Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

175 results about "LACTIC ACID/UREA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lactic acid, salicylic acid and urea are all keratolytics that are often used in the treatment of skin conditions such as psoriasis, dermatitis, eczema, corns and calluses.

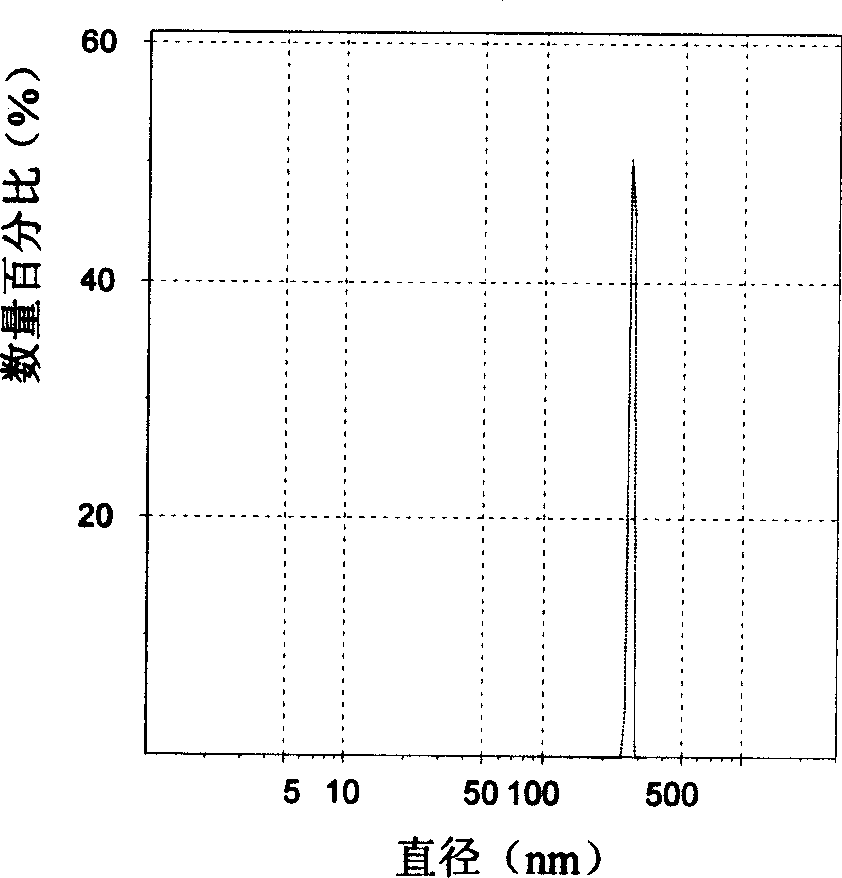

Preparation method for injectable poly(L-lactic acid) microsphere

The invention discloses a preparation method for an injectable poly(L-lactic acid) microsphere. The preparation method comprises the following steps: (1) preparing an organic solution of poly(L-lacticacid); (2) preparing an aqueous solution of sodium carboxymethylcellulose / mannitol; (3) adding the organic solution of poly(L-lactic acid) into the aqueous solution of sodium carboxymethylcellulose / mannitol drop by drop, carrying out uniform mixing, and then removing an organic solvent in the mixed solution; and (4) lyophilizing the solution obtained in the step (3) so as to obtain the injectablepoly(L-lactic acid) microsphere. According to the preparation method of the invention, a mixed solvent of sodium carboxymethylcellulose and mannitol is used as a stabilizer; when the freeze-dried mixture is redissolved, the poly(L-lactic acid) microsphere can be uniformly dispersed in the solution, and good injectable effect is obtained; and the preparation method of the invention is simple in process steps and suitable for mass preparation and industrial application.

Owner:普丽妍(南京)医疗科技有限公司

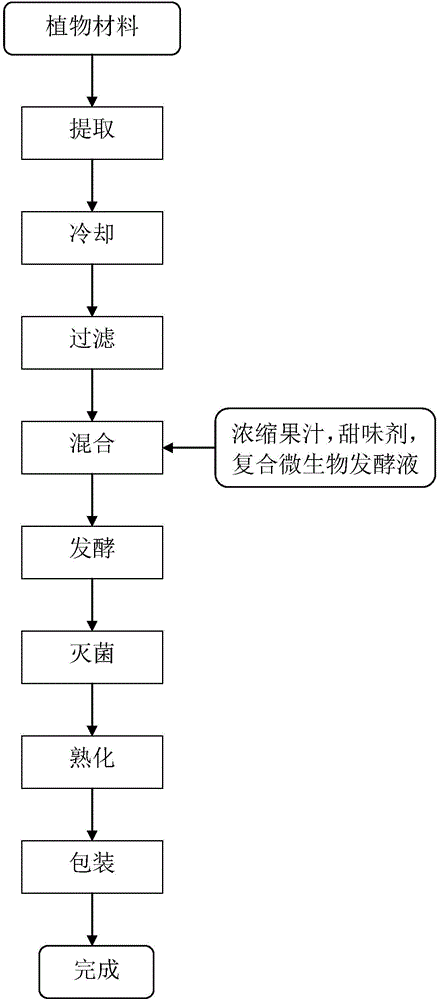

Preparation method for vegetable lactic drinks process by using lactic acid fermented solution

InactiveCN105077464AImprove qualityExcellent external competitivenessMilk preparationFood scienceMicroorganismLactic acid bacterium

The invention relates to a preparation method for vegetable lactic drinks process by using lactic acid fermented solution. The preparation method comprises the following steps that plant raw material and -8 times of water are poured into a pressure can and heated at the temperature of 70 to 80 DEG C; five to seven h of liquid is extracted from the pressure can with the pressure of 500 to 700 mmHg; extract liquid is cooled to the temperature of lower than 40 DEG C; impurities are filtered via a filter; 82 to 88 % by weight of plant raw material, 8 to 12% by weight of concentrated juice, 2 to 4% by weight of composite microorganism fermentation liquid and 2 to 4% by weight of sweetening agent are evenly mixed and fermented for 4 to 8 hours at the temperature of 25 to 45 DEG C; the plant material fermentation liquid after fermented is filtered via the filter and disinfected for 13 to 17 seconds at the temperature of 63 to 75 DEG C; then the plant fermentation liquid is cured in the a curing chamber for 22 to 26 hours at the temperature of 1 below to 8 DEG C; and at last the liquid is filled into a container for package. The lactic acid fermented drink has high performance and high quality.

Owner:金英旭

Method for preparing L-lactic acid and/or L-lactate

InactiveCN102517346AReduce manufacturing costMicroorganism based processesFermentationFlocculationMicroorganism

The invention discloses a method for preparing L-lactic acid and / or L-lactate. The method sequentially comprises the following steps of: a) preparing an L-lactic acid fermentation solution by microbial fermentation; b) treating the L-lactic acid fermentation solution by adopting any one of flocculation, filtration, centrifuging and ultra-filtration to obtain a clear fermentation solution; c) performing acidolysis and filtration on the clear fermentation solution to obtain acidolysis filtrate; d) decolorizing the acidolysis filtrate to obtain a decolorized solution; and e) separating the decolorized solution by adopting anion adsorption exchange resin, and thus obtaining the L-lactic acid and / or the L-lactate. By adopting the technical scheme, the method only has five steps, and a nano membrane filtration step and a molecular distillation step are not used any more, so compared with the conventional method, the method has the advantages of a few steps, low equipment purchasing cost and using cost, low energy consumption and easily controlled production cost. By adopting the method, the manufacturing cost of the L-lactic acid and / or the L-lactate is low.

Owner:安徽中粮生化格拉特乳酸有限公司

Method for producing lactic acid by using food waste

ActiveCN102424831AReduce pollutionMicroorganism based processesFermentationPectinaseResource utilization

The present invention discloses a method for producing lactic acid by using food waste, and relates to the field of fermentation. According to the present invention, a biological bacteria liquid and an enzyme preparation are adopted to treat the food waste, wherein the food waste is rich in starch, cellulose, fat, protein and other substances; the food waste is subjected to sealing fermentation for 48-84 hours at a temperature of 30-37 DEG C to produce the lactic acid; the fermented liquor is detected by a biological sensor, the highest lactic acid content is 20 g / L, and 100 g of the food waste can produce 15 g of the lactic acid with the conversion; the biological bacteria liquid comprises bnfillus licheniformis, bacillus larvae, bacillus natto, bacillus subtilis and lactobacillus plantarum; the enzyme preparation comprises the following components: amylase, cellulase, lipase, protease and pectinase. The purpose of the present invention is to reduce the environmental pollution causedby the food waste, change the waste into valuables, and carry out resource utilization for the food waste.

Owner:天津北洋百川生物技术有限公司

Compositions containing bacterium capable of converting lactic acid into butyric acid and method of preventing/treating hyperlactic acidemia in digestive tract and colon cancer by using the same

