A kind of preparation method of corrugated paper and corrugated board

A corrugated cardboard and corrugated paper technology, applied in the direction of paper/cardboard layered products, special paper, paper products, etc., to avoid deformation under pressure, increase antibacterial, and improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

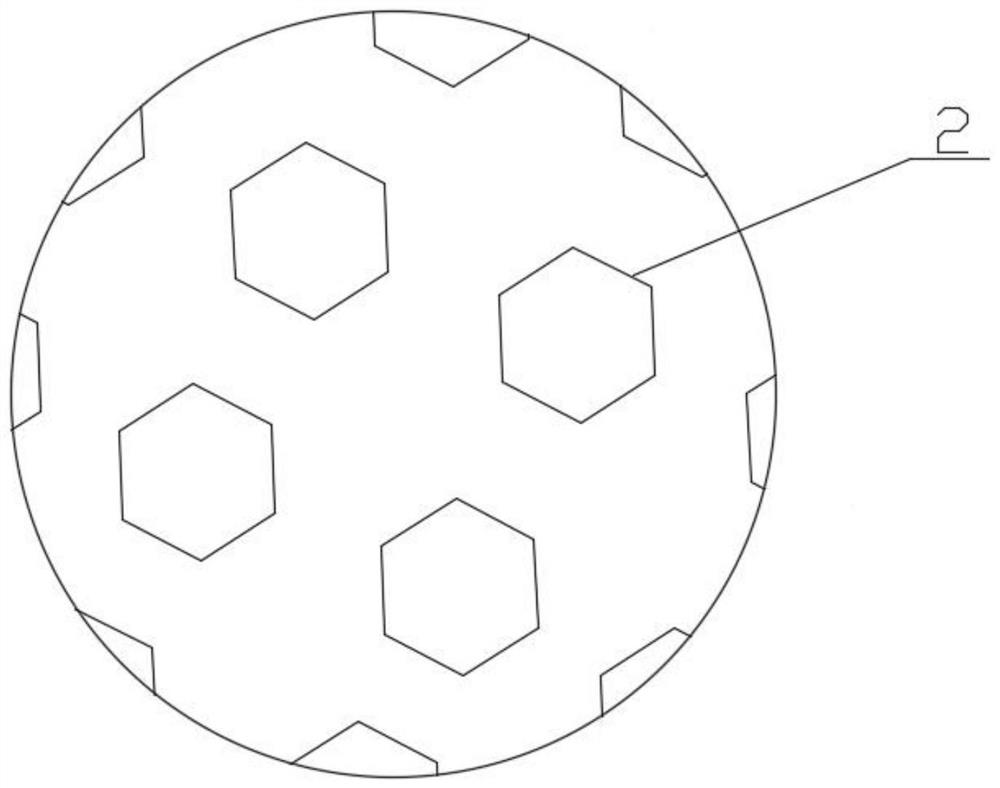

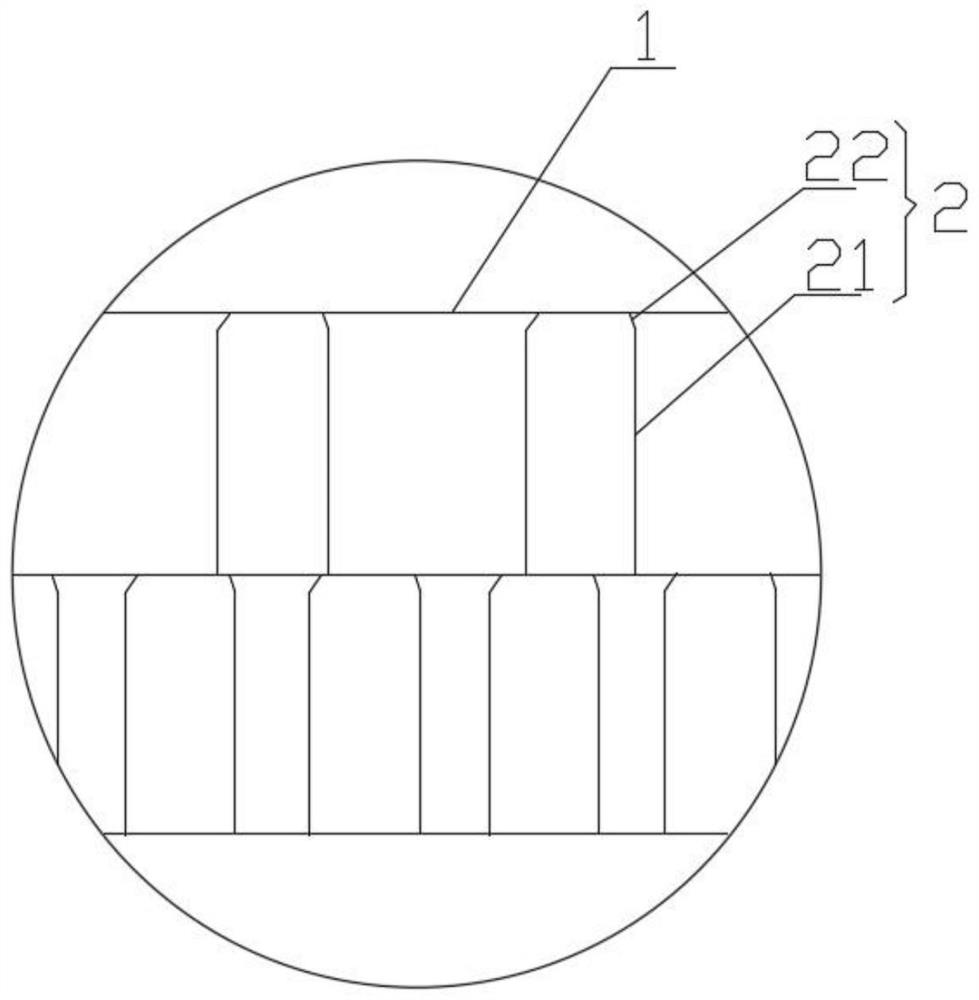

Image

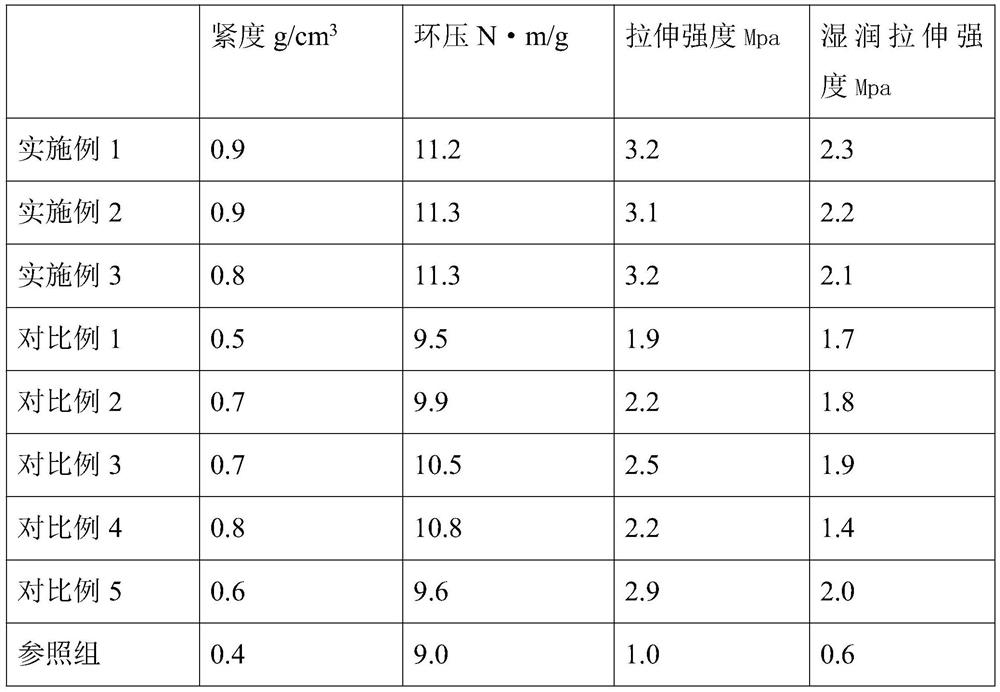

Examples

Embodiment 1

[0030] A preparation method of corrugated paper, comprising the following steps:

[0031] S1, soak the plant fibers in a sodium hydroxide solution with a mass fraction of 5% at room temperature for 30 minutes, and cut them into short plant fibers with a length of 3-6 mm;

[0032] S2, washing the above-mentioned short plant fibers, soaking in an ethylenediamine solution with a mass fraction of 75% for 120 min, washing and drying to obtain the treated plant fiber raw materials;

[0033] S3, 50kg of processed plant fiber raw materials, 20kg of water glass glue, 30kg of inorganic oxide particles with a particle size of 0.01 to 2mm, 10kg of auxiliary agents are mixed, stirred, corrugated, and formed into corrugated paper.

[0034] Among them, the components of the inorganic oxide particles are: 10 kg of silicon dioxide, 10 kg of magnesium hydroxide, 10 kg of aluminum hydroxide; 5 kg of stearic acid and 5 kg of cellulose acetate.

Embodiment 2

[0036] A preparation method of corrugated paper, comprising the following steps:

[0037] S1, soak the plant fiber in a sodium hydroxide solution with a mass fraction of 5% at room temperature for 40 minutes, and cut it into short plant fibers with a length of 3-6 mm;

