Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Destabilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

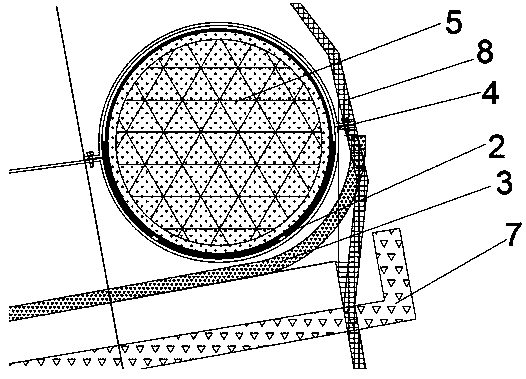

Magnetic induction tomography system and method

InactiveCN101341424AEasy inversionImprove spatial resolutionDiagnostic recording/measuringSensorsResearch ObjectEddy current

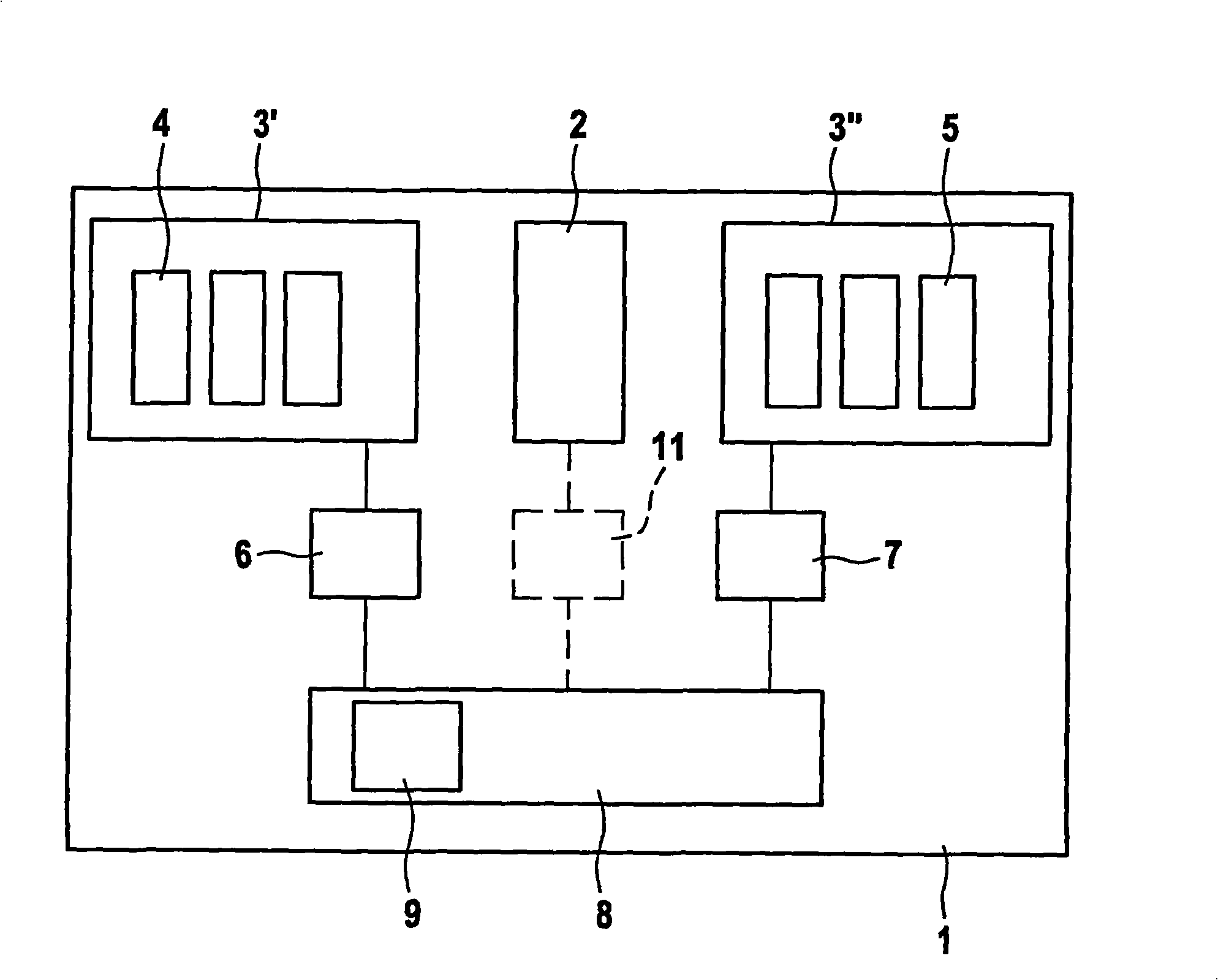

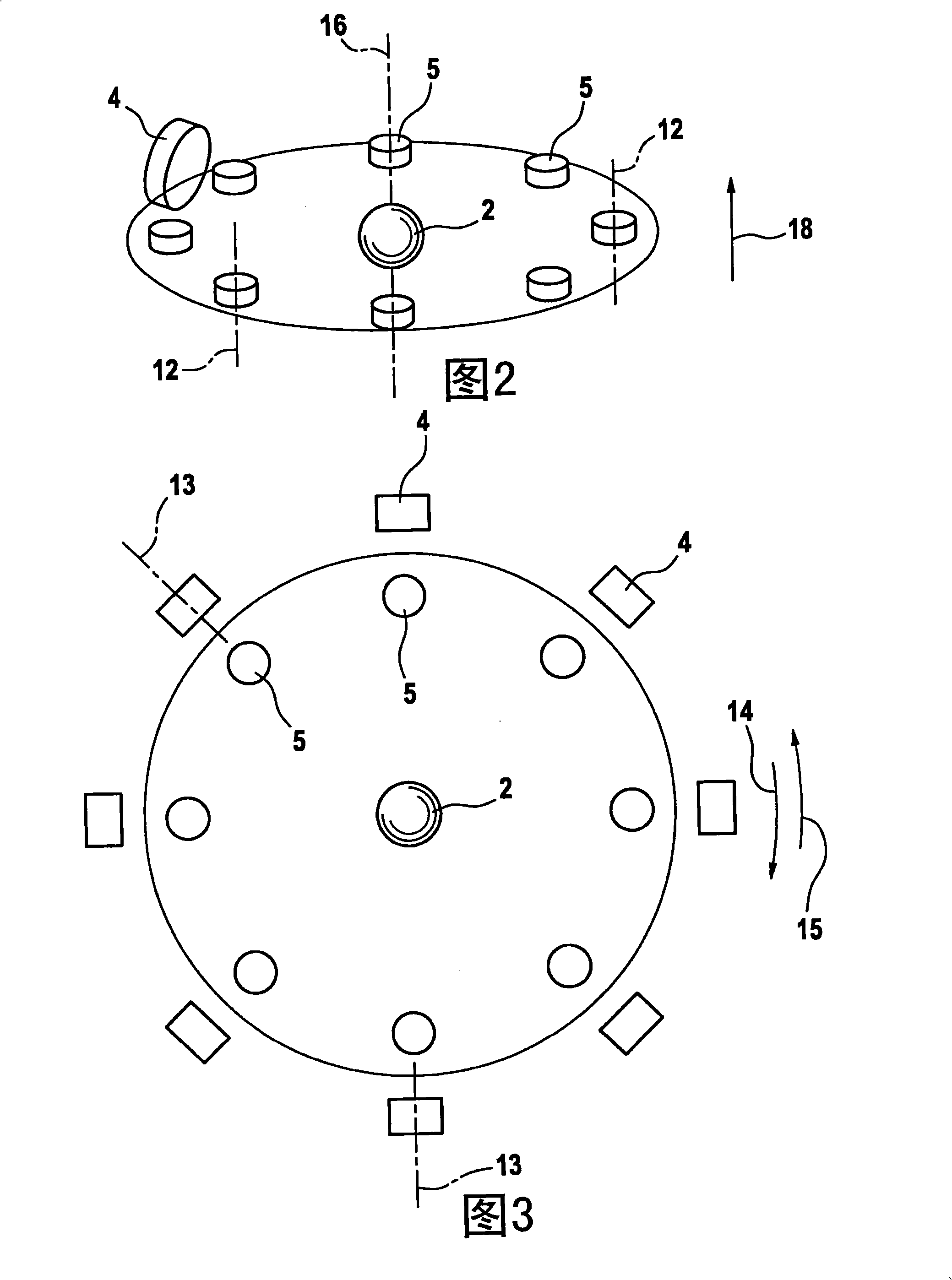

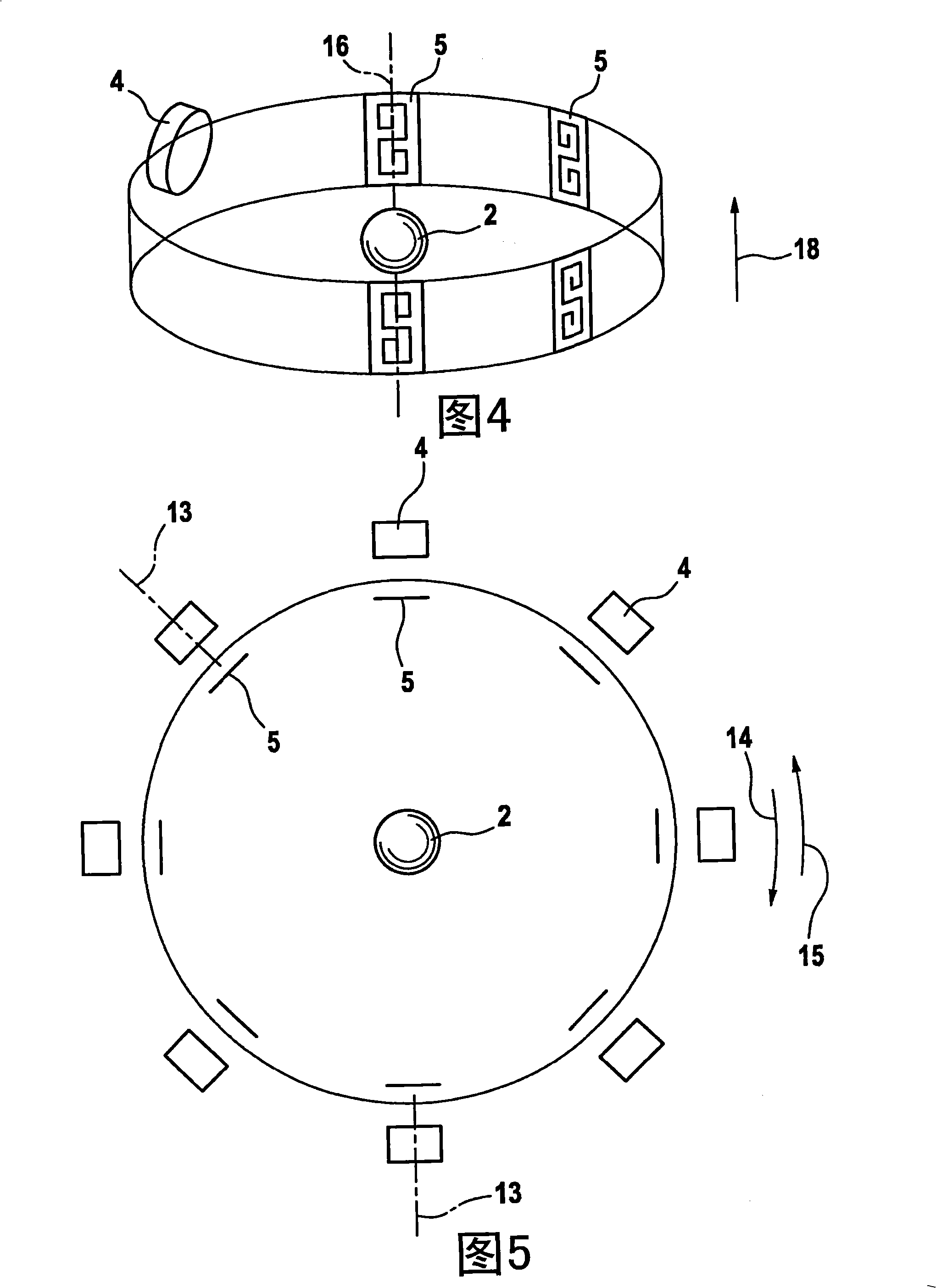

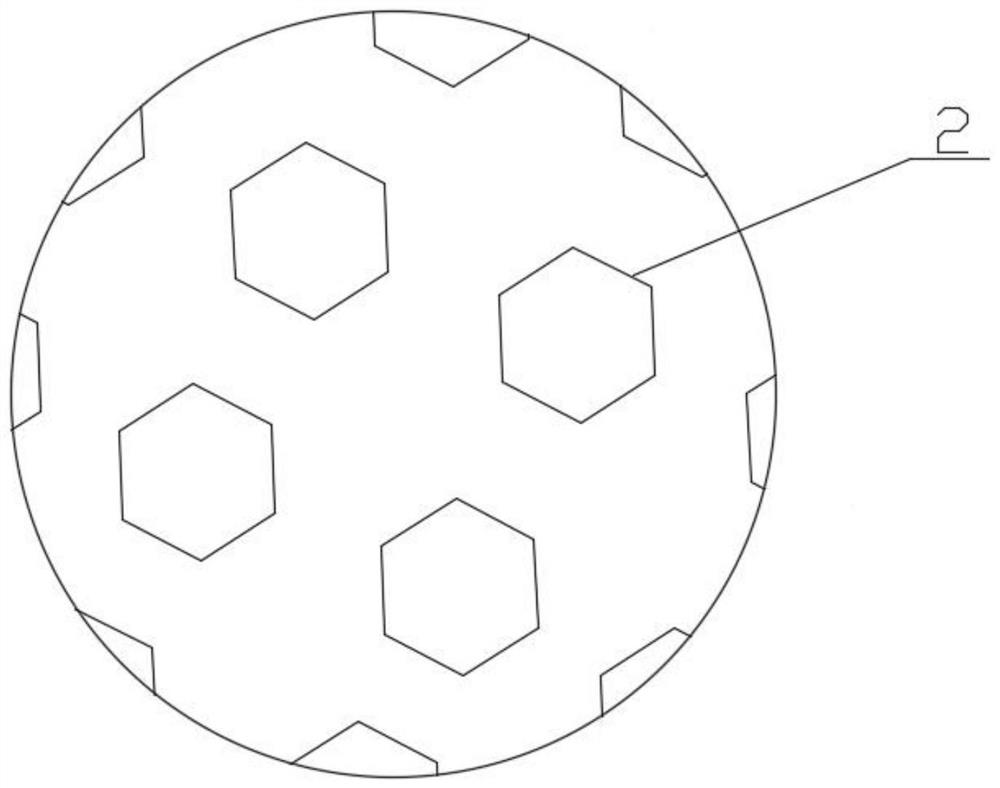

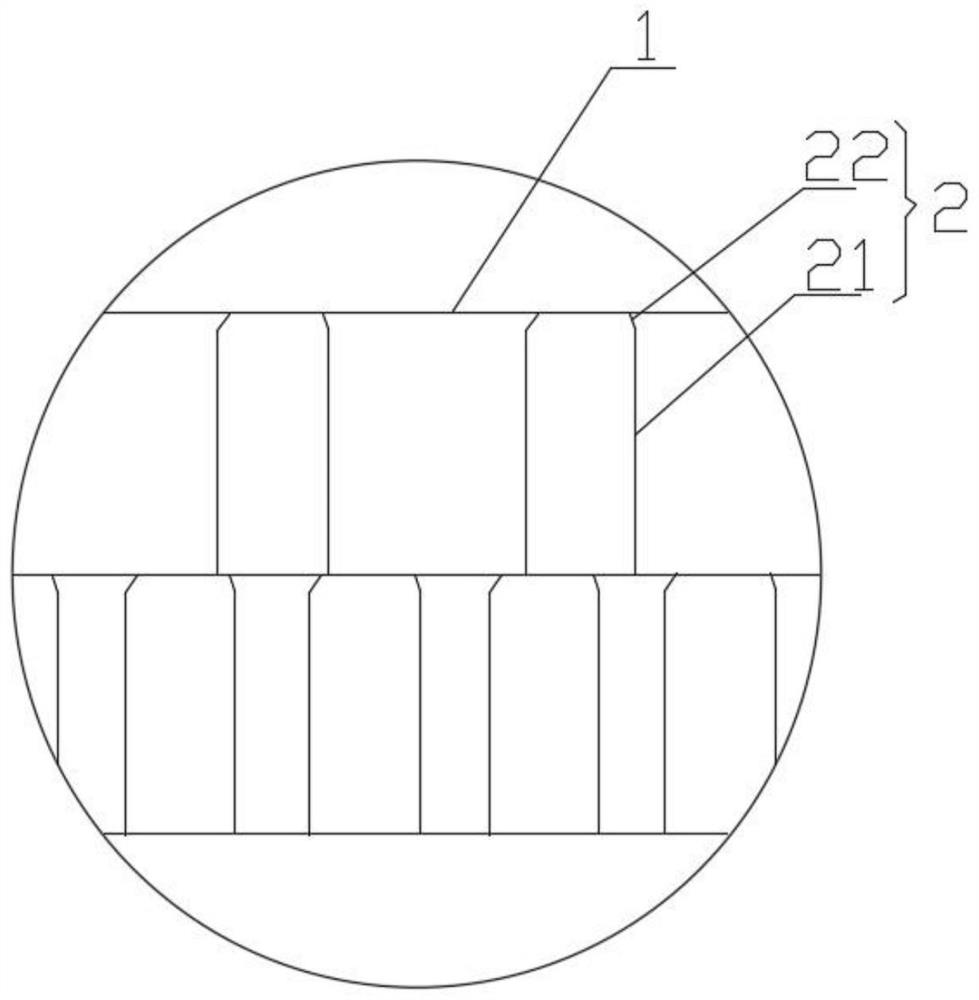

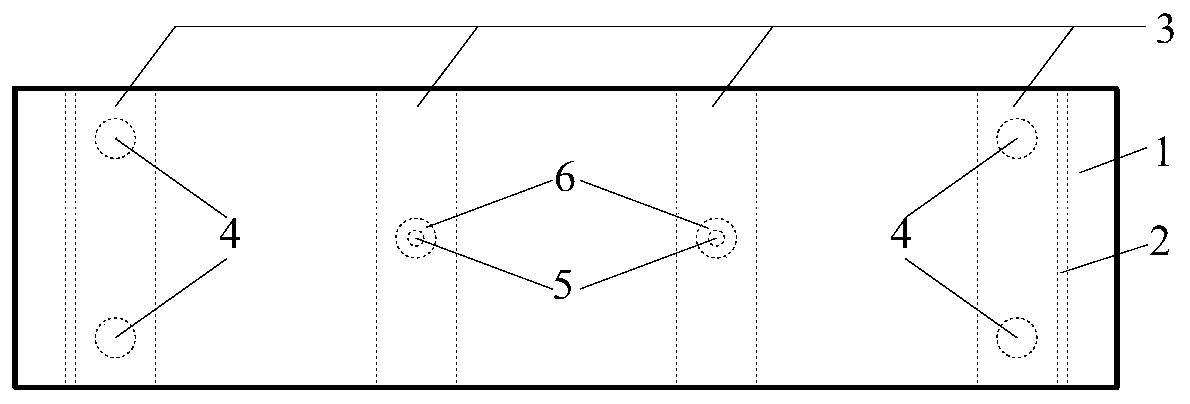

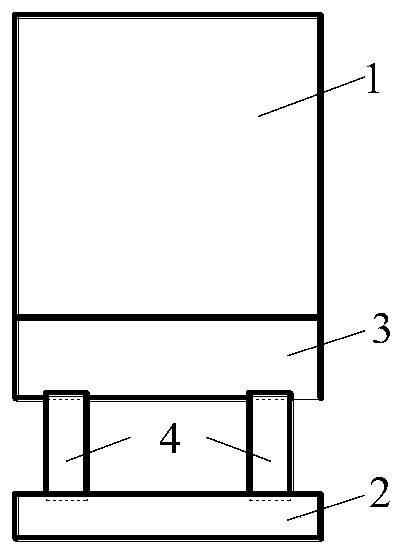

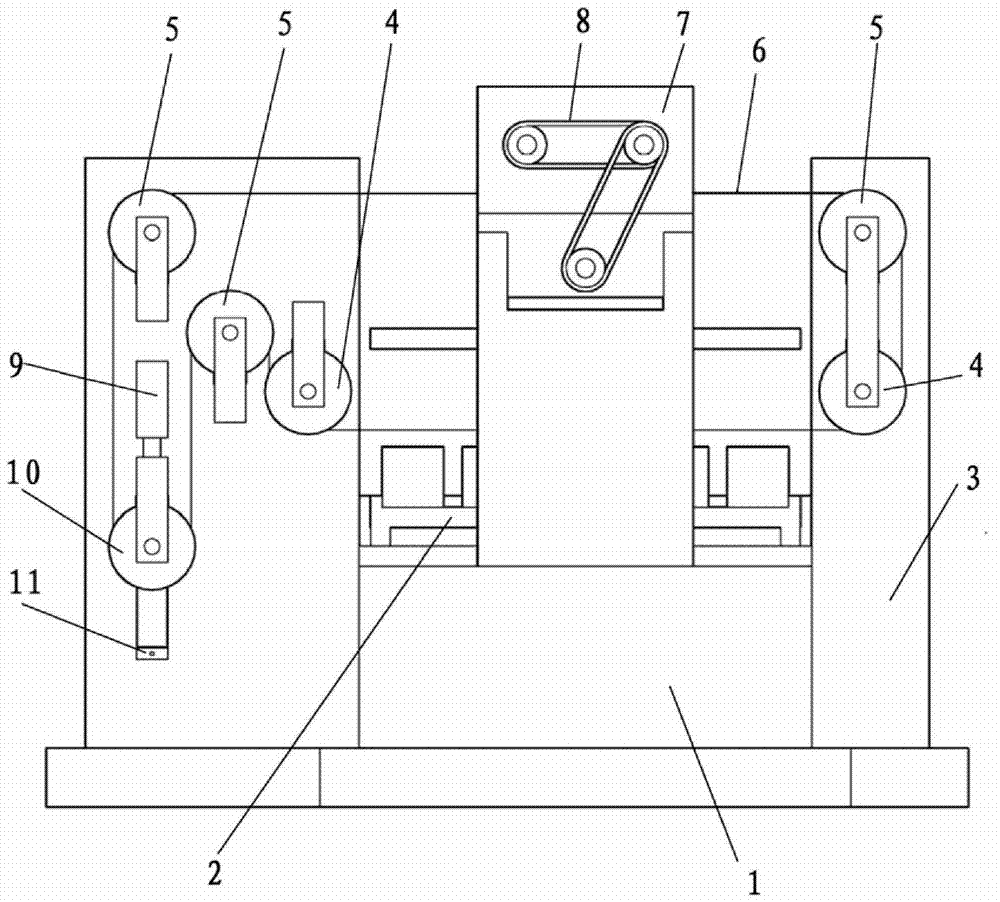

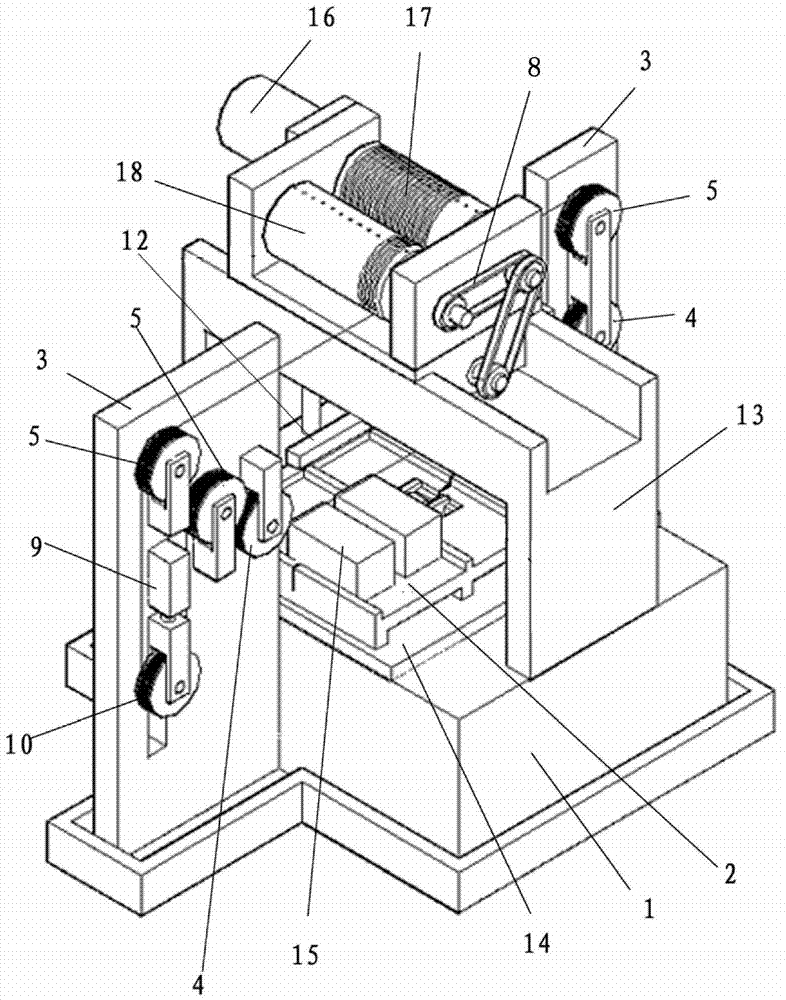

The present invention relates to a magnetic induction tomography system and method for studying the electromagnetic properties of an object. In order to provide a high resolution MIT technique without the need of increasing the number of coils, a magnetic induction tomography system (1) for studying the electromagnetic properties of an object (2) is suggested, the system comprising one or more generator coils (4) adapted for generating a primary magnetic field, said primary magnetic field inducing an eddy current in the object (2), one or more sensor coils (5) adapted for sensing a secondary magnetic field, said secondary magnetic field being generated as a result of said eddy current, and means (6, 7, 8, 9) for providing a relative movement between one or more generator coils (4) and / or one or more sensor coils (5) on the one hand and the object (2) to be studied on the other hand.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