Owner:KYODOKEN INST FOR ANIMAL SCI RES & DEV +1

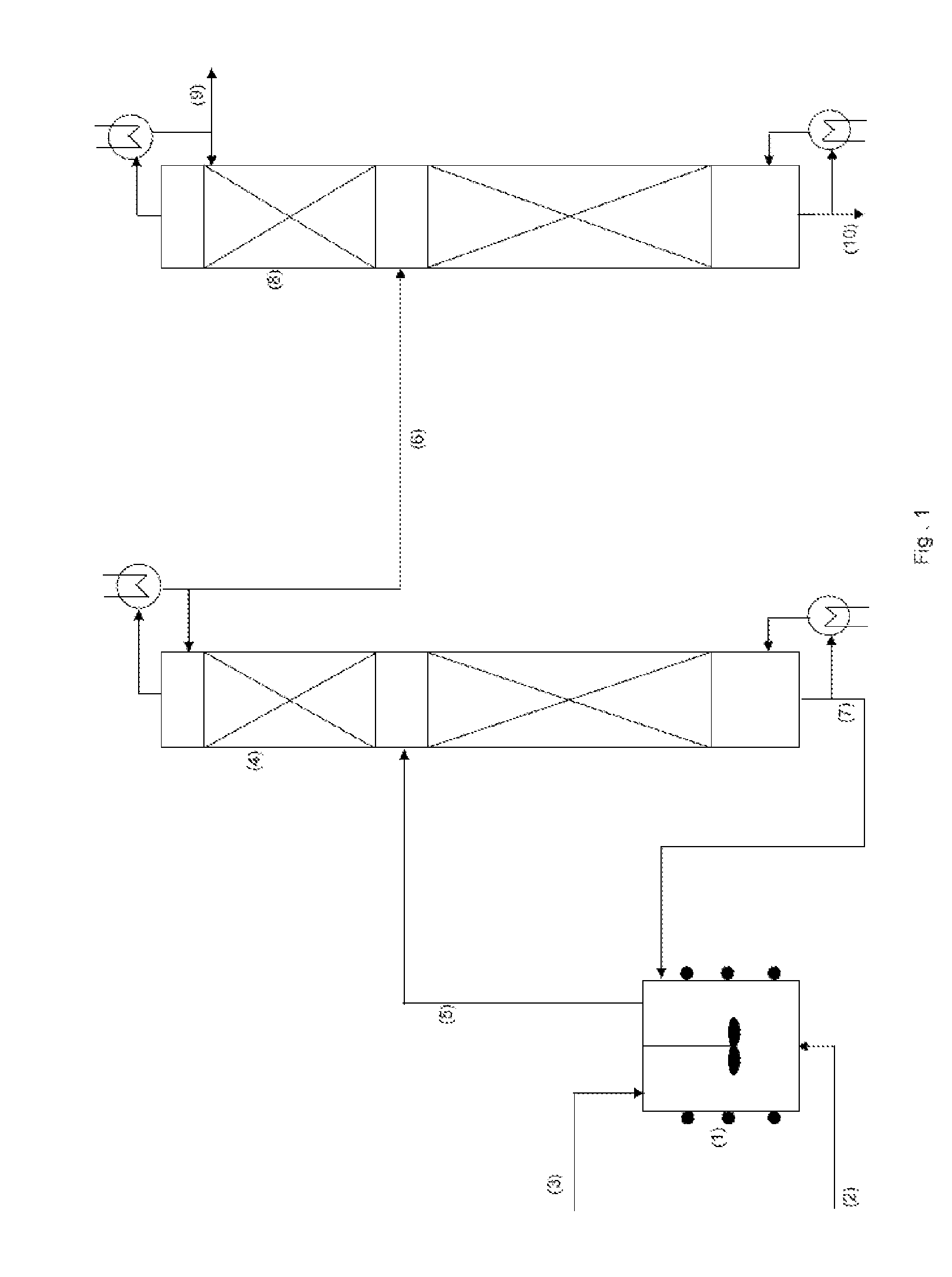

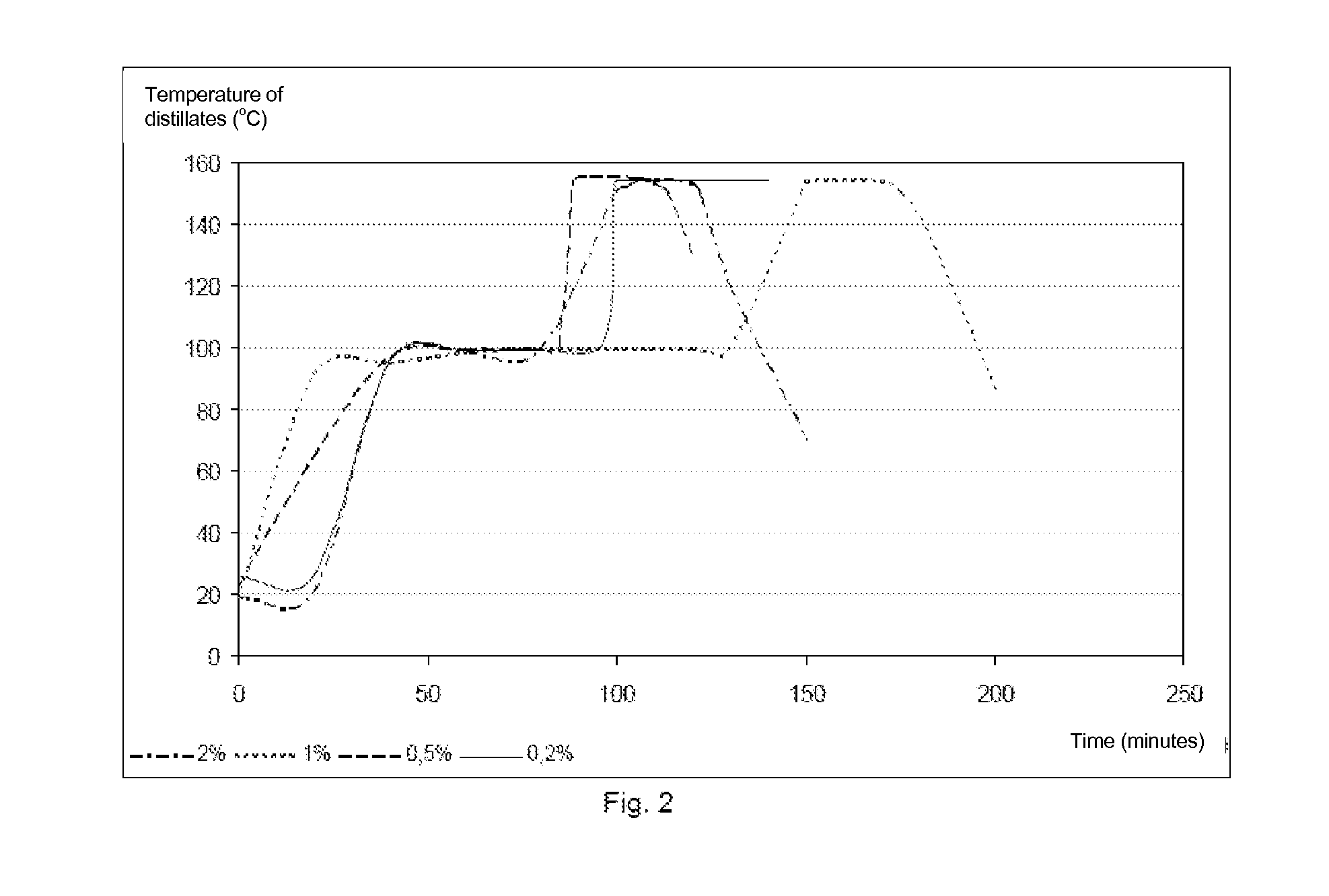

Continuous Process for Obtaining a Lactic Ester

InactiveUS20110160480A1Further reducedOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

Continuous method for obtaining a lactic ester, characterised in that it comprises the following steps:a) esterification reaction of a composition comprising an alcohol in the presence of a composition comprising lactic acid in excess,b) extraction of a vapour phase from this reaction medium, containing lactic ester, alcohol, water and traces of lactic acid;c) distillation of the vapour phase obtained at step b) in order to recover the lactic ester, alcohol and water at the top;d) distillation of the fraction obtained at step c) in order to recover the purified lactic ester at the bottom.

Owner:GALACTIC SA (BE)

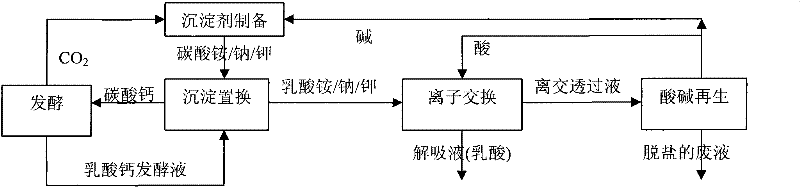

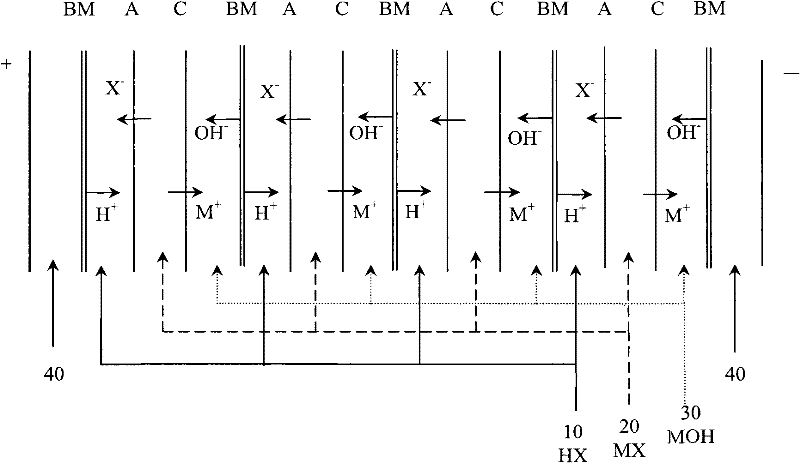

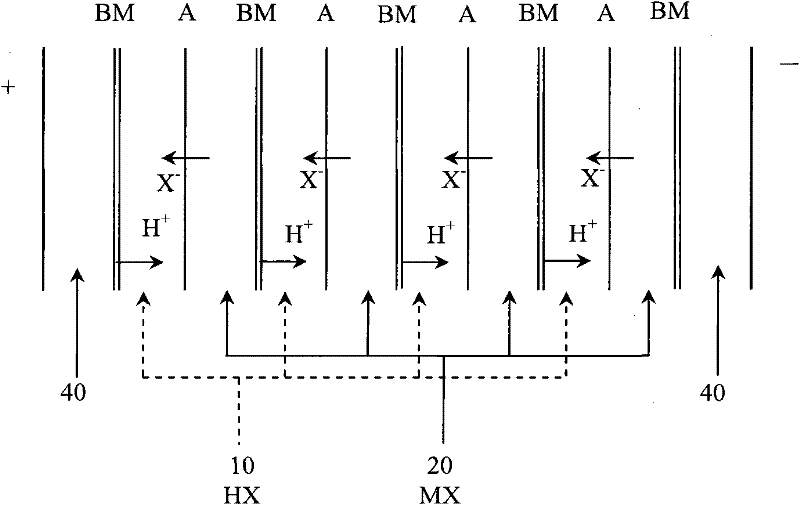

Method for clean production of lactic acid by calcium salt process

InactiveCN102220388AAvoid defectsAvoid it happening againMicroorganism based processesFermentationSlagSulfate

The invention relates to a method for clean production of lactic acid by a calcium salt process, which comprises: regulating the pH value of fermentation liquid by using CaCO3; adding carbonate to perform a precipitation displacement reaction to obtain solution of soluble lactate and a CaCO3 precipitate; loading the solution of soluble lactate on an anion exchange column, so that lactates are absorbed onto the column and ion exchange permeate passing through the anion exchange column is obtained; eluting the anion exchange column with acid to obtain extrication liquid containing lactic acid; and subjecting the ion exchange permeate to bipolar membrane electrodialysis to obtain regenerated acid, alkali and desalted waste solution. The method for clean production of lactic acid by the calcium salt process completely overcome the drawback of production of calcium sulfate waste slag in production of lactic acid by the conventional production technique and can be connected with the conventional lactic acid fermentation step directly.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

L-lactic acid producing strain and method for producing L-lactic acid using same

ActiveCN109628339AEasy to produceImprove acid production performanceBacteriaMicroorganism based processesLACTIC ACID/UREAFermentation

The invention relates to an L-lactic acid producing strain and a method for producing L-lactic acid using the same. When the L-lactic acid producing strain Lr-ALTHT is used for producing L-lactic acidthrough fermentation at higher temperature, the acid producing speed and the optical purity of products are significantly improved, namely the L-lactic acid producing strain Lr-ALTHT can significantly improve the L-lactic acid producing performance. Accordingly, the production of L-lactic acid can be greatly improved by using the L-lactic acid producing strain Lr-ALTHT to produce the L-lactic acid through fermentation. The L-lactic acid producing strain Lr-ALTHT has the advantages that the fermentation cost is low, the production period can be shortened, needed energy consumption by temperature controlling in fermentation production is reduced, cooling water is saved, bacterial contamination is reduced, and the L-lactic acid producing strain Lr-ALTHT is environmentally friendly.

Owner:JILIN COFCO BIOCHEM +2

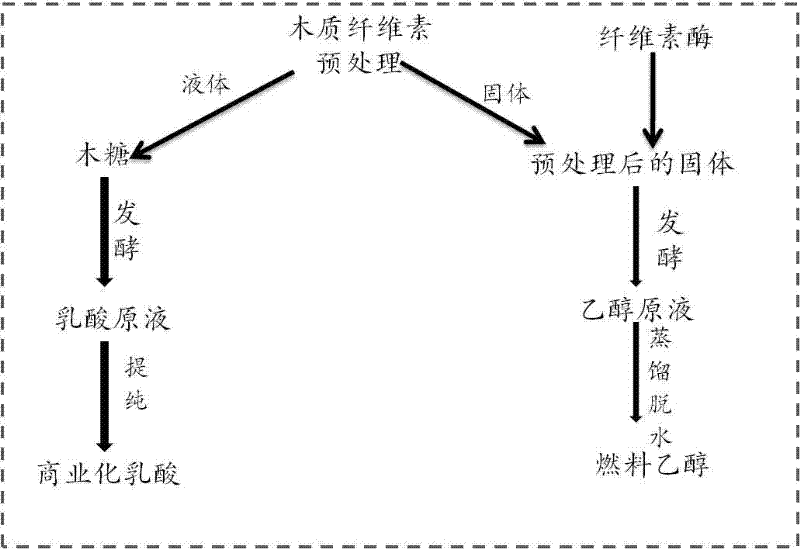

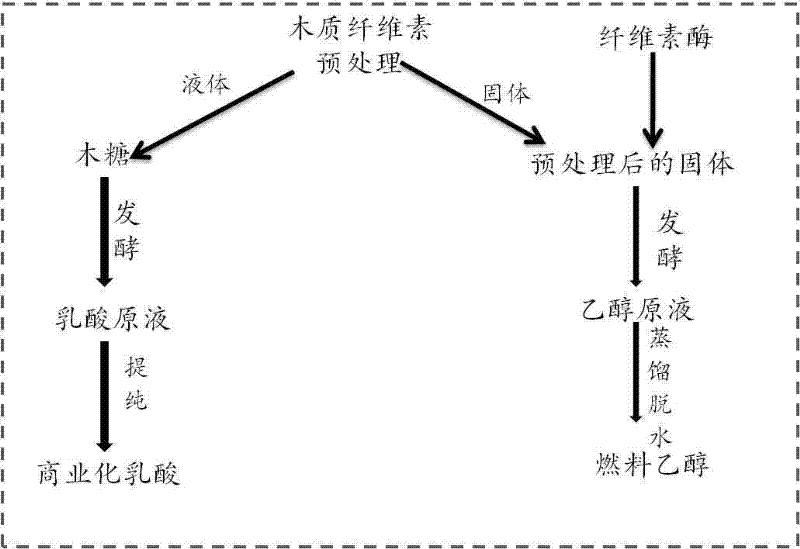

Method for co-production of lactic acid and alcohol by lignocellulose

InactiveCN102363795AUtilize high efficiency and high valueAvoid the disadvantages of high cost and difficult to make profitable productionBiofuelsMicroorganism based processesHigh concentrationChemical products

