Automobile clutch gear with sintered copper, aluminum and steel based on powder metallurgy technology and manufacturing method of automobile clutch gear

A technology of powder metallurgy and sintered copper, which is applied in the direction of mutually meshing clutches, clutches, and mechanically driven clutches. High-volume rapid production and supply requirements, simplified production process, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

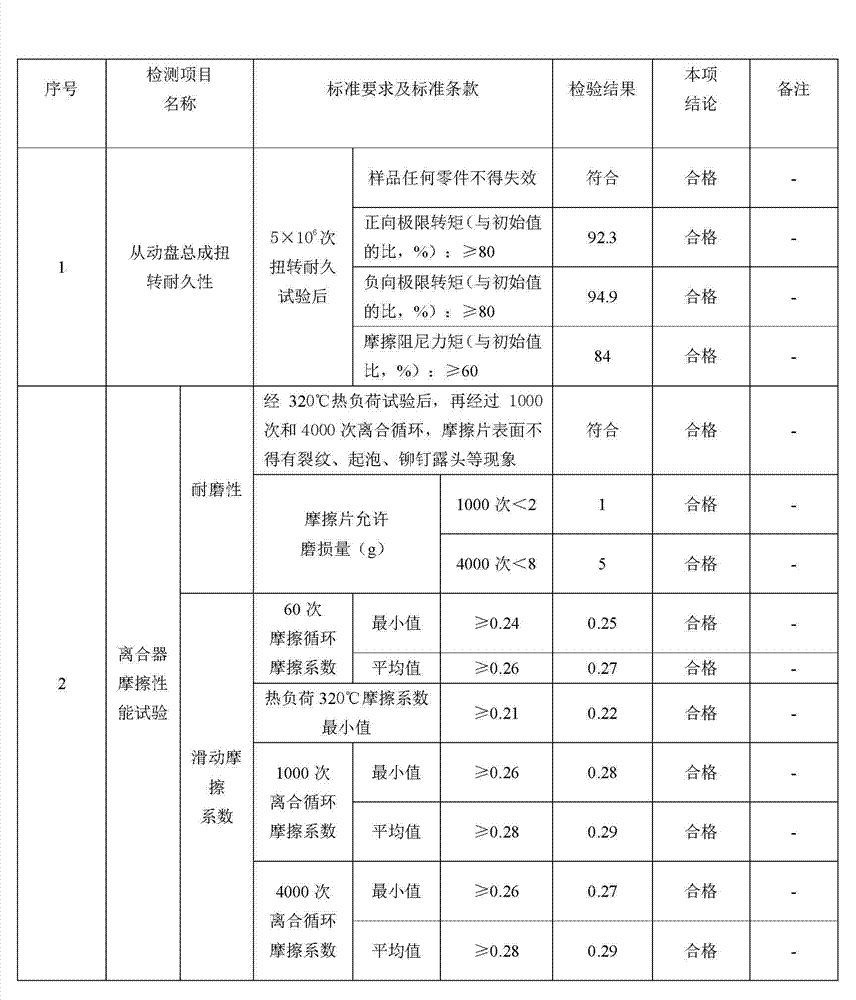

Image

Examples

Embodiment 1

[0012] Example 1: An automobile clutch gear based on powder metallurgy technology sintered copper-aluminum steel, with electrolytic iron powder as the matrix, and the weight percentages of the remaining components are: scrap steel powder 25, copper powder 1.5, manganese sulfide powder 1.4, waste aluminum powder 2.5, molybdenum disulfide 0.4, chromium powder 1.3, graphite 1, ake wax less than 45 microns 1.4, stearic acid less than 45 microns 1.7. Add up to 100%.

[0013] Production involves the following steps:

[0014] (1) Weigh each raw material according to the weight of the constituent raw materials, crush it to 300-400 mesh, mix it evenly, then put it into a mold and place it on a press with a pressure of 7.5T / CM 2 Under the condition of pressing and molding;

[0015] (2) Place the pressed compact in a mesh belt furnace for sequential sintering at a temperature of 600-650°C for 30-40 minutes; at a temperature of 800-850°C for 60-90 minutes; the temperature is controlled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com