly wear-resistant strip flux-cored wire belongs to the welding field of material processing project. The aim of the invention is to settle the problem of wearing on the sleeve by the wear-resistant strip. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention adopts steel strip for packaging the flux core powder which accounts for 22-37% of total weight of flux-cored wire. The flux core powder comprises the following substances by mass percent: 10-30% of high carbon ferro-chrome, 8-17% of ferroboron, 0.5-4% of ferromolybdenum, 5-10% of nickel powder, 1-3% of low carbon ferrosilicium, 2-8% of medium-carbon ferromanganese and the balance of electrolytic iron powder. The preparing method of the invention adopts the prior art. The sleeve-friendly wear-resistant strip flux-cored wire provided by the invention can effectively increase the using safety of wear-resistant strip, reduce the wearing on the sleeve and prolong the lifetime of drill pipe.

Owner:BEIJING GABBARD ENG & TECH

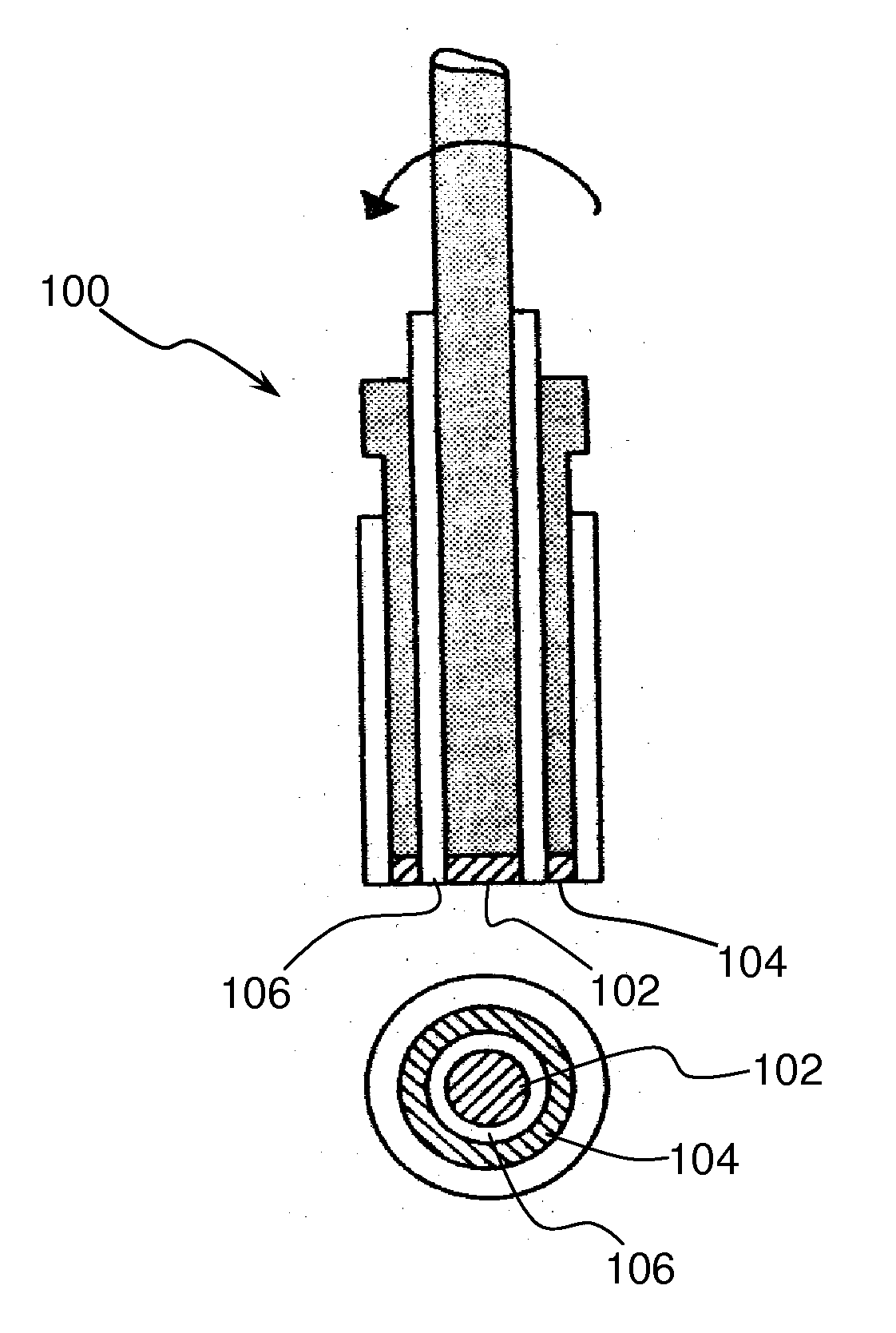

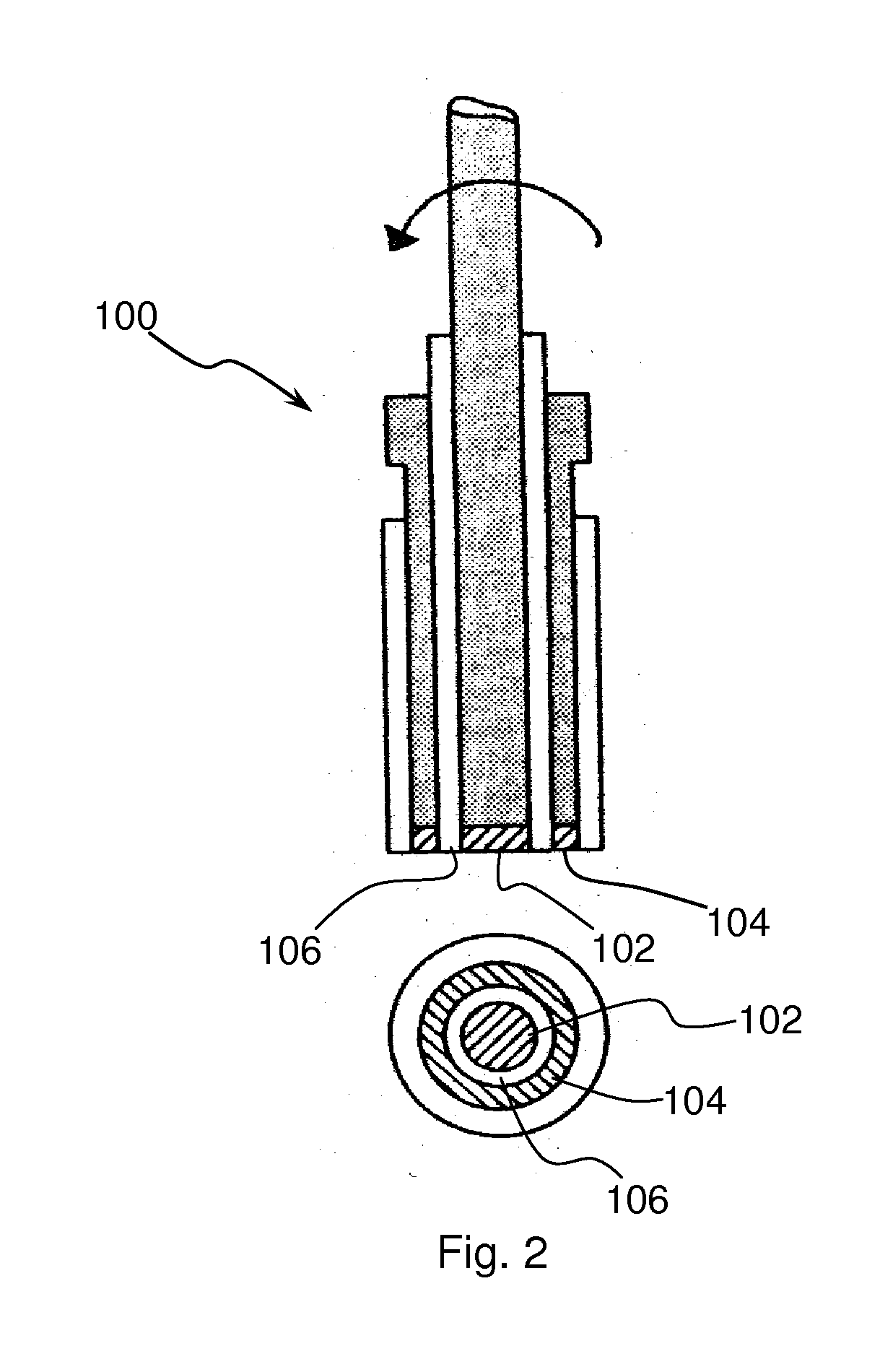

Electrolysis method for producing nickel foil

ActiveCN103031578AImprove yieldReduce processing costsElectroforming processesSilver plateConstant speed

The invention relates to an electrolysis method for producing a nickel foil, being applicable to the field of electrolytic production of a nickel foil. The electrolysis method for producing the nickel foil comprises the following steps of: by taking a lead-silver board or a titanium board as an anode, and a titanium roller or a stainless steel bar which is capable of rotating and controlling a rotating speed as a cathode, controlling a distance between the cathode and the anode to 9-15mm; circularly filling an electrolytic solution which consists of 200-300g / L of nickle sulfate and 40-45g / L of boric acid and is 1.7-3.5 in pH value into an electrolytic bath; turning on the power supply of the electrolytic bath and controlling a voltage, so that cathode current density is 21-35A / dm<2>; controlling the temperature of the electrolytic solution to 50-60 DEG C; rotating the titanium roller or the stainless steel bar at a constant speed, so as to peel off a nickel foil which is electrolytically deposited on the titanium roller or the stainless steel bar through the continuous rotation of the titanium roller or the stainless steel bar; and washing and drying the obtained nickel foil, and coiling the nickel foil into continuous and coiled nickel foil, to obtain the product. The nickel foil produced by the electrolytic process of the system, through the electrolytic deposition, is wide and thin, is moulded once, is comparatively high in yield and is low in processing cost.

Owner:山东雍申电子科技有限公司

Method for concentrating gold from pyrite inclusion-type gold ore

The invention relates to a method for concentrating gold from pyrite inclusion-type gold ore. The pyrite inclusion-type gold ore is gold-containing sulfur ore with high recovery value. The roasted ore of pyrite inclusion-type gold ore is used as raw material and proportionally mixed with charred coal, lime and quartz; and the resulting mixture is fed into a smelting furnace and undergoes the reduction smelting at a temperature ranging from 1450 DEG C to 1600 DEG C, so as to produce gold-rich pig iron. The gold-rich pig iron as an anode plate is electrolyzed by the diaphragm electrolysis technique in an electrolysis system containing ferrous sulfate or ammonium sulfate aqueous solution, so as to produce electrolytic iron and gold-rich anode mud. The method increases the resource utilization rate and is environment-friendly.