The invention discloses a method for co-production of lactic acid and alcohol by lignocellulose. The co-production method comprises the following steps of: (A) preprocessing the lignocellulose, converting the hemicellulose in the lignocellulose into soluble xylose, and getting the xylose liquid and the solid; (B) concentrating the xylose liquid obtained in the step (A), fermenting the microbe, which can produce the lactic acid by taking the xylose as the carbon source, to get the lactic acid fermentation coarse liquid, and purifying the fermentation coarse liquid to get the high-purity lactic acid; (C) hydrolyzing the solid obtained in the step (A) into glucose with cellulose, fermenting the microbe, which can produce the alcohol with the glucose, to produce the alcohol-containing fermentation broth, and distilling and dehydrating the alcohol-containing fermentation broth to get the high-concentration alcohol. In the method provided by the invention, different components in the lignocellulose are used for producing energy and bulk chemical products including the fuel alcohol and the lactic acid, production technology is simple, products have high additional value, and waste materials are turned into valuable things, so that the method has strong economic and social meaning.

Owner:熊鹏

Catalyst for preparing lactides from lactic acid and method for preparing lactides from lactic acid

ActiveCN109894109AIncrease chance of contactBreak dehydration balanceOrganic chemistryCatalyst activation/preparationDepolymerizationLactide

The invention provides a catalyst for preparing lactides from lactic acid and a method for preparing lactides from lactic acid. The catalyst uses butyl titanate and zinc nitrate as raw materials; a sol-gel method is used for preparation to obtain a ZnO-TiO2 composite oxide; then, the ZnO-TiO2 composite oxide is loaded to graphene oxide; hydrothermal sealed treatment is performed to obtain a catalyst. After lactic acid dewatering, the catalyst is used for catalysis; depolymerization is performed at 5.0 to 15.0 kPa and 140 to 150 DEG C; depolymerization is performed at 500 to 100 Pa and 160 to 200 DEG C; coarse lactides are obtained; after purification, lactides are obtained. In the catalyst, the dispersion degree of ZnO and TiO2 particles is increased by graphene; the catalysis capability of active ingredients is improved. Particles with different valence states achieve mutual action in crystal lattices; the speed of the lactic acid polycondensation reaction and the oligomer depolymerization reaction is accelerated; meanwhile, the temperature required in the reaction process is lowered. The prepared lactides have high purity and high yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing lactic acid by catalytic oxidation of 1,2-propylene glycol

ActiveCN102249892AImprove efficiencyHigh selectivityOrganic compound preparationCarboxylic compound preparationCatalytic oxidationLACTIC ACID/UREA

The invention discloses a method for preparing lactic acid by catalytic oxidation of 1,2-propylene glycol. The 1,2-propylene glycol can be catalyzed with high efficiency and high selectivity to synthesize the lactic acid by using a gold-based catalyst and using oxygen or air as an oxidant. The operation conditions are mild, the conversion rate of the 1,2-propylene glycol reaches 92 percent, and the selectivity of the lactic acid is 99 percent.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

New process for extracting lactic acid from lactic acid fermentation liquid

ActiveCN102976923ASimple processFully removedOrganic compound preparationCarboxylic compound separation/purificationFiltration membraneIon-exchange resin

The invention discloses a new process for extracting lactic acid from lactic acid fermentation liquid. The process flow comprises the following steps: preparing the fermentation liquid, deproteinizing, removing bacteria, decolorizing with activated carbon, performing plate and frame filtration, filtering with an inorganic ceramic membrane, cooling by a plate type heat exchanger, filtering with an organic nano-filtration membrane, concentrating and performing primary crystallization, performing centrifugal drying, performing resolvation, performing acidolysis, passing through an ion exchange resin column and concentrating to obtain a finished product. The process flow performs membrane filtration twice, namely the filtration with the inorganic ceramic membrane and the filtration with the organic ceramic membrane, wherein the filtration with the inorganic ceramic membrane can remove small insoluble solid impurities, bacteria, colloidal substances, macromolecular sugars and other impurities in filtrate; the filtration with the organic nano-filtration membrane can remove low-molecular weight sugars and multivalent ions in the filtrate; and the purity of the finally prepared finished product lactic acid is as high as 95%-98%, the crystallization yield of the lactic acid is improved from original 70% to above 85%, and the production cost is greatly reduced.

Owner:QINGDAO KEHAI BIOLOGICAL

Method for synthesizing caproic acid by catalyzing lactic acid through microorganisms

ActiveCN104357496AHigh substrate selectivityMature methodMicroorganism based processesFermentationMicroorganismMetabolite

The invention relates to a method for synthesizing caproic acid by catalyzing lactic acid through microorganisms. According to the method, specific functional florae are adopted to biologically synthesize caproic acid from lactic acid in a culture liquid or wastewater. By adopting the method that lactic acid is adopted as the electron donor for producing caproic acid, the efficiency is increased by more than 20% when being compared with that of a conventional method that ethanol is adopted as an electron donor for producing caproic acid, the toxicity resistance concentration of the caproic acid functional bacterium to metabolites (caproic acid) is increased by more than 2 times when being compared with that of reported caproic acid bacteria, and the caproic acid functional bacterium has the characteristics of high conversion rate and high stress resistance. When the lactic acid as a non-fuel substance which is easy to obtain is converted into caproic acid, the conversion efficiency is high, and the high industrial practicability is achieved.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Bacterium capable of producing lactic acid, and method for producing lactic acid

The present invention provides: a lactic acid-producing Escherichia coli including an enzymatic activity of at least one NAD-dependent lactate dehydrogenase and an enzymatic activity of at least one NAD-independent lactate oxidoreductase, both of which are enhanced so as to decompose one of D-lactic acid or L-lactic acid and to produce the other one of D-lactic acid or L-lactic acid; and a lactic acid production method using the lactic acid-producing Escherichia coli.

Owner:MITSUI CHEM INC

Stable liquid kit for measuring lactic acid

ActiveCN102507915AAvoid poor bottle opening stabilityRapid responseBiological testingLactate dehydrogenasePreservative

The invention discloses a stable liquid kit for measuring lactic acid, characterized in that the liquid kit is liquid double-reagent composed of a reagent 1 and a reagent 2; the ingredients and concentrations of the reagent 1 are as follows: 0.05-0.5 M of buffering solution with pH of 5.5-6.5, 20-200 mg / L of alpha / beta-naphthol, 20-200 mg / L of coenzyme and 0.1-10 g / L of preservative; the ingredients and concentrations of the reagent 2 are as follows: 0.05-0.5 M of buffering solution with pH of 8.5-9.5, 20-200 KU / L of lactate dehydrogenase, 0.1-100 g / L of stabilizer and 0.1-10 g / L of preservative. The liquid kit of the invention has the advantages of good accuracy and precision and good bottle opening stability, and the liquid kit can be stably stored for at least 15 days if being opened at 2-8 DEG C, so that the liquid kit can satisfy the clinical examination demand.

Owner:NINGBO MEDICAL SYSTEM BIOTECHNOLOGY CO LTD

Method for producing L-lactic acid through continuous fermentation

ActiveCN102174600AReduce manufacturing costBroad industrial prospectsMicroorganism based processesFermentationContinuous fermentationLactic acid fermentation

The invention provides a method for producing L-lactic acid through continuous fermentation. The method adopts the crop waste saccharification liquid as a carbon source and produces L-lactic acid through continuous fermentation with lactobacillus, performs primary inoculation and proliferation and repeatedly utilizes thalli for multiple times, reduces the workload in strain preparation, simplifies the fermentation process and reduces the labor intensity; and moreover, the strain is subjected to continuous fermentation acclimation, the fermentation period of L-lactic acid is shortened from 50-55 hours to 24-30 hours, the fermentation intensity of L-lactic is obviously improved, and the production efficiency is improved by over 50%. The method provided by the invention has a simple process and strong continuity, is easily applied to industrial production and can obviously reduce the production cost of L-lactic acid.

Owner:ANHUI BBCA FERMENTATION TECH ENG RES

Method for producing L-lactic acid by fermenting bagasse cellulose

InactiveCN103627739AReduce manufacturing costSolve difficultyMicroorganism based processesFermentationHydrolysateCellulase

The invention discloses a method for producing L-lactic acid by fermenting bagasse cellulose. The method is characterized by using bagasse as a raw material, carrying out raw material pretreatment and cellulose enzymolysis and producing L-lactic acid by using moulds as fermentation strains and enzymatic hydrolysate of bagasse cellulose as a carbon source through fermentation with free cells or immobilized cells. The method has the beneficial effects that the raw material is accessible and is low in cost; the amount of reducing sugar obtained through enzymolysis is higher than that of reducing sugar in other reports, the fermentation period is short, the fermentation liquor is easy to separate, and the conversion rate of the product is high; not only can free fermentation be adopted but also immobilized fermentation can be carried out, and the immobilized cells for immobilized fermentation can be reused and have stable acid yields and high lactic acid conversion rates. In short, the method is suitable for industrially producing L-lactic acid by efficiently converting bagasse cellulose, greatly reduces the production cost of lactic acid, solves the problems of difficulty in control of a lactobacillus fermentation process and difficulty in separation and purification caused by the free cells, and has good industrial application prospects.

Owner:GUANGXI UNIV

Nano particles of poly-lactic acid or polyethyllactide propyllactide for packing plant extract

InactiveCN1644605AGood curative effectHigh yieldPharmaceutical non-active ingredientsLactidePolyvinyl alcohol

A polylactic PLA or poly-cyclic diester lactide PLGA nanometer particle for coating plant extract and its production are disclosed. PLA or PLGA nanometer particle is characterized by: coating plant extract as core matter with PLA or PLGA as shell membrane and forming nanometer spherical particle matter. The production is carried out by taking PLA or PLGA with good biological compatibility as carrier, taking polyvinyl alcohol PVA as emulsifier, and adopting solvent evolution method. Its advantages include low cost, simple process, to improve water soluble ability of main components, to improve plant extract adsorptive rate and biological utilizing rate.

