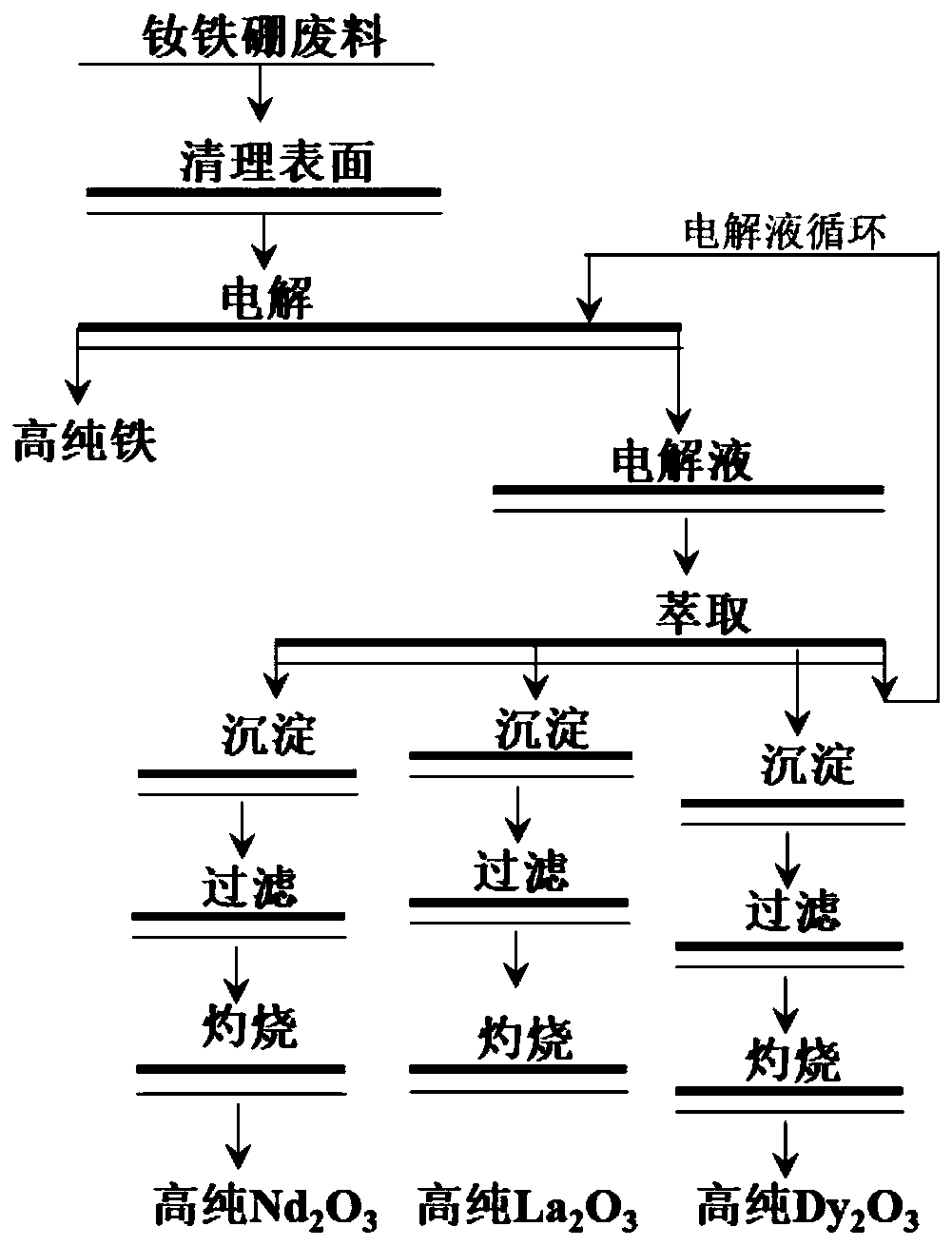

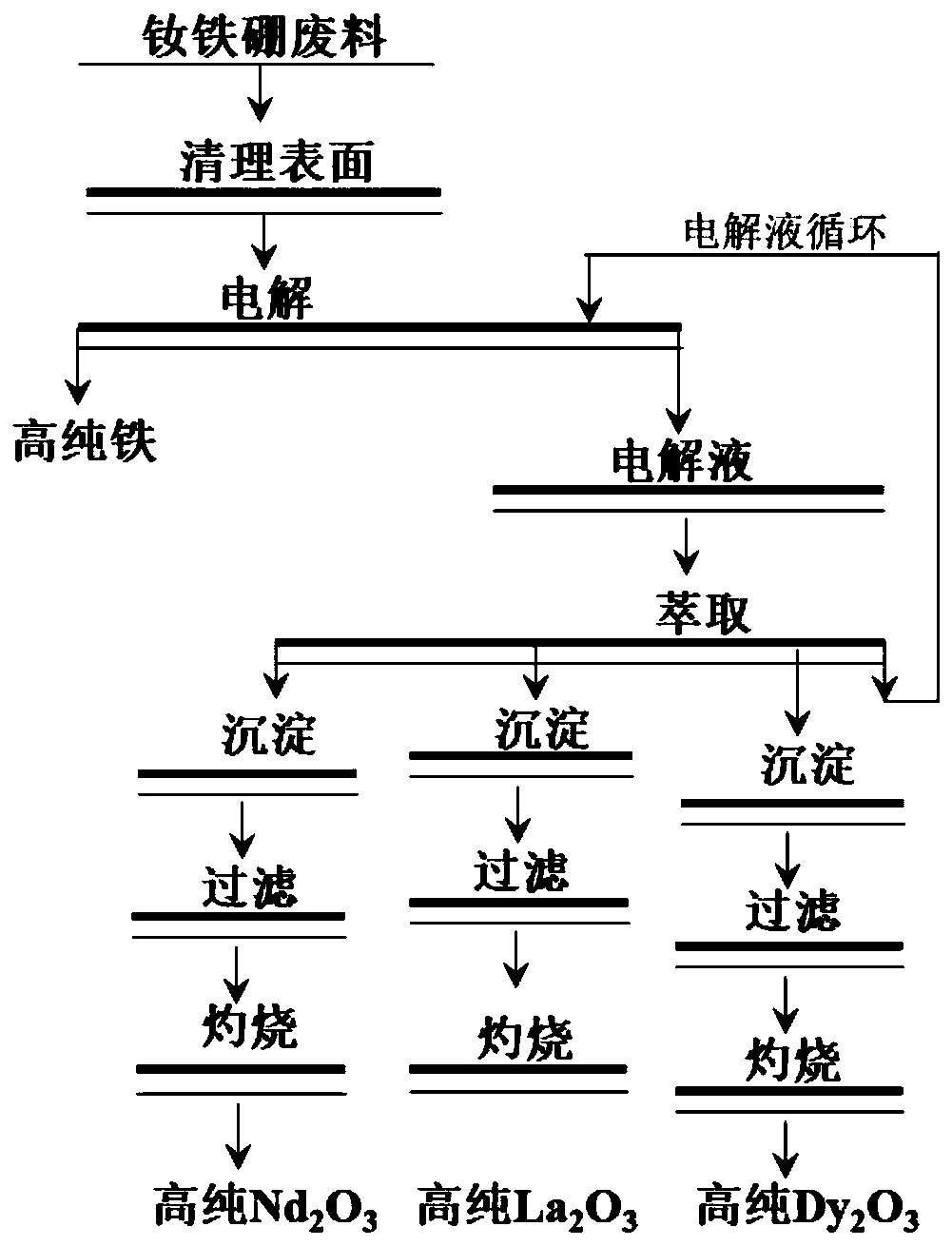

Nd-Fe-B waste solution electrolysis regeneration method

A technology of electrolytic regeneration and neodymium iron boron, which is applied in construction waste recycling, photographic technology, instruments, etc., can solve the problem of low iron utilization efficiency and achieve the effect of high value-added utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Refrigerator door magnetic strip debris, the main components (multiple test range values) are: TFe 61.62% ~ 63.12%, Nd 21.31% ~ 22.97%, Pr 3.03% ~ 3.86%, La 1.39% ~ 1.72%, B 9.16% ~10.03%; as FeSO 4 ·7H 2 O Prepare a solution with a concentration of 0.98mol / L-1.03mol / L as the electrolytic solution; the electrolysis temperature is room temperature (12°C-27°C); the anode of the electrolytic cell is the refrigerator door magnetic strip debris, and the cathode is a high-purity iron plate; the electrolysis pH is 2.5 ~3.62, current density 20mA / cm 2 ~200mA / cm 2 (initial to final process value).

[0033] Use process:

[0034] (1) Electrodes. Weigh 500g of NdFeB waste material, and place the debris in the anode basket after being gathered by the magnetism of the waste material; clean the surface of the high-purity iron plate; place the anode basket and the cathode plate in the electrolyte;

[0035] (2) Electrolyte. FeSO 4 ·7H 2 O was prepared into 3L of electrolyte sol...

example 2

[0039] Disassemble the magnetic block of the motor, the main components (multiple test range values) are: TFe 61.73% ~ 63.09%, Nd 21.47% ~ 22.85%, Pr 3.14% ~ 3.89%, La 1.34% ~ 1.68%, B 9.22% ~ 10.01%; as FeSO 4 ·7H 2 O Prepare a solution with a concentration of 0.99mol / L-1.05mol / L as the