[0038] S2, washing the above-mentioned short plant fibers, soaking in an ethylenediamine solution with a mass fraction of 75% for 160 min, washing and drying to obtain the treated plant fiber raw materials;

[0039] S3, 40kg of processed plant fiber raw materials, 10kg of water glass glue, 20kg of inorganic oxide particles with a particle size of 0.01 to 2mm, and 20kg of additives are mixed, stirred, corrugated, and formed into corrugated paper.

[0040] Among them, the components of the inorganic oxide particles are: 10 kg of silicon dioxide, 5 kg of magnesium hydroxide, 5 kg of aluminum hydroxide; 10 kg of stearic acid and 10 kg of cellulose acetate.

Embodiment 3

[0042] A preparation method of corrugated paper, comprising the following steps:

[0043] S1, soak the plant fiber in a sodium hydroxide solution with a mass fraction of 5% at room temperature for 30 minutes, and cut it into short plant fibers with a length of 3-6 mm;

[0044] S2, washing the above-mentioned short plant fibers, soaking in an ethylenediamine solution with a mass fraction of 75% for 120 min, washing and drying to obtain the treated plant fiber raw materials;

[0045] S3, 45kg of processed plant fiber raw materials, 15kg of water glass glue, 25kg of inorganic oxide particles with a particle size of 0.01 to 2mm, and 20kg of auxiliary agents are mixed, stirred, corrugated, and formed into corrugated paper.

[0046] Among them, the components of inorganic oxide particles are: silicon dioxide 10kg, magnesium hydroxide 10kg, aluminum hydroxide 5kg; stearic acid 10kg, cellulose acetate 10kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com