Owner:HUNAN UNIV

Polylactic acid compound preparation method

The invention discloses a polylactic acid compound preparation method which is as follows: under an inert atmosphere reacting a lactide monomer, an unsaturated monomer and a catalyst composition in a solvent at above 180 to 250 DEG C under airtight conditions to obtain a polylactic acid compound. According to the method, the reaction can be performed at high temperature (greater than 180 DEG C) to obtain the un-discolored crosslinked polylactic acid compound, and the technical prejudice is overcome to obtain the high molecular weight crosslinked polylactic acid compound. According to the method, by the use of the unsaturated monomer for modification of lactic acid, carbon-carbon double bonds are opened for the crosslinking reaction to obtain the crosslinked netlike polylactic acid compound, the mechanical property of the polymer modified compound can be effectively improved, and the thermal stability of the polylactic acid compound can be improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

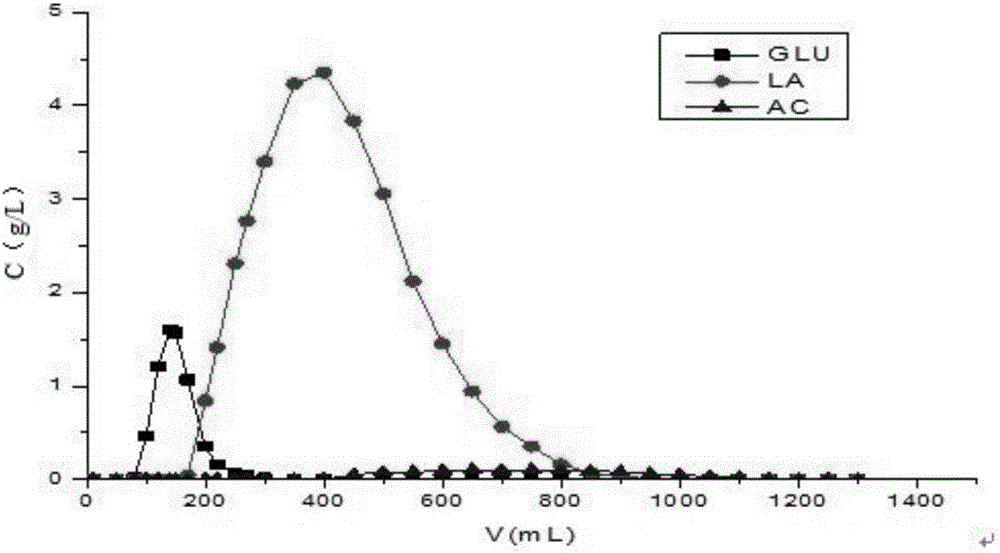

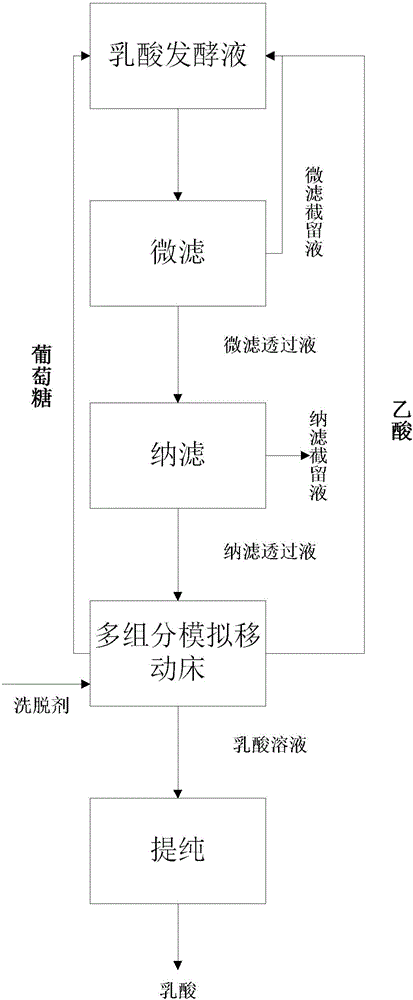

Method for continuously extracting high-purity lactic acid from lactic acid fermented broth

ActiveCN106755143AAchieve recyclingRealize continuous fermentationFermentationCarboxylic compound separation/purificationLactic acid bacteriumFiltration membrane

The invention discloses a method for continuously extracting high-purity lactic acid from a lactic acid fermented broth. The method comprises the following steps: (1) preparing a fermentation medium, inoculating lactic acid bacteria, and conducting anaerobic fermentation in a fermentation tank to obtain the lactic acid bacterium fermented broth; (2) using a micro-filtration membrane to primarily separate the lactic acid fermented broth obtained in the step (1), enabling a micro-filtration trapped fluid to flow back to the fermentation tank to continue to ferment, using a nano-filtration membrane to secondarily separate after using a micro-filtration permeate liquid to regulate the pH value, so as to obtain a nano-filtration trapped fluid and a nano-filtration permeate liquid; (3) taking the nano-filtration permeate liquid obtained in the step (2), refining in a multi-component simulated moving bed, concentrating and purifying a collected lactic acid solution to obtain a finished product of the lactic acid; enabling collected glucose and acetic acid to flow back to the fermentation tank for cyclic utilization. The method is green and environmentally friendly, the cyclic utilization of glucose and circular fermentation are realized, the inoculation amount is saved, the purity of the prepared finished product of the lactic acid is high, and the process continuity and the production efficiency are improved.

Owner:NANJING UNIV OF TECH

Preparation method of hollow polylactic acid microcapsules consisting of poly(L-lactic acid) and poly(D-lactic acid)

InactiveCN105435722AOvercome uniformity issuesOvercome the thicknessMicroballoon preparationMicrocapsule preparationControlled releaseMicrosphere

The invention relates to a preparation method of hollow polylactic acid microcapsules consisting of poly(L-lactic acid) and poly(D-lactic acid). The method comprises steps as follows: adding a poly(L-lactic acid) solution or a poly(D-lactic acid) solution to calcium carbonate particles, and performing oscillation and centrifugal washing to obtain single-layer polylactic acid microspheres; adding the poly(D-lactic acid) solution or the poly(L-lactic acid) solution to the single-layer polylactic acid microspheres, and performing oscillation and centrifugal washing to obtain double-layer polylactic acid microspheres; repeating the steps to obtain multi-layer polylactic acid microspheres; adding an acid solution to the multi-layer polylactic acid microspheres, removing calcium carbonate, and performing centrifugal washing to obtain the hollow polylactic acid microcapsules. The assembly process is simple, the condition is mild, and no special equipment is required; the particle size distribution of the prepared polylactic acid microcapsules is uniform, the particle size and the capsule wall thickness can be controlled accurately, so that controlled release of substances carried in the microcapsules is realized, and the preparation method can be widely applied to fields of drug sustained release, cosmetics and the like.

Owner:DONGHUA UNIV

Method for extracting and separating L-lactic acid from ammonium lactate fermentation material liquid

ActiveCN104557515ASpecific adsorptionAchieve purificationPreparation from carboxylic acid saltsCarboxylic compound separation/purificationSpecific adsorptionCoupling

The invention discloses a method for extracting and separating L-lactic acid from an ammonium lactate fermentation material liquid. The method comprises the following steps: (1) pre-treating the ammonium lactate fermentation material liquid; (2) carrying out sulphuric acidolysis on ammonium lactate; (3) adding an acidolysis material liquid and a coupling adsorbent in a centrifugal extractor respectively, and extracting L-lactic acid through coupling adsorption at 15-25 DEG C; (4) separating an organic phase from a water phase; and (5) adding the organic phase and hot water at 55-65 DEG C in the centrifugal extractor respectively, and extracting L-lactic acid through backcoupling adsorption. The method disclosed by the invention is capable of rapidly extracting and separating L-lactic acid from the lactic acid acidolysis liquid, changing the process route of separating various impurities from L-lactic acid one by one, and directly separating L-lactic acid through coupling adsorption by virtue of a coupling adsorption agent so as to leave the various impurities in a raffinate; because the coupling adsorption agent in the method disclosed by the invention has a specific adsorption property on L-lactic acid, the purpose of further purifying L-lactic acid is achieved, and a decolouring process and most of hybridization processes in the existing processes are removed.

Owner:河南金丹乳酸科技股份有限公司

Furan dioctyl phthalate-lactic acid-dihydric alcohol copolymer and preparation method thereof

InactiveCN103980468AReduce utilizationIncrease the proportion of rigid structural elementsFiberFuran

The invention relates to a furan dioctyl phthalate-lactic acid-dihydric alcohol copolymer and a preparation method thereof. The preparation method comprises the following steps: firstly, preparing oligolactic acid in a lactic acid polymerization mode, subsequently preparing furan dioctyl phthalate dihydric alcohol ester by using furan dioctyl phthalate and dihydric alcohol, and finally copolymerizing the oligolactic acid with the furan dioctyl phthalate dihydric alcohol ester, thereby obtaining a target product, namely, the furan dioctyl phthalate-lactic acid-dihydric alcohol copolymer. The vitrification temperature of the copolymer of the series is 10-90 DEG C, and the weight-average molecular weight is 5000-150000. The copolymer prepared by using the method can be completely degraded, is good in thermal property and mechanical property, and has good application prospect in the fields of degradable plastics, degradable fibers, agricultural plastic mulching films, controlled-released medicine carriers and the like.

Owner:NANJING UNIV OF TECH

Method for preparing lactic acid through selective catalytic conversion of ethylene glycol

ActiveCN110357770AHigh selectivityHigh purityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAlkaline earth metalCatalytic oxidation

The invention specifically relates to a method for preparing lactic acid through selective catalytic conversion of ethylene glycol, belonging to the technical field of fine chemical engineering. The invention provides an azacyclocarbene metal complex catalyst for the selective catalytic conversion of ethylene glycol to produce lactic acid at first. According to the method of the invention, ethylene glycol and methanol are used as raw materials, an alkali metal or alkaline earth metal hydroxide is used as a base, an azacyclocarbene metal complex is used as a catalyst, and a closed reaction is carried out at 100-200 DEG C for 0.5-12 h to prepare lactic acid. Compared with the prior art, the method of the invention has the following advantages: the cheap and easily-available ethylene glycol and methanol are used as substrates; a catalytic oxidation reaction is performed under mild conditions; quantitative lactic acid yield is obtained; reaction conversion efficiency is high; operation iseasy; high-purity lactic acid can be obtained without complicated post-treatment; and the method is suitable for large-scale industrial application.