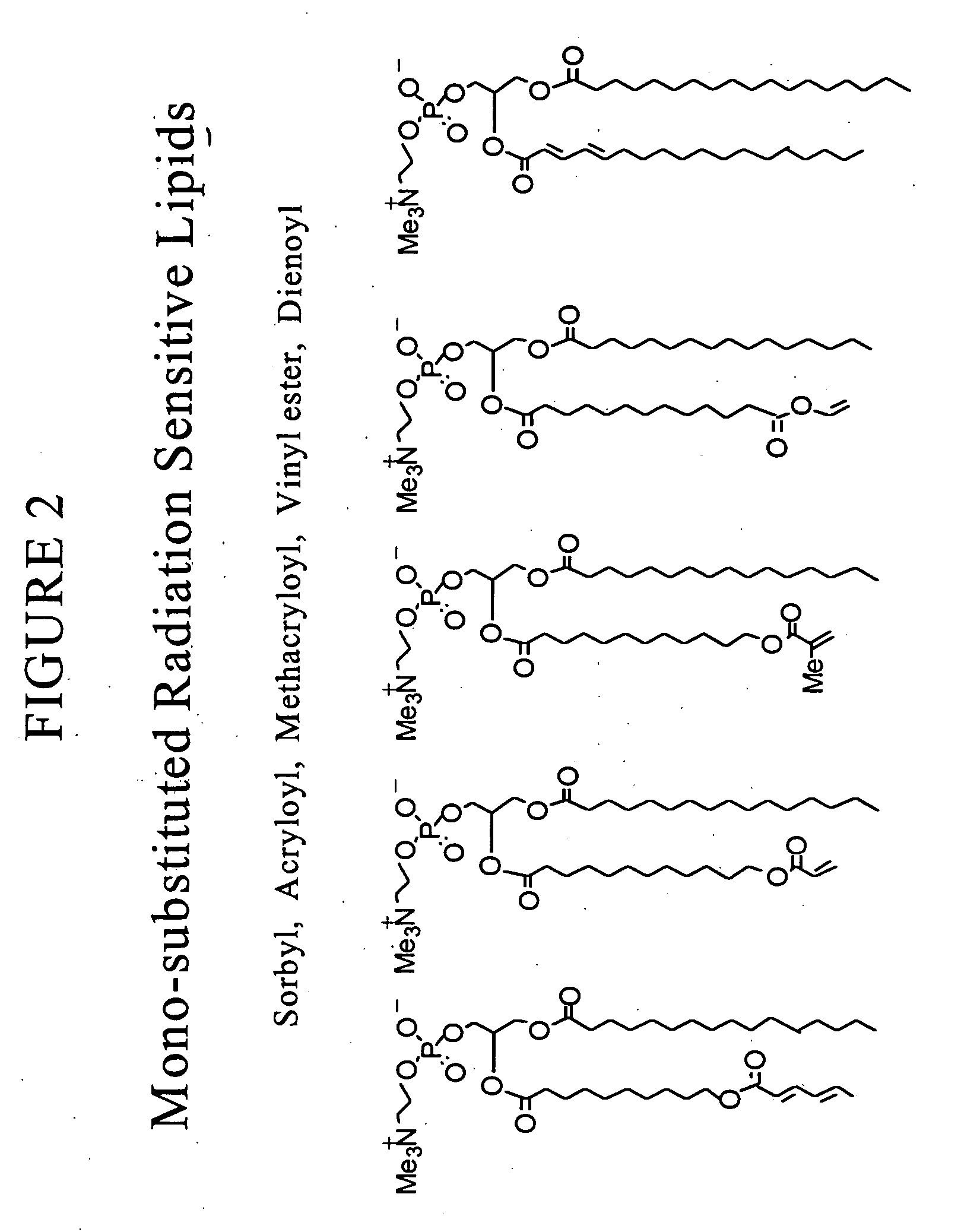

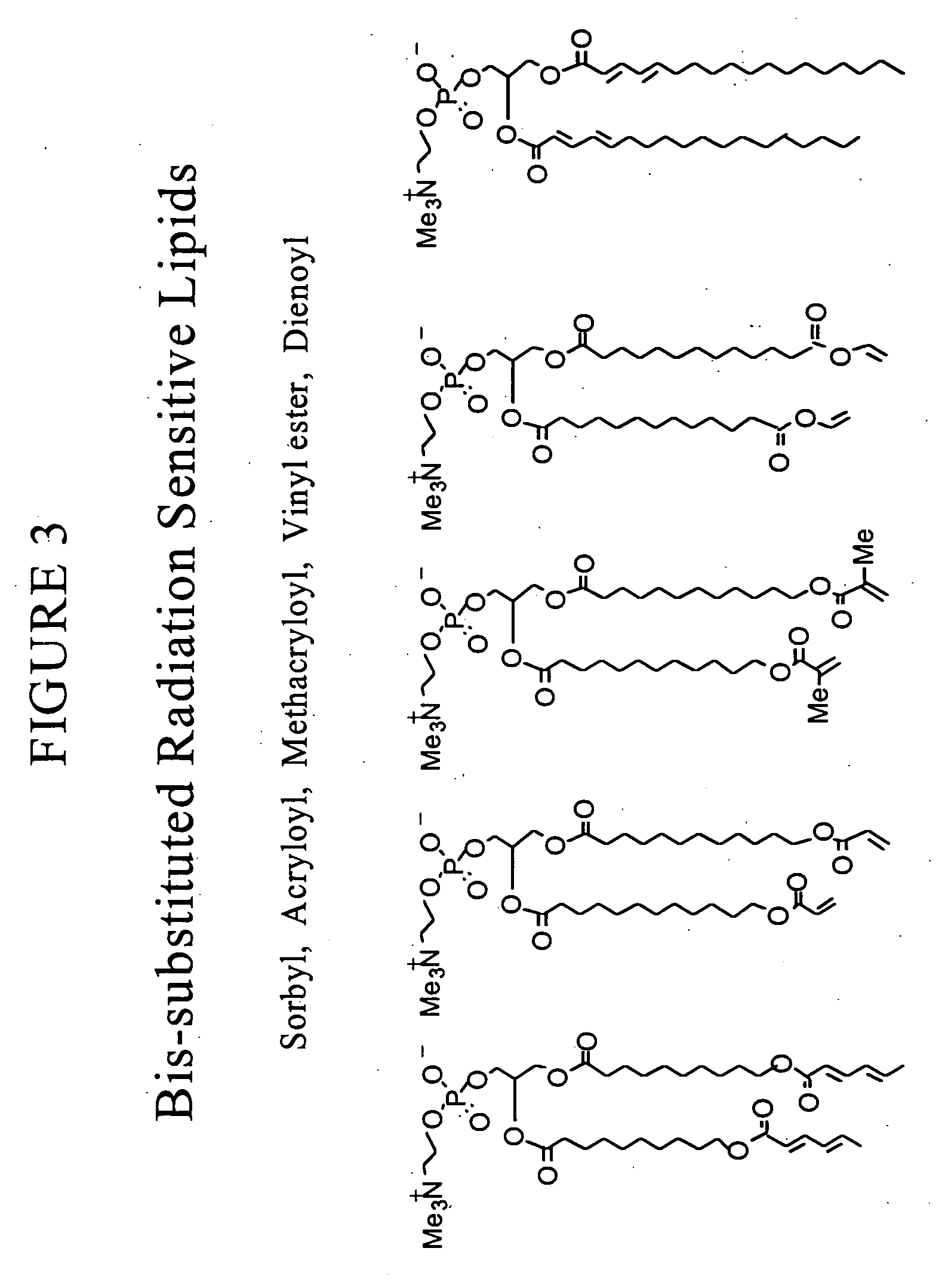

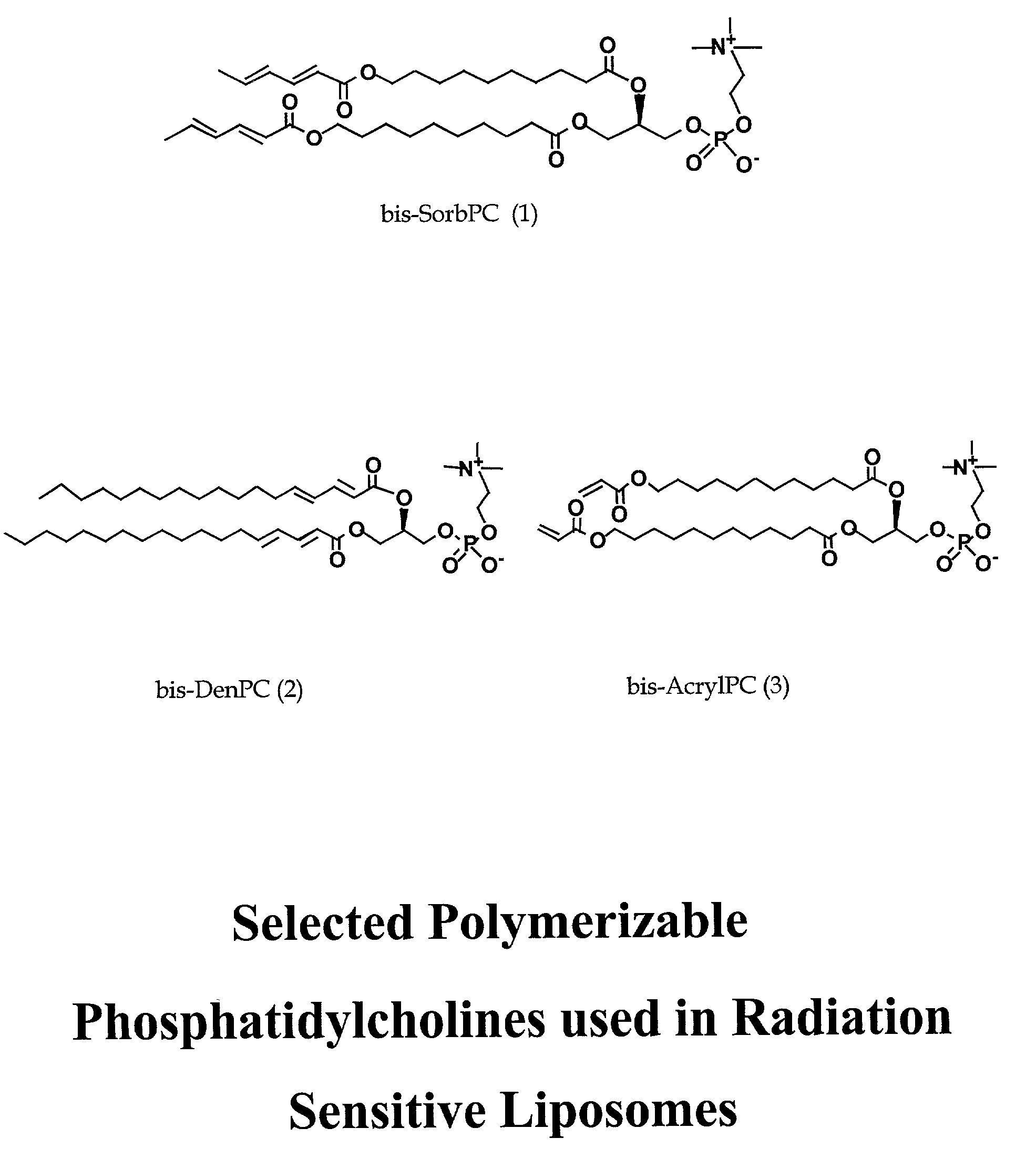

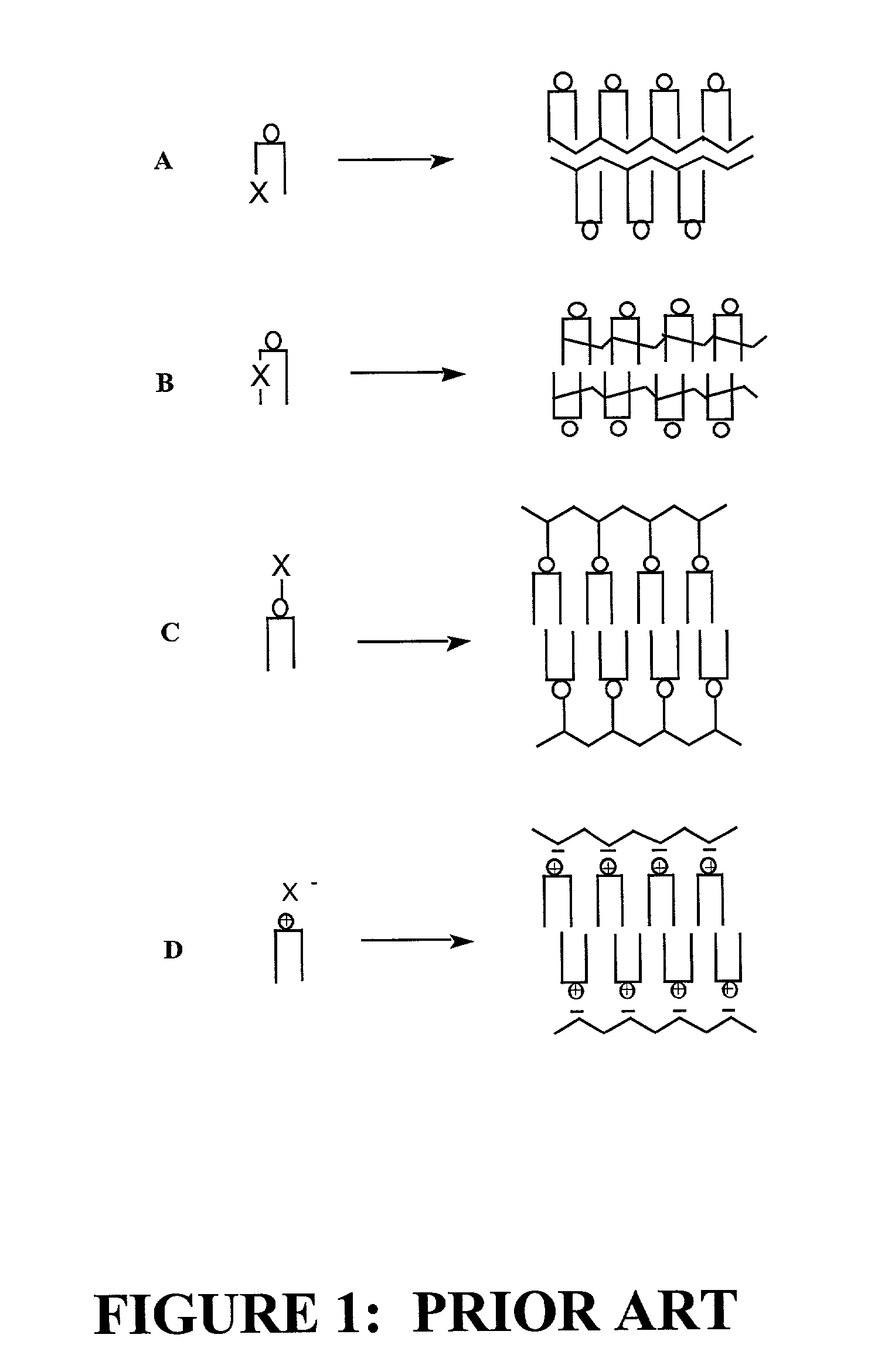

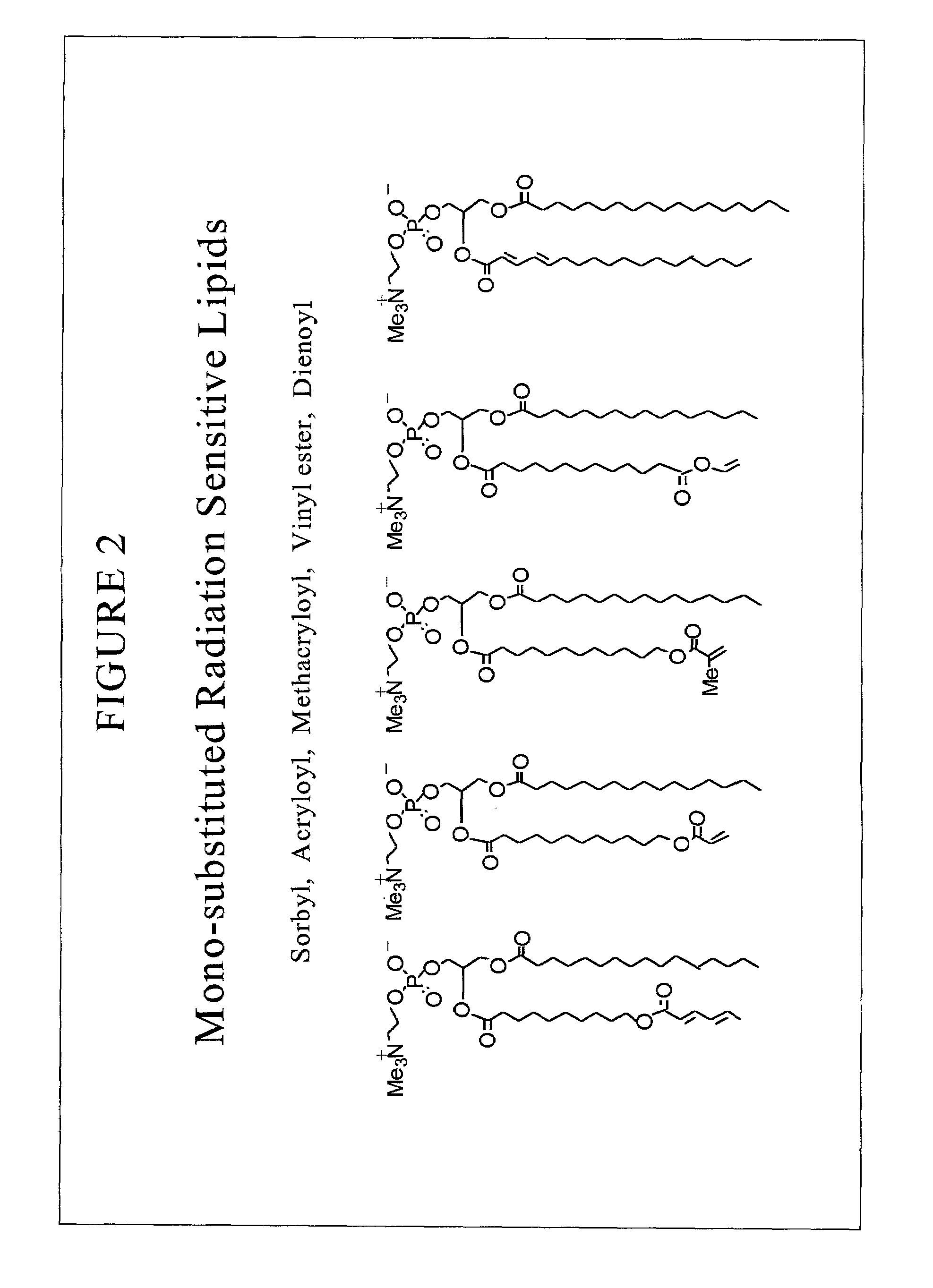

Radiation sensitive liposomes

InactiveUS20060099141A1Efficient convenient meanDestabilizing the liposomal membraneNervous disorderIn-vivo radioactive preparationsLipid formationDiagnostic agent

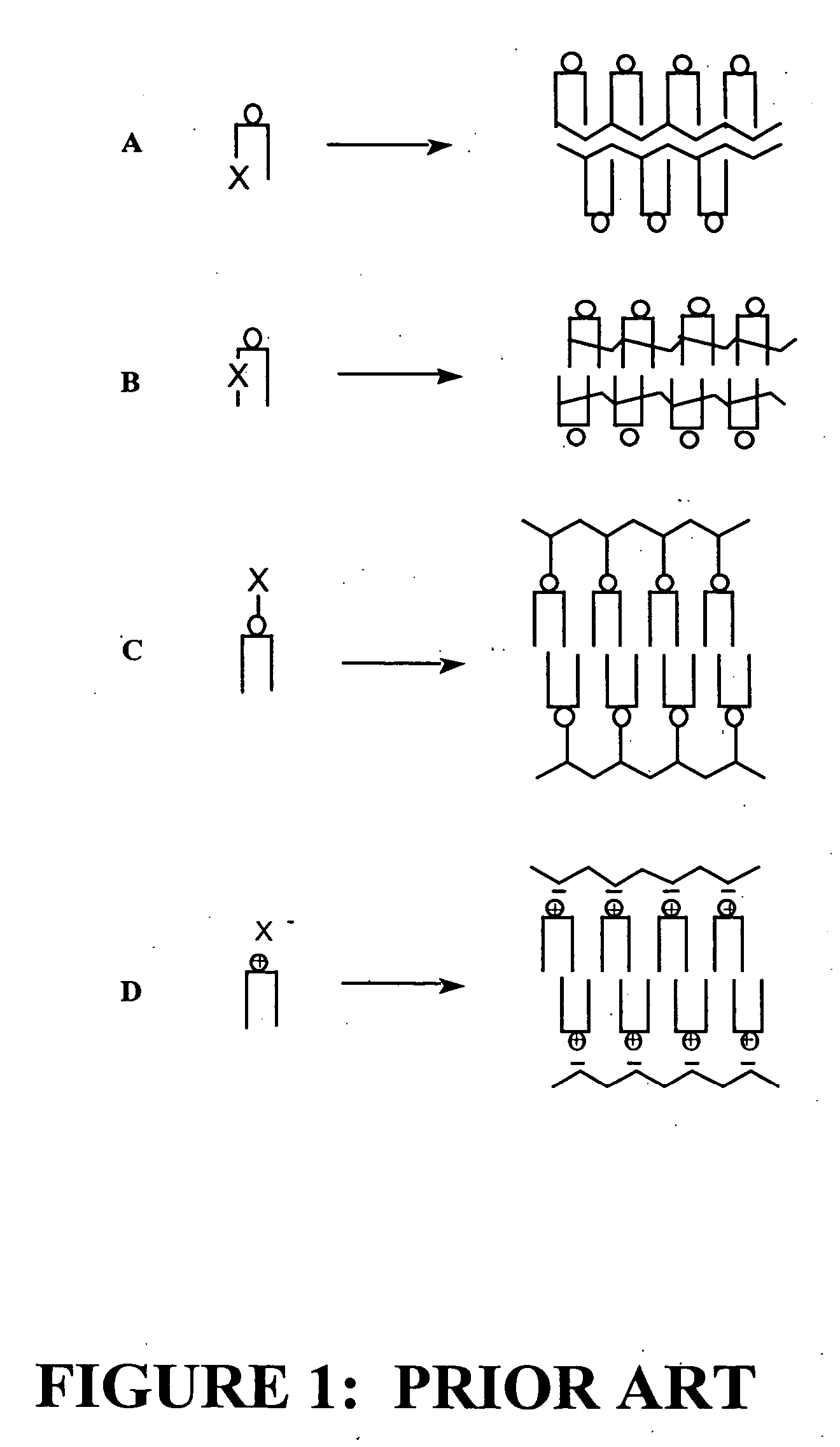

The present invention relates to a radiation sensitive liposome, and the use of this liposome as carrier for therapeutic and diagnostic agent(s). In particular, the invention encompasses a liposomal delivery system, comprising a stable liposome-forming lipid and a polymerizable colipid, a fraction of which polymerizable colipid polymerizes upon exposure to ionizing, radiation, thereby destabilizing the liposomal membrane. Destabilization of liposomes allows for leakage of liposomal contents. The present invention further contemplates methods of diagnosing and treating conditions and diseases that are responsive to liposome-encapsulated or associated agents.

Owner:VARIAN MEDICAL SYSTEMS

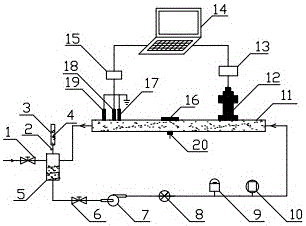

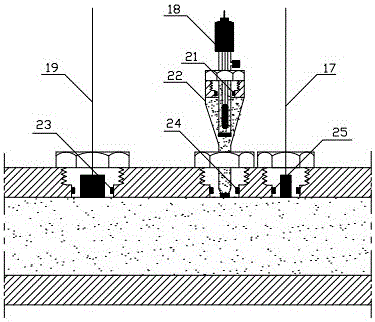

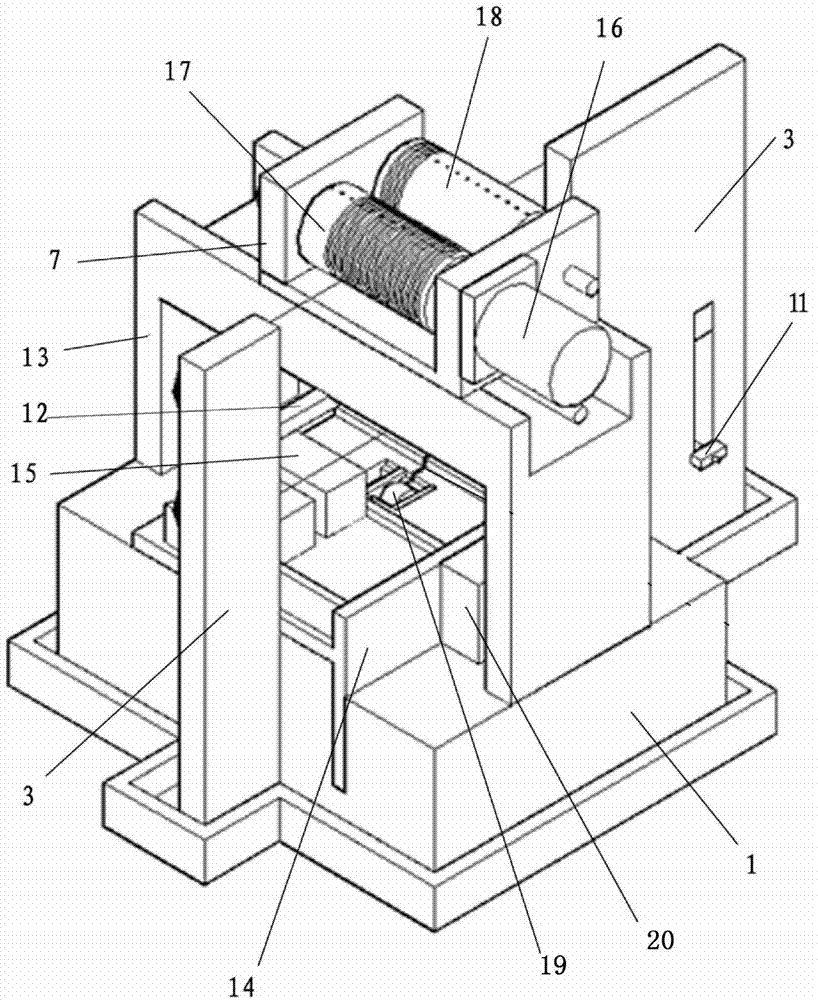

Device and method for evaluating inhibitor film integrity under scouring work conditions

InactiveCN105823703AAccurate measurementReal-time online monitoring Online monitoring of corrosion statusWeather/light/corrosion resistanceMaterial analysis by optical meansObservation unitEngineering

The invention discloses a device and method for evaluating inhibitor film integrity under scouring work conditions and belongs to the technical field of petrochemical engineering corrosion and protection. The device comprises a supplied flow circulating unit, a shear force measuring unit, an electrochemical monitoring unit, a camera shooting observation unit, a test piece testing unit and an inhibitor injection unit. By means of the device and method, evaluation of integrity of an inhibitor film can be achieved. Firstly, flow shear force is measured through the shear force measuring unit under different scouring work conditions, the corrosion rate is measured through the test piece testing unit, online corrosion monitoring is conducted through the electrochemical monitoring unit, the surface appearance of a test piece is observed and recorded through the camera shooting observation unit, integrity of the inhibitor film is comprehensively evaluated through data comparison and analysis, critical parameters are obtained when integrity of the inhibitor film is damaged, finally an inhibitor is injected through the inhibitor injection unit so that the inhibitor film can be repaired to be complete, and therefore monitoring and evaluation of stability, damage and repair of the inhibitor film are achieved.