Owner:CENT SOUTH UNIV +1

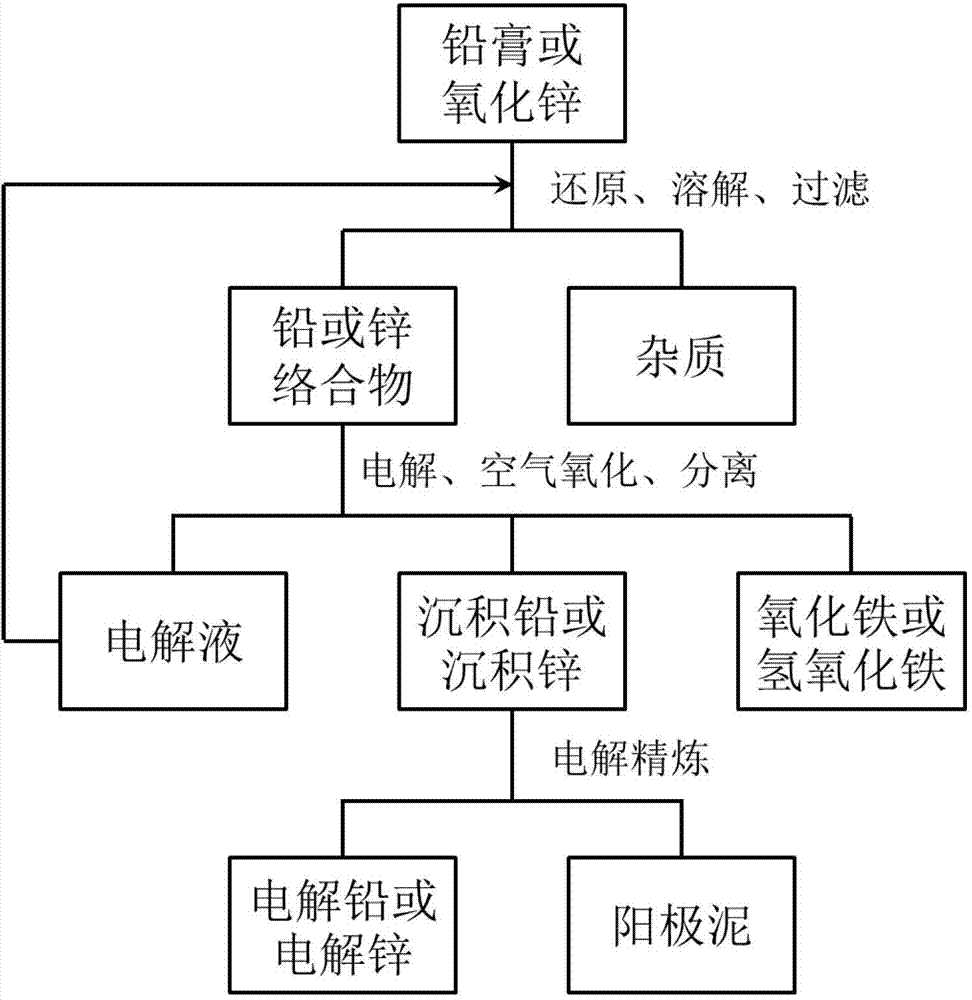

Metal electrolytic method in alkaline solutions

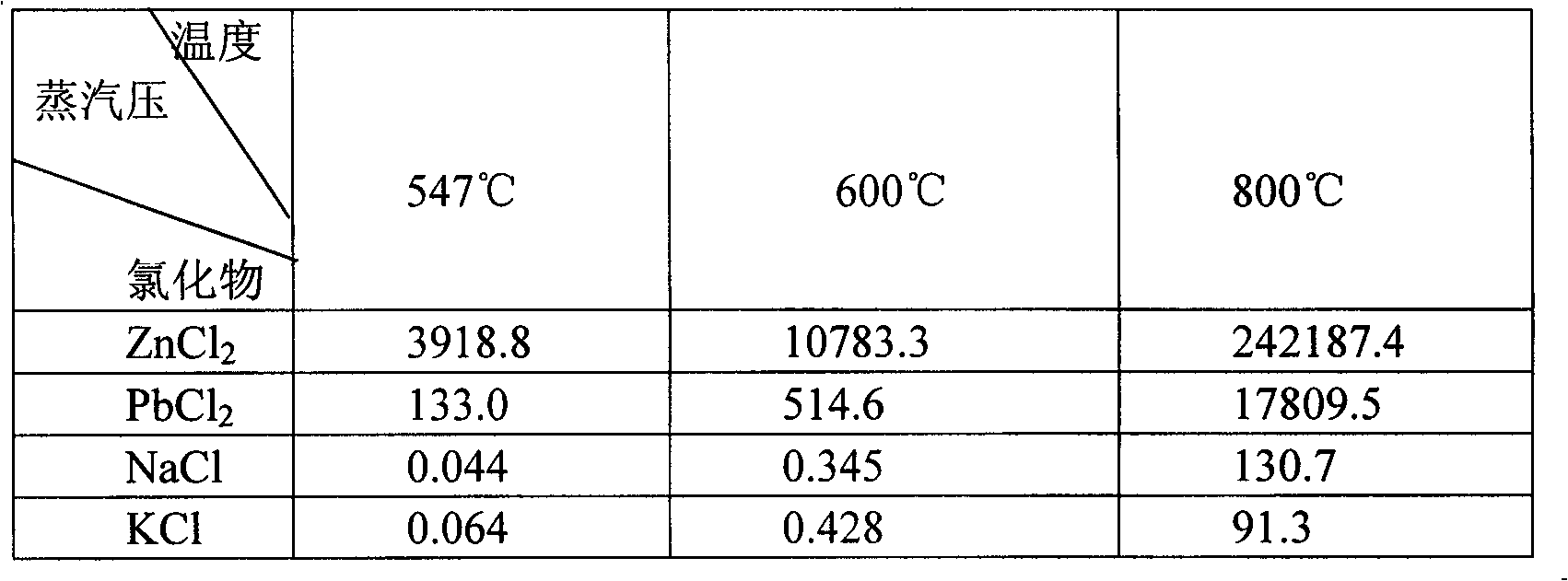

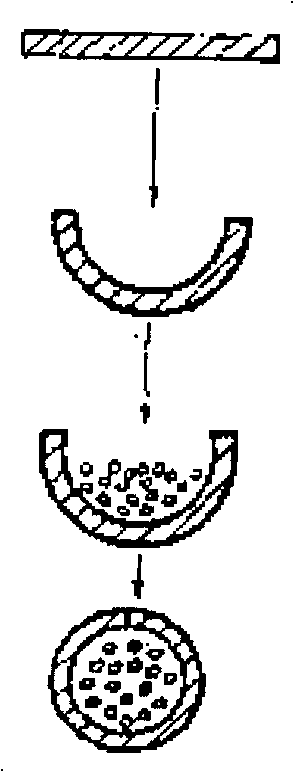

ActiveCN103540954AReduce oxidationHigh purityPhotography auxillary processesFerric hydroxideZinc compounds

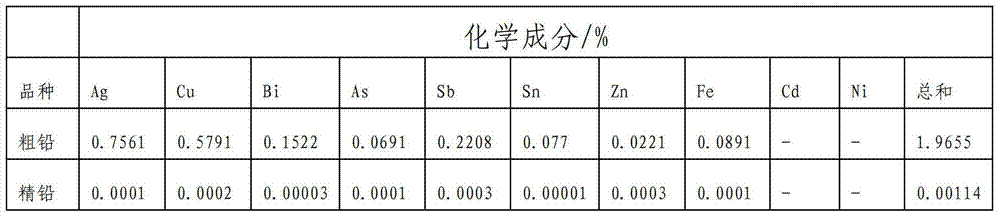

The invention discloses a metal electrolytic method in alkaline solutions, which comprises the following steps: casting deposited lead or deposited zinc or commercially available crude lead or crude zinc to a 0.2-6 cm thick anode plate, and preparing a lamelliform cathode through pure lead, pure zinc or an inert electrode; electrolytic refining in alkaline electrolyte, and finally obtaining high-purity electrolytic lead or electrolytic zinc on the cathode, wherein the metal electrolytic method further comprises: 1) dissolving a lead compound or a zinc compound into the alkaline electrolyte, and adding a reducing agent to reduce lead dioxide existing in the lead compound or the zinc compound to a soluble lead complex; and 2) selecting the lamelliform cathode prepared by the pure lead, pure zinc or inert electrode in the electrolysis process, selecting the anode as iron with purity larger than 94%, and finally obtaining the deposited lead or deposited zinc on the cathode. According to the metal electrolytic method disclosed by the invention, the lead compound or the zinc compound is dissolved under an alkaline condition through a complexing agent, the electrolytic lead or electrolytic zinc is obtained by electrolyzing the cathode, and a byproduct ferric oxide or ferric hydroxide is obtained by separation.

Owner:北京中金瑞丰环保科技有限公司

Method for preparing solid state powder of potassium ferrate by adopting one-step method and electricity chemistry

InactiveCN101525754AHigh purityAvoid it happening againElectrode shape/formsDiaphragmsOrganic synthesisPotassium hydroxide

The invention provides a method for preparing solid state powder of potassium ferrate by adopting a one-step method and electricity chemistry; a diaphragm type electrobath can directly prepare the solid state powder of potassium ferrate with the purity of 94.0%-98.1% with anodes of electrolytic irons with the direct current density of 0.10-0.42 A / dm<2> by the one-step method in a concentrated potassium hydroxide solution containing additive, the corresponding current efficiency is 79.6%-67.5%, and the electric power consumption is 1.9-2.8 kWh / (kg K2FeO4). The product prepared by the invention is suitable for serving as a high-effective water treatment agent, organic synthetic oxidizer and anode active material of alkaline super-iron battery; the method can be used for continuous raw material production, has high efficiency and low cost; the electrolyte can be recycled and has no pollution to environment.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

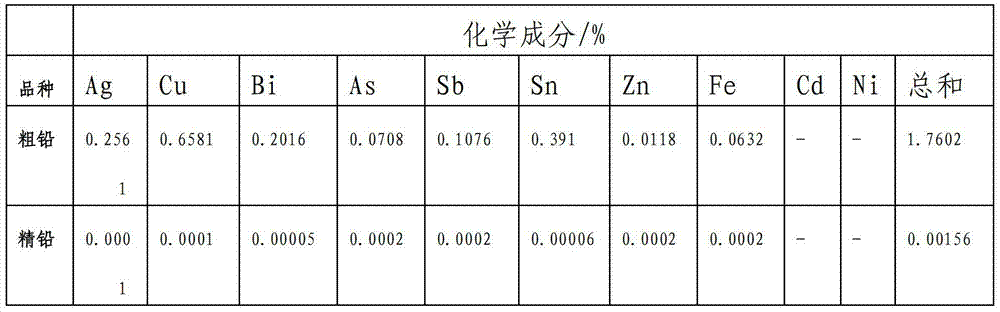

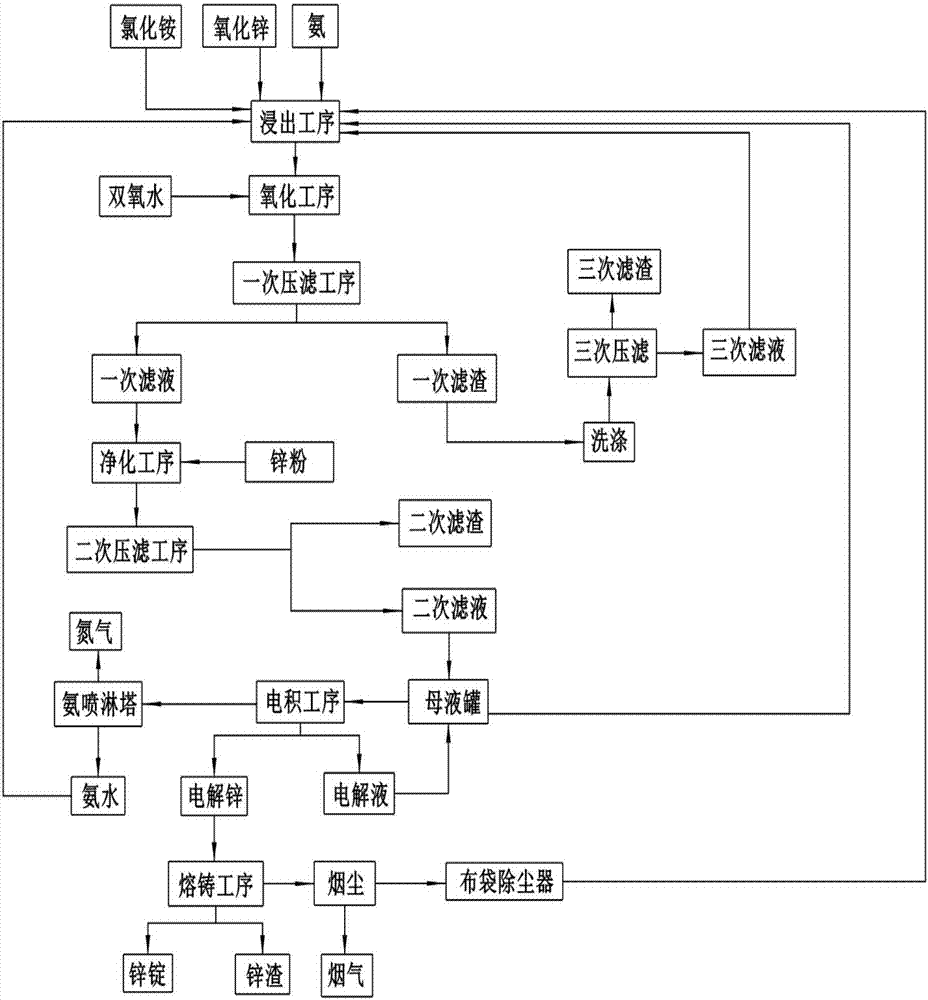

Electrolytic zinc production technology

InactiveCN107099665AHigh purityReduce manufacturing costPhotography auxillary processesElectrolysisHydrogen peroxide

The invention belongs to the technical field of metal zinc smelting and relates to a technological method for producing a zinc ingot through the electrolytic method. The main technological steps of a production technology are that firstly, zinc oxide is put into an ammonia and ammonium chloride aqueous solution, and the ammonia and ammonium chloride solution is used as a leaching agent; secondly, hydrogen peroxide is added into obtained leachate for reaction to remove iron in the leachate; thirdly, after being subjected to filter pressing, zinc power is added into filtrate for purification; fourthly, secondary filer pressing is conducted, and filtrate is successively conveyed into a mother liquor tank and an electrolytic tank and subjected to electrodeposition treatment in an electrolyte; and fifthly, electrolytic zinc is obtained in a cathode plate and subjected to melting and casting treatment to obtain the zinc ingot and zinc slag. By adoption of the production technology, resource recycling is achieved, the high-purity zinc ingot product is obtained, the technology is simple and efficient, and production cost is saved.