Owner:FUDAN UNIV

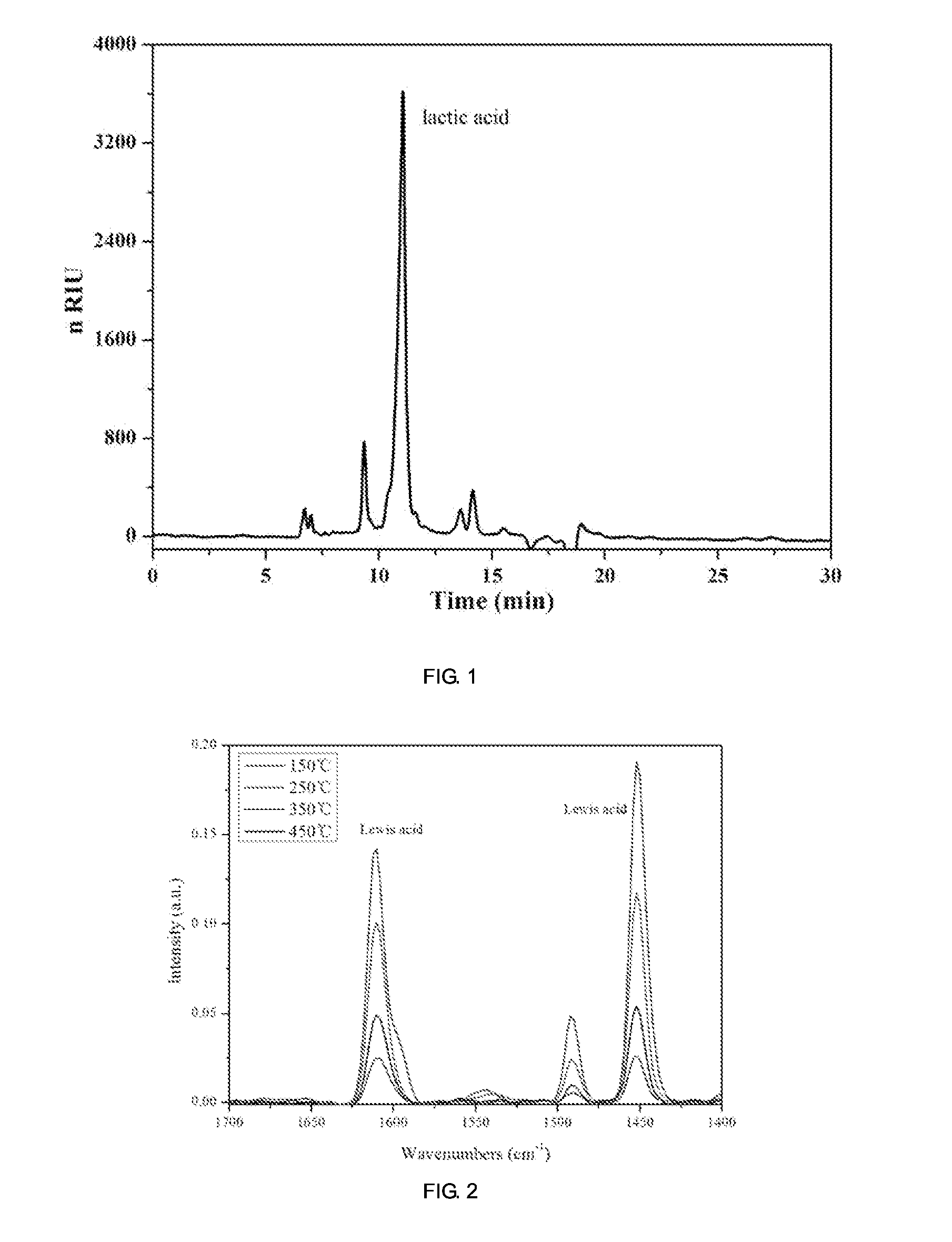

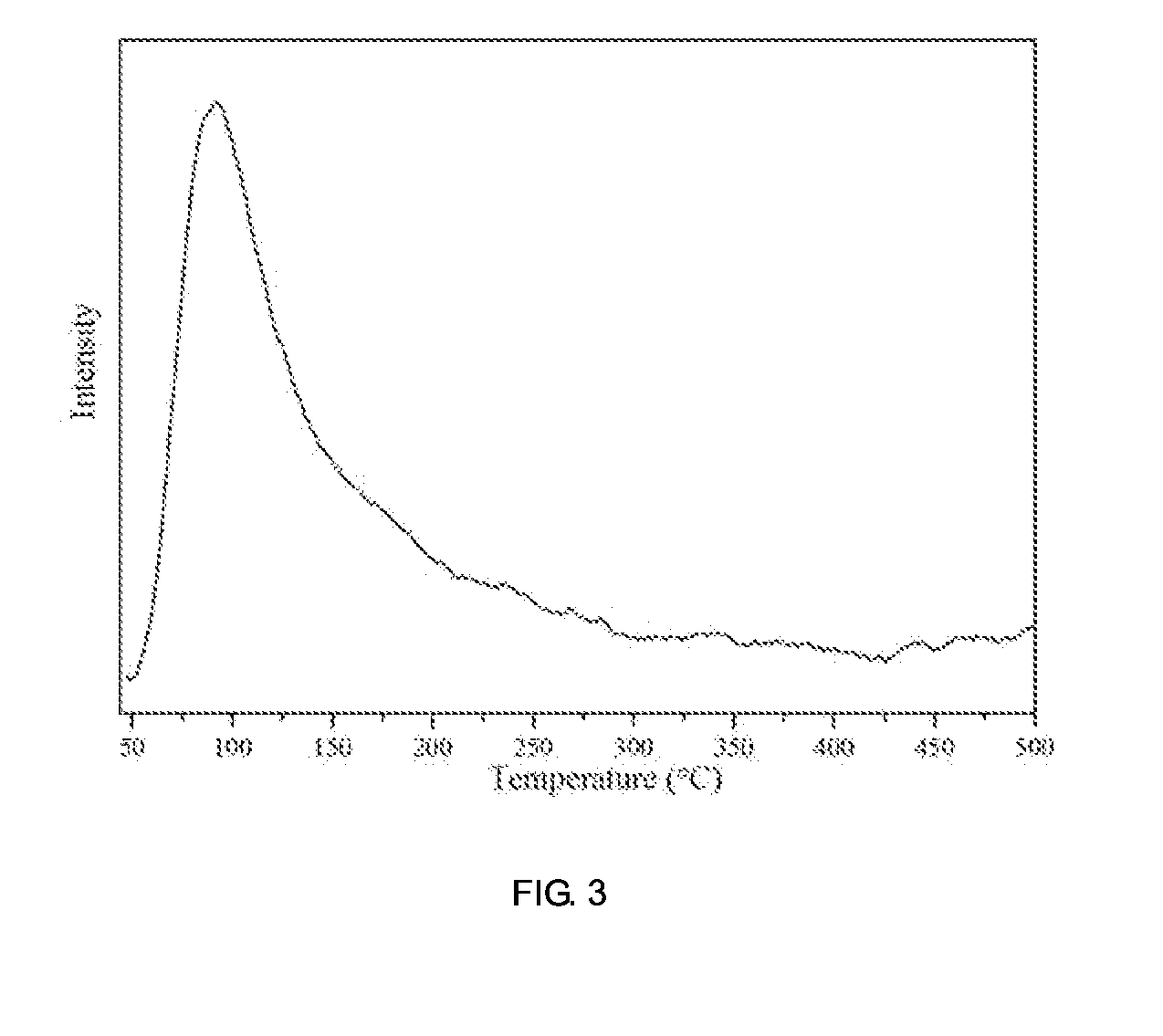

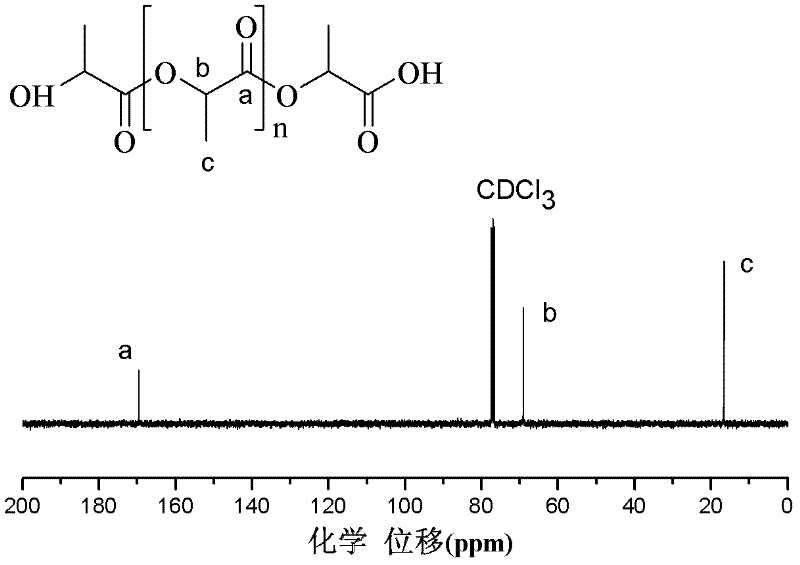

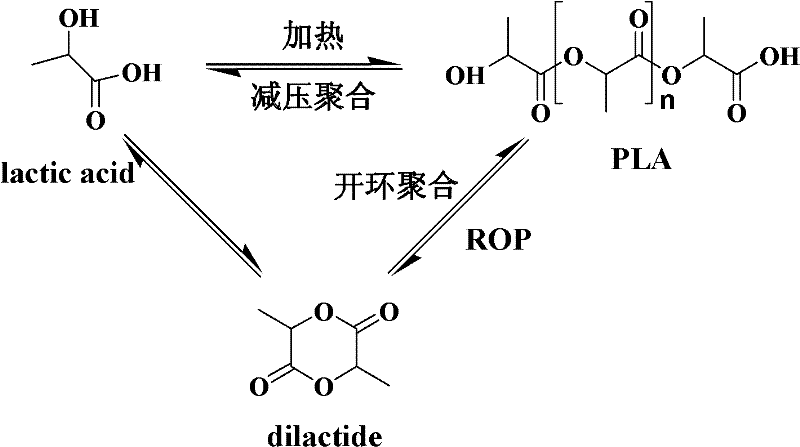

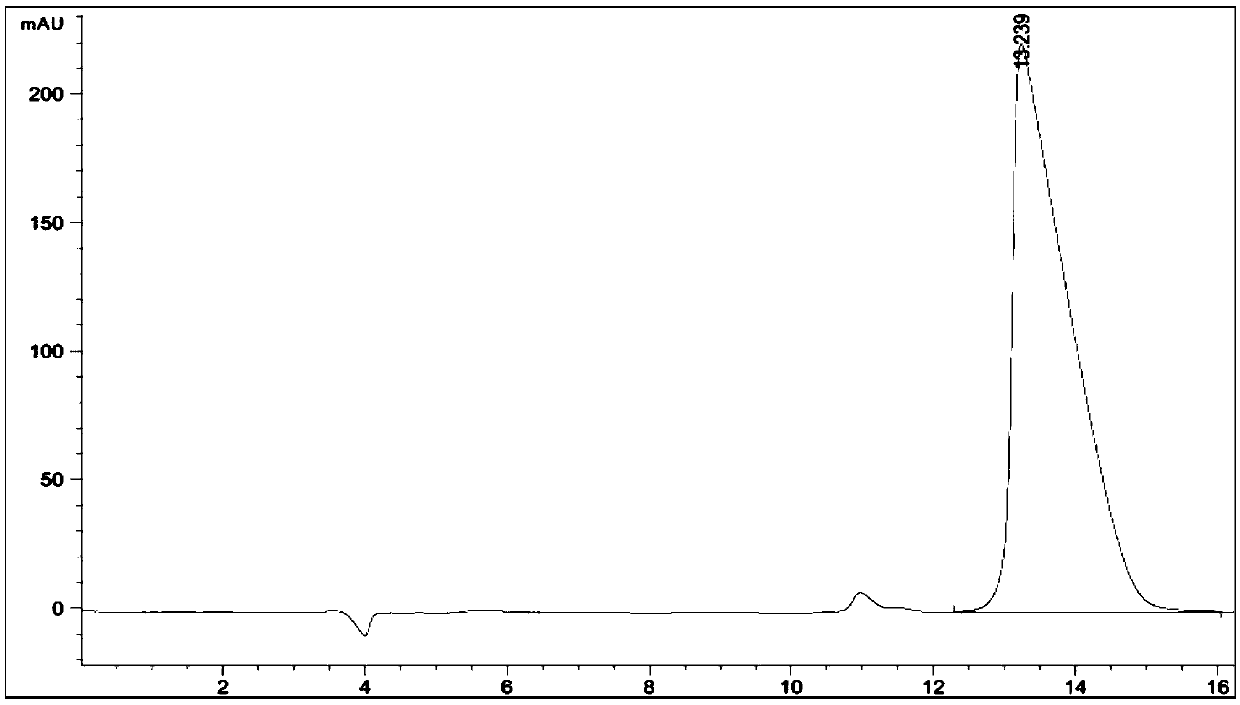

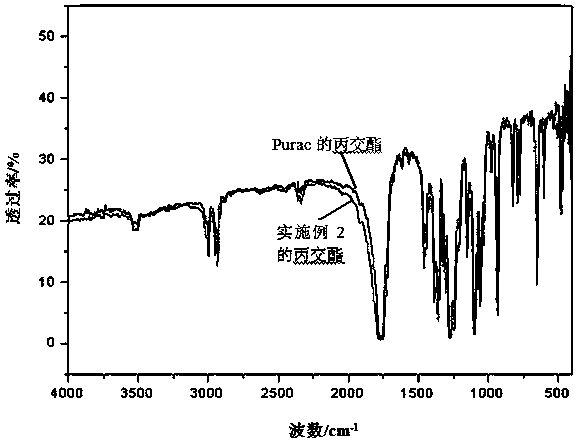

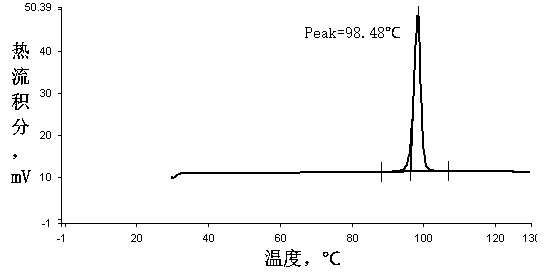

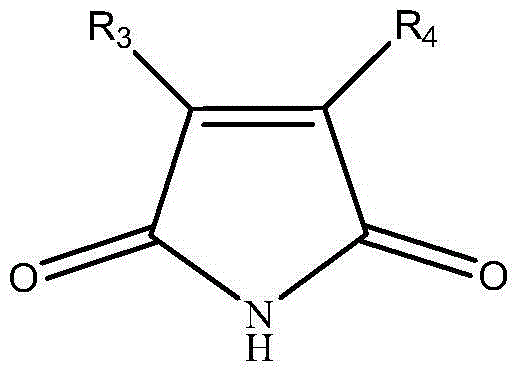

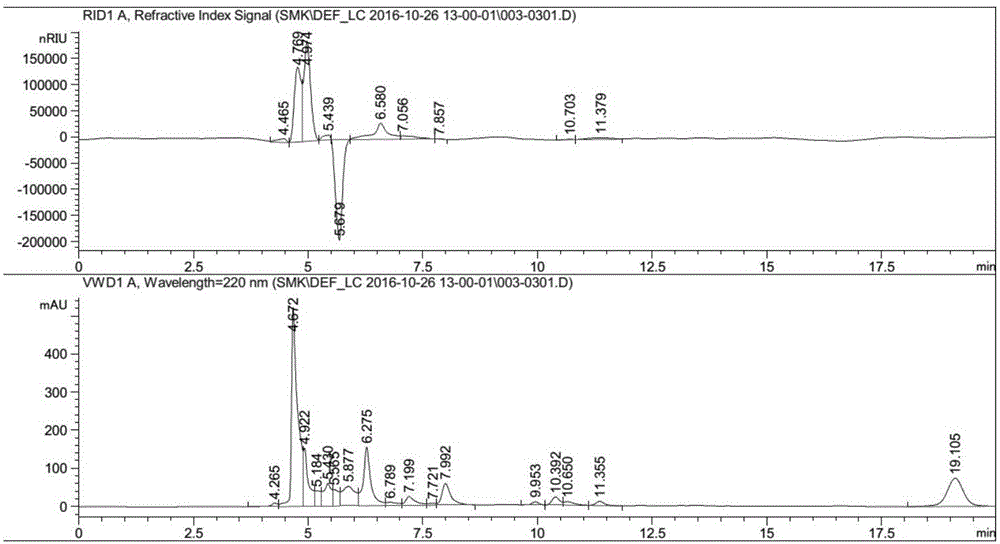

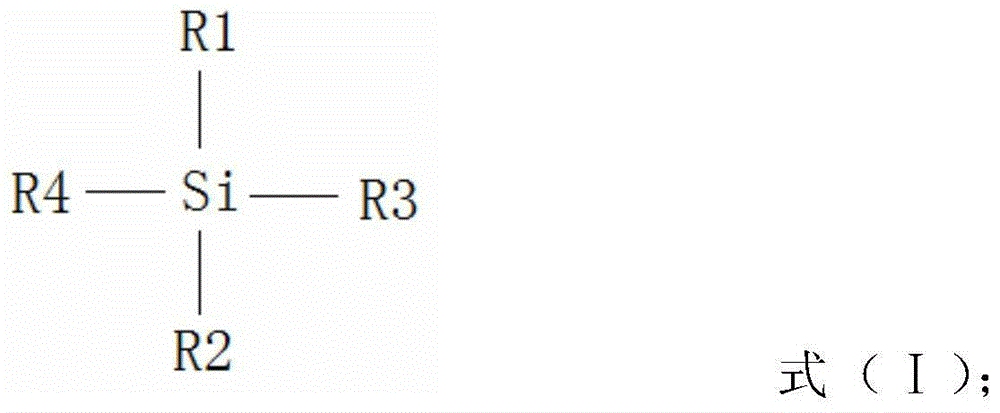

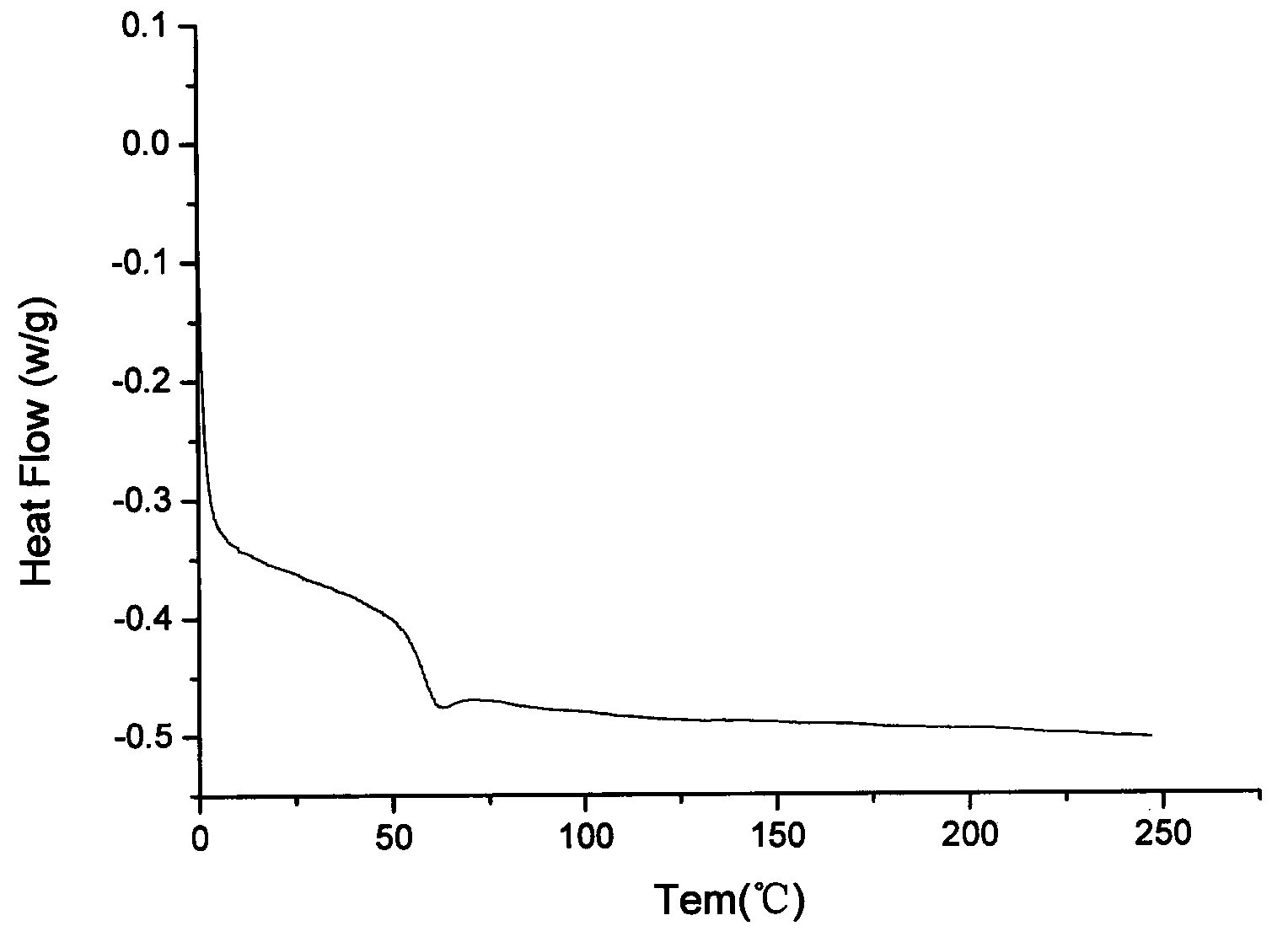

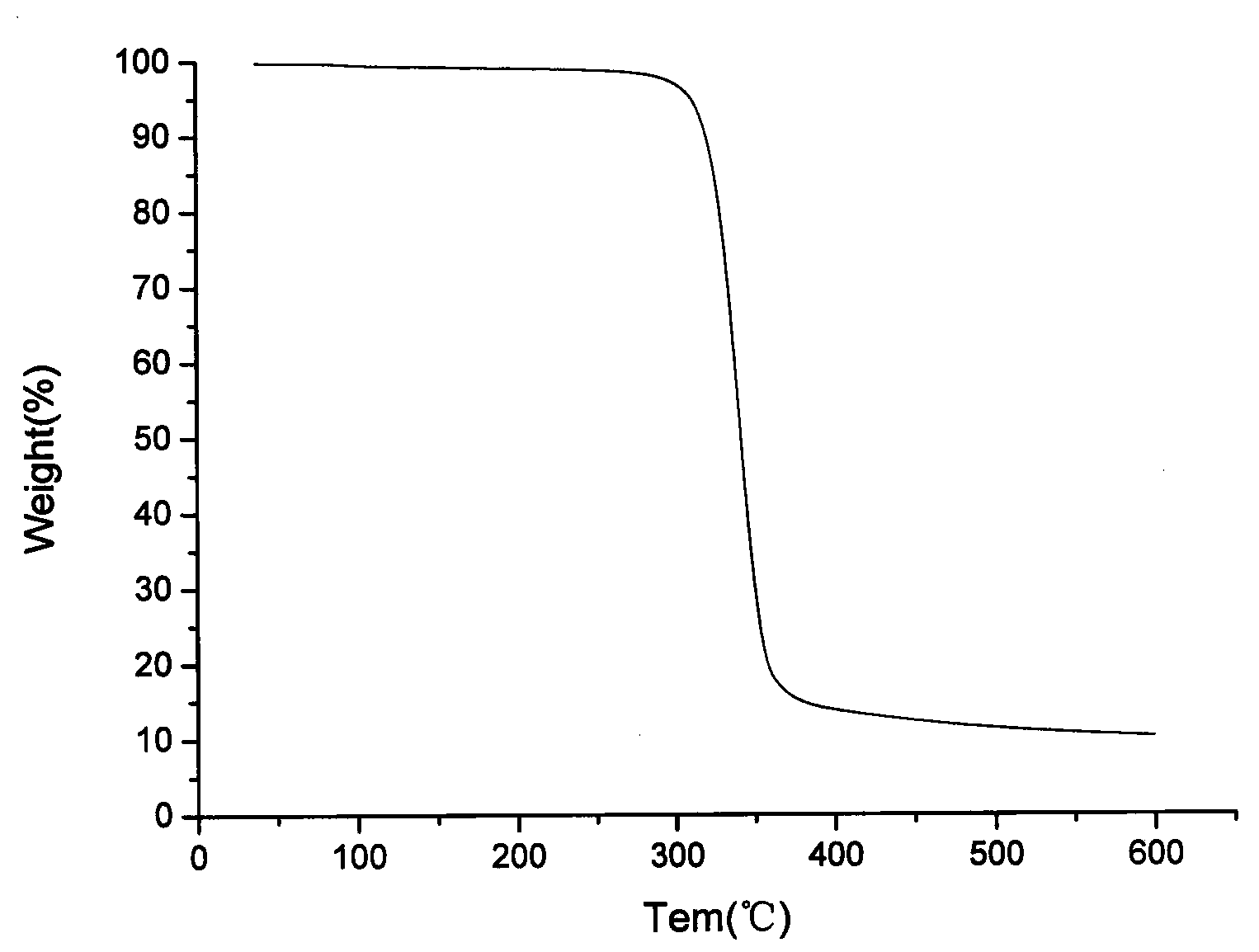

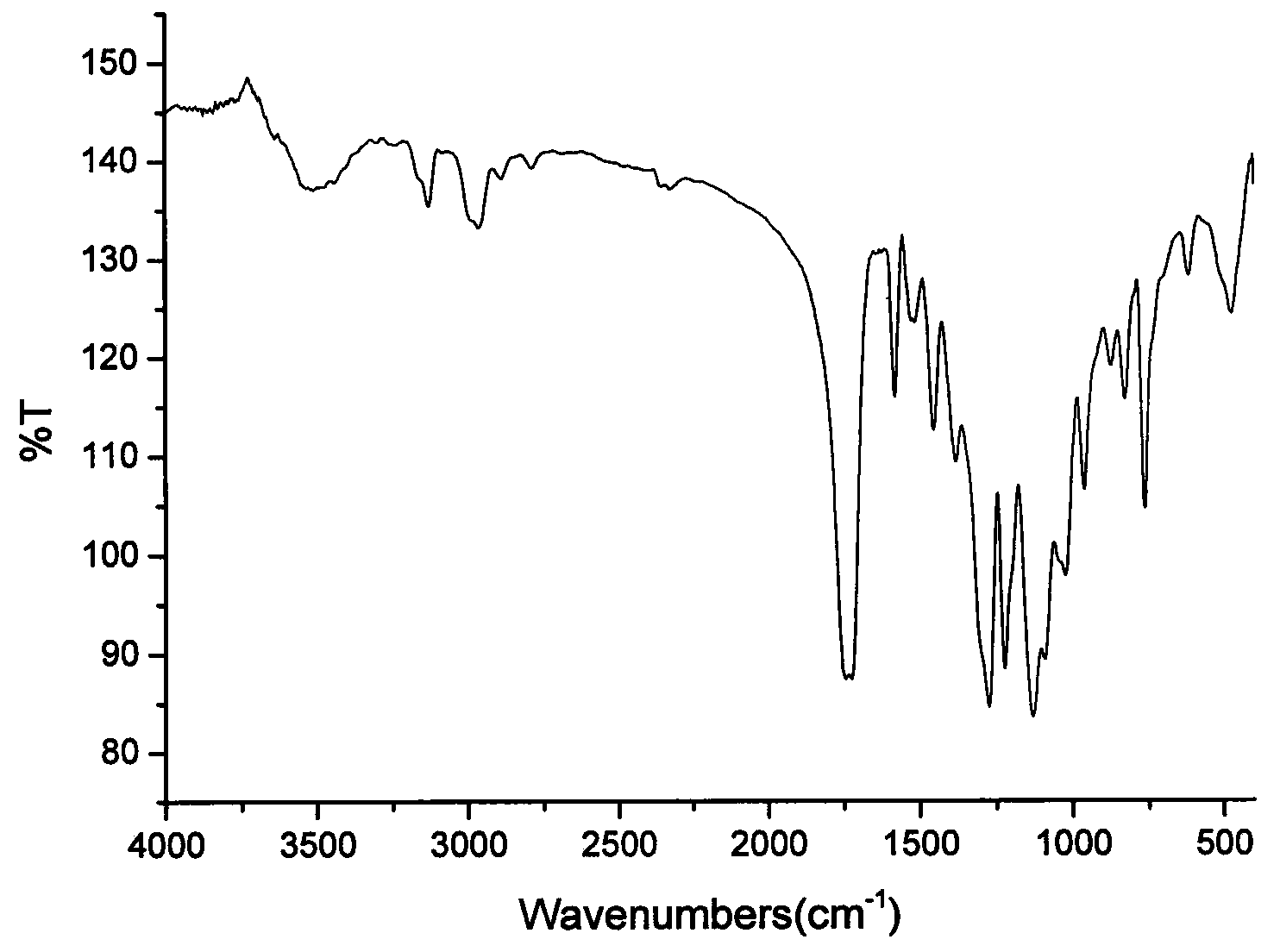

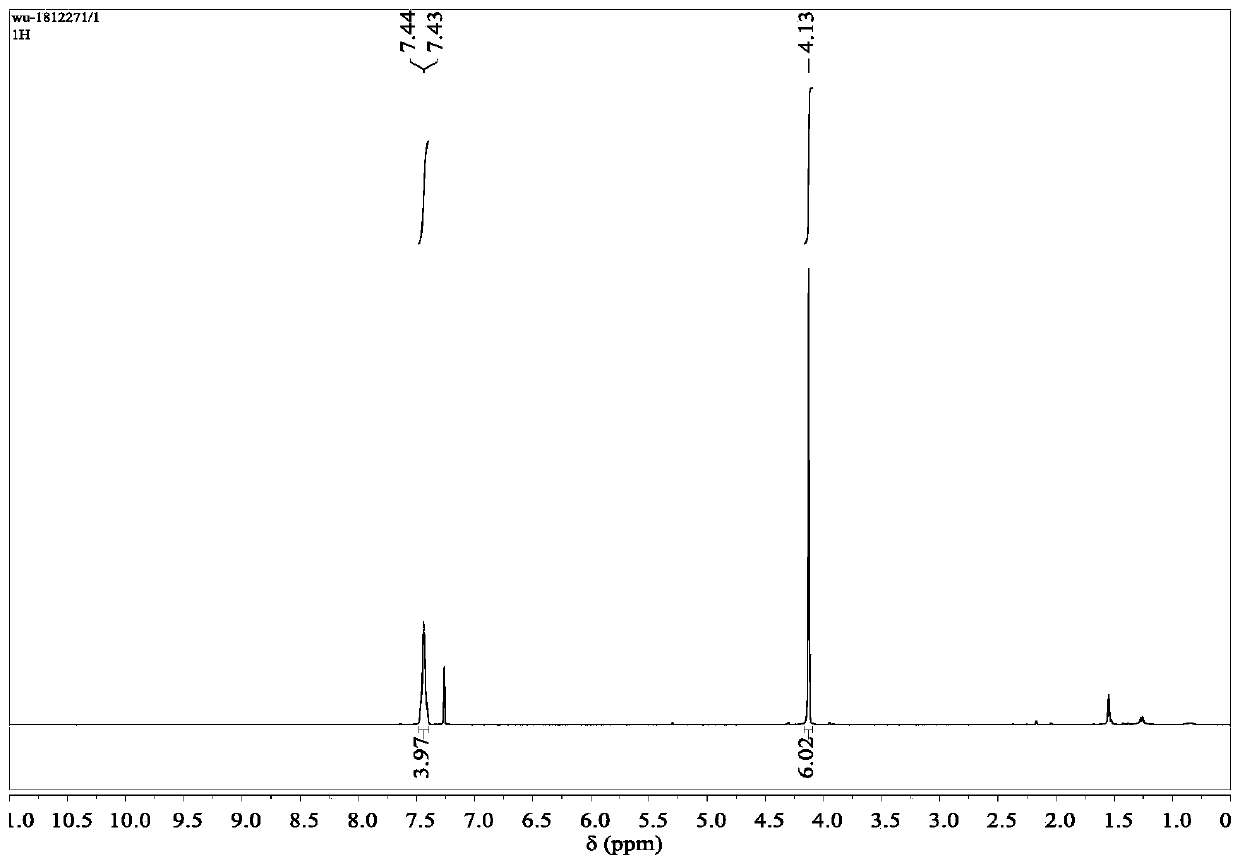

Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD)

The invention discloses a method for synthesizing medical biodegradable polylactic acid by directly performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD). According to the method, the polylactic acid product which is high in biosecurity is obtained by taking the TBD as a catalyst, and an industrial grade lactic acid aqueous solution of which the mass content is 90 percent as monomers, and by solvent-free (body) and two-stage condensation polymerization. According to the method, a tin catalyst which has cytotoxicity is eliminated, and the used catalyst has biocompatibility and biosecurity; the synthesized polylactic acid does not contain any metal and other toxic component and is suitable for medical and medicinal fields; the environment-friendly biodegradable polylactic acid is synthesized by an environment-friendly process (in which any reagent is not used and any toxic product is not