Owner:SOUTHWEST PETROLEUM UNIV

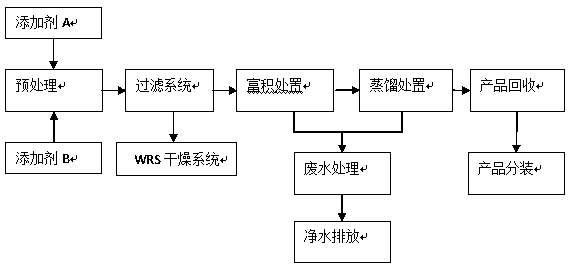

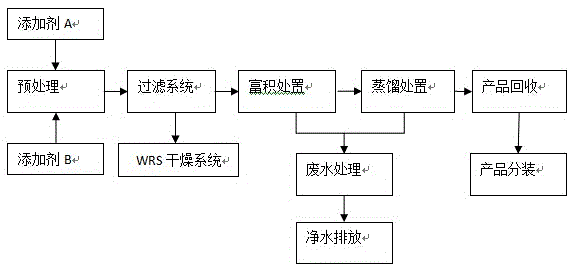

Method for recycling water-based paint detergent waste liquid

ActiveCN104230086AReduce pollutionRuns clean and smoothEther separation/purificationMultistage water/sewage treatmentWater basedLiquid waste

The invention discloses a method for recycling water-based paint detergent waste liquid. The method comprises the following steps: pre-treating the water-based paint detergent waste liquid, sorting, removing foreign matters, adding an additive A and an additive B, and producing demulsification reaction to form a mixture of paint slag and a solution; after the waste liquid is completely subjected to the demulsification reaction, feeding the waste liquid into a filtering system, performing solid-liquid separation, and completely separating the solution from the paint slag; performing harmless treatment on the paint slag; performing solvent accumulation on the solution, and separating a small part of water from most of a solvent mixture; treating the separated wastewater, discharging by standard, performing solvent purification on the solvent mixture, treating the separated wastewater and discharging by standard. According to the method, valuable ingredients in the waste liquid can be recycled and the rest wastewater is treated as conventional wastewater; the wastewater treatment difficulty is greatly lowered; the method is safe and environment-friendly.

Owner:CHENGDU YUANYONG TECH DEV

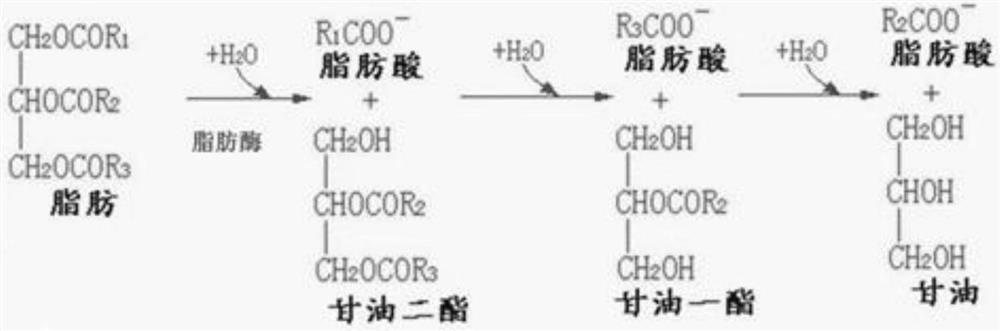

Grease-like sewage treatment method and chemical agent

ActiveCN104003495AQuick condensationDestabilizationFatty/oily/floating substances removal devicesLiquid separationChemical industryOil and grease

The invention relates to a grease-like sewage treatment method and a chemical agent and belongs to the technical field of grease-like chemical-industry type sewage treatment. According to the technical scheme, the chemical agent includes 0.2-0.5% of sodium alkyl benzene sulfonate, 0.5-0.7% of zeolite, 10-15.5% of sodium carbonate, 5-7.3% of calcium hydroxide, 4-9.5% of triacylglycerol acylhydrolase, 1-2.5% of cellulose, 1-3% of sodium percarbonate, 23-36.7% of polyaluminum chloride and 18-24.3% of ferrous sulfate. The grease-like sewage treatment method and the chemical agent have the advantages that the existence forms of water-in-oil and oil-in-water are thoroughly broken, a large quantity of SS, chromaticity colors, grease and COD can be quickly removed, efficiency is high, performance is reliable, the requirement for temperature changes is low, hardening and corroding are avoided, and sewage cannot cause secondary pollution in the later period.