Owner:宁夏鼎辉科技有限公司

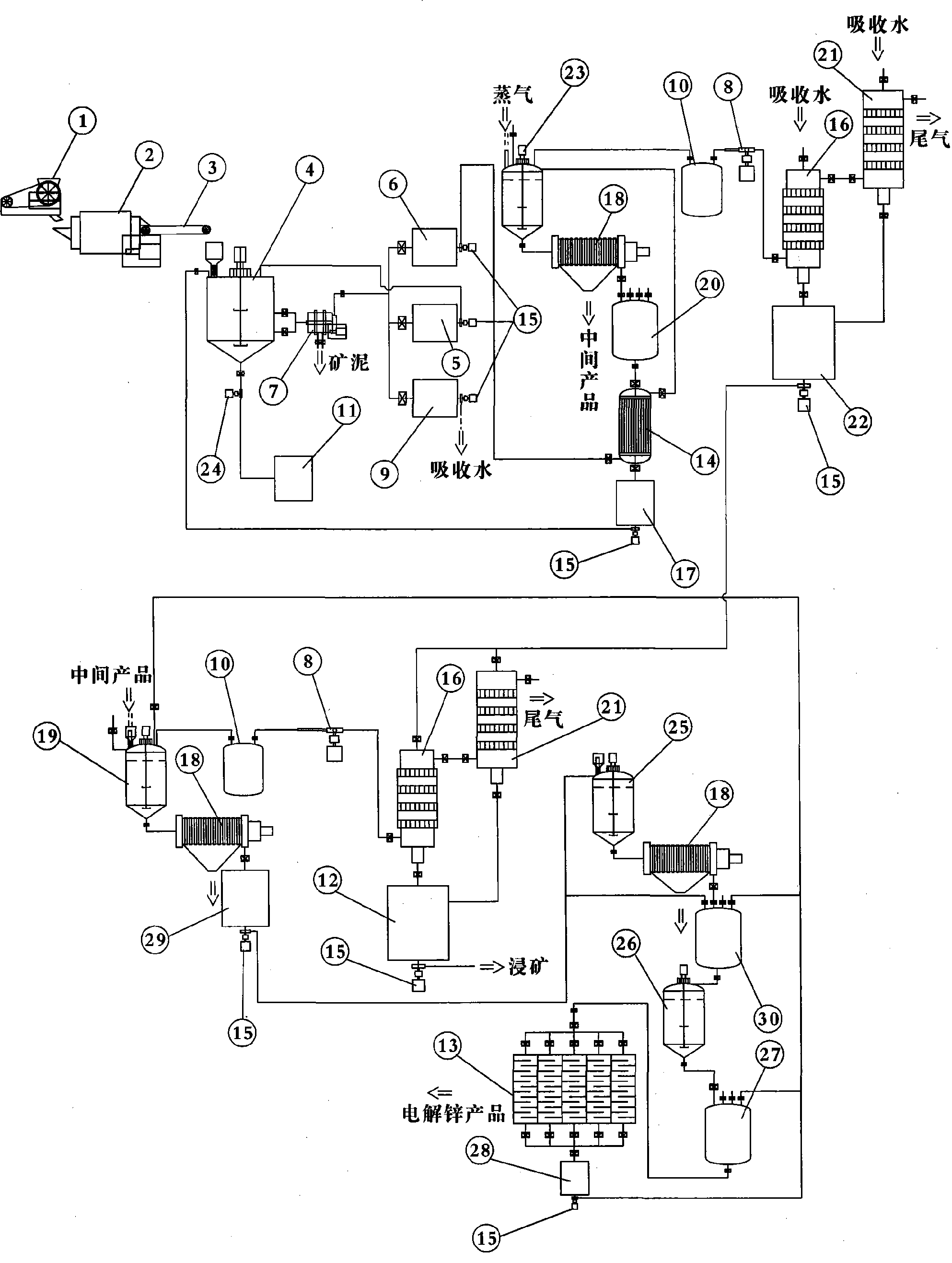

Method for producing electrolytic zinc from zinc oxide-containing materials

InactiveCN101545115APhotography auxillary processesProcess efficiency improvementElectrolysisHydrolysis

The invention provides a method for producing electrolytic zinc from zinc oxide-containing materials. The method adopts the steps of powder crushing, ammonia leaching, hydrolysis, first stage recovery of leaching agent, liquid preparation, second stage recovery of the leaching agent, impurity removal as well as electrolysis to produce the electrolytic zinc. The method is particularly suitable for processing low-grade zinc oxide ores; firstly, the ores are prepared into mineral powder; by taking mixed solution of caustic soda and carbon-ammonia or mixed solution of ammonia water and carbon-ammonia as a leaching agent, the leaching agent and the mineral powder are subjected to two-stage or three-stage reaction in a sealed stir bucket to obtain a leach solution of zinc; the leach solution is vacuum-heated to distill ammonia components and hydrolyze the ammonia components to basic zinc carbonate; the ammonia components are absorbed by an absorber for standby; the basic zinc carbonate is dissolved by sulfuric acid or waste solution of electrolytic zinc to prepare a solution and remove impurities so as to prepare a zinc electrolyte, and CO2 generated during the reaction is absorbed by the absorption liquid for cyclic ore soaking; finally, the zinc electrolyte is mixed with the electrolytic waste solution, the mixture is sent to an electrolytic plant to produce the metal zinc by electrolysis, and the electrolytic waste solution is sent to the liquid preparation procedure for reutilization. The method has the advantages of low energy consumption, low cost and reutilization of waster used in production, and can fully utilize developing zinc resources.

Owner:谷亮

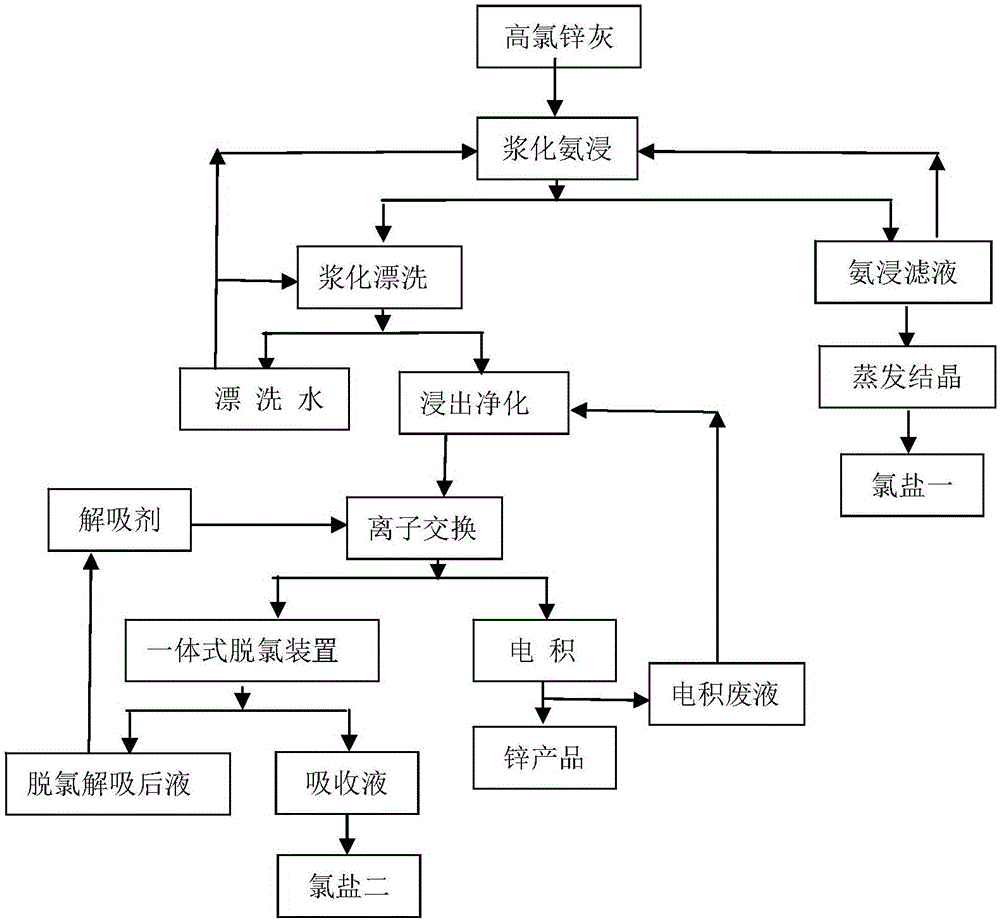

Method for producing electrolytic zinc through high-chloride zinc ash material ammonia leaching ion exchange combined process

InactiveCN106399715AIncreased concentration of chloride ionsReduce water volumeChloride preparationPhotography auxillary processesLiquid wasteFiltration

The invention discloses a method for producing electrolytic zinc through a high-chloride zinc ash material ammonia leaching ion exchange combined process. The method comprises the steps that (1) high-chloride zinc ash is made into slurry, ammonia is added to conduct ammonia leaching; ammonia leaching filter residues and ammonia leaching filtrate are obtained after filtration; if the concentration of chloride ions in the filtrate is less than 80 g / L, slurrying and ammonia leaching are conducted again; and if the concentration of chloride ions in the filtrate is greater than 80 g / L, a way is opened, and chlorine salt I is recovered; the ammonia leaching filter residues are rinsed to obtain rinsing water and after-rinsed zinc ash, the after-rinsed zinc ash is subjected to sulfuric acid leaching to obtain a zinc sulfate solution and leaching residues, and the leaching residues are used for recovery of zinc and lead; chloride ions are removed from the zinc sulfate solution by using ion exchange resin, the zinc sulfate solution is subjected to electrodeposition sending and zinc is recovered after dechlorination, and an ion exchange desorption after-solution is subjected to dechlorination to generate chlorine salt II and returns to the ion exchange resin as a desorption reagent. Through the method, high-efficiency and low-cost impurity removal and harm removal of high-chloride zinc ash with the treatment effect which is several times higher than the treatment limit effect obtained through an existing dechlorination process is realized; a new acceptable raw material source is provided for production of electrolytic zinc; emissions of waste liquor and waste residues are avoided, and the environmental protection effect and economic and social benefits are remarkable.

Owner:吉首市金湘资源科技开发有限公司

Fe-Based Amorphous Alloy Strip

ActiveUS20090242082A1Increase flux densityExcellent soft magnetic propertiesInorganic material magnetismAlloyAlternating current

The present invention provides a Fe—B—Si system amorphous alloy thin strip excellent in high magnetic flux density, thermal stability, amorphous formability improved workability and low core loss. The present invention further provides a Fe—B—Si system amorphous alloy thin strip which has the reduced cost without using high purity iron resources such as an electrolytic iron as iron resources used in an amorphous alloy thin strip, and also has core loss less than 0.10 W / kg at W13 / 50 in soft magnetic property in alternating-current field. The Fe—B—Si system amorphous alloy thin strip according to the present invention contains an appropriate amounts of N, C, P to improve thermal stability, amorphous formability, workability (brittleness), and core loss without deteriolating magnetic flux density, and contains, in atomic %, B: 5-25%, Si: 1-30%, N: 0.001-0.2%, C: 0.003-10%, P: 0.001-0.2% and the balance being Fe and unavoidable impurities, and optionally contains Co or Ni substituted to less than 15% of the Fe amount, or Cr at less than 5% substituted to the Fe amount. Further, Mn: 0.15-0.5 mass %, S: 0.004-0.05 mass % can be included.