generated) by using the environment-friendly catalyst; the polymerization reaction is convenient to realize and practicable; raw materials are low in cost, and the industrial production is easy to realize; and the synthesized product is narrow in molecular weight distribution, and the molecular weight can be regulated from 1.0*10<4> to 4.0*10<4>.

Owner:NANJING UNIV

Genetic engineering bacteria for producing lactic acid and 3-hydroxybutyrate copolyester, construction method and application thereof

The invention discloses genetic engineering bacteria for producing lactic acid and 3-hydroxybutyrate copolyester, and a construction method and application thereof. The genetic engineering bacteria for producing lactic acid and 3-hydroxybutyrate copolyester are obtained by the following steps: knocking out the poxB gene, pflB gene and aceEF gene of a recipient bacterium; and increasing the contentof protein encoded by the phaA gene, phaB gene, phaC gene and pct gene. With the genetic engineering bacteria, lactic acid and 3-hydroxybutyrate copolyester can be synthesized by the use of glucose and acetic acid, and the polymer yield of the recombinant bacteria in the shake-flask culture can reach a high level. The ratio of lactic acid to 3-hydroxybutyrate monomer can be controlled by changingthe concentration of glucose and acetic acid. The invention has a good application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Method of transforming biomass into lactic acid with modified beta zeolites

ActiveUS20160046555A1Readily availableMolecular sieve catalystsOrganic compound preparationNoble gasHigh pressure

A method of transforming biomass into lactic acid using modified beta zeolites is disclosed. The one-step preparation process of preparing catalyst in the invention is mild, economical and convenient. The biomass used as precursor is economic and easy to get. Meanwhile, the reaction process doesn't need to be protected by noble gases with high pressure. The catalyst can be reused and the yield of lactic acid is high.

Owner:TONGJI UNIV

Method for preparing polylactic acid from lactic acid under catalysis of titanium composite catalyst

The invention relates to a method for preparing polylactic acid from lactic acid under catalysis of a titanium composite catalyst, belonging to the technical field of polymer materials. The method comprises the steps of: removing water from a raw material under normal pressure by an inert gas blowing method; gradually reducing pressure for pre-polycondensing: pre-polycondensing under low vacuum degree of 1000-10000Pa and high vacuum degree of 20-1000Pa at the temperature of 60-160 DEG C for 1-10h to obtain a lactic acid prepolymer; and carrying out melt polycondensation on the lactic acid prepolymer as a raw material in the presence of the titanium composite catalyst to finally prepare polylactic acid. The method has the advantages that any organic solvent is not used, the production equipment is simple, operation is convenient, industrialized continuous production is easy to realize, and the obtained product namely polylactic acid has higher molecular weight.