Owner:TANGSHAN HENGTONG SCI & TECH

Radiation sensitive liposomes

InactiveUS6989153B2Facilitated releaseEfficient convenient meanUltrasonic/sonic/infrasonic diagnosticsBiocideLipid formationDisease

The present invention relates to a radiation sensitive liposome, and the use of this liposome as carrier for therapeutic and diagnostic agent(s). In particular, the invention encompasses a liposomal delivery system, comprising a stable liposome-forming lipid and a polymerizable colipid, a fraction of which polymerizable colipid polymerizes upon exposure to ionizing radiation, thereby destabilizing the liposomal membrane. Destabilization of liposomes allows for leakage of liposomal contents. The present invention further contemplates methods of diagnosing and treating conditions and diseases that are responsive to liposome-encapsulated or associated agents.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA +1

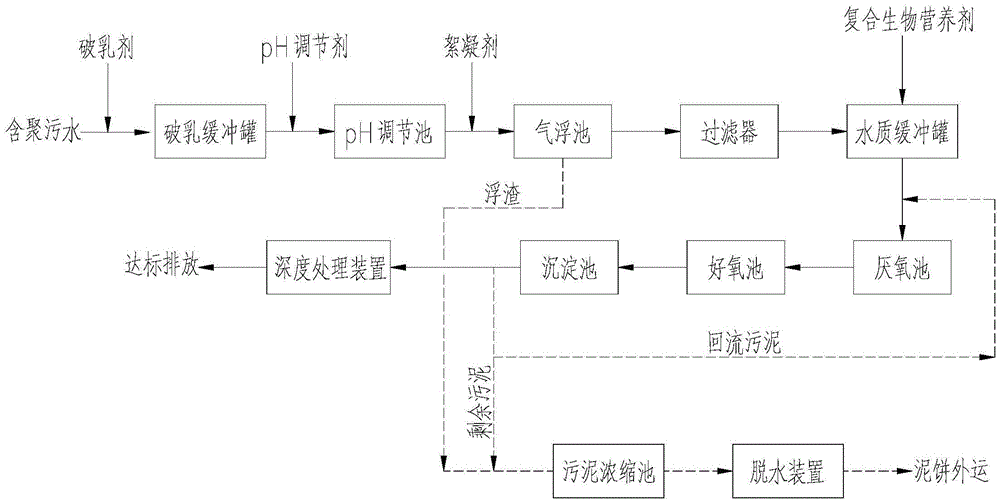

Biochemical treatment method for improving polymer-containing sewage matrix of oil field

InactiveCN105523692AImprove oxygen transfer efficiencyAvoid easy cloggingWaste water treatment from quariesTreatment involving filtrationDemulsifierAfter treatment

The invention relates to a biochemical treatment method for improving polymer-containing sewage matrix of the oil field. Polymer-containing sewage is firstly added with a demulsifier and enters a demulsification buffer tank for demulsification, after a pH regulator is added to effluent of the demulsification buffer tank, the effluent enters a pH regulating tank and enters a floatation tank for floatation after pH is regulated, and a flocculant adding point is arranged at an inlet of the floatation tank; effluent of the floatation tank enters a filter, is filtered and then enters a water buffer tank, a compound biological nutritional agent is added, effluent of the water buffer tank sequentially enters an anaerobic tank and an aerobic tank for treatment and performs mud-water separation through a settling pond, a liquid supernatant of the settling pond is discharged after meeting the standard, a part of sludge at the bottom of the settling pond flows back to the front end of anaerobic tank, the remaining sludge and dross produced during floatation enter a sludge concentration tank and are concentrated and dewatered by a dewatering device. The treatment efficiency is high, the load impact resistance ability is high, the operation is stable and standard discharge after treatment of the polymer-containing sewage of the oil field is realized.

Owner:天津市振津石油天然气工程有限公司

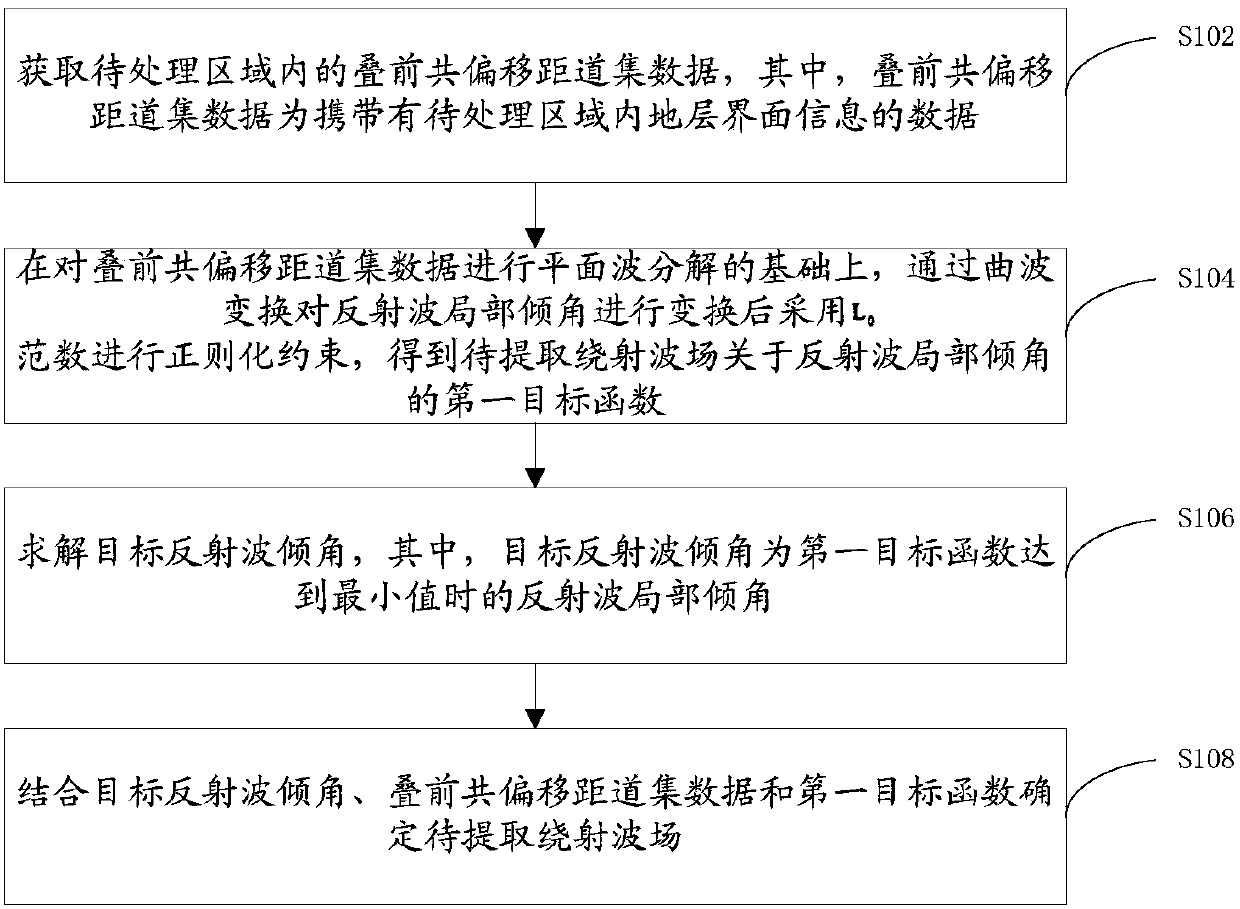

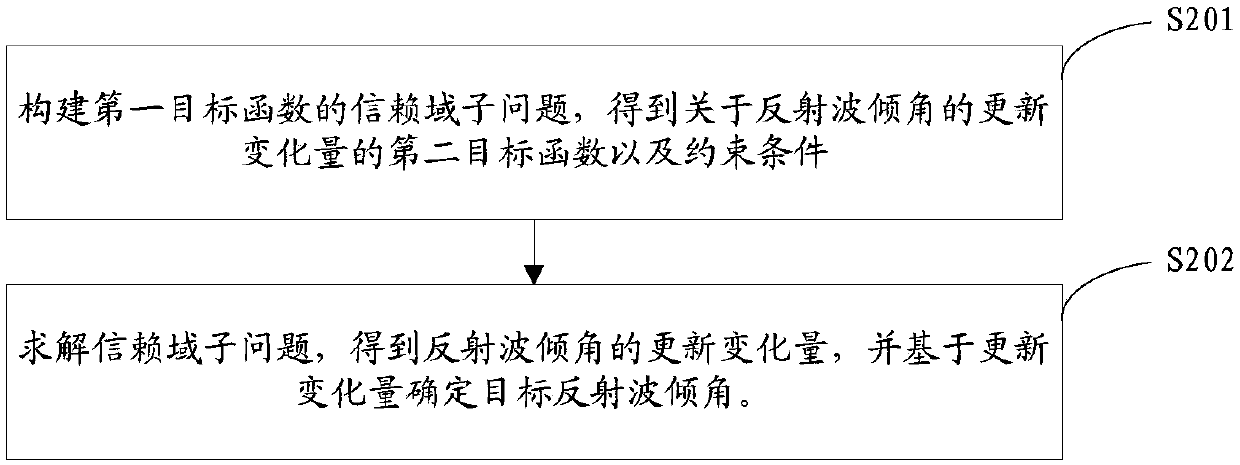

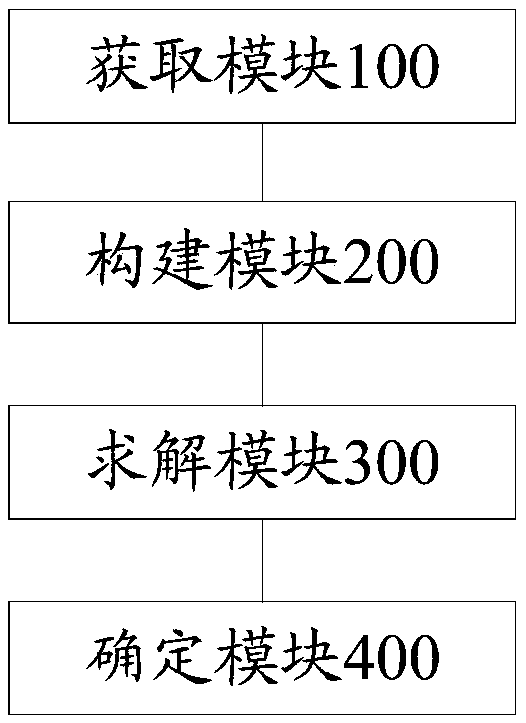

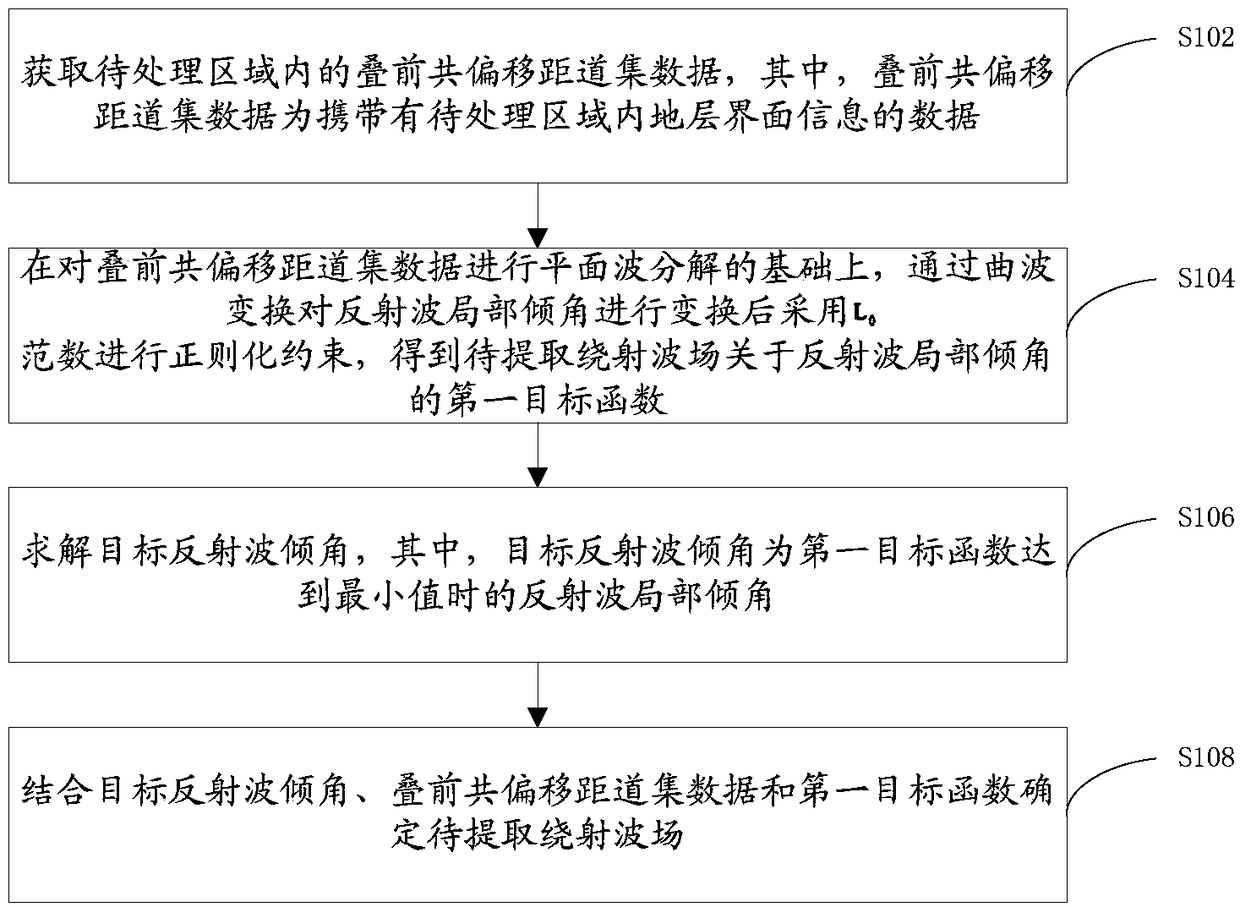

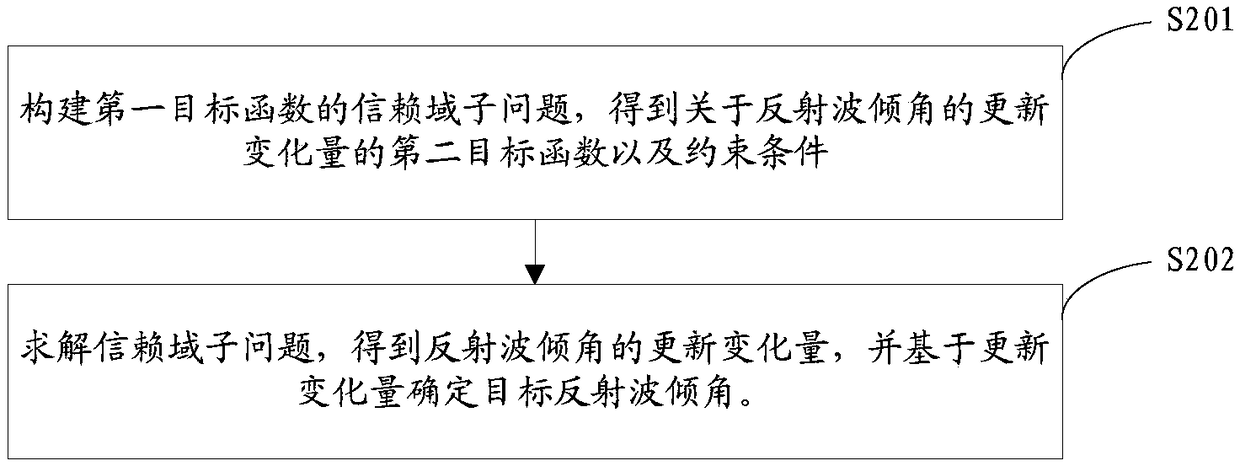

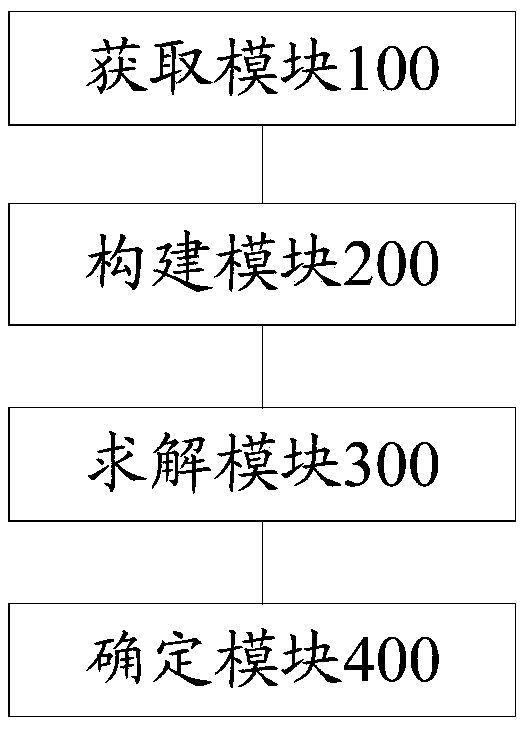

Diffracted wave field extraction method and device

ActiveCN107942374ADestabilizationAlleviate the technical problem of poor precision of diffracted wavesSeismic signal processingReflected wavesWave field

The invention provides a diffracted wave field extraction method and device, and relates to the technical field of diffraction field extraction. The method includes: obtaining a pre-stack common-offset gather data in an area to be processed, wherein the pre-stack common-offset gather data carries the stratum interface information in the area to be processed; on the basis of plane wave decomposition on the pre-stack common-offset gather data, transforming the local dip angle of a reflected wave by curvelet transform and then performing regular constraint by using the L0 norm so as to obtain thefirst objective function of the diffracted wave field to be extracted relative to the local dip angle of the reflected wave; and solving the target reflection wave dip angle by a trust region algorithm, wherein the target reflection wave dip angle is the reflection wave dip angle when the first objective function reaches the minimum; and determining the diffraction wave field to be extracted by combining the target reflected wave dip angle, the pre-stack common-offset gather data and the first objective function. The method and device alleviate a technical problem that the diffraction wave extracted by the traditional diffraction wave extraction method is poor in accuracy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