Owner:NIPPON STEEL CORP

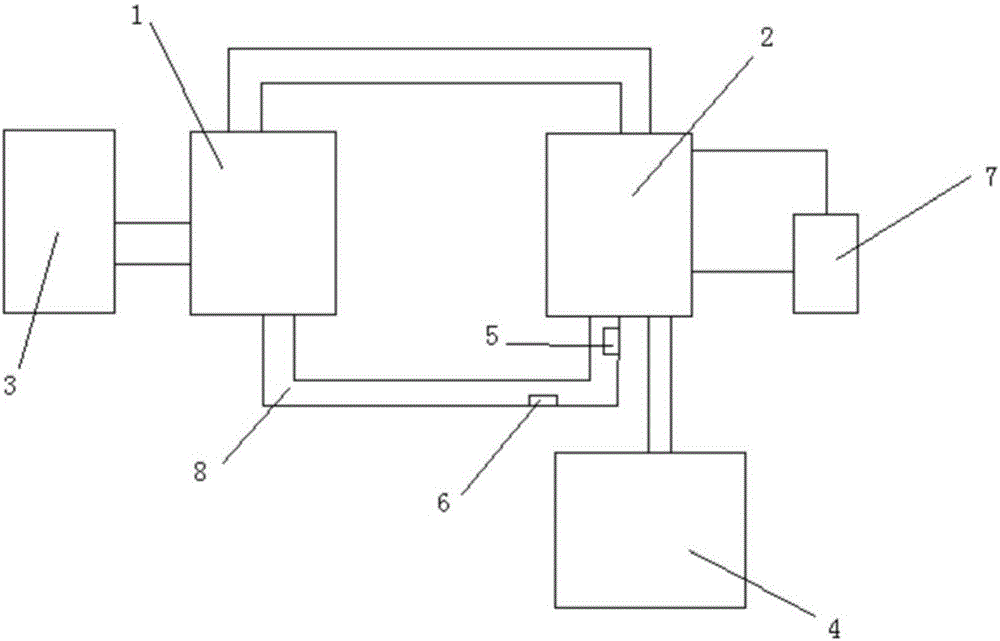

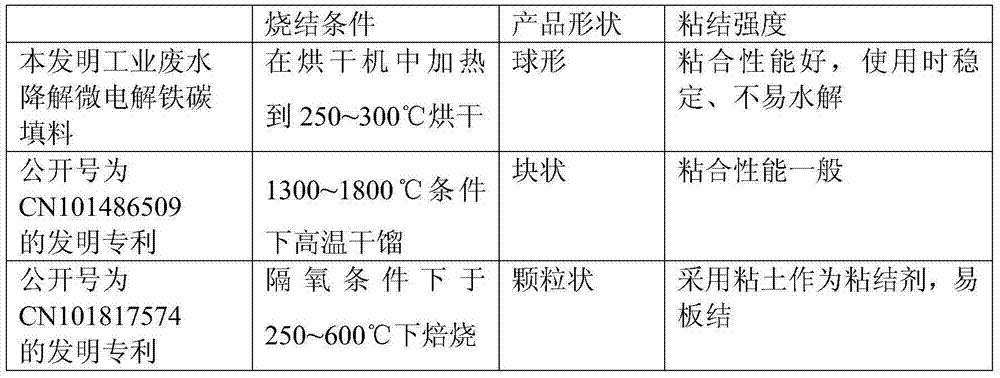

Industrial wastewater degradation/microelectrolysis iron-carbon filler and preparation method thereof

ActiveCN104724794ANo hardeningPassivation phenomenon noWater/sewage treatmentTreatment effectAdhesive

The invention discloses an industrial wastewater degradation / microelectrolysis iron-carbon filler which is composed of the following components in parts by weight: 55-70 parts of iron powder, 30-40 parts of activated carbon and 1-2 parts of adhesive. The carbon content of the iron powder is 4%. The adhesive is composed of the following components in parts by weight: 5-6 parts of sodium silicate, 1-3 parts of calcium chloride and 1-3 parts of hydroxypropyl cellulose. The invention also discloses a preparation method of the industrial wastewater degradation / microelectrolysis iron-carbon filler. The industrial wastewater degradation / microelectrolysis iron-carbon filler does not have the phenomenon of hardening or passivation. The adhesive is stable and can not be easily hydrolyzed when in use. The preparation method is simple and reasonable, and can implement preparation in conventional equipment under mild conditions. The industrial wastewater degradation / microelectrolysis iron-carbon filler is spherical, and has the advantages of large sewage contact surface and favorable pollutant treatment effect.

Owner:WUHAN STEEL NEW MATERIAL

Method for producing electrolytic zinc from zinc material with high-content of fluorin and silicon dioxide

ActiveCN101126164ARealize comprehensive utilizationAchieve recyclingPhotography auxillary processesProcess efficiency improvementElectrolysisSilicon dioxide

The invention belongs to the technical field of the copper metallurgy and discloses the method which adopts zinc material with high content of fluorine and silicon dioxide to produce electrolysis zinc in the producing process of wet processing zinc metallurgy. The producing method comprises the following process: raw material blending 1, zinc out immersing 2, segregating and obtaining neutral supernatant fluid 3, supernatant fluid removing the fluorine 4, removing impurity 5, obtaining purified zinc sulfate solution 6 and obtaining metallic zinc through zinc sulfate solution electrolysis 7. The invention has the technical property that the supernatant fluid is added with potassium sulphate or calcium sulphate to remove the fluorine before removing other impurities, or the neutral zinc sulfate solution is added with silicon dioxide and potassium sulphate and calcium sulphate to remove the fluorine and to purify the zinc sulfate solution. The invention is not only able to extract zinc element from the materials containing high content of fluorine and silicon dioxide and achieves the comprehensive utilization of the zinc metallurgy raw materials, but also achieves the recirculation of the potassium fluosilicate and reduces the resource waste and environmental pollution. Therefore, the invention is applicable to the producing process of wet processing zinc metallurgy.

Owner:HULUDAO ZINC IND CO LTD

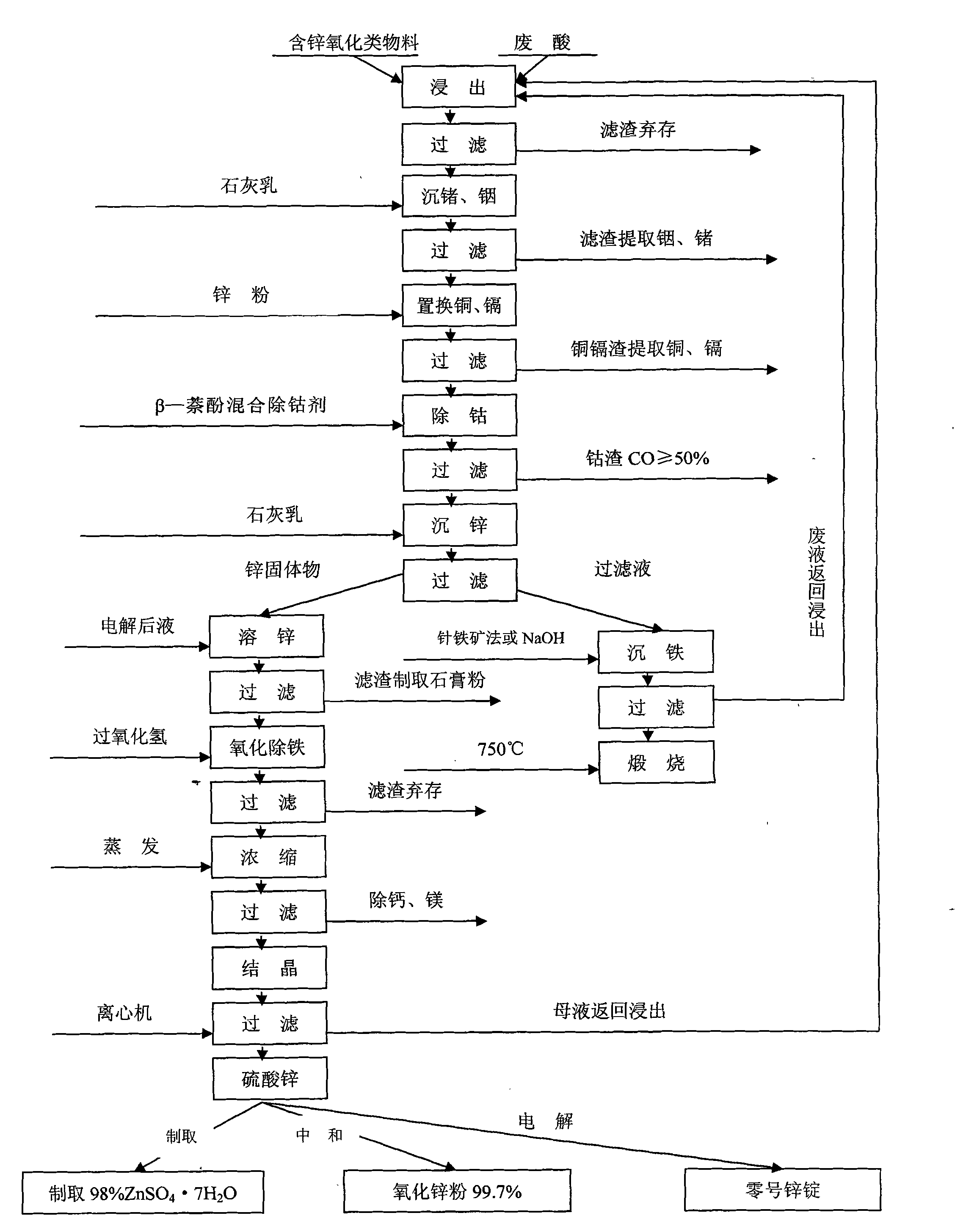

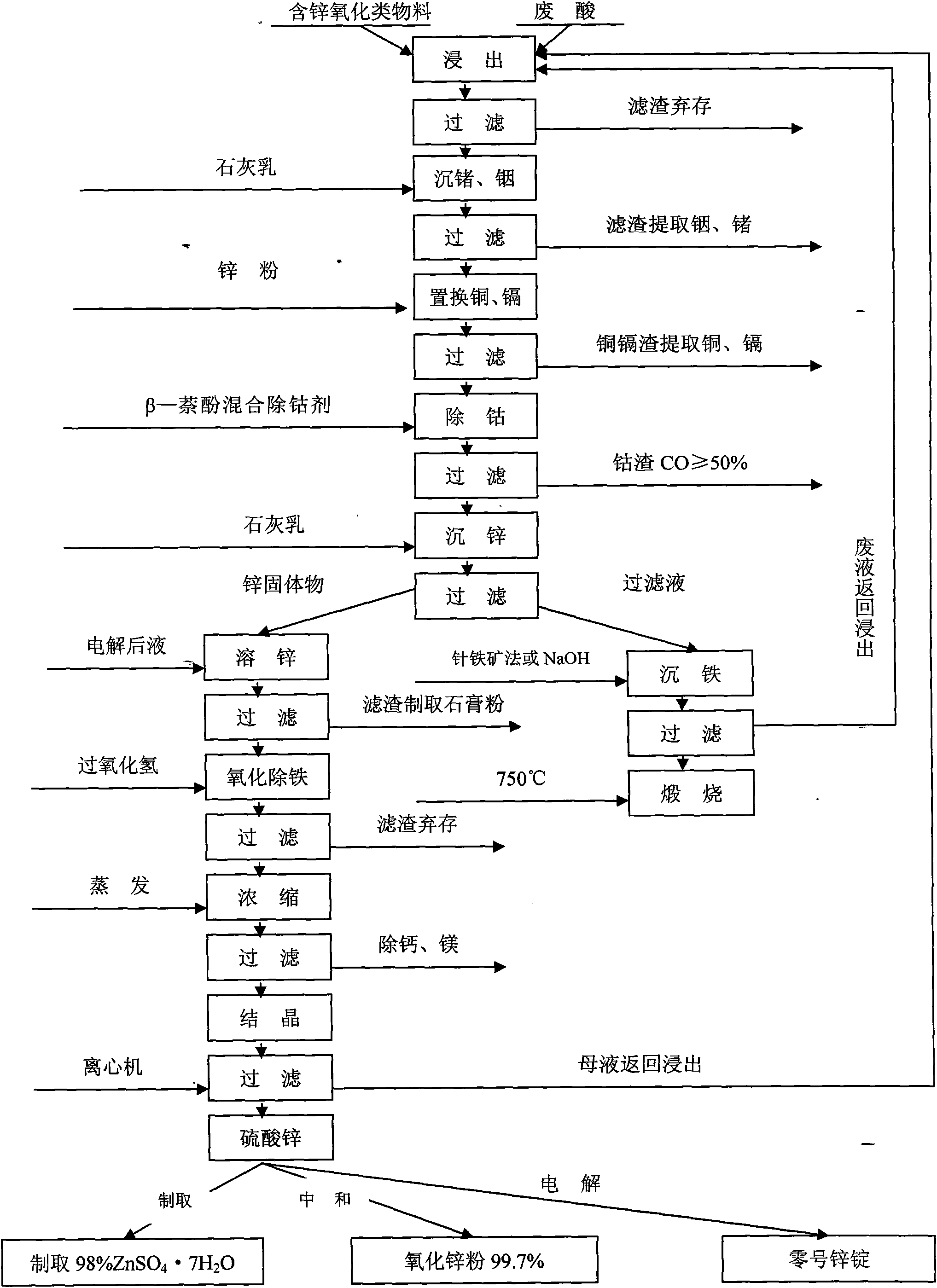

Method for extracting electrolytic zinc from oxide material containing less than 20% of zinc by using waste acid in titanium white plant