Owner:BEIJING UNIV OF CHEM TECH

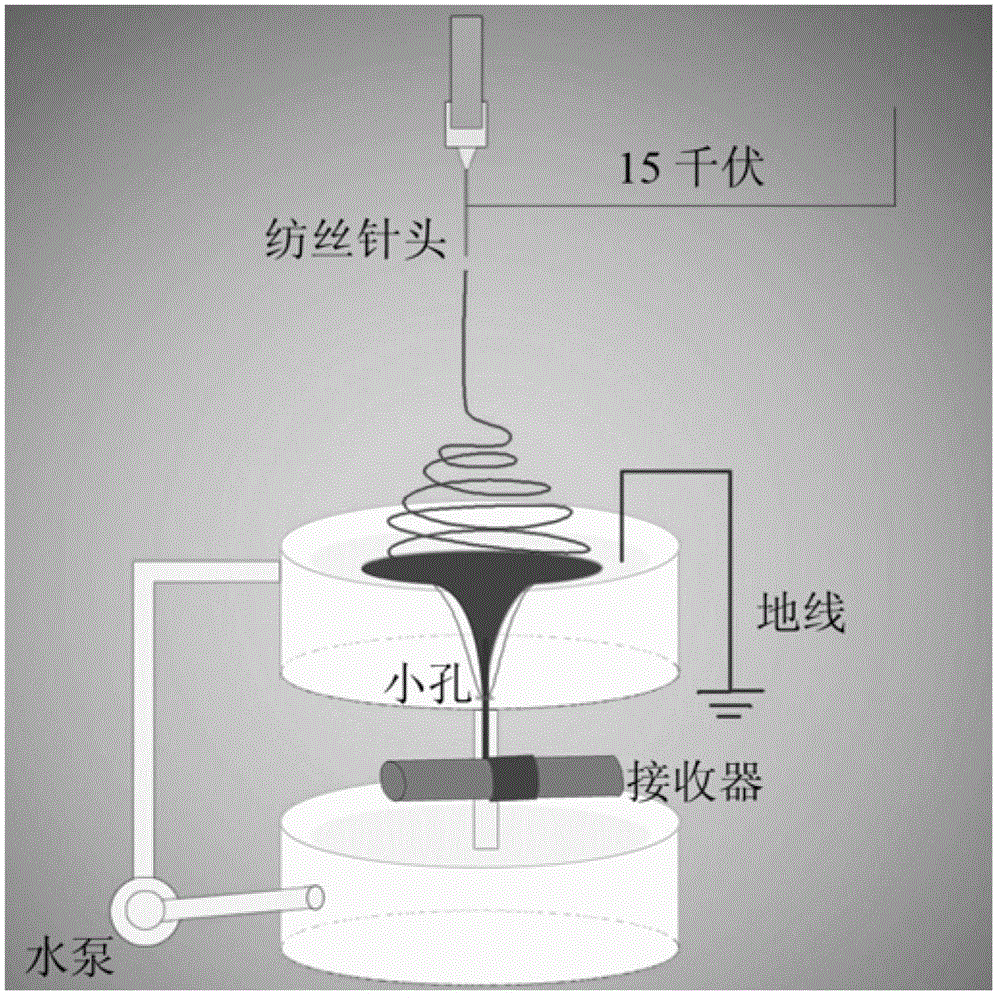

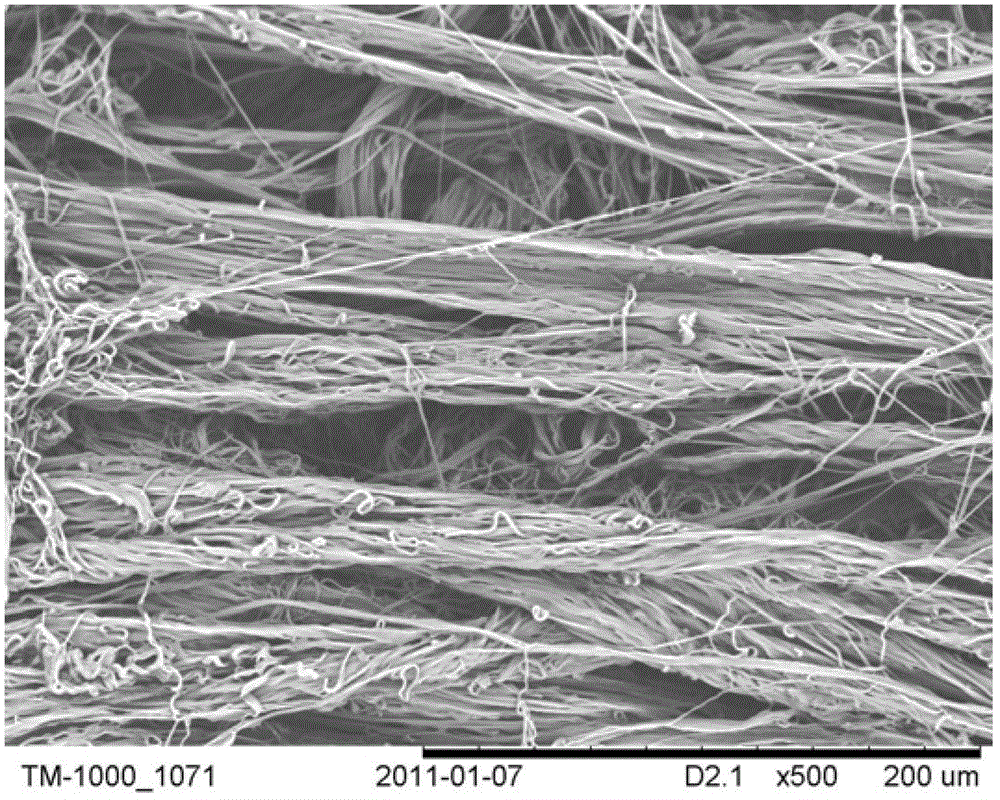

Method for preparing collagen/lactic acid-caprolactone copolymer composite fiber bracket

ActiveCN103147229AHigh simulationPromote growthNon-woven fabricsProsthesisCell-Extracellular MatrixElectrospinning

Owner:DONGHUA UNIV

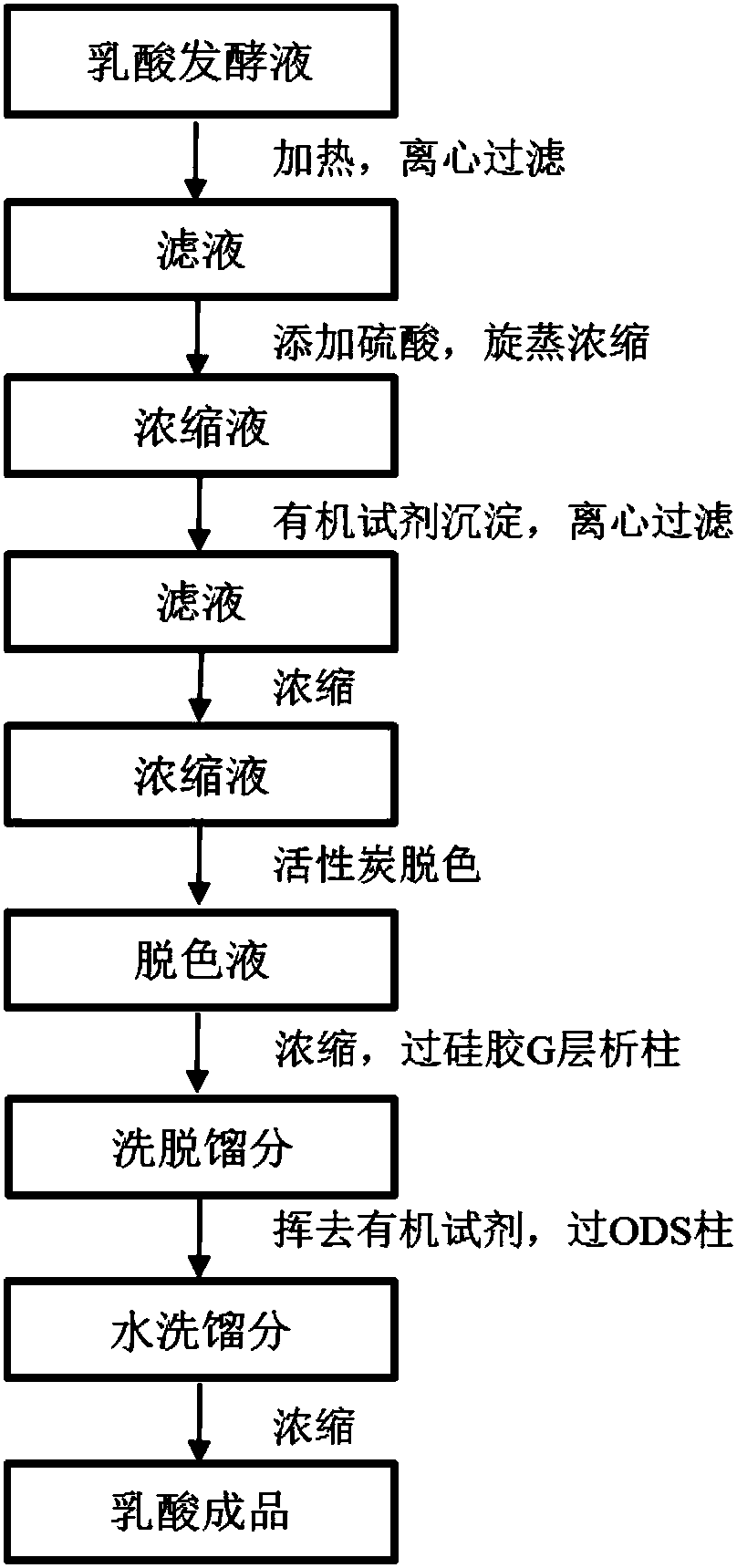

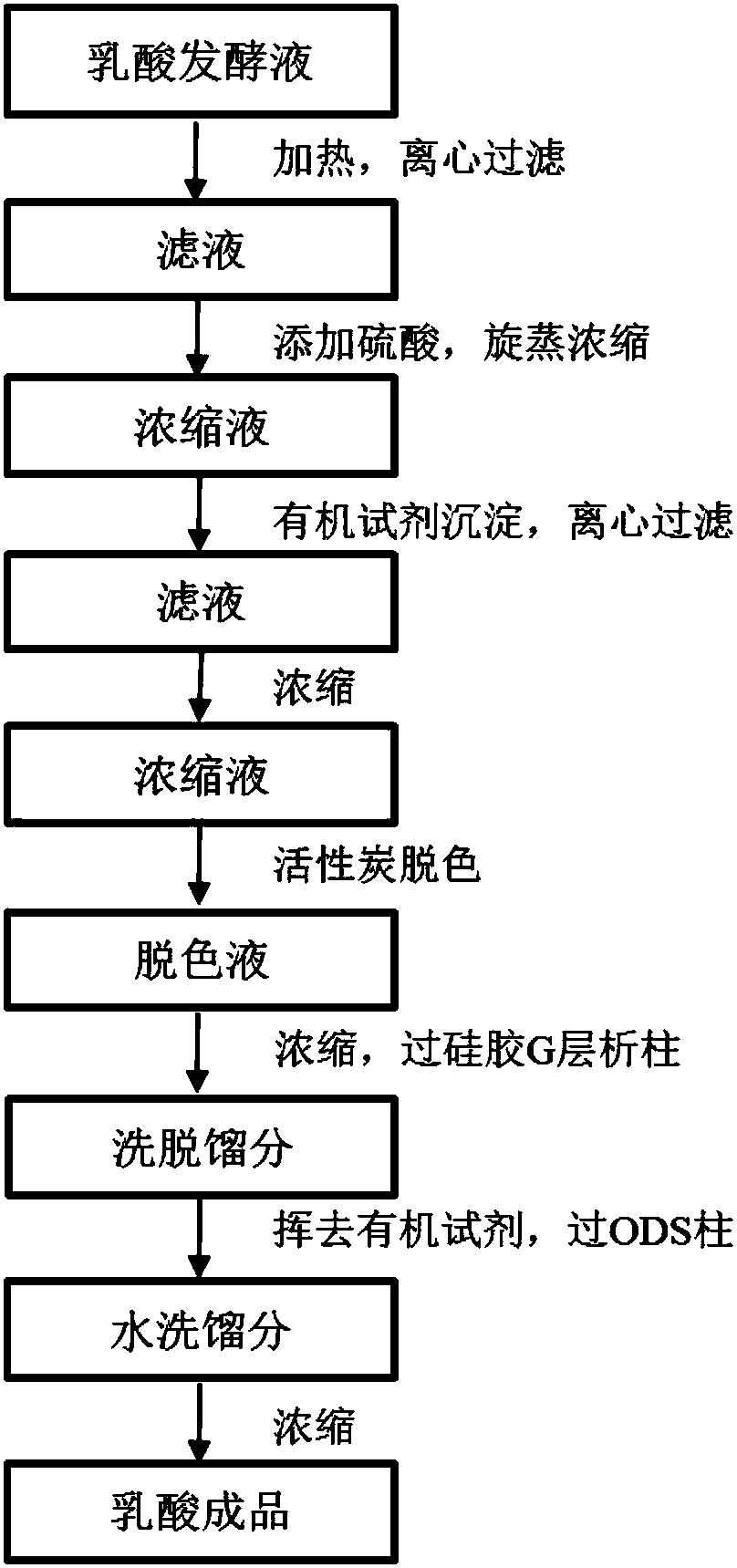

Method for separating and purifying lactic acid from lactic acid fermentation broth

ActiveCN109956859AAvoid lossLow viscosityCarboxylic compound separation/purificationSilica gelChromatography column

The invention relates to the field of microbial separation and purification, in particular to a method for separating and purifying lactic acid from a lactic acid fermentation broth. The method mainlycomprises the following steps: performing heat treatment on the lactic acid fermentation broth, removing insoluble impurities such as thallus and the like; performing acid treatment; performing concentration; performing organic reagent precipitation; performing centrifugal filtration; performing concentration; performing decoloration; performing silica gel chromatography column; performing ODS column; and performing concentration to obtain the finished product. According to the method, the lactic acid finished product is obtained, the purity of the product is 93% or more, and the recovery rate of lactic acid is 67% or more. In the preparation process, the loss of main components is reduced, the material is saved, the discharge of waste liquid is reduced, and the treatment time is shortened.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD) Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD)](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/1f2d5575-2e67-42c5-bbef-07cf274cb281/BDA00002259912400021.PNG)

![Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD) Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD)](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/1f2d5575-2e67-42c5-bbef-07cf274cb281/BDA00002259912400022.PNG)

![Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD) Process method for synthesizing medical biodegradable polylactic acid by performing polycondensation on lactic acid through catalysis of 1,5,7-triazabicyclo[4.4.0]decane-5-ene (TBD)](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/1f2d5575-2e67-42c5-bbef-07cf274cb281/FDA00002259912300011.PNG)