Method for recycling water-based paint detergent waste liquid

A water-based paint and cleaning agent technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the waste of available resources, high requirements for equipment materials, and secondary pollution of the environment and other issues to achieve the effect of saving labor, reducing processing difficulty, and reducing equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

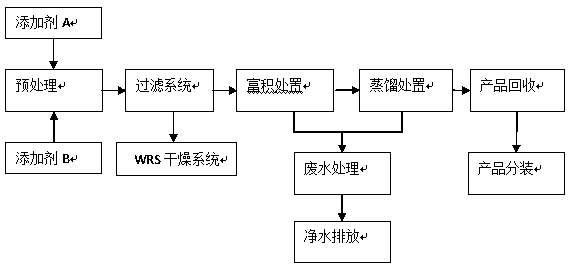

[0035] The invention discloses a method for recycling the waste liquid of a water-based paint cleaning agent. The waste liquid of the water-based paint cleaning agent is pretreated to classify it, and after removing foreign matter, additives A and B are added to carry out demulsification reaction to form paint residue Mixture with solution; after the demulsification reaction of the waste liquid is complete, it enters the filtration system for solid-liquid separation to completely separate the solution and paint residue; the paint residue is sent to the WRS-OR organic waste (resource) utilization system for harmless treatment ; The solution enters the disposal for solvent enrichment, so that a small part of the water is separated from most of the solvent mixture; the separated wastewater is discharged after wastewater treatment to reach the standard, and the solvent mixture enters the distillation treatment for solvent purification. Set the temperature and time to separate the sol...

Embodiment 2

[0037] As the best embodiment of the present invention, the steps are:

[0038] 1. Primary selection of waste liquid: remove impurities from the waste liquid of water-based paint cleaner, such as cleaning rags and other debris.

[0039] 2. Demulsification reaction:

[0040] 2.1 First, add additive A to the waste liquid of the water-based paint cleaning agent, stir evenly at room temperature, quickly and effectively demulsify the waste liquid, forming a mixture of paint residue and solution; add additive B after the solid-liquid mixture is completely separated to adjust the pH of the material .

[0041] 2.1.1 Function of Additive A: The stability of the dispersed particles of the waste liquid of paint cleaning agent is poor, and it is more sensitive to shearing force, heat and pH value. According to the quality of the waste liquid at room temperature: Additive A=100: (1.5~5) Compared with, it destroys the stability of dispersed particles, breaks the particles and separates them to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com