Test device of load-deformation complete curve for testing four-point flexural-tensile concrete sample

A technology for concrete specimens and test devices, applied to measuring devices, using stable bending force to test material strength, using stable tension/compression to test material strength, etc., can solve test failure, end damage, and high cost and other problems, to achieve the effect of stable damage, simple processing and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

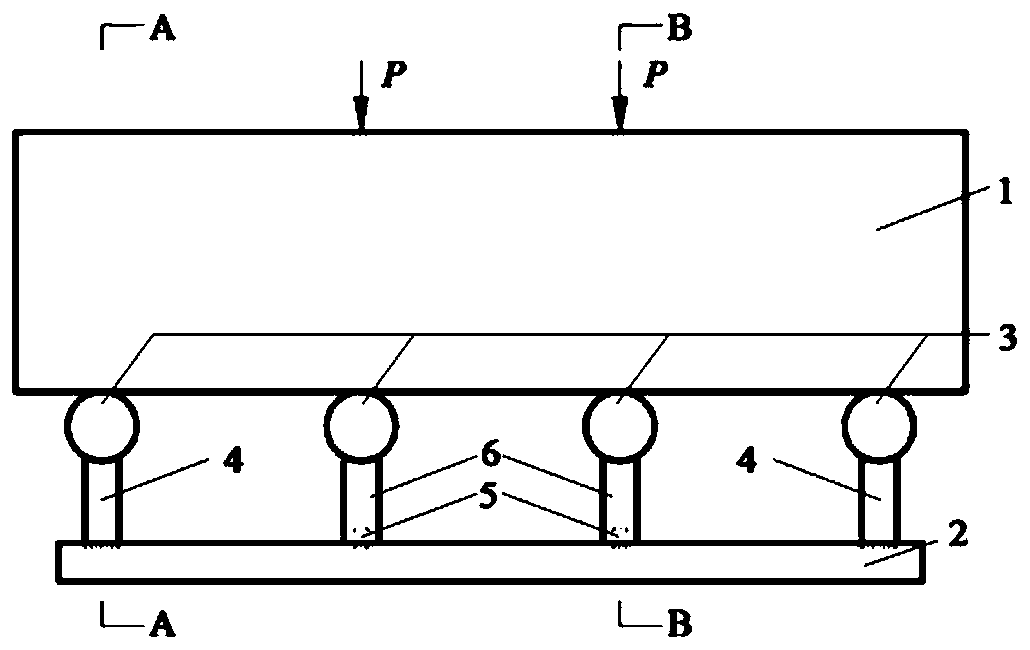

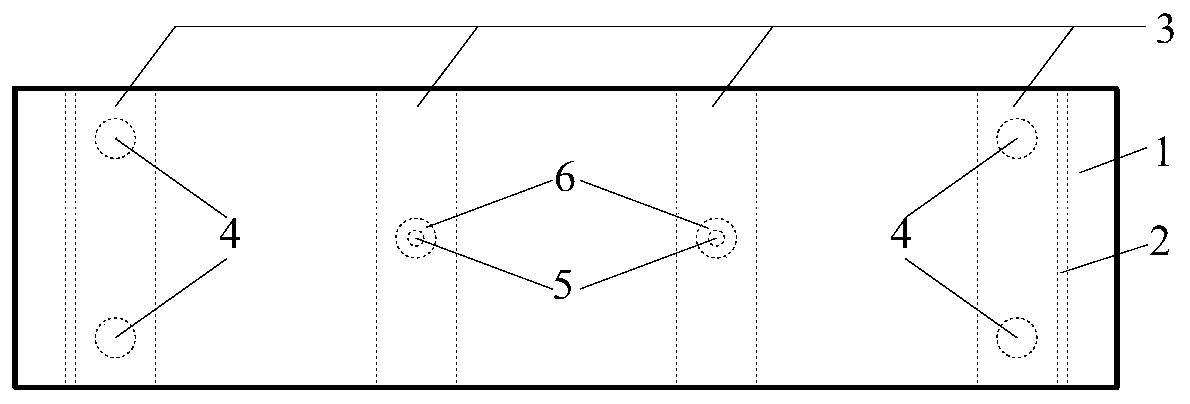

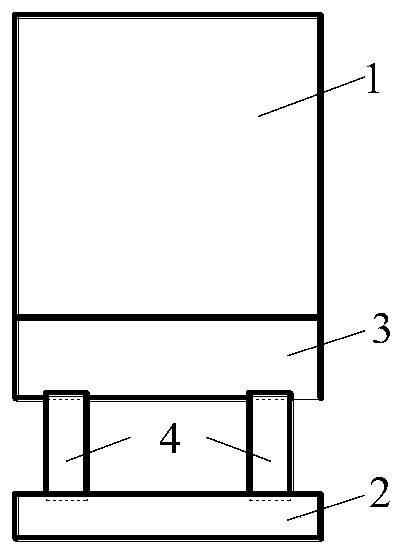

[0019] Such as Figure 1 to Figure 4 As shown, the present invention comprises a steel plate 2, a first round steel 3, a second round steel 4, a third round steel 5 and a pressure sensor 6, two second round steels 4 are respectively fixed on the left and right sides of the steel plate 2, and the left and right two The second round steel 4 on one side is symmetrically distributed, and the two second round steel 4 on the same side are symmetrically distributed with respect to the horizontal centerline of the steel plate 2 . There are two pressure sensors 6 between the second round steel 4 on the left and right sides, and the two pressure sensors 6 are located on the horizontal center line of the steel plate 2, and are symmetrically distributed about the vertical center line of the steel plate 2 . The horizontal distance between the second round steel 4 and the pressure sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com