InactiveCN101974682ASolve processing problemsIncrease leachingProcess efficiency improvementZinc hydroxideElectrolysis

The invention discloses a method for producing electrolytic zinc, which comprises the following steps: (1) producing the electrolytic zinc from oxide material containing less than 20% of zinc serving as a raw material and by taking waste acid in a titanium white plant as a leaching agent, namely by using two wastes; (2) grinding the oxide material to obtain 80 to 100-mesh material and leaching zinc in the material by using the waste acid for about 3 to 4 h so as to obtain soluble zinc sulfate; (3) filtering and adding lime milk to regulate the pH value to 5.4 and hydrolyze impurities and rare metals in the solution to be separated out in the form of precipitate; (4) adding zinc powder into the solution without the impurities so that copper and cadmium in the solution perform replacement reaction to generate cooper and cadmium-containing precipitates which are commonly called 'copper and cadmium slag'; (5) separating the zinc from ferrous iron in the solution without cobalt, namely, hydrolyzing zinc sulfate in the solution by using lime milk as a precipitant to generate white zinc hydroxide precipitate; (6) filtering the zinc hydroxide precipitate, heating the obtained solution to about 70 DEG C and introducing air to oxidize the ferrous iron to ferric iron; and adding a proper amount of oxidant so as to oxidize the ferrous iron in the solution to the ferric iron and separate out the ferric iron in the form of precipitate, namely, removing iron by a 'goethite process'; (7) dissolving the precipitate by the electrolyzed solution and filtering, wherein the filter residue is used for preparing 'gypsum', the solution is subjected to impurity removal, evaporation, concentration and crystallization, the crystallization mother solution is returned to the leaching process, and the crystal is dissolved by water and used for preparing electrolyte; and (8) electrolyzing, stripping, melting and casting into a zinc ingot.

Owner:PANZHIHUA SHUOSHENG IND & TRADING

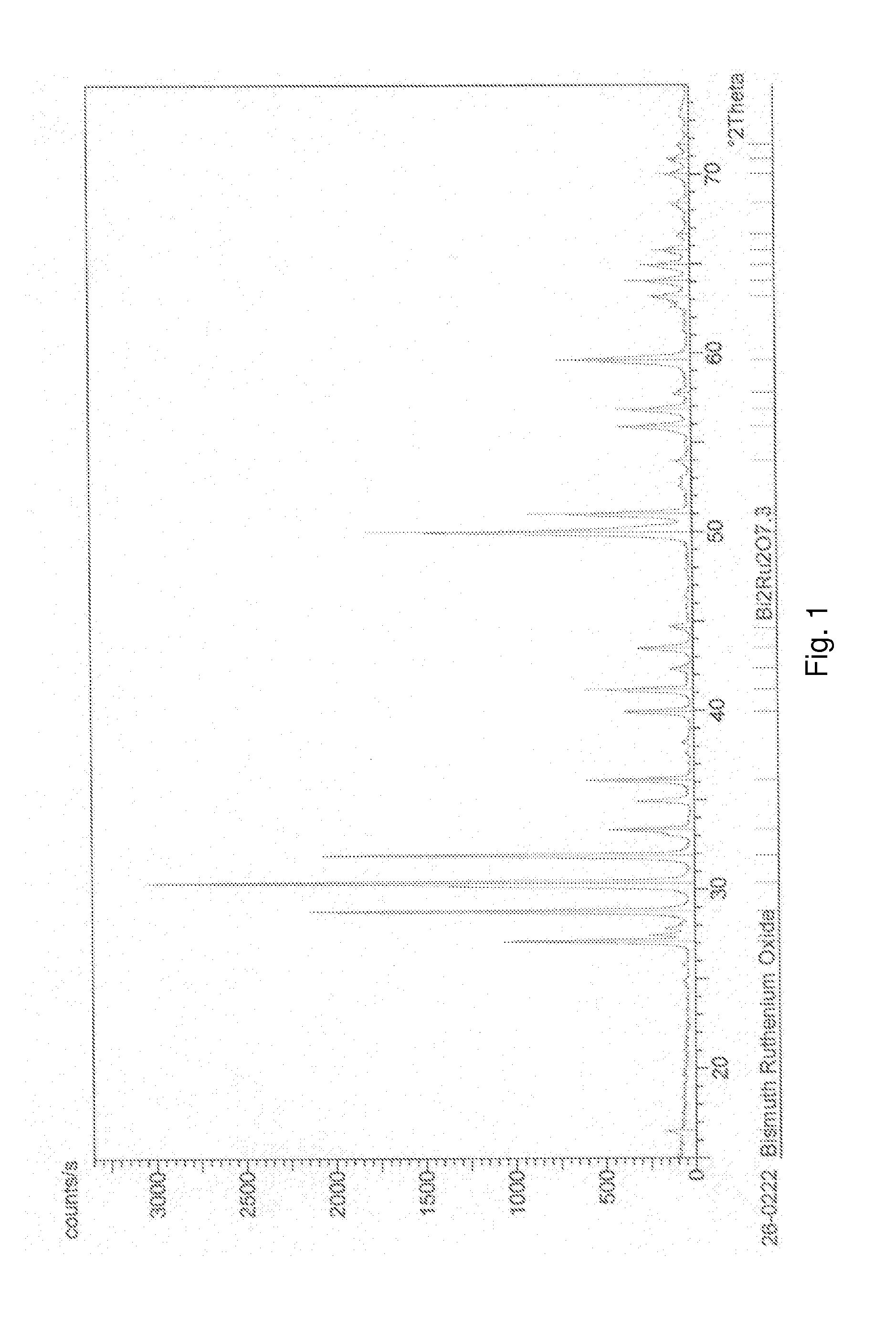

Bismuth metal oxide pyrochlores as electrode materials for electrolytic ozone and perchlorate generation

InactiveUS20110226634A1Safe and effective replacementCellsPhotography auxillary processesElectrolysisLead dioxide

Novel bismuth based mixed metal oxide materials with pyrochlore structure are disclosed as anodes for electrolytic generation of ozone and perchlorate salts. These materials have high electrical conductivity and excellent stability in acidic electrolytes. These materials are more environmentally friendly than lead dioxide and less expensive than platinum.

Owner:CERAMTEC

Pressure leaching method for high silica zinc oxide ore

The invention relates to a hydrometallurgical technology for zinc oxide ore, in particular to a leaching method for high silicon zinc oxide ore. The method of the invention is as follows: the high silicon zinc oxide ore and commercial zinc waste electrolyte with Zn2+ of free sulphuric acid are in size mixing, and then are putted into an autoclave to perform pressuring and leaching reaction, the reacted ore slurry undergoes liquid-solid separation to obtain leaching solution with zinc, and the obtained leaching solution with zinc is processed to obtain electrolytic zinc through a conventional mature technology. The leaching method for high silicon zinc oxide ore intensifies the leaching process of zinc in zinc oxide ore, realizes zinc leaching with high efficiency in the high silicon zinc oxide ore; through using the leaching method for the high silicon zinc oxide ore, silicon in the ore almost is remained in residue in the process of pressuring and leaching, the silica content of the leaching solution is less than 0.8 percent, and the ore slurry easy to filter is obtained; and the leaching solution with zinc is processed to obtain the electrolytic zinc through the conventional mature technology directly.

Owner:KUNMING UNIV OF SCI & TECH

Electrolysis method of polymetallic blister copper

InactiveCN101392388AAutomatic fall offOvercoming anode passivationPhotography auxillary processesProcess efficiency improvementSludgeCupric nitrate

The invention provides an electrolytic method of polymetallic raw copper. The method takes raw copper as an anode, a copper plate or stainless steel as a cathode and carries out electrolysis under the process conditions as follows: (1) the electrolytic solution contains 10g / l to 30g / l of nitric acid, 15g / l to 180g / l of cupric nitrate and the residual quantity of water, which form a cupric nitrate- nitric acid system which keeps the components of the electrolytic solution in the concentration range of the system during the electrolytic process; (2) salt chloride is added into the electrolytic solution and during the electrolytic process, the concentration of the chloride ion is kept between 1 to 10g / l; and (3) cathode current density 100A / m<2> to 300A / m<2>. During the electrolytic process, the method can loosen the anode sludge to cause the anode sludge to fall off automatically, thus overcoming the anodic passivity and the electrolytic process can be conducted smoothly. The method also has the advantages of lowering the cost for separating copper and other metal, shortening the production cycle and reducing environment pollution.

