Electrolytic zinc production technology

A production process, electrolytic zinc technology, applied in photography technology, photography auxiliary technology, instruments, etc., can solve the problems of increasing waste treatment costs, increasing production costs, large power consumption, etc., to achieve simple and efficient production process and save production costs , the effect of reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

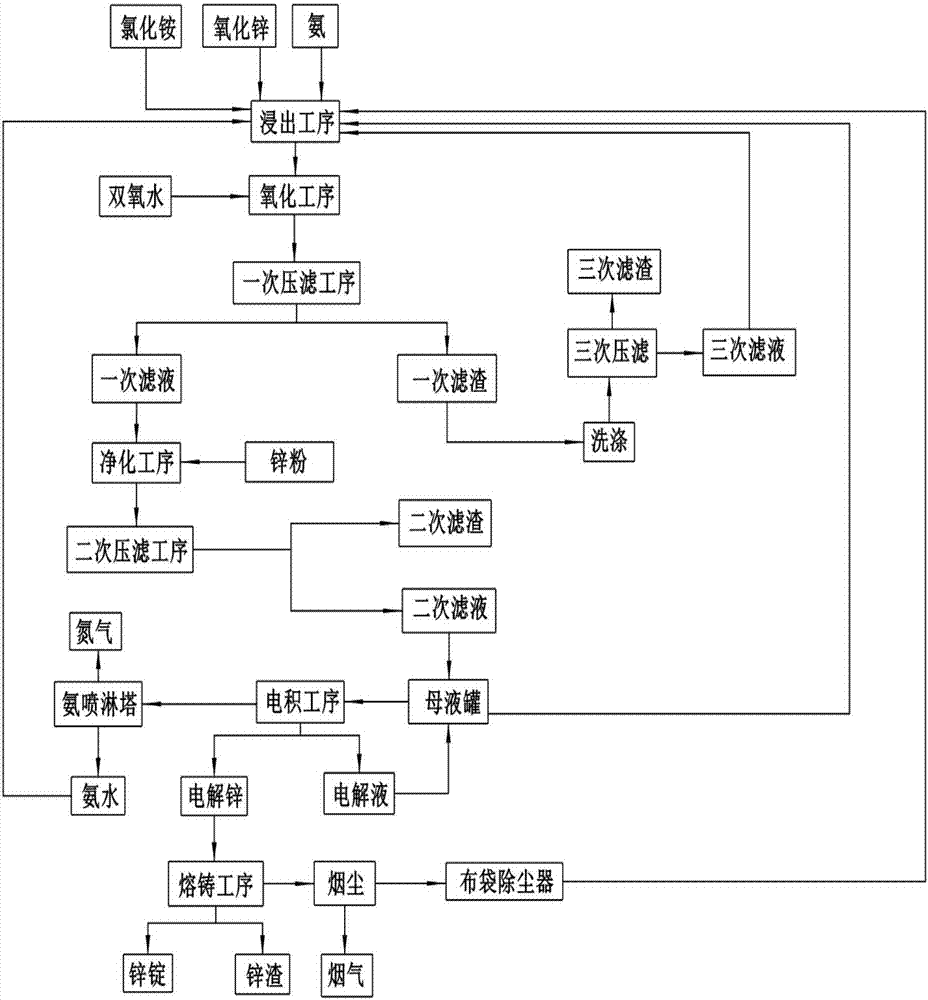

Image

Examples

Embodiment 1

[0025] A production process of electrolytic zinc, comprising the following process steps:

[0026] (1) Leaching process: put zinc oxide into the aqueous solution of ammonia and ammonium chloride, use ammonia and ammonium chloride solution as the leaching agent, leaching the zinc in the material, and obtaining the leachate, wherein, the stirring speed is 60 rpm, and the reaction The temperature is 30°C, the reaction time is 4 hours, and the concentration of ammonium chloride is 250g / l; in this step, the leaching rate of zinc oxide is 89%;

[0027] (2) Oxidation process: add hydrogen peroxide with a mass concentration of 0.3% to the leachate, and react at 60°C for 0.5 hours to remove iron in the leachate, and then perform a pressure filtration to obtain a filtrate and a filter residue, wherein the hydrogen peroxide The dosage is to add 15L per ton of leaching solution, and the stirring speed is 60 rpm;

[0028] (3) Purification process: add zinc powder to the primary filtrate, ...

Embodiment 2

[0033] (1) Leaching process: put zinc oxide into the aqueous solution of ammonia and ammonium chloride, use ammonia and ammonium chloride solution as the leaching agent, leaching the zinc in the material, and obtaining the leachate, wherein, the stirring speed is 60 rpm, and the reaction The temperature is 60°C, the reaction time is 2 hours, and the concentration of ammonium chloride is 200g / l; in this step, the leaching rate of zinc oxide is 93%;

[0034] (2) Oxidation process: add hydrogen peroxide with a mass concentration of 0.3% to the leachate, and react at 30°C for 2 hours to remove iron in the leachate, and then perform a filter press to obtain a filtrate and a filter residue, wherein hydrogen peroxide The dosage is to add 20L per ton of leaching solution, and the stirring speed is 60 rpm;

[0035] (3) Purification process: add zinc powder to the primary filtrate, react at 30°C for 1 hour, then perform secondary pressure filtration to obtain secondary filtrate and seco...

Embodiment 3

[0040](1) Leaching process: put zinc oxide into the aqueous solution of ammonia and ammonium chloride, use ammonia and ammonium chloride solution as the leaching agent, leaching the zinc in the material, and obtaining the leachate, wherein, the stirring speed is 60 rpm, and the reaction Temperature is 45 ℃, and the reaction time is 3 hours, and the concentration of ammonium chloride is 350g / l; In this step, the leaching rate of zinc oxide is 96%;

[0041] (2) Oxidation process: add hydrogen peroxide with a mass concentration of 0.3% in the leachate, react at 45°C for 1 hour, use to remove iron in the leachate, and then perform a pressure filtration to obtain a filtrate and a filter residue, wherein the hydrogen peroxide The dosage is to add 18L per ton of leaching solution, and the stirring speed is 60 rpm;

[0042] (3) Purification process: add zinc powder to the primary filtrate, react at 45°C for 1.2 hours, then perform secondary pressure filtration to obtain secondary filt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com