Preparation process of test-liner environment-friendly kraft cardboard paper

A preparation process and kraft box technology, applied in papermaking, paper machine, wet end of paper machine, etc., can solve problems such as the quality of kraft linerboard paper cannot be guaranteed, reduce environmental damage and increase fracture length. , The effect of reducing the cost of papermaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the invention clearer, the invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

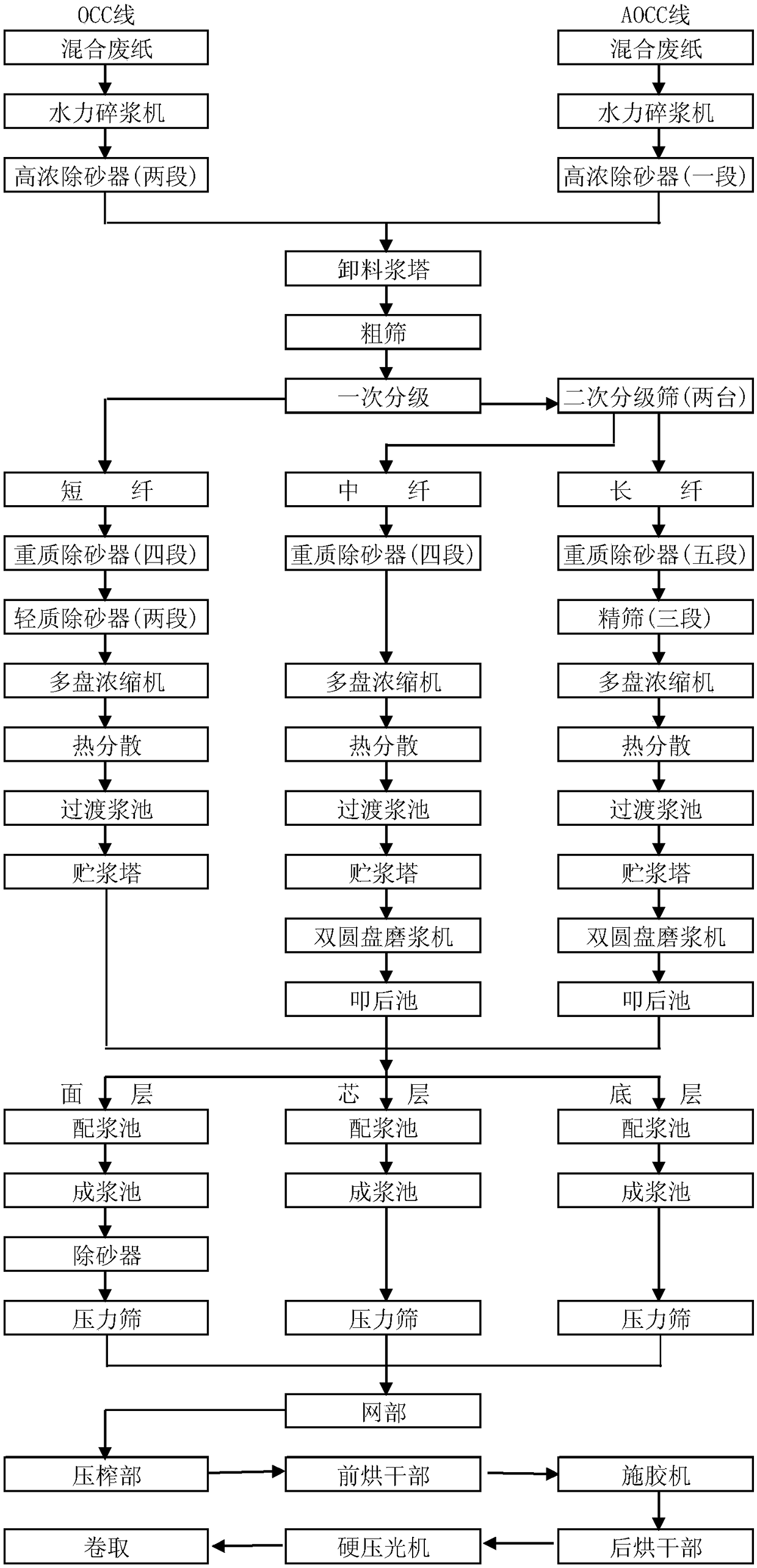

[0031] Such as figure 1 As shown, the present invention provides a preparation process of high breakage-resistant and environmentally friendly kraft liner paper, which is used to prepare waste paper into kraft liner paper. The waste paper includes 100% American old corrugated box waste paper, and the high The burst resistance index of the burst-resistant and environmentally friendly kraft linerboard is ≥3.8kPa m / g, and the preparation process of the high burst-resistant environmentally friendly kraft linerboard comprises the following steps:

[0032] A: Send the waste paper to the raw material yard to break up and sort the garbage, and send the sorted waste paper to the hydropulper of the OCC line and AOCC line through the chain conveyor;

[0033] B: The hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com