Owner:SIHUI CITY HONGMING PRECIOUS METALS +1

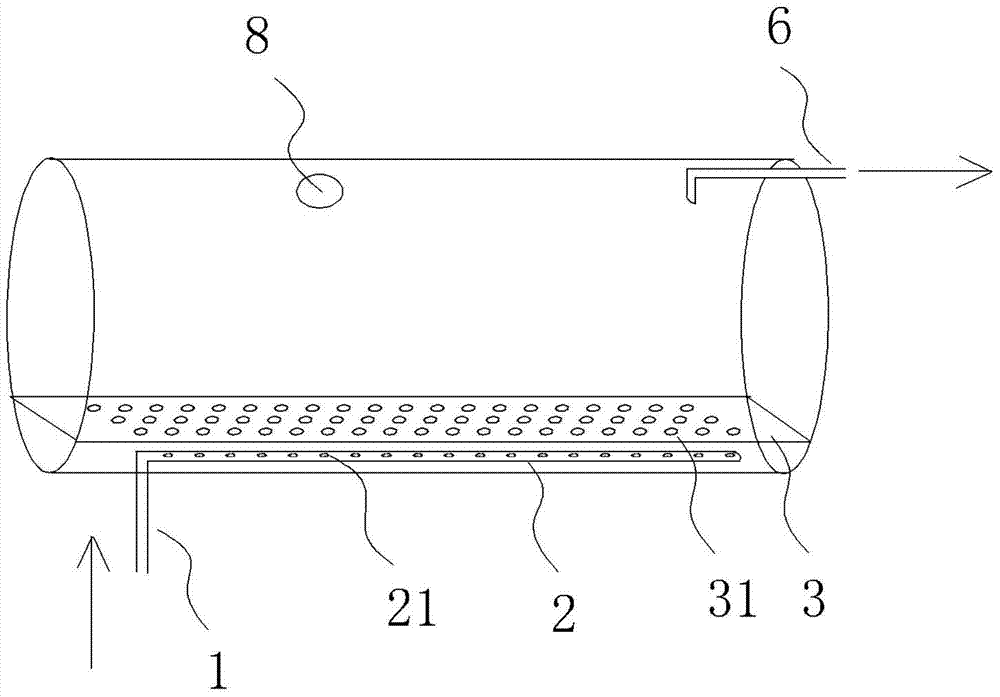

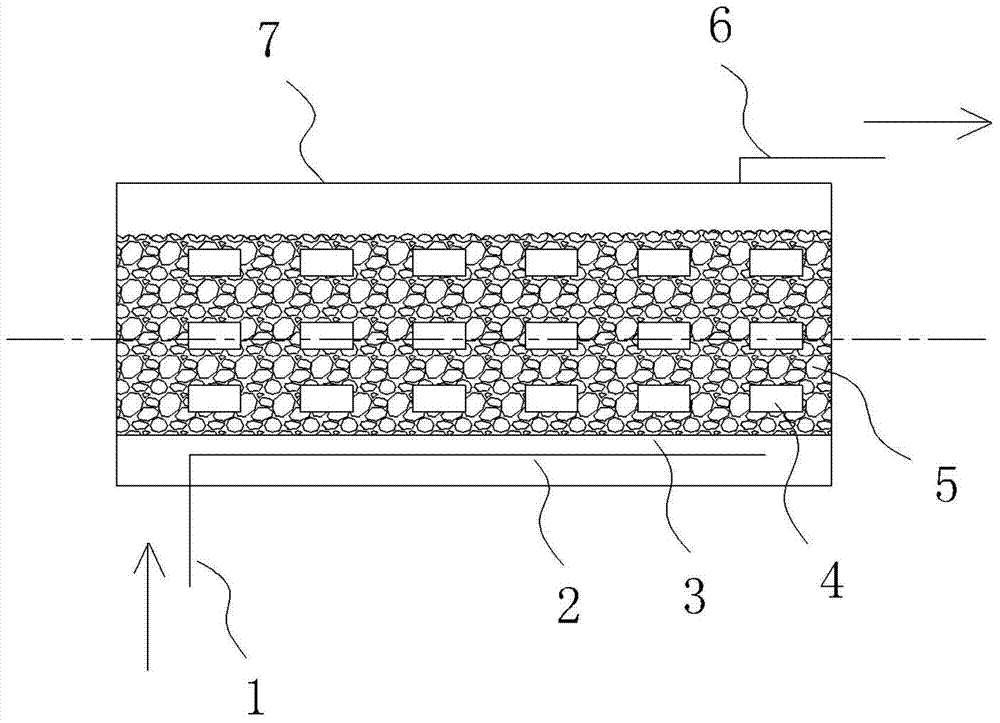

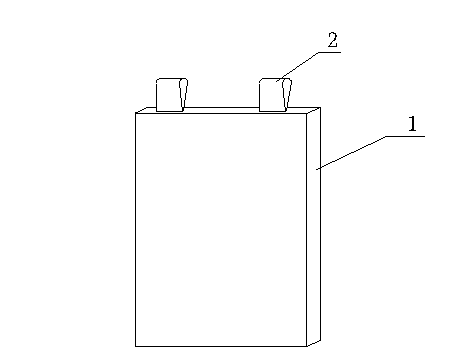

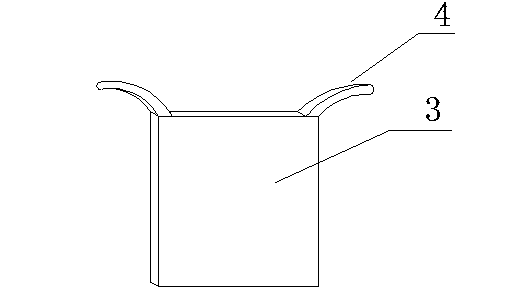

Micro-electrolysis intensifying treater and method for treating wastewater by using same

InactiveCN103613174AEasy to handleImprove responseWater/sewage treatmentTreatment effectElectrolysis

The invention discloses a micro-electrolysis intensifying treater and a method for treating wastewater by using the same. The micro-electrolysis intensifying treater comprises a micro-electrolysis reactor, a micro-electrolysis iron carbon filler and a permanent magnet, wherein the micro-electrolysis iron carbon filler is adsorbed on the periphery of the permanent magnet to form a micro-electrolysis intensifying unit; the micro-electrolysis intensifying unit is arranged inside the micro-electrolysis reactor. According to the embodiment of the invention, the micro-electrolysis intensifying unit is formed by adding innumerable permanent magnets inside the micro-electrolysis treater, so that innumerable magnetic fields which are uniformly distributed can be produced, electrons orderly move and repeatedly move, long-chain substances and circular-chain substances are thoroughly decomposed, and the treatment effect of the micro-electrolysis wastewater is improved.

Owner:湖北纽太力环境科技股份有限公司

Producing method of electrolytic copper powder

InactiveCN103866352AImprove qualityHigh purityPhotography auxillary processesProcess efficiency improvementCopperEnergy consumption

The invention discloses a producing method of electrolytic copper powder. The method comprises steps of: inserting an electrolytic copper plate that is a raw material into a conductive copper bar so as to adopt the inserted copper plate as a copper negative plate, electrolyzing in an electrolytic tank, filtering obtained electrolytic copper powder and a mixed solution containing electrolyte, elutriating, drying and reducing the wet electrolytic copper powder, smashing and screening. In the electrolytic process, the copper ion concentration in the electrolyte is 5-7 g / L, the sulfuric acid concentration is 120-150 g / L, the electrolytic temperature is 45-55 DEG C, the current in the electrolytic tank is 13000 A, the powder scrapping time is 30-40 min for one time of powder scrapping, and the electrolyte is fed in a manner of feeding in a direction parallel to the negative plate and the positive plate. The method omits a step of casting melt electrolytic copper into the positive plate of a certain specification and shapes, effectively reduces the production cost and improves the quality of the produced electrolytic powder. The produced electrolytic powder has a size not more than 200 meshes and is high in purity. Electrolysis can be normally performed in the electrolytic tank when the voltage is 1.6-1.8 volts, thus largely reducing the energy consumption. The electrolytic efficiency can be 80-85%.