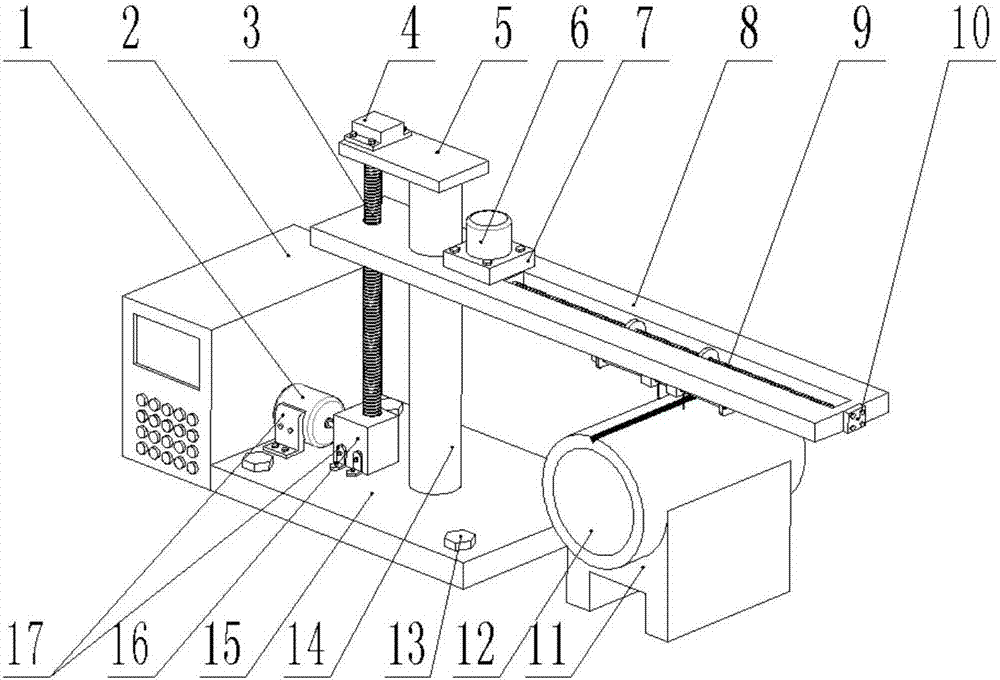

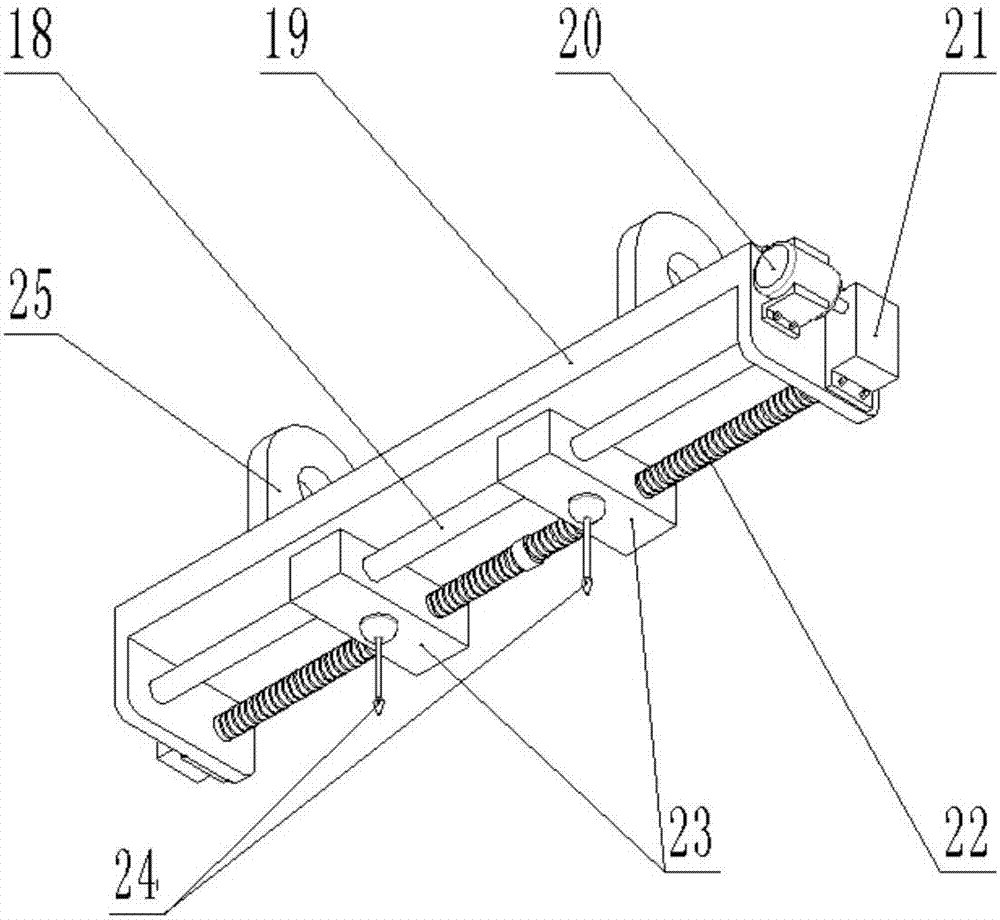

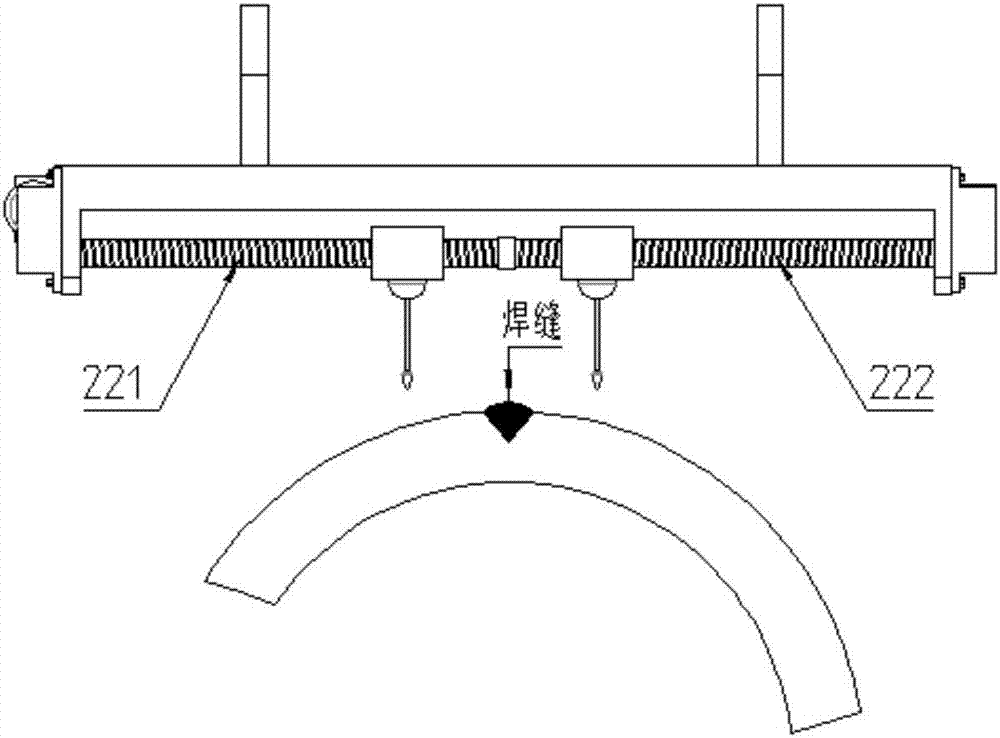

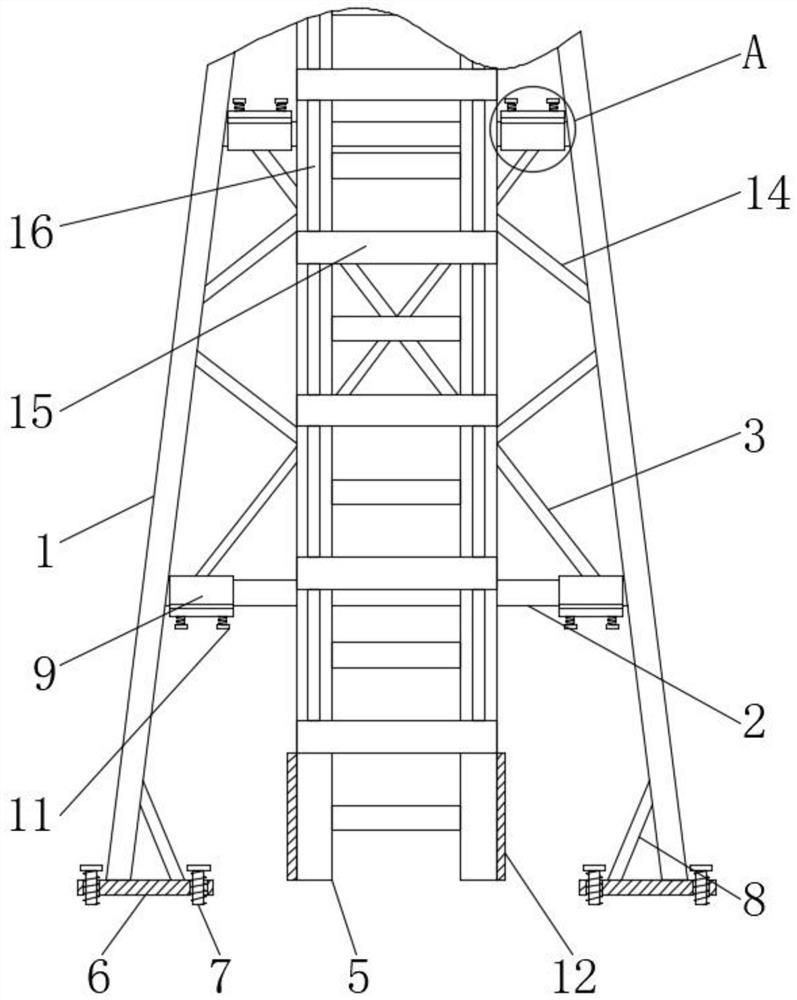

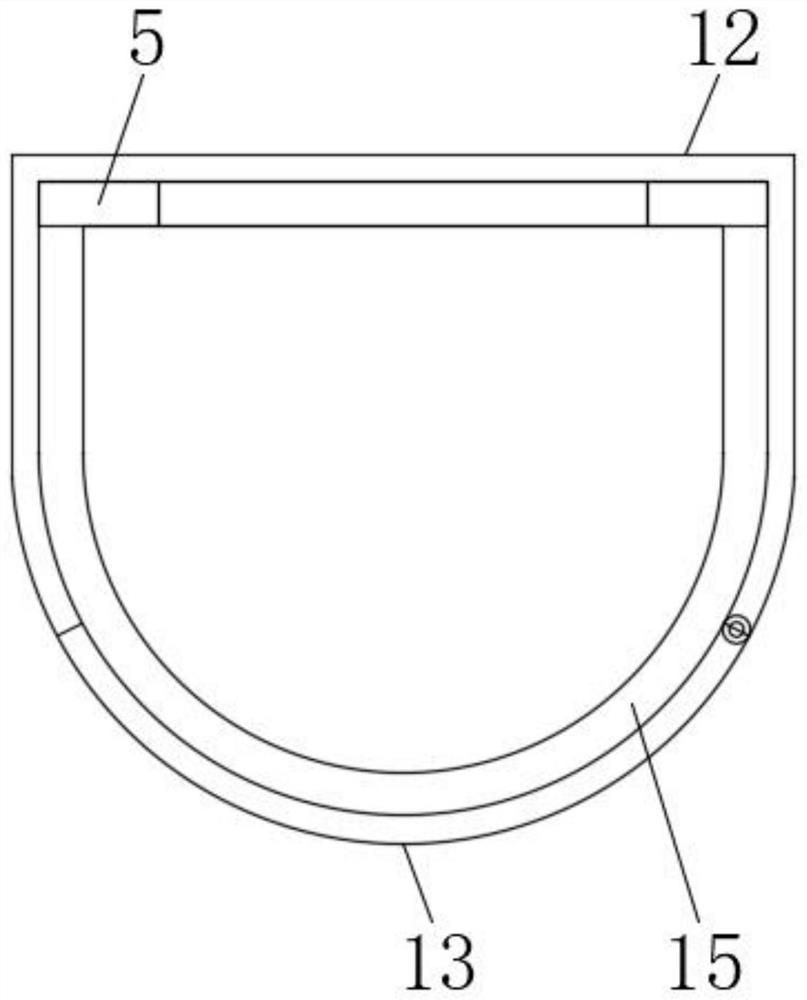

Double-edge flame heating method submerged arc pipe welding line residual stress removal device and process

ActiveCN106884086ASolving problems with large residual stressesImprove inner qualityFurnace typesProcess efficiency improvementNumerical controlHeat-affected zone

The invention discloses a double-edge flame heating method submerged arc pipe welding line residual stress removal device and process. The device comprises a numerical control operation table, a lifting plate vertical transmission mechanism, a hoisting type connecting plate horizontal transmission mechanism, two sliding block symmetrical transmission mechanisms, two flame spraying guns, a submerged arc pipe conveying base and a base. The process includes the steps that firstly, according to the size of the diameter of a submerged arc pipe, adjusting buttons control the flame spraying guns and a welding line to keep a set vertical distance; secondly, according to the welding line zone area, the adjusting buttons control the horizontal distance of the flame spraying guns and the welding line, symmetrical heating of different positions of the welding line is achieved; and finally, according to the different positions of the two edges of the welding line, the mixing ratio of combustible gas including methane and oxygen is adjusted, and heating to the welding line area with different flame temperatures is achieved. The device and process are simple in structure, convenient to operate and high in adaptability, the temperature difference of the welding line in the circumferential direction is effectively reduced, residual stress of the welding line and a heat influence area is removed, and the submerged arc pipe welding line quality is improved.

Owner:TAICANG FANSHENG ELECTRONICS TECH CO LTD

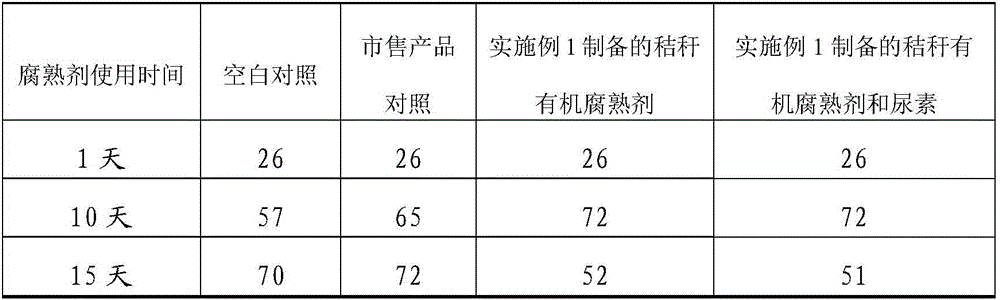

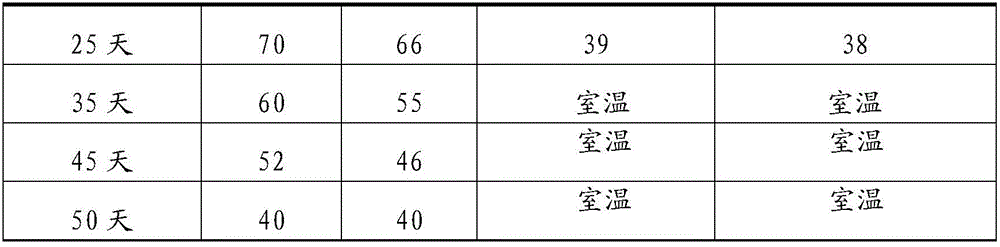

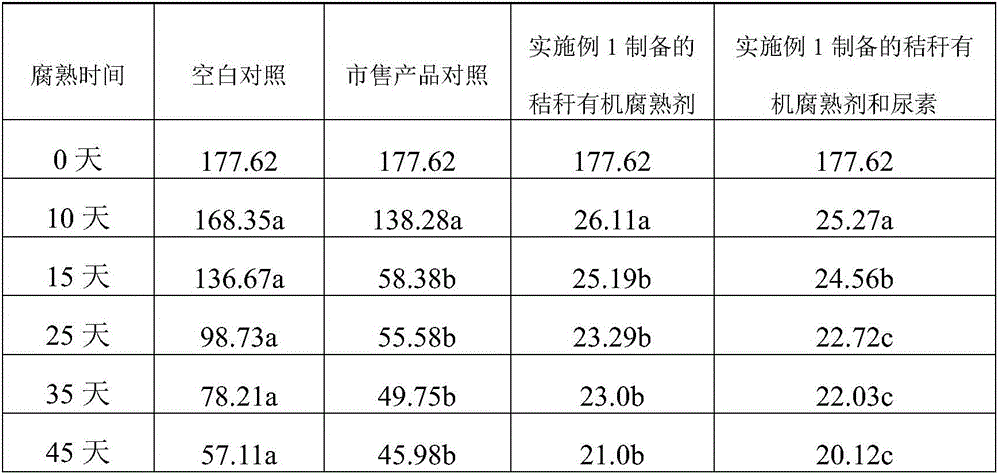

Straw organic decomposition agent and preparation method thereof

InactiveCN106318884AEasy to useThe use effect is more effective than similar products in the marketFungiBacteriaAdditive ingredientDecomposition

A straw organic decomposition agent is prepared from bacillus subtilis, brewer's yeast and aspergillus oryzae, the content of bacillus subtilis is larger than or equal to 15 billion cfu / g, the content of the brewer's yeast is larger than or equal to 20 billion cfu / g, the content of aspergillus oryzae is larger than or equal to 500 million cfu / g, and the number of effective living bacteria in the decomposition agent is larger than or equal to 265 million per gram. In the straw organic decomposition agent, only three original strains exist, bacteria, fungus living bacteria and an enzymic preparation are compounded, multiple components achieve a synergistic effect in the decomposition process, a cellulase preparation is cultured by mixing bacillus subtilis, brewer's yeast, aspergillus oryzae and the like, multiple kinds of cellulase systems are generated, good applicability is achieved, lignin ingredients in straw can be damaged fast, cellulose and hemicellulose in organic materials are exposed, and the decomposition time of the straw is shortened. A method for screening strains is efficient and practical, the production and fermentation process is simple, the production period is short, the number of the living bacteria and the enzyme activity level are high and stable, the use effect of the prepared decomposition agent is superior to that of an existing product, and wide industrialization prospects are achieved.

Owner:JIANGSU ZHIFENG BIOLOGICAL TECH CO LTD

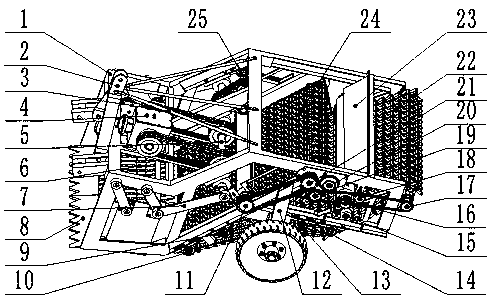

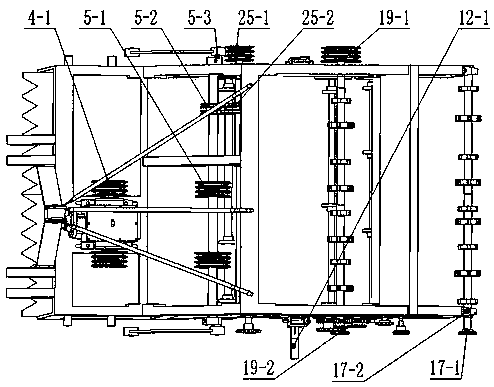

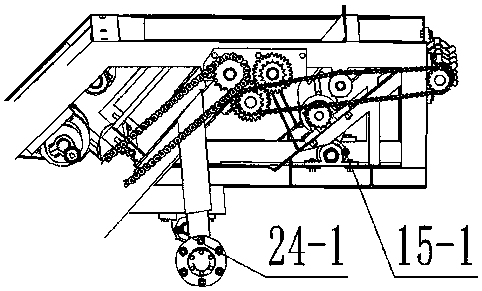

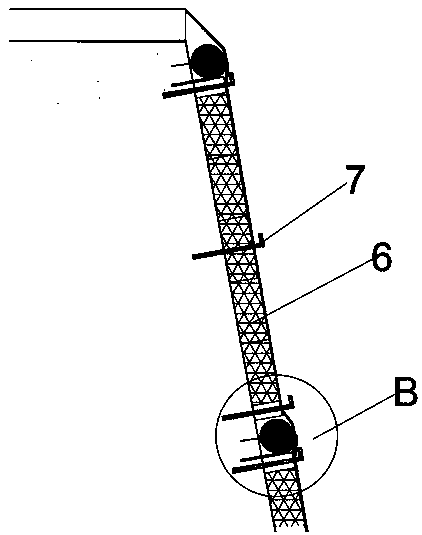

Excavator for Chinese medicinal herbs

PendingCN108541441AReduce excavation costsHigh degree of mechanizationDiggersMedicinal herbsGround roller

The invention provides an excavator for Chinese medicinal herbs. The excavator comprises a frame and a transmission system, wherein the frame is provided with a roller shaft; two ends of the roller shaft are respectively provided with a ground roller; the frame is provided with a hanging device; the front end of the frame is provided with a soil shoveling mechanism; a vibrating sieve device is arranged at the rear of the soil shoveling mechanism and connected with the frame through a crank rocker mechanism; the frame located at the rear of the vibrating sieve device is obliquely provided witha front soil-sieving conveying device; the frame located at the rear of the front soil-sieving conveying device is obliquely provided with a rear soil-sieving conveying device; the frame located abovethe central part of the front soil-sieving conveying device is provided with a first pressure roller device which matches with the front soil-sieving conveying device; and the frame located above thecentral part of the rear soil-sieving conveying device is provided with a second pressure roller device which matches with the rear soil-sieving conveying device. The excavator provided by the invention is a Chinese medicinal herb excavating and harvesting combined machine which can complete a plurality of processes like deep loosening, soil sieving and soil-herb separation by one time.

