Industrial wastewater degradation/microelectrolysis iron-carbon filler and preparation method thereof

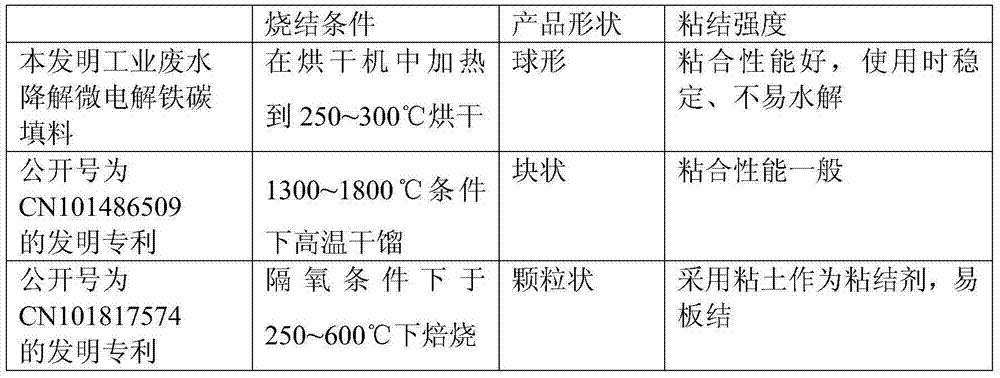

A technology of industrial wastewater degradation and micro-electrolysis of iron, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The problem is that the preparation method is simple and reasonable, the conditions are mild, and the effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The micro-electrolytic iron-carbon filler for degrading industrial wastewater consists of the following components: 65 parts by weight of iron powder, 35 parts by weight of activated carbon and 1.5 parts by weight of binder;

[0043] Iron powder is iron powder with 4% carbon content;

[0044] The binder consists of 6 parts by weight of sodium silicate, 2 parts by weight of calcium chloride and 2 parts by weight of hydroxypropyl cellulose.

[0045] The method for preparing the above-mentioned organic pollutant degradation micro-electrolytic iron-carbon filler comprises the following steps:

[0046] (1) Prepare binder: mix sodium silicate, calcium chloride and hydroxypropyl cellulose uniformly by weight to obtain binder;

[0047] (2) Mixing: put iron powder, activated carbon and binding agent into the mixer by weight ratio and mix evenly;

[0048] (3) into a ball: put the raw material mixed in the step (2) into a ball into a ball;

[0049] (4) Drying and forming: heat ...

Embodiment 2

[0051] The micro-electrolytic iron-carbon filler for degrading industrial wastewater consists of the following components: 55 parts by weight of iron powder, 30 parts by weight of activated carbon and 1 part by weight of binder;

[0052] Iron powder is iron powder with 4% carbon content;

[0053] The binder consists of 5 parts by weight of sodium silicate, 1 part by weight of calcium chloride and 1 part by weight of hydroxypropyl cellulose.

[0054] The preparation method is as in Example 1, wherein the drying temperature in step (4) is 300°C.

Embodiment 3

[0056] The micro-electrolytic iron-carbon filler for degrading industrial wastewater consists of the following components: 70 parts by weight of iron powder, 40 parts by weight of activated carbon and 2 parts by weight of binder;

[0057] Iron powder is iron powder with 4% carbon content;

[0058] The binder consists of 6 parts by weight of sodium silicate, 3 parts by weight of calcium chloride and 3 parts by weight of hydroxypropyl cellulose.

[0059] The preparation method is as in Example 1, wherein the drying temperature in step (4) is 260°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com