Owner:CHONGQING YOUYAN ZHONGYE NEW MATERIAL

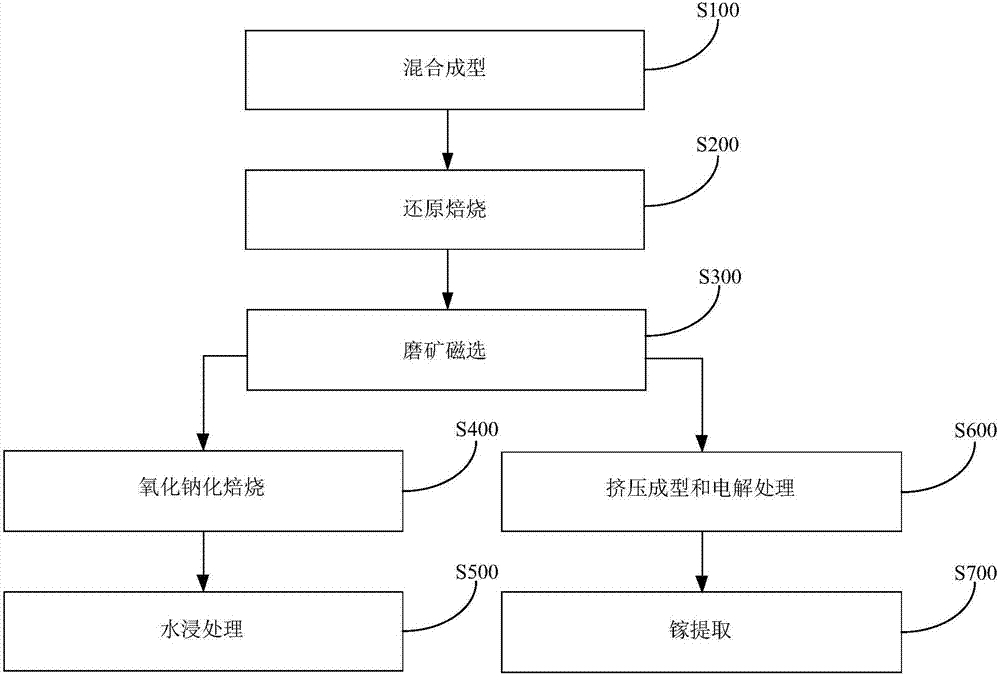

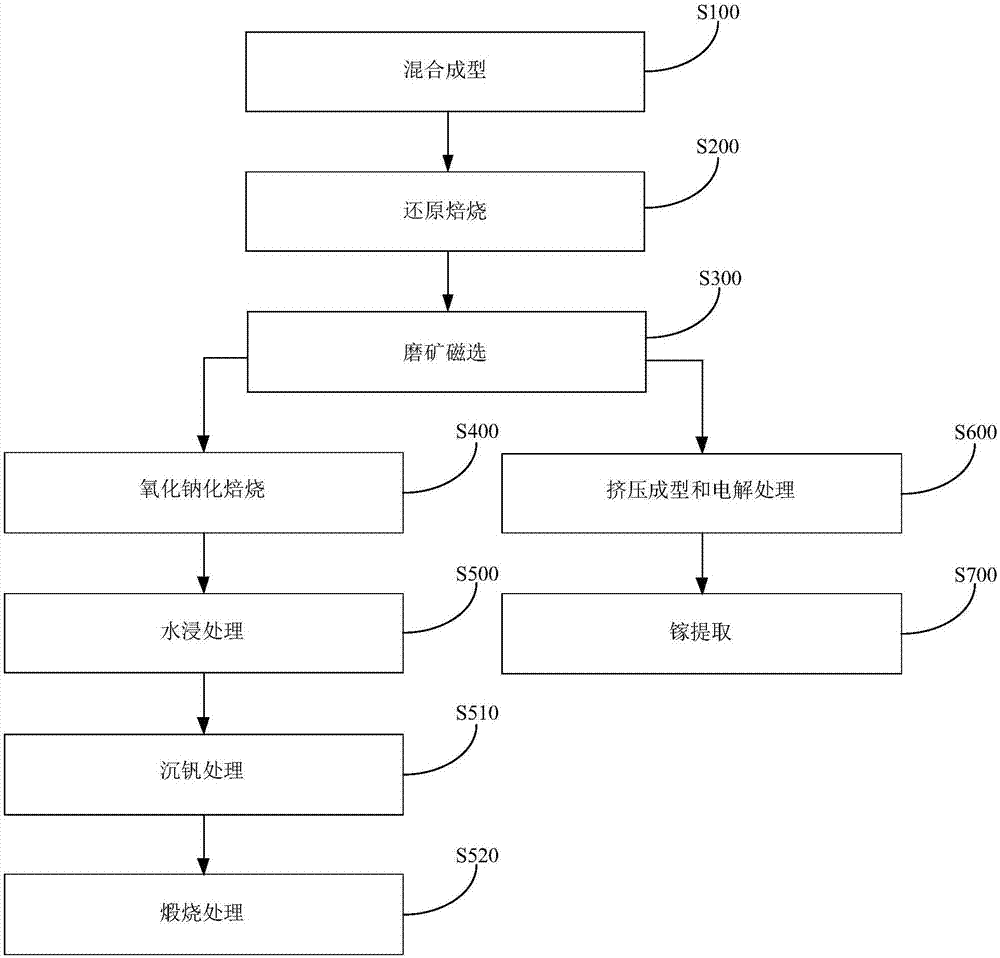

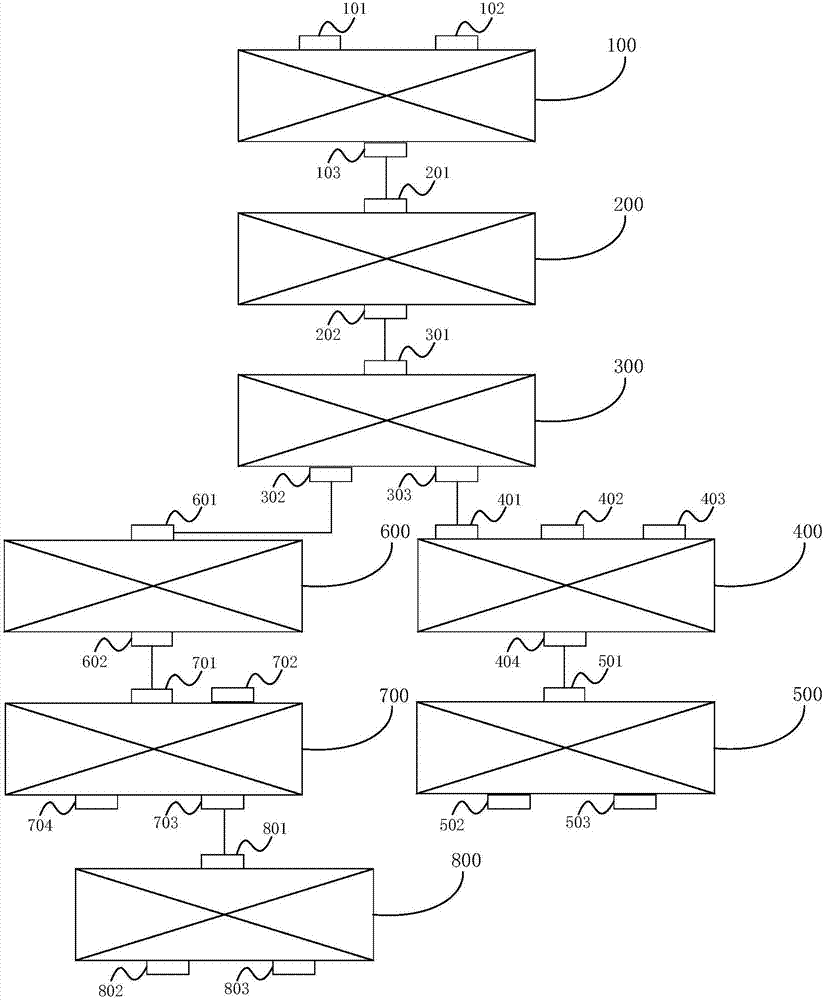

Method and system for treating vanadium extraction tailings

The invention provides a method and system for treating vanadium extraction tailings. The method comprises the steps that the vanadium extraction tailings and reduced coal are mixed and formed, so that mixed pellets are obtained; reduction roasting treatment is conducted on the mixed pellets, so that metalized pellets are obtained; ore grinding magnetic separation treatment is conducted on the metalized pellets, so that iron powder containing gallium and vanadium-rich slag are obtained; the vanadium-rich slag and sodium salt are mixed and treated through oxidation sodium salt roasting, so that water-soluble sodium vanadate clinker is obtained; water leaching treatment is conducted on the water-soluble sodium vanadate clinker, so that vanadium pentoxide and first tailings are obtained; extrusion forming is conducted on the iron powder containing gallium to obtain iron anodes containing gallium, and electrolysis treatment is conducted on the iron anodes containing gallium, so that anode slime containing gallium and electrolytic iron are obtained; and gallium in the anode slime containing gallium is extracted, so that metal gallium and second tailings are obtained. By the adoption of the method, comprehensive recycling of iron elements, vanadium elements and gallium elements in the vanadium extraction tailings can be achieved, the electrolytic iron, the vanadium pentoxide and the metal gallium are obtained, and the problems that the utilization ratio of the vanadium extraction tailings is low, and the vanadium extraction tailings are stacked and abandoned for a long time are fundamentally solved.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Metal ceramic bonding agent diamond tool bit prepared by microwave sintering and preparation method thereof

The invention provides a metal ceramic bonding agent diamond tool bit prepared by microwave sintering and a preparation method thereof. The diamond tool bit comprises the following substances of, by mass, 3 parts of diamond, 55 parts of electrolytic iron-copper-nickel-manganese alloy powder, 20 parts of copper powder, 10 parts of tin powder, 5 parts of zinc oxide and 12 parts of titanium dioxide.According to the diamond tool bit and the preparation method thereof, energy conservation and environmental protection can be realized, the working environment can be improved, and the labor intensityof workers can be reduced; due to the fact that holding force of a matrix to the diamond is enhanced, the service life and sharpness of the diamond tool bit are prolonged, so that electricity consumption of customers can be reduced in the product use process, more than 60% of electricity is saved compared with similar products, and production cost of the customers is reduced; according to a formula, the zinc oxide and the titanium dioxide inorganic substances are contained in a matrix, so that the red hardness of the diamond tool bit and the shape maintaining line of the product in the usingprocess are improved, and therefore the sharpness and the service life of the diamond tool bit are further enhanced, and the advantage of high cost performance of the product is achieved.

Owner:GUANGDONG NADE NEW MATERIALS CO LTD

Method for directly using aluminum and aluminum alloy ash for electrolytic production and recycling

InactiveCN101619396AOptimize process flowDoes not affect the later fusion processProcess efficiency improvementElectrolysisSlag

The invention relates to aluminum and aluminum alloy ash directly using for an electrolytic production recycling method, comprising the following steps: 1) when the aluminum alloy is melted and matched, adding 0.1-0.2%, based on the total weight of the aluminum alloy, of slagging agent by a nitrogen producing machine when the aluminium alloy is heated to 760-780 DEG C; 2) and standing the aluminum alloy for 10-15 minutes at retained temperature after adding the slagging agent, and then carrying out slag removal; 3) transporting the removed aluminum ash into a residue field and cooling the removed aluminum ash naturally; 4) collecting the aluminum ash when the temperature is reduced to normal temperature; 5) transporting the aluminum ash collected in step 4 to an electrolytic plant, adding the aluminum ash into an electrolytic bath; and 6) transporting the aluminum generated in the electrolytic bath into a smelting furnace to carry out aluminum alloy melting and matching, then continually recycling the aluminum ash generated by the melted and matched aluminum alloy. The invention has simple and convenient process flow, and doses not affect the melting and matching process in later stage; not only saves the cost, but also prevents pollution, really realizes economic recycling, and has significant economic benefits.

Owner:SHANDONG BINZHOU BOHAI PISTON

Fe-based amorphous alloy strip

ActiveUS7744703B2Easy to crackIncrease flux densityInorganic material magnetismAlloyAlternating current

The present invention provides a Fe—B—Si system amorphous alloy thin strip excellent in high magnetic flux density, thermal stability, amorphous formability improved workability and low core loss. The present invention further provides a Fe—B—Si system amorphous alloy thin strip which has the reduced cost without using high purity iron resources such as an electrolytic iron as iron resources used in an amorphous alloy thin strip, and also has core loss less than 0.10 W / kg at W13 / 50 in soft magnetic property in alternating-current field. The Fe—B—Si system amorphous alloy thin strip according to the present invention contains an appropriate amounts of N, C, P to improve thermal stability, amorphous formability, workability (brittleness), and core loss without deteriolating magnetic flux density, and contains, in atomic %, B: 5-25%, Si: 1-30%, N: 0.001-0.2%, C: 0.003-10%, P: 0.001-0.2% and the balance being Fe and unavoidable impurities, and optionally contains Co or Ni substituted to less than 15% of the Fe amount, or Cr at less than 5% substituted to the Fe amount. Further, Mn: 0.15-0.5 mass %, S: 0.004-0.05 mass % can be included.

Owner:NIPPON STEEL CORP

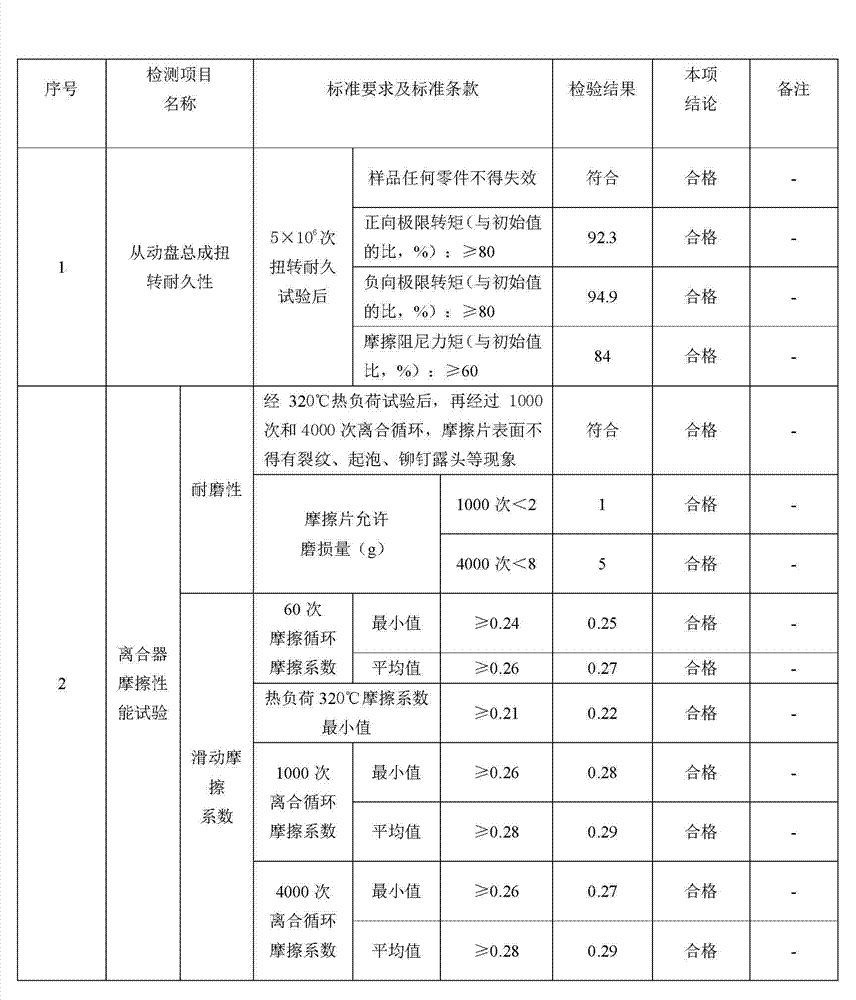

Automobile clutch gear with sintered copper, aluminum and steel based on powder metallurgy technology and manufacturing method of automobile clutch gear

ActiveCN102756123AImprove performance and stabilityImprove accuracyPortable liftingInterengaging clutchesAlloyStearic acid

The invention discloses an automobile transmission gear with sintered copper, aluminum and steel based on a powder metallurgy technology and a manufacturing method of the automobile transmission gear. The automobile transmission gear takes electrolytic iron powder as a base material and also comprises the following components in weight percentage: 20%-30% of waste steel powder, 1.2%-1.8% of copper powder, 1.2%-1.5% of manganese sulfide powder, 2%-3% of waste aluminum powder, 0.2%-0.6% of molybdenum disulfide, 1.2%-1.5% of chromium powder, 0.8%-1.2% of graphite, 1.2%-1.6% of micrometer acrawax with the size being less than 45 microns and 1.5%-1.8% of stearic acid with the size being less than 45 microns. According to the invention, the waste steel powder, the waste aluminum powder and alloy materials thereof are combined, a sintering process is adopted, and the characteristics of stable performance and few uncontrollable impurity elements of the smelted waste steel powder, thus being good for improving the performance stability of a powder metallurgy product; secondly, the clutch gear has the advantages of high equal division precision, good wear resistance and excellent gear face hardness and pressure resistance, and can meet factory requirements; and meanwhile, a production process is greatly simplified and can meet the requirements on large-bath rapid production and material supply.