electrolytic solution; the electrolysis temperature is room temperature (12°C-27°C); the anode of the electrolytic cell is a disassembled magnet block of the motor, and the cathode is a high-purity titanium plate; the electrolysis pH is 2 .5~3.62, current density 20mA / cm 2 ~500mA / cm 2 (initial to final process value).

[0040] Use process:

[0041] (1) Electrodes. Weigh 512g of NdFeB waste material, connect the anode of the power supply after the two magnetic blocks are assembled by means of waste magnetism; clean the surface of the high-purity titanium plate; place the anode magnetic block and the cathode plate in the electrolyte;

[0042] (2) Electrolyte. FeSO 4 ·7H 2 O was prepared...

example 3

[0046] Zero miscellaneous waste NdFeB permanent magnet debris, the main components are: TFe 62.87% ~ 62.95%, Nd 22.39% ~ 22.57%, Pr 3.26% ~ 2.31, La 1.42% ~ 1.59%, B 9.45 ~ 9.46%; FeSO 4 ·7H 2 O to prepare FeSO with a concentration of 1.51mol / L~1.53mol / L 4 The solution is used as the electrolytic solution; the electrolysis temperature is room temperature (15°C-28°C); the anode of the electrolytic cell is a waste NdFeB magnet, and the cathode is a high-purity titanium plate; the electrolysis pH is 2.5-3.62, and the current density is 20mA / cm 2 ~200mA / cm 2 (initial to final process value).

[0047] Use process:

[0048] (1) Raw material (anode material) preparation. Cut and obtain 3g ~ 5g NdFeB magnetic block, grind it with a grinder to remove the pollutants on the surface of the magnetic block to expose the fresh surface, weigh and record its weight;

[0049] (2) Cathode material preparation. Take a small piece of pure iron sheet, cut it regularly, wipe off the surface i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com