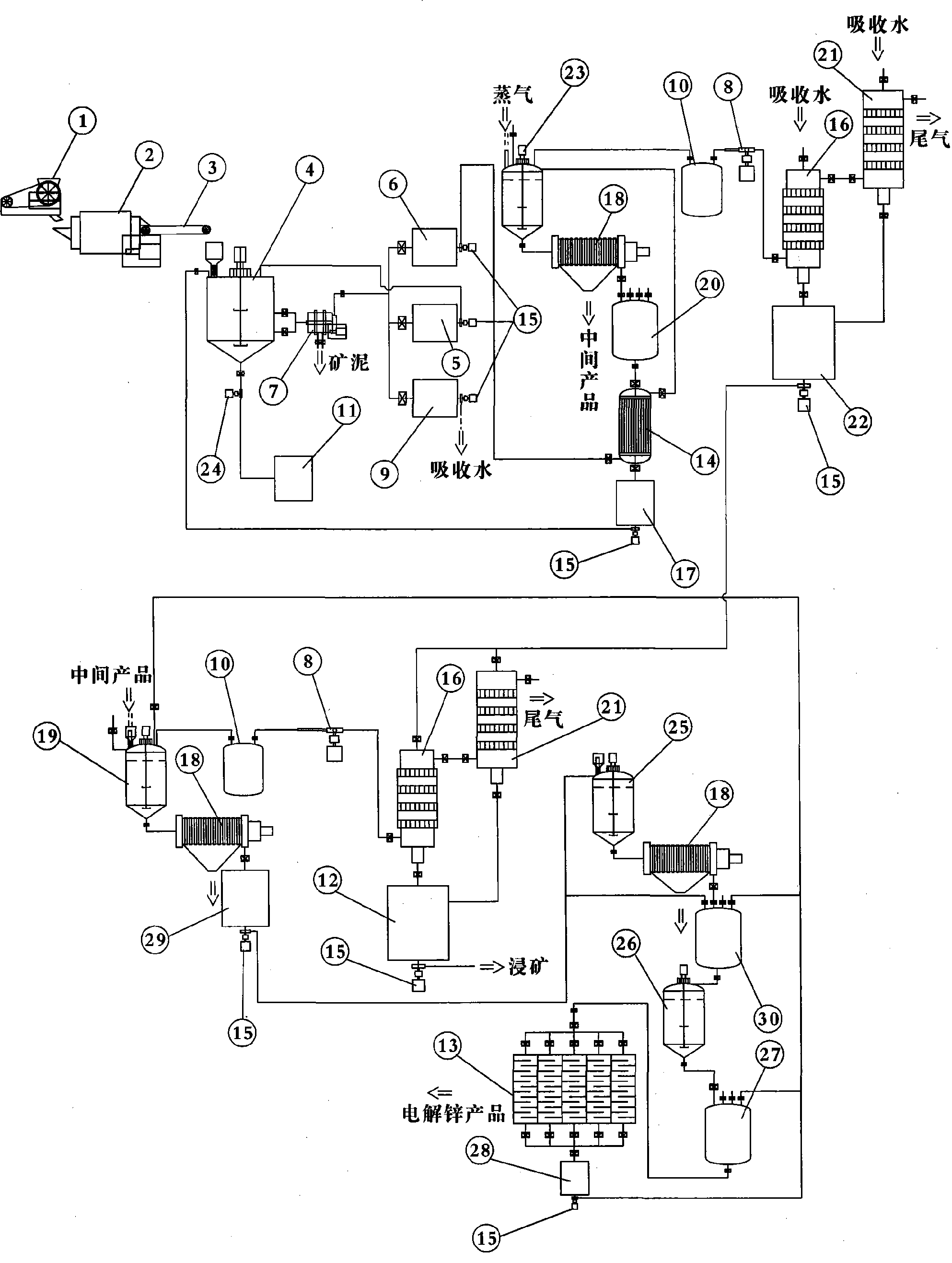

Method for producing electrolytic zinc from zinc oxide-containing materials

A technology for electrolysis of zinc and zinc oxide, which can be used in photography technology, instruments, photography auxiliary technology and other directions, and can solve the problems of low solubility of material and liquid, long leaching cycle, and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] A low-grade zinc oxide ore with a zinc content of 8% is put into the inlet of the crusher, and the crusher crushes the ore to less than 30mm. Then, the crushed ore is ground into a fine powder with a particle size of less than 100 mesh by a ball mill, and the ground powder is transported to the mixing tank feeder by a conveyor. Then, the mixed solution of ammonia and carbon ammonia (the concentration of ammonia water is 6%, and the concentration of carbon ammonia is 5%) in the mixing tank is used as the leaching agent, and the stirring device is opened first, and then the feeder is opened to make the leaching solution and the mineral powder. Reaction, the liquid-solid volume ratio is 2.5:1, react for 2 hours, turn off the stirring device, the generated zinc complex solution, ore sand and ore slime will naturally settle to the mixing tank for 30 minutes by their own weight, and open the feed liquid in the middle and lower part of the mixing tank Valve, the feed liquid fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com