Preparation method of iron-carbon micro-electrolytic filler

A technology of iron-carbon micro-electrolysis and iron filings, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc. Weakness and other problems, to achieve the effect of promoting the reaction efficiency of the primary battery, enhancing the structural strength, and being easy to industrialize production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

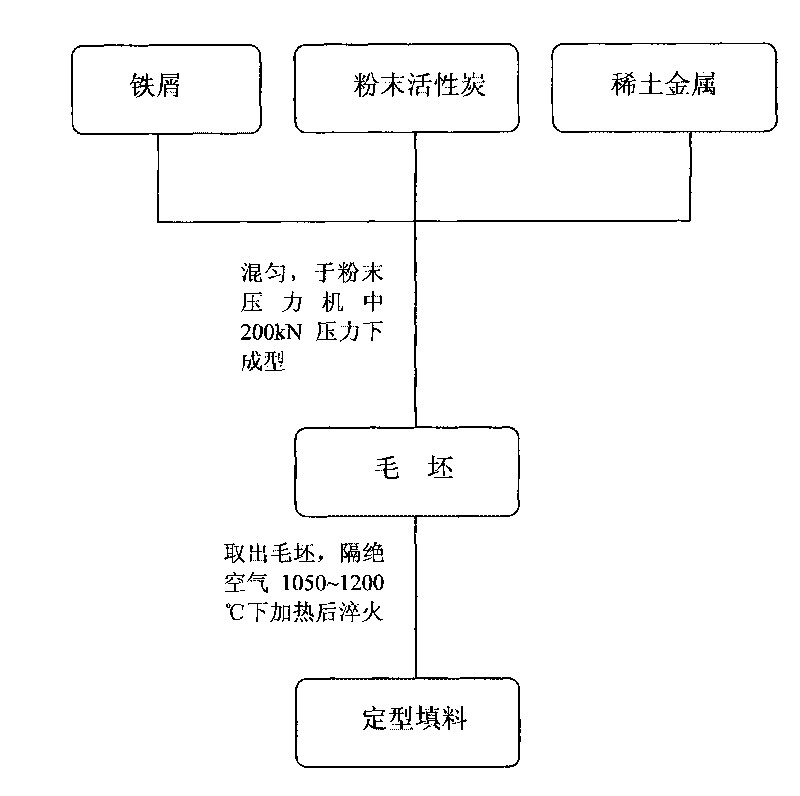

[0020] First use 5% hydrochloric acid to pickle the iron filings with a particle size of less than 60 mesh for 20 minutes, and rinse them with water; then put the iron filings, powdered activated carbon and rare earth metals with a particle size of -B-2) After mixing evenly according to the following mass percentage, add it to a model in the shape of a Pall ring. The diameter of the Pall ring is 50 mm, the height is 30 mm, and it is coated with release oil. In the mixture, iron filings account for 85%, powdered activated carbon accounts for 14.91-14.99%, and rare earth metal accounts for 0.01-0.09%. The mixture is pressed and formed by a powder press under a pressure of 200kN, and the blank is taken out to obtain a blank. After the blank is taken out, it is isolated from the air and heated at 1050-1200°C for 90-100 minutes, then quenched, and finally the shaped iron-carbon micro-electrolytic filler is obtained.

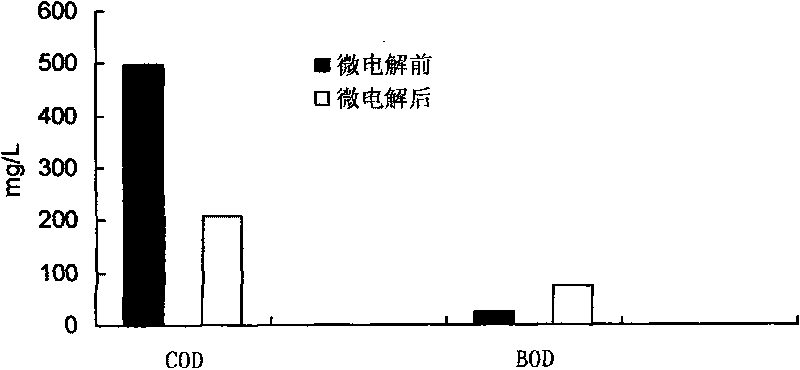

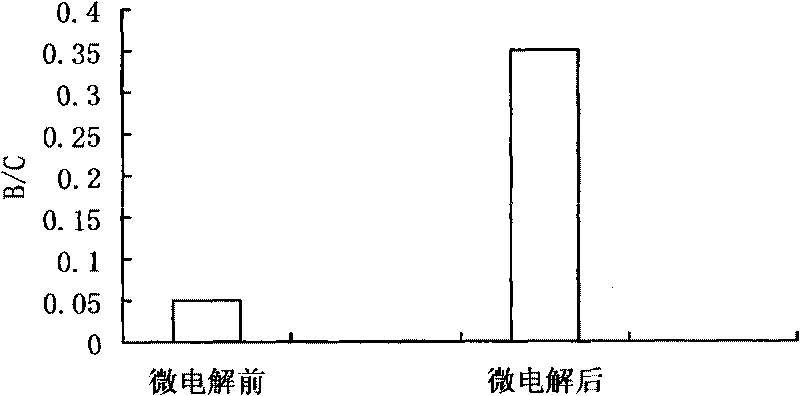

[0021] The effect of the iron-carbon micro-electrolytic filler p...

Embodiment 2

[0024] The iron-carbon micro-electrolytic filler prepared in Example 1 was used to treat coking wastewater. The water used in the experiment was taken from a coking plant to adjust the water quality of the pool: COD was 3780mg / L, volatile phenol was 524mg / L, and the chroma was 400. First adjust the pH to 3, after micro-electrolysis treatment, the reaction time is 90min, micro-aeration, after the reaction, adjust the pH with sodium hydroxide, measure its COD, phenol value and chroma, see the treatment effect image 3 Shown: after the reaction, the effluent COD is 2170mg / L, and the removal rate is 42.6%; the volatile phenol is 295mg / L, and the removal rate is 43.7%; the chroma is 50, and the removal rate is 87.5%. During the continuous experiment, the shape of the filler remained good, and no cracking and hardening occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com