Owner:GANSU AGRI UNIV

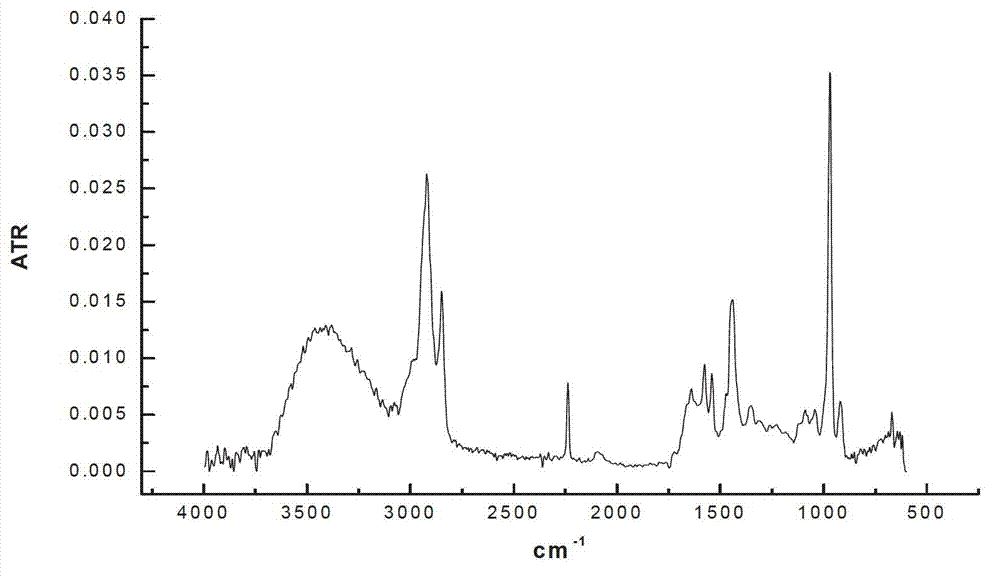

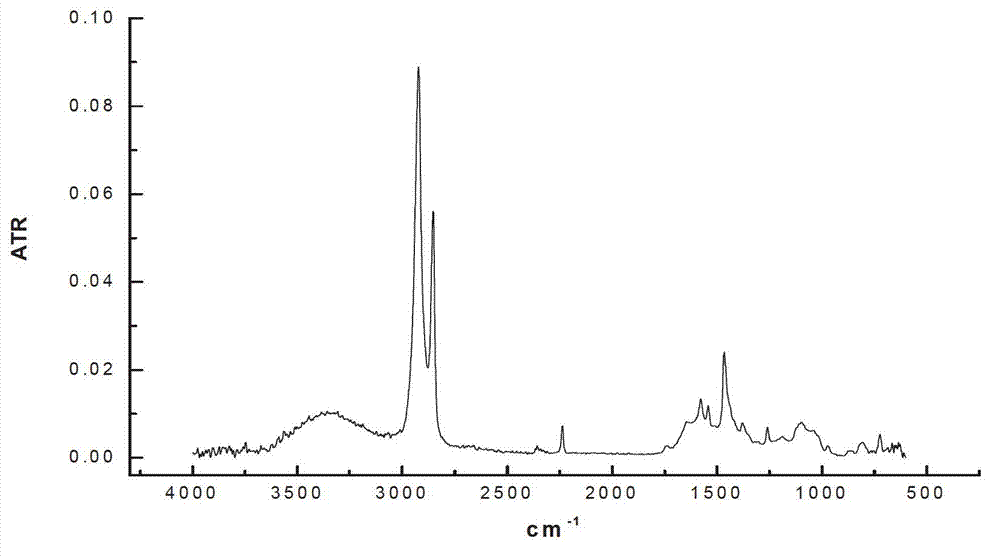

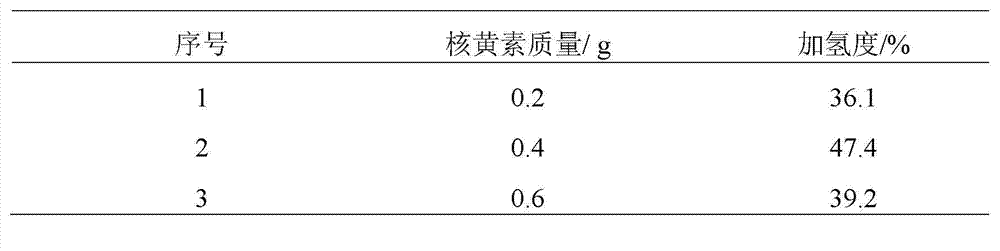

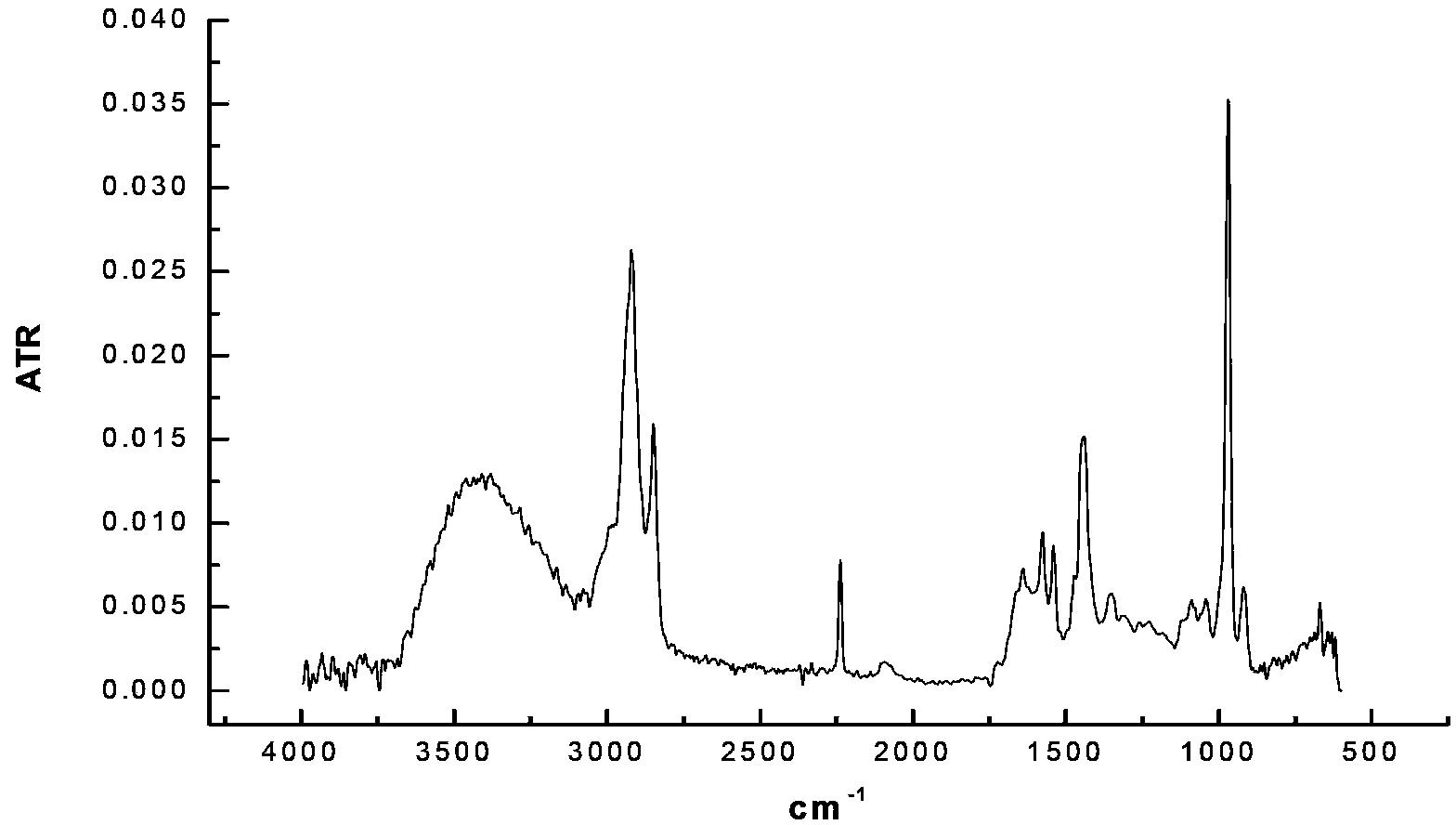

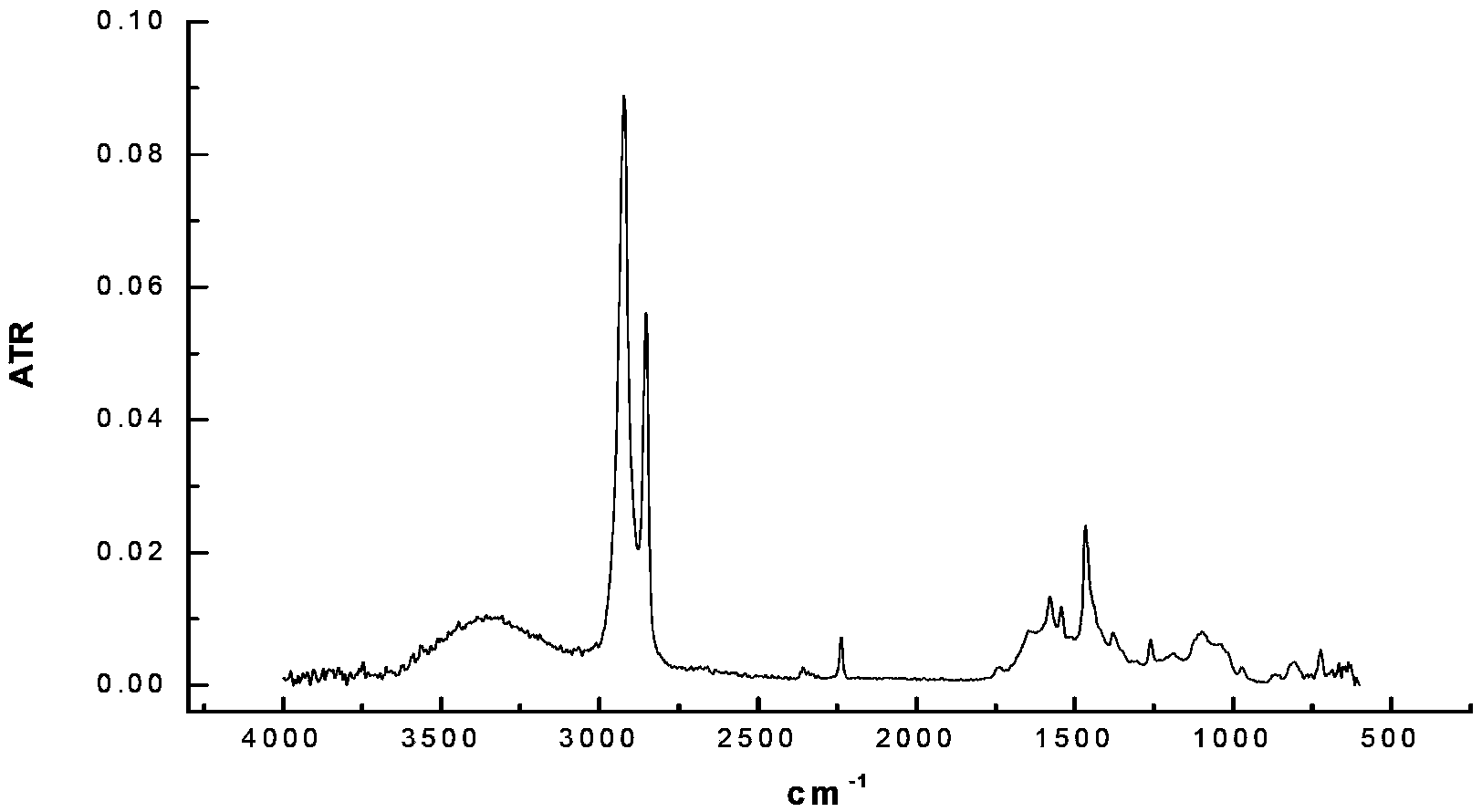

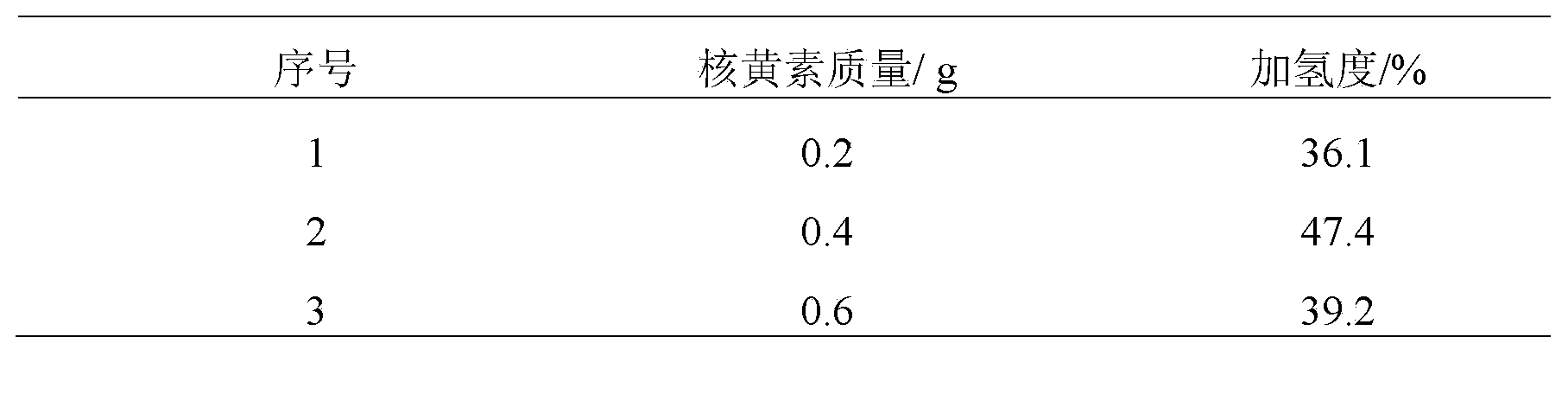

Hydrogenation method for organic catalyst normal-pressure catalytic butyronitrile rubber latex

The invention provides a hydrogenation method for organic catalyst normal-pressure catalytic butyronitrile rubber latex, belonging to the field of the in-situ normal-pressure hydrogenation of the butyronitrile rubber latex. The invention provides a novel method for carrying out the hydrogenation research on the macromolecule butyronitrile rubber latex by a hydrazine hydrate / riboflavin catalyst system under the air condition, and developing the in-situ hydrogenation of the green organic compounds--riboflavin catalyst on the butyronitrile rubber latex, wherein the riboflavin catalyst is firstly used in an aqueous dispersion rubber latex system. Compared with the existing inorganic catalyst such as the copper sulfate, the ferric sulfate, the ferrous sulfate or the boric acid, the riboflavin organic catalyst has the advantages that the riboflavin organic catalyst is green and environment-friendly, and is easy to prepare, the latex can not be broken, the stability of the butyronitrile rubber latex can not be influenced due to the stable existence of the riboflavin organic catalyst and the rubber latex and the like, furthermore, a hydrogenated intermediate generated by a hydrazine hydrate / riboflavin catalyst system is stable, so that the hydrogenated butyronitrile rubber latex of which the hydrogenation degree is larger than 90% can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

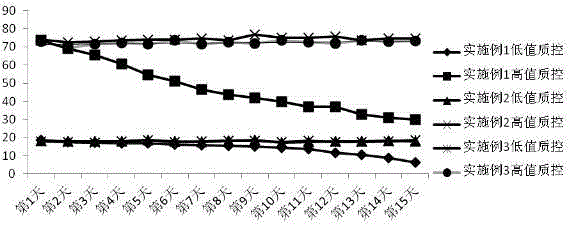

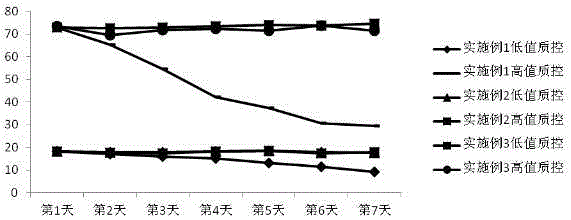

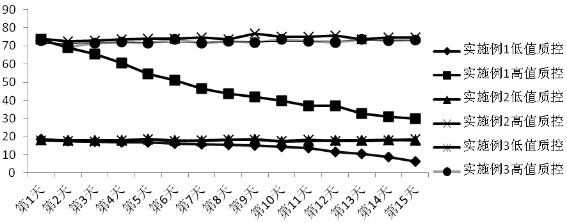

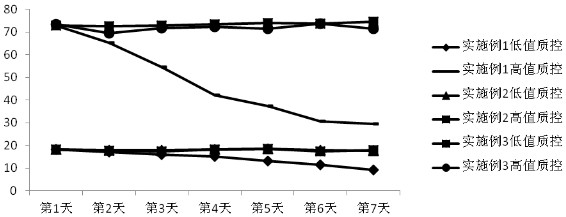

High-stability single-reagent liquid-state blood ammonia (AMM) detection reagent

ActiveCN106811505ASimplify the operation of useGuaranteed stabilityMicrobiological testing/measurementIonBlood ammonia

The invention relates to a blood ammonia (AMM) detection reagent and in particular relates to a high-stability single-reagent liquid-state blood ammonia (AMM) detection reagent. The reagent is mainly prepared from main substances including a buffering solution, LDH (Lactate Dehydrogenase), a heavy metal ion chelating agent, an ionic balance agent, a preservative, alpha-KG, NADH.NA2, a surfactant, a protecting agent and the like. According to the reagent, a single reagent of glutamate dehydrogenase two-point method and kinetic method is established; the utilization operation is effectively simplified and the stability of effective components of a product is guaranteed; the metal chelating agent is properly selected so that the inhibition, caused by the heavy metal ions, on the activity of an enzyme in the reagent is effectively removed; interference on the enzyme is not caused; the protecting agent is properly added so that the stability of the enzyme and the stability of key substrates in the reagent are effectively protected; the substances are added so that the stability of a single-reagent product provided by the invention is effectively guaranteed and the reagent is greatly convenient for utilization and popularization clinically.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