Owner:WUHU HEFENG CLUTCH

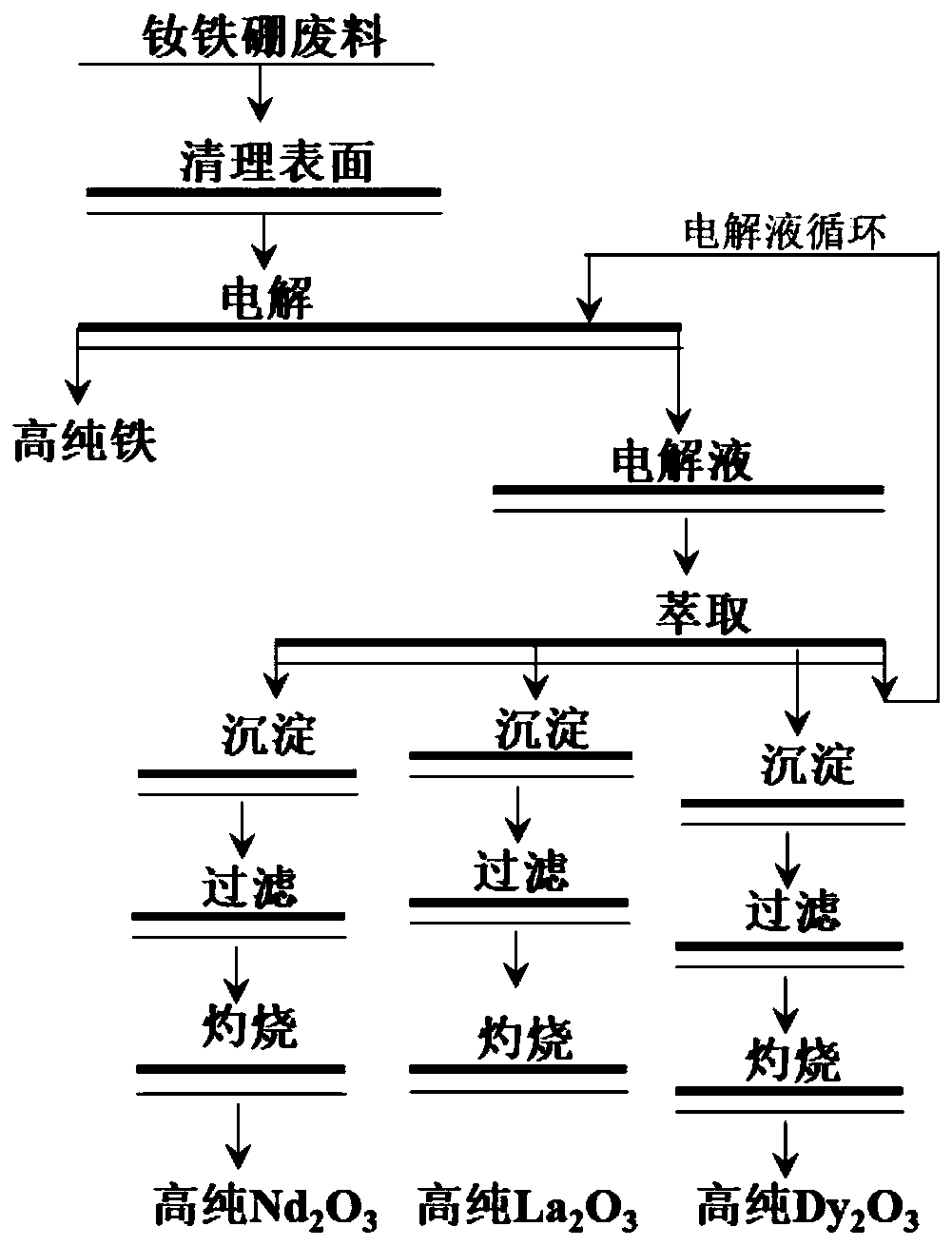

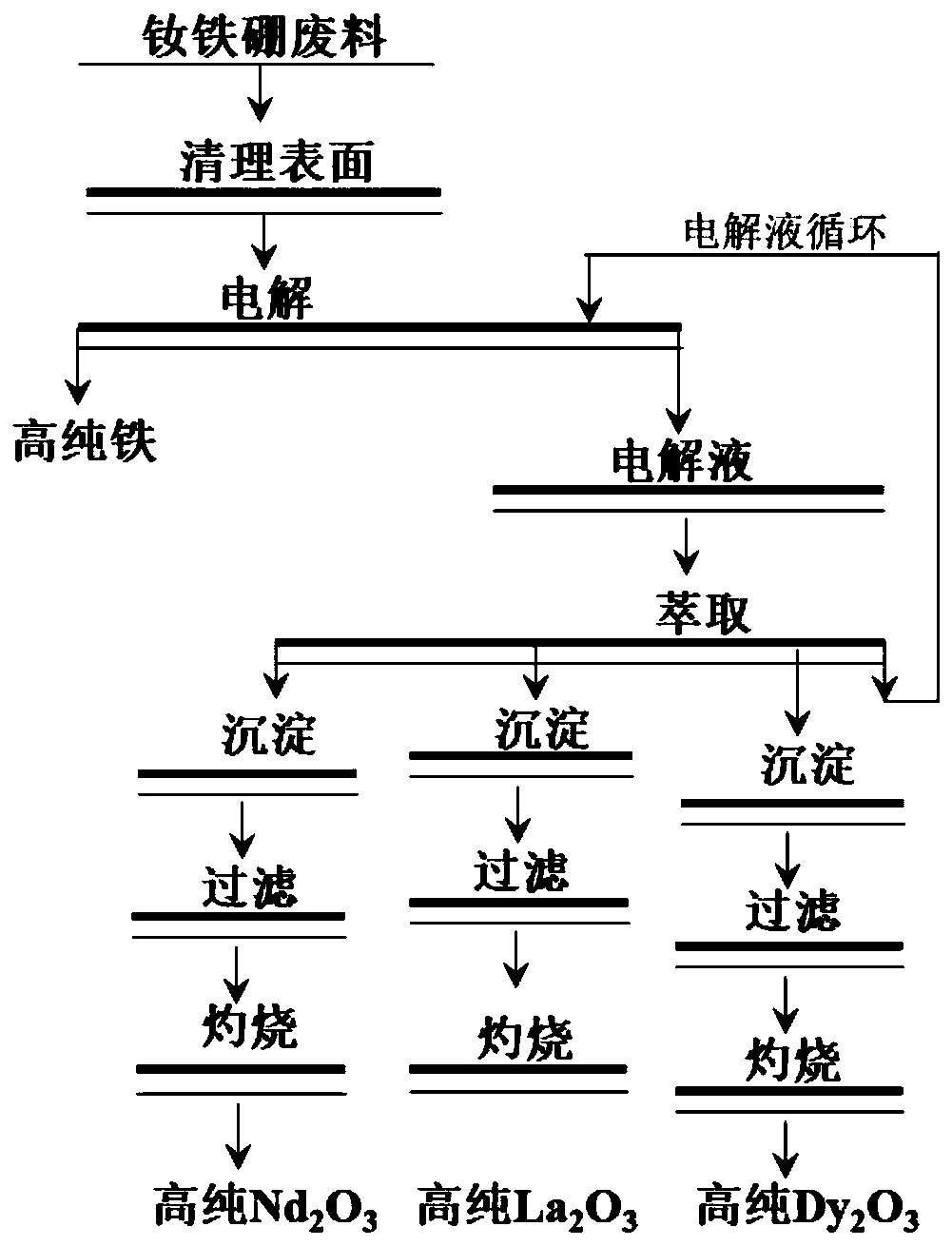

Nd-Fe-B waste solution electrolysis regeneration method

ActiveCN111154980APhotography auxillary processesConstruction waste recoveryElectrolytic agentRare-earth element

The invention belongs to the field of renewable resources and particularly relates to a Nd-Fe-B waste solution electrolysis regeneration method. The Nd-Fe-B waste solution electrolysis regeneration method comprises the steps of firstly, removing an anticorrosive layer on the surface of a Nd-Fe-B dismantled waste material; gathering the waste materials into a whole through the Nd-Fe-B magnetism toserve as an anode of an electrolysis system, wherein in the electrolytic process, the anode is dissolved, rare earth and iron ions go into a solution, the iron ions are separated out at a cathode to become high-purity iron, and the rare earth is enriched in electrolyte in an ionic state; and recycling rare earth elements in the electrolyte in a solvent extraction mode after completion of electrolysis and producing rare earth oxides or further producing rare earth metals. Through the Nd-Fe-B waste solution electrolysis regeneration method, a high-purity electrolytic iron product can be directlyrecycled in the electrolytic process, Nd, La, Dy and other rare earth ions left in the electrolyte are separated through extraction, the technological process has the requirement for the temperatureand can be implemented at normal temperature, and the high value-added utilization of iron and rare earth is realized.

Owner:UNIV OF SCI & TECH BEIJING

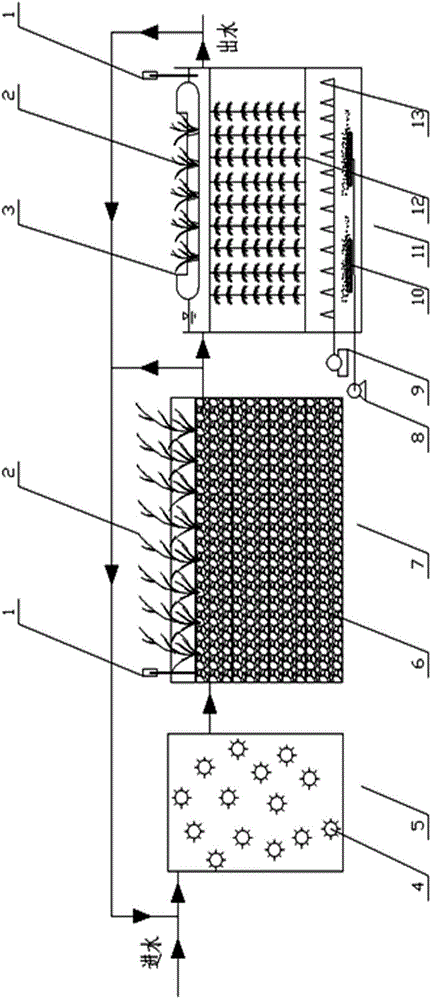

Device and method for using industrial wastes to control lake eutrophication

InactiveCN104787987AImprove water clarityClear waterEnergy based wastewater treatmentMultistage water/sewage treatmentFiberConstructed wetland

The invention discloses a device for using industrial wastes to control lake eutrophication. A micro vortex coagulation device is arranged in a closed pre-dam; effluent water of the closed pre-dam enters a micro-electrolytic constructed wetland; the micro-electrolytic constructed wetland is filled with micro-electrolytic iron-carbon fillers; plants grow on the micro-electrolytic iron-carbon fillers; one dosing device is buried at a water inlet position of the micro-electrolytic constructed wetland; the effluent water of the micro-electrolytic constructed wetland enters the closed pre-dam and a nano aeration river respectively; a nano aeration tray is arranged in the nano aeration river; a necking aeration head is arranged above the nano aeration tray; carbon fiber fillers are perpendicularly laid above the necking aeration head; an ecological floating island floats on the surface of the nano aeration river; plants grow on the ecological floating island; the other dosing device is buried at a water outlet position of the nano aeration river; effluent water of the nano aeration river is connected to the inflow water of the closed pre-dam. The invention further discloses a method for lake eutrophication. With adoption of the device, the content of aromatic ring substances in the treated sewage is reduced by more than 99%.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for manufacturing check valve core by powder metallurgy

InactiveCN102773485AImprove production continuityIncrease profitProcess efficiency improvementIron powderHigh volume manufacturing

The invention discloses a method for manufacturing a check valve core by powder metallurgy. The method includes steps of a, preparing a mixed material: using electrolytic iron powders as base materials, and mixing the electrolytic iron powders with other components of, by weight, 35%-40% of scrap steel powders, 5%-6% of recirculated iron powders, 3.5%-3.8% of manganese powders, 0.4%-0.5% of molybdenum powders, 0.3%-0.5% of chromium powders, 0.3%-0.5% of molybdenum disulfide powders, 0.8%-1.1% of waste aluminum powders, 1.8%-2.0% of graphite and 1.5%-2.0% of stearic acid which is smaller than 45 microns; and b, performing pressing molding: feeding the evenly mixed powder metallurgy material to a press machine, and performing the pressing molding by means of a mold to form the check valve core. The method for manufacturing the check valve core by the powder metallurgy is high in production continuity, high in material utilization, suitable for volume-producing and capable of reducing costs.

Owner:ANHUI FANCHANG COUNTY WANNAN VALVE CASTING

Comprehensive recovery method for neutralized deposited iron slag in zinc hydrometallurgy

ActiveCN107190151AHigh purityHigh activityPhotography auxillary processesProcess efficiency improvementRecovery methodFerric hydroxide

The invention discloses a compressive recovery method for neutralized deposited iron slag in zinc hydrometallurgy. The compressive recovery method is characterized by comprising the steps that the neutralized deposited iron slag in the zinc hydrometallurgy is washed with hot water at the temperature of 80-90 DEG C, and zinc sulfate washing liquid and iron hydroxide slag are obtained; the iron hydroxide slag is leached with the mixed liquid of hydrochloric acid, ammonium chloride and calcium chloride, iron chloride leaching liquid and leaching slag mainly containing calcium sulfate, bismuth oxychloride and antimony oxychloride are obtained; Fe3+ is reduced into Fe2+ by adding iron electrolytic iron powder or scrap iron to the iron chloride leaching liquid, meanwhile, impurities including As, Sb, Bi, Cu, Pb and Ge are replaced and purified, and iron dichloride purified liquid and purified slag are obtained; and the electrolytic iron powder is obtained by electrolyzing the iron dichloride purified liquid, residual electrolyte is returned for chlorination leaching, and iron powder purified slag and chlorination leaching slag are combined into raw materials for extracting valuable metals of Bi and Sb. According to the compressive recovery method for the neutralized deposited iron slag in the zinc hydrometallurgy, the electrolytic leaching electrolytic iron powder method is used for comprehensive recovery and treatment of the neutralized deposited iron slag in the zinc hydrometallurgy, and the purposes of short process, low pollution, low cost and high benefits are achieved.

Owner:六盘水中联工贸实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com