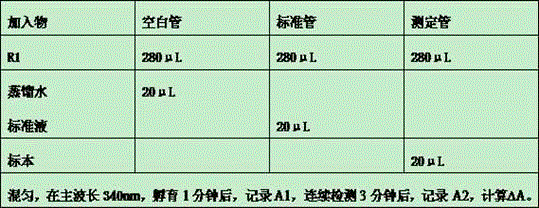

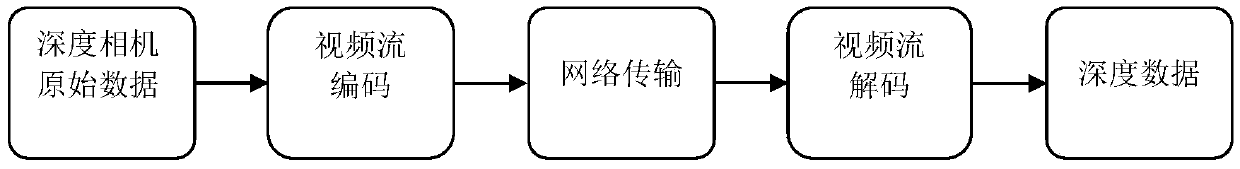

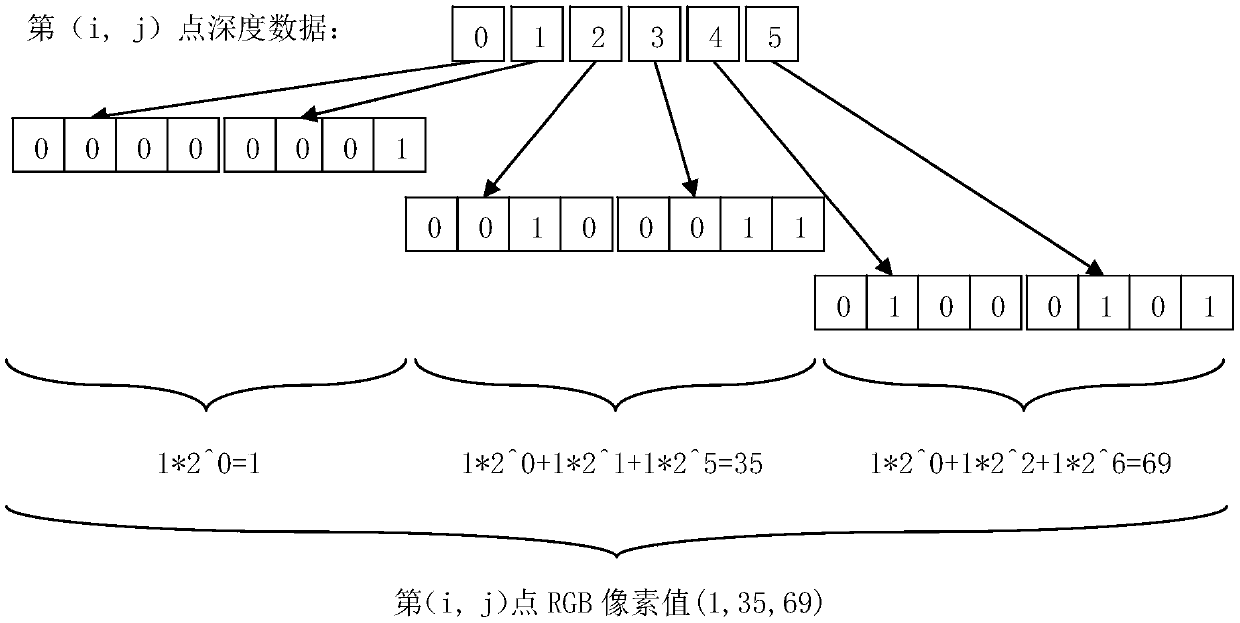

Depth data transmission method and device

ActiveCN111447427AIncrease the number of concurrencyReduce precision lossDigital video signal modificationTransmissionComputer hardwareTransmission protocol

The invention relates to the field of data transmission, and discloses a depth data transmission method, which comprises the following steps of: encoding depth data into an RGB image according to a predetermined encoding format; transmitting the RGB image by adopting a video stream transmission protocol; receiving the RGB image; and decoding the received RGB image into the depth data according toa predetermined decoding format. The transmission bandwidth pressure can be effectively reduced, the network concurrence number is increased, and the depth information precision loss caused by transmission errors in the transmission process can be effectively reduced.

Owner:杭州云深弘视智能科技有限公司

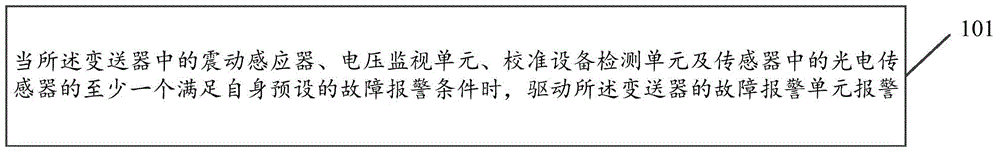

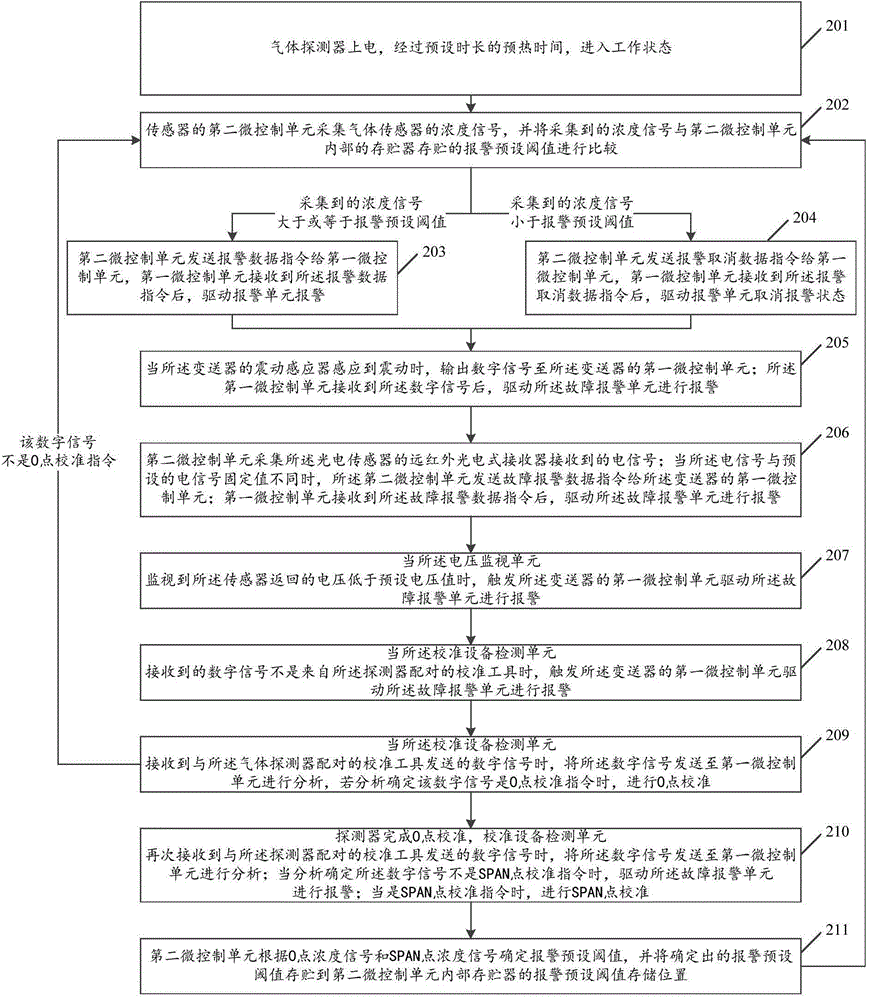

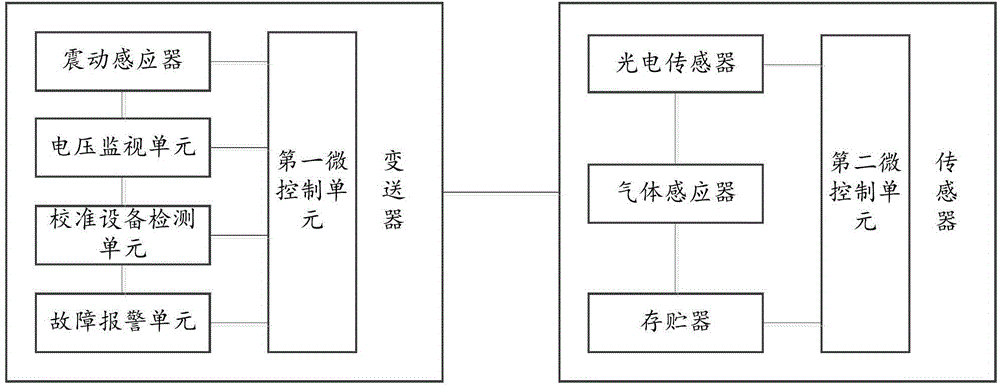

Gas detector and alarm method

The invention provides a gas detector and an alarm method. The method comprises that when at least one of a vibration inductor, a voltage monitor unit and a calibration equipment detection unit of a transmitter and a photoelectric sensor of a sensor meets a preset fault alarm condition, a fault alarm unit of the transmitter is driven to give an alarm. According to the gas detector and the alarm method provided by embodiments of the invention, abnormal conditions which may occur to the transmitter, an air inlet of the sensor and connection lines between the transmitter and the sensor, and non-standard calibration are monitored through the vibration inductor, the voltage monitor unit, the calibration equipment detection unit and photoelectric sensor, so that the accuracy and stability of the gas detector is prevented from being influenced by various factors, the operational stability of the gas detector is improved, and the user safety is effectively ensured.

Owner:AVIC OFFSHORE ENG

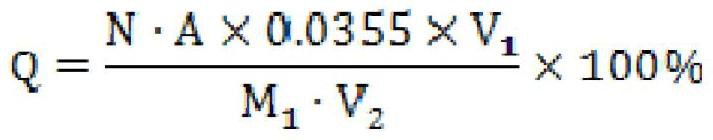

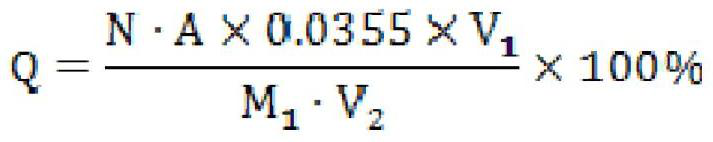

Method for detecting chlorine ion content of sea sand

PendingCN112730733ADestabilizationRelease fullyMaterial analysis by observing effect on chemical indicatorChemical analysis using titrationEnvironmental chemistrySoil science

The invention discloses a method for detecting the chlorine ion content of sea sand. The detection method comprises the following steps: drying naturally humid sea sand to constant weight, performing sieving, adding deionized water, performing stirring, performing heating, performing standing, and performing filtering to obtain a chloride ion dissolution solution of the sea sand; adding a phenolphthalein reagent into chloride ion dissolution liquid of sea sand, and adjusting the dissolution liquid to be neutral by using an HNO3 solution or a NaOH solution; then adding an H2O2 solution into the dissolved-out liquid to remove the influence of sulfur ions; continuously adding a potassium chromate solution as an indicator, and determining the content of chloride ions in the dissolution solution by adopting a silver nitrate titration method. According to the detection method, chloride ions in the sea sand can be fully released, the influence of factors such as pH values and sulfur ions in the sea sand on the detection result is eliminated, the detection precision is improved, the detection result is more accurate and reliable, and a reliable basis is provided for the use of the sea sand in the engineering field.

Owner:山西省交通建设工程质量检测中心(有限公司)

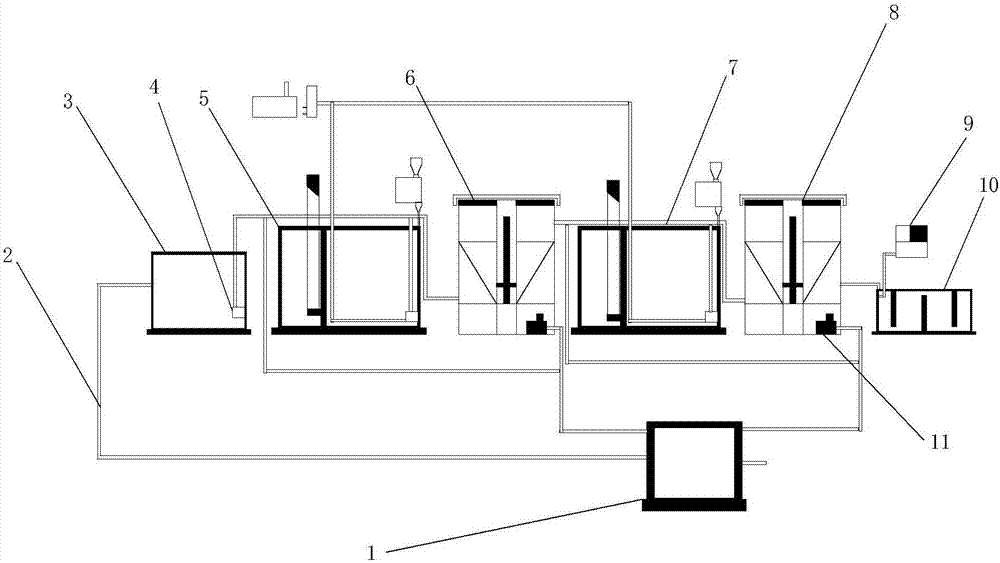

High-concentration organic waste water treatment device

InactiveCN107365029AEasy to operate and manageFast separationWater treatment parameter controlSpecific water treatment objectivesZoogloeaMicroorganism

The invention belongs to the technical field of waste water treatment and discloses a high-concentration organic waste water treatment device. The high-concentration organic waste water treatment device comprises a water inlet adjusting tank, a first-class biochemical pool, a first-class physico-chemical pool, a second-class biochemical pool, a second-class physico-chemical pool, a disinfection pool and a sludge pool. According to the high-concentration organic waste water treatment device, implantation conditions are provided for activated sludge microorganisms, a zoogloea flocculated under the auxiliary function of a fluidized bed is denser, the treatment capacity is comparatively strong, and the sludge-water separation speed is comparatively high, so that the discharged water of the physico-chemical pools are clearer, and the water quality is comparatively good.

Owner:张继全

A kind of preparation method of corrugated paper and corrugated board

ActiveCN112060267BIncrease roughnessImprove hydrophilicityFlexible coversWrappersCardboardPlant fibre

The present invention provides a preparation method of corrugated paper, which includes the following steps: S1, infiltrating plant fibers with alkaline solution, and cutting them into short plant fibers; S2, washing the above short plant fibers, dipping in ethylenediamine solution, and washing and drying to obtain the treated plant fiber raw material; S3, mixing, stirring, corrugating, and molding the treated plant fiber raw material, binder, inorganic oxide particles, and auxiliary agents to make corrugated paper. The invention solves the mechanical problems such as the strength of the product by mixing the raw materials for the preparation of the corrugated paper, and then designs the specific progressive impact-resistant deformation of the paperboard to buffer the strong impact force, and cooperates with the high-strength design of the corrugated paper to avoid the impact damage of the paperboard. The problem.

Owner:武汉金凤凰纸业有限公司

Construction method of ecological re-greening of high-steep side slope of river channel

InactiveCN109555082ADestabilizationPromote germinationClimate change adaptationCoastlines protectionFiberVegetation

The invention discloses a construction method of ecological re-greening of a high-steep side slope of a river channel. The construction method includes the following steps that (1) inspection and danger removal operation are conducted on the slope surface, and unstable geological hidden troubles need to be first stabilized during being found; (2) a plurality of semi-arc type rigid micro-platformsare laid horizontally and uniformly at the top of the slope surface, and are used for dividing the slope surface horizontally; (3) the lower parts of the semi-arc type rigid micro-platforms are lockedand supported through semi-arc type anchor rod combining wall clamps; (4) flexible polypropylene long fiber rods are horizontally laid in arc-shaped grooves of the semi-arc type rigid micro-platforms, and the staggered survival rate of a vegetation root system staggered network is increased; (5) three-dimensional vegetation bodies are paved with the intervals of the micro-semi-arc type rigid micro-platforms and locked with anchor rods; and (6) the whole slope is swept and sprayed with seed layers through a vehicle-mounted spray-seeding vehicle. According to the construction method of ecological re-greening of the high-steep side slope of the river channel, the construction time is short, rapid beautification of the surrounding environment can be achieved, the effect of urban landscape isimproved, and remarkable economic and ecological benefits are achieved.

Owner:荟岩环境科技无锡有限公司

A kind of method of regeneration and utilization of water-based paint cleaning agent waste liquid

ActiveCN104230086BReduce pollutionRuns clean and smoothEther separation/purificationMultistage water/sewage treatmentForeign matterLiquid waste

The invention discloses a method for recycling water-based paint detergent waste liquid. The method comprises the following steps: pre-treating the water-based paint detergent waste liquid, sorting, removing foreign matters, adding an additive A and an additive B, and producing demulsification reaction to form a mixture of paint slag and a solution; after the waste liquid is completely subjected to the demulsification reaction, feeding the waste liquid into a filtering system, performing solid-liquid separation, and completely separating the solution from the paint slag; performing harmless treatment on the paint slag; performing solvent accumulation on the solution, and separating a small part of water from most of a solvent mixture; treating the separated wastewater, discharging by standard, performing solvent purification on the solvent mixture, treating the separated wastewater and discharging by standard. According to the method, valuable ingredients in the waste liquid can be recycled and the rest wastewater is treated as conventional wastewater; the wastewater treatment difficulty is greatly lowered; the method is safe and environment-friendly.

Owner:CHENGDU YUANYONG TECH DEV

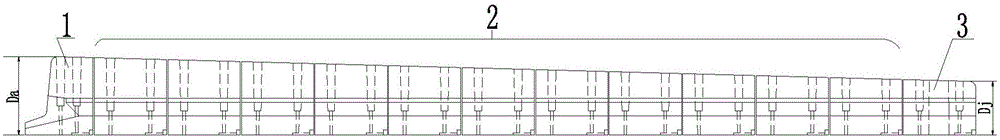

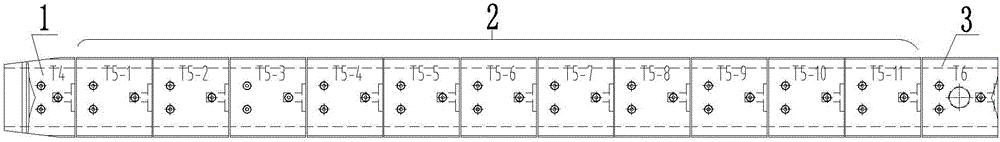

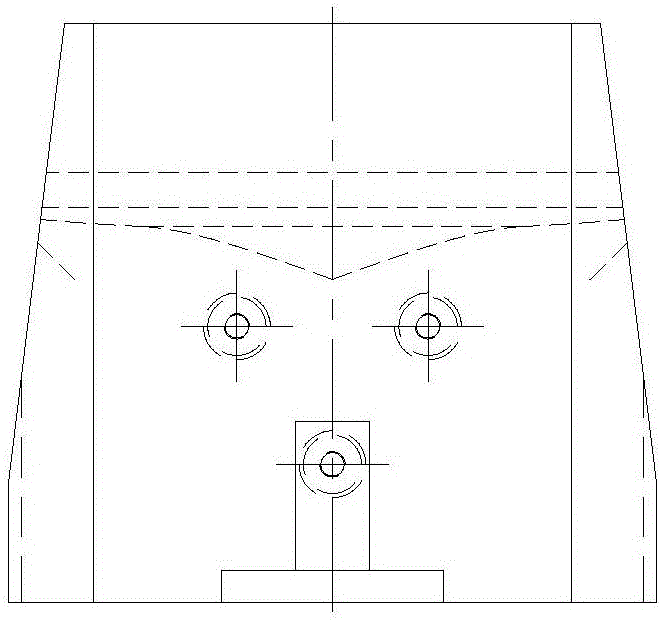

High-coking-chamber top-mounted coke oven with combined oven door lining blocks

ActiveCN106367086AImprove high-directional stabilityImpact resistanceCoke oven brickworkCoke oven doors/closuresEngineeringCoke oven

The invention discloses a high-coking-chamber top-mounted coke oven with combined oven door lining blocks. The coke oven comprises a coke-side oven door and a machine-side oven door. The lining blocks are mounted on the coke-side oven door and the machine-side oven door. The high-coking-chamber top-mounted coke oven is characterized in that each lining block comprises a head block, a tail block and a plurality of connection blocks between the head block and the tail block; the head blocks, the connection blocks and the tail blocks are arranged in the shape of strips sequentially; the block thickness from each tail block to the corresponding head block is increased from small Dj to large Da, and accordingly, the cross section of an inner cavity of a high coking chamber is in the shape of a trapezoid. After 10 years of operation of an oven body, an oven body heat engineering system starts to age, and coke pouring conditions deteriorate; after use of the designed oven door lining blocks, height stability of finished coke cakes is improved effectively, impact of door-free production of the coke oven is resisted, and the problem of coke cake collapse of the coke oven is solved.

Owner:MAANSHAN IRON & STEEL CO LTD

Hot-rolled weather-resistant angle steel tower

The invention discloses a hot-rolled weather-resistant angle steel tower, and belongs to the technical field of angle steel towers. The hot-rolled weather-resistant angle steel tower comprises a tower frame, wherein a mounting assembly is fixedly mounted at the bottom of the tower frame; supporting frames are fixedly mounted on the inner side of the tower frame at equal intervals; reinforcing rods are arranged between the supporting frames; and the reinforcing rods are fixedly connected with the supporting frames through punching-free connecting assemblies. According to the hot-rolled weather-resistant angle steel tower disclosed by the invention, the supporting frames are arranged, so that the tower frame can be assisted to support, and therefore, using stability of a tower body is improved; the punching-free connecting assemblies are arranged, so that the reinforcing rods can be connected with the supporting frames, and the supporting frames are prevented from being punched and mounted, and therefore, stability of the supporting frames is prevented from being damaged; an anti-climbing assembly is arranged, so that a non-professional operator can be prevented from climbing onto the angle steel tower through a climbing ladder; and a barbed rope is arranged, so that the non-professional operator can be prevented from climbing onto the angle steel tower through the supporting frames, the tower body and the reinforcing rods, and therefore, a man-made falling risk is avoided.

Owner:江苏振光电力设备制造有限公司

Machining technology for metal ceramic flange

The invention relates to a machining technology for a metal ceramic flange. The machining technology is characterized by comprising the steps that firstly, powdery raw materials are added into a container according to the weight ratio and are evenly stirred, and then a proper amount of water is added for even stirring; secondly, the surface of the inner wall of a die is coated with a layer of release agent, the die is filled with the raw materials, and the raw materials in the die are pressed through a pressing plate; thirdly, the die is heated to evaporate water in the flange, and then the flange in the die is pressed after evaporation; fourthly, die releasing is conducted on the formed flange, and then some burrs are cut; fifthly, the flange obtained after die releasing is put into a combustion furnace to be heated for 15 min to 25 min at the temperature ranging from 600 DEG C to 800 DEG C, and then sintering is conducted for 10 min to 20 min at the temperature ranging from 1200 DEG C to 1300 DEG C; sixthly, after sintering forming is conducted, the temperature is gradually reduced to 200 DEG C, and the flange is taken out and cooled to the room temperature; and seventhly, the cooled flange is checked, and some burrs are ground. According to the machining technology, the steps are simple, operation is easy, the produced flange is high in hardness and small in weight, and the production cost is saved.

Owner:ZHANGJIAGANG HUARI FLANGE

A highly stable single-reagent liquid blood ammonia (amm) detection reagent

ActiveCN106811505BGuaranteed stabilityEasy to operateMicrobiological testing/measurementActive agentAcyl CoA dehydrogenase

The invention relates to a blood ammonia (AMM) detection reagent and in particular relates to a high-stability single-reagent liquid-state blood ammonia (AMM) detection reagent. The reagent is mainly prepared from main substances including a buffering solution, LDH (Lactate Dehydrogenase), a heavy metal ion chelating agent, an ionic balance agent, a preservative, alpha-KG, NADH.NA2, a surfactant, a protecting agent and the like. According to the reagent, a single reagent of glutamate dehydrogenase two-point method and kinetic method is established; the utilization operation is effectively simplified and the stability of effective components of a product is guaranteed; the metal chelating agent is properly selected so that the inhibition, caused by the heavy metal ions, on the activity of an enzyme in the reagent is effectively removed; interference on the enzyme is not caused; the protecting agent is properly added so that the stability of the enzyme and the stability of key substrates in the reagent are effectively protected; the substances are added so that the stability of a single-reagent product provided by the invention is effectively guaranteed and the reagent is greatly convenient for utilization and popularization clinically.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

Diffraction wave field extraction method and device

ActiveCN107942374BDestabilizationAlleviate the technical problem of poor precision of diffracted wavesSeismic signal processingWave fieldReflected waves

The invention provides a diffracted wave field extraction method and device, and relates to the technical field of diffraction field extraction. The method includes: obtaining a pre-stack common-offset gather data in an area to be processed, wherein the pre-stack common-offset gather data carries the stratum interface information in the area to be processed; on the basis of plane wave decomposition on the pre-stack common-offset gather data, transforming the local dip angle of a reflected wave by curvelet transform and then performing regular constraint by using the L0 norm so as to obtain thefirst objective function of the diffracted wave field to be extracted relative to the local dip angle of the reflected wave; and solving the target reflection wave dip angle by a trust region algorithm, wherein the target reflection wave dip angle is the reflection wave dip angle when the first objective function reaches the minimum; and determining the diffraction wave field to be extracted by combining the target reflected wave dip angle, the pre-stack common-offset gather data and the first objective function. The method and device alleviate a technical problem that the diffraction wave extracted by the traditional diffraction wave extraction method is poor in accuracy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

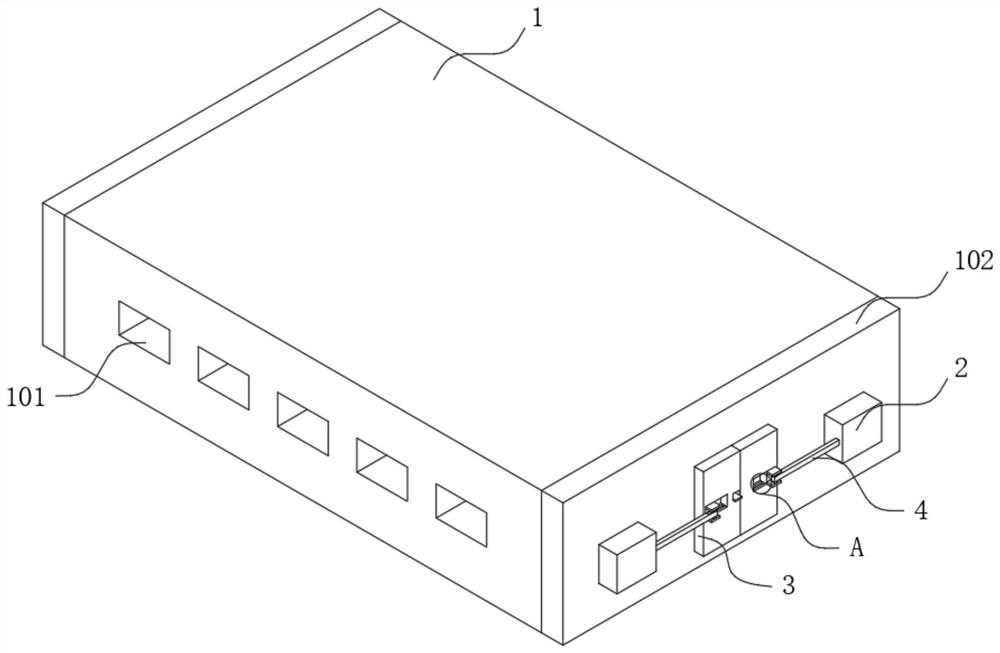

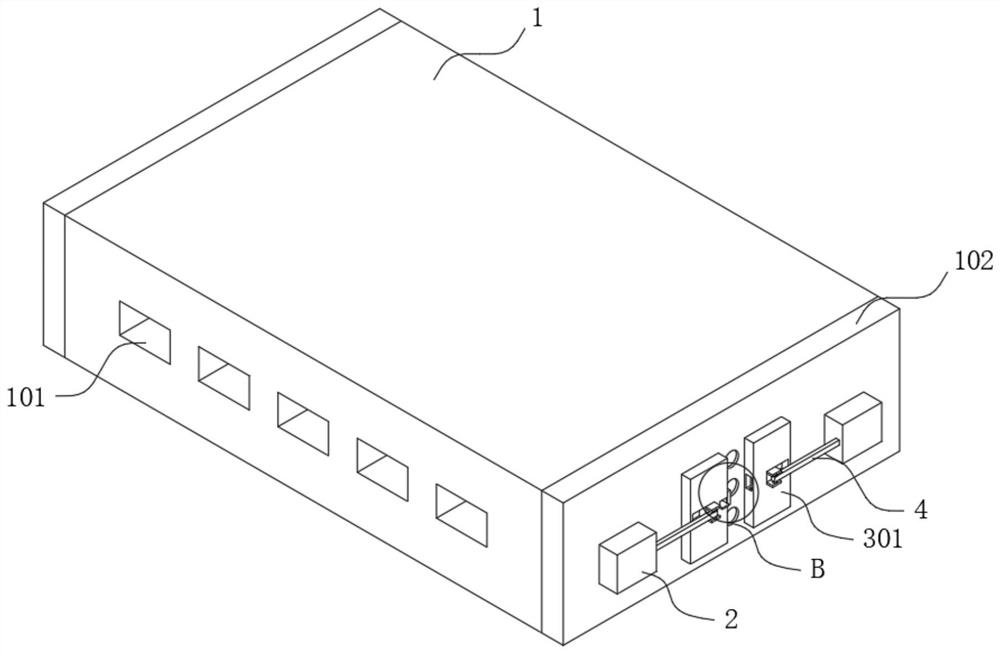

Communication engineering-based switch with built-in power supply structure

InactiveCN113825035AHeat dissipationPrevent moistureCasings/cabinets/drawers detailsSelection arrangementsMechanical engineeringPhysics

The invention discloses a communication engineering-based switch with a built-in power supply structure. The switch comprises a switch body, a supporting mechanism, a positioning mechanism and an anti-falling mechanism. Side plates are fixedly connected to two sides of the switch body, two movable blocks are rotatably connected to one sides of the two side plates, heat dissipation holes are formed in the middle parts of the two side plates, and the heat dissipation holes are formed in the middle parts of the two movable blocks; the supporting mechanism is arranged on one side of the side plate and comprises a left supporting plate, a right supporting plate, a sliding groove, a connecting rod and a sliding block, the positioning mechanism is arranged in the sliding block, and the anti-falling mechanism is arranged at the joint of the left supporting plate and the right supporting plate. The beneficial effects of the invention are that through the design of the left supporting plate and the right supporting plate, when the switch body is used, the left supporting plate and the right supporting plate play a role of supporting legs, and when the switch body is not used, the left supporting plate and the right supporting plate can be spliced at the outer sides of the heat dissipation holes; therefore, external dust can be prevented from entering the switch body.

Owner:马良华

Hydrogenation method for organic catalyst normal-pressure catalytic butyronitrile rubber latex

The invention provides a hydrogenation method for organic catalyst normal-pressure catalytic butyronitrile rubber latex, belonging to the field of the in-situ normal-pressure hydrogenation of the butyronitrile rubber latex. The invention provides a novel method for carrying out the hydrogenation research on the macromolecule butyronitrile rubber latex by a hydrazine hydrate / riboflavin catalyst system under the air condition, and developing the in-situ hydrogenation of the green organic compounds--riboflavin catalyst on the butyronitrile rubber latex, wherein the riboflavin catalyst is firstly used in an aqueous dispersion rubber latex system. Compared with the existing inorganic catalyst such as the copper sulfate, the ferric sulfate, the ferrous sulfate or the boric acid, the riboflavin organic catalyst has the advantages that the riboflavin organic catalyst is green and environment-friendly, and is easy to prepare, the latex can not be broken, the stability of the butyronitrile rubber latex can not be influenced due to the stable existence of the riboflavin organic catalyst and the rubber latex and the like, furthermore, a hydrogenated intermediate generated by a hydrazine hydrate / riboflavin catalyst system is stable, so that the hydrogenated butyronitrile rubber latex of which the hydrogenation degree is larger than 90% can be obtained.

Owner:BEIJING UNIV OF CHEM TECH

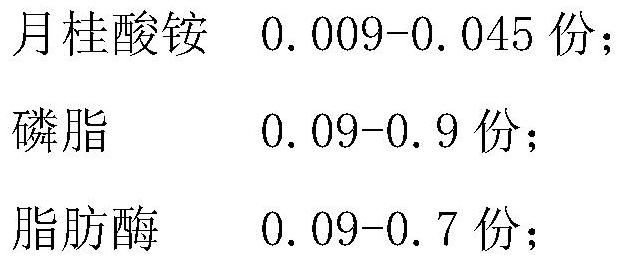

A kind of natural latex stabilizer and its application

The invention discloses a natural rubber latex stabilizer and a method for rapidly improving the mechanical stability of natural rubber latex under low-ammonia storage. Low-ammonia natural rubber latex, add 0.1-0.8 parts (dry weight) of water-soluble phospholipids and 0.1-0.6 parts (dry weight) of lipase, and stir evenly at room temperature. This method uses lipase to quickly hydrolyze phospholipids to increase the negative charge of latex particles and the thickness of the hydration film, which can quickly improve the mechanical stability of concentrated natural latex stored in low ammonia, and make the mechanical stability of concentrated natural latex reach the national standard within 30 days The specified minimum limit of 650 seconds and maintain good process operation performance. At the same time, the mass fraction of ammonia in the concentrated natural latex can be controlled below 0.2%, which is suitable for the development trend of low-ammonia preservation of natural latex.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

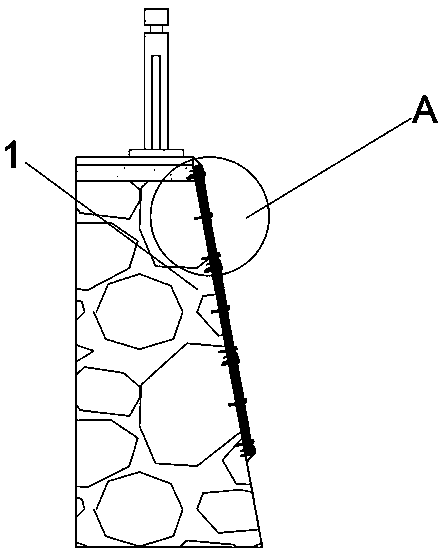

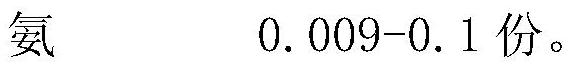

Test device of load-deformation complete curve for testing four-point flexural-tensile concrete sample

ActiveCN109932253ADestabilizationEasy to processMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesSmall sampleTest room

The present invention discloses a test device of a load-deformation complete curve for testing a four-point flexural-tensile concrete sample. The device comprises a steel plate, first round steel, second round steels, third round steel and a pressure sensor. The second round steels are fixed at two sides of the steel plate, the pressure sensor is arranged between the second round steels, the pressure sensor is fixed on the steel plate through the third round steel, and the top portions of the second round steel and the pressure sensor are provided with the first round steel configured to put aconcrete sample. The device is simple in processing, and low in manufacturing cost, can be customized according to the size of the concrete sample, namely can be used for measuring the whole curve ofa wet sieving concrete small sample, and can be also used for measuring the whole curve of a full-level matched concrete large sample; and moreover, the device provided by the invention can perform test in a common concrete test machine having no limitation for the ultimate load and the clearance of the test machine to achieve stable damaging of the concrete sample, and therefore, the test deviceof the load-deformation complete curve for testing the four-point flexural-tensile concrete sample is specially suitable for test rooms short of test conditions (implosion test machines).

Owner:HOHAI UNIV

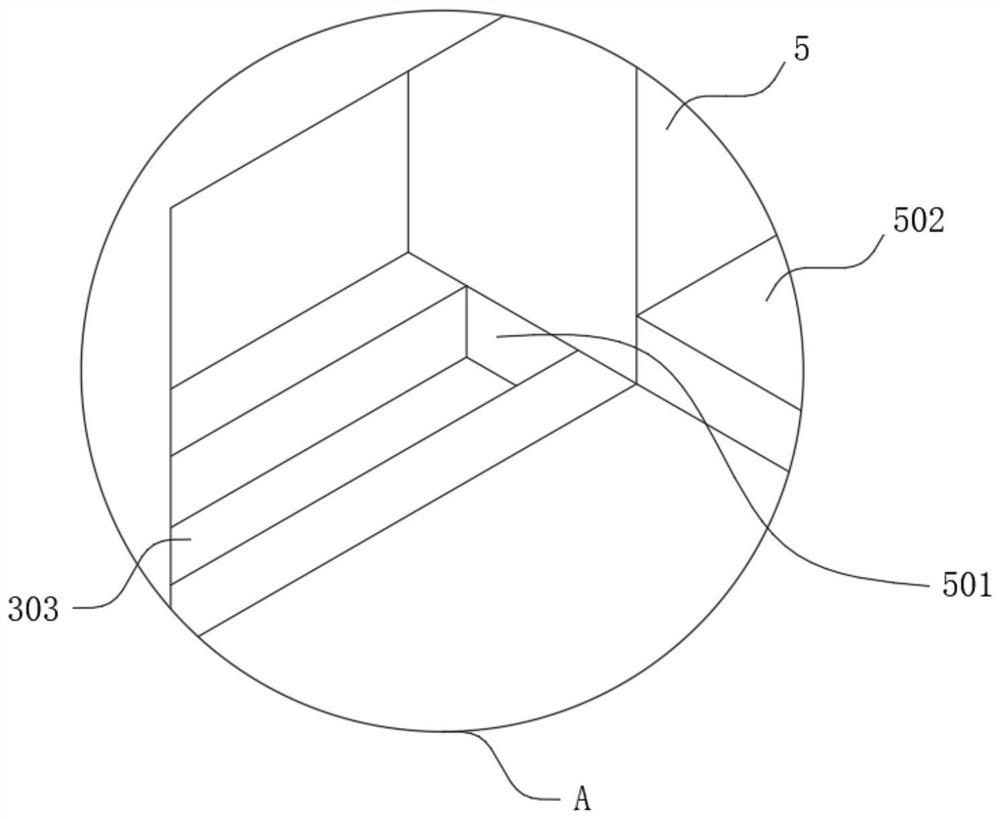

A Diamond Wire Cutting Machine with Completely Planar Wiring

ActiveCN103395130BReduce replacement frequencySave time and costFine working devicesStone-like material working toolsWire cuttingEngineering

The invention relates to a diamond wire electrical discharge machine capable of completely flat wiring, and aims to provided the diamond wire electrical discharge machine having the advantages that a diamond wire is long in service life, wheels are free of abrasion, wiring is simple, structure is simple, size is small and cost is low on the basis of guaranteeing the normal cutting function. The technical scheme is that the diamond wire electrical discharge machine capable of completely flat wiring comprises a machine body, a wire storing mechanism, a wire conveying mechanism and a lifting platform, and the wire storing mechanism, the wire conveying mechanism and the lifting platform are all disposed on the machine body. The diamond wire electrical discharge machine is characterized in that the wire conveying mechanism comprises a group of forward wheels, a group of tensioning wheels and a group of cutting wheels, each of the forward wheel, the tensioning wheel and the cutting wheel is provided with at least two grooves arraying along the axial direction of the same, the grooves with the same serial number in all the forward wheels, the tensioning wheels and the cutting wheels form one group, namely a wire conveying channel of the diamond wire, and groove bottoms of all the grooves of the same group locate in the same plane.

Owner:曹爱苗

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com