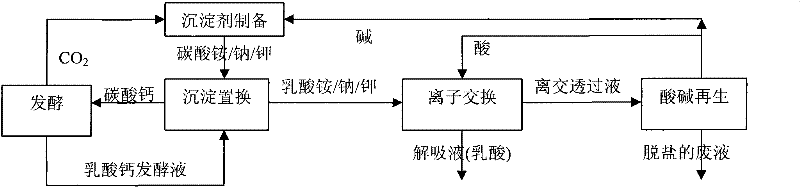

Method for clean production of lactic acid by calcium salt process

A technology of clean production and calcium salt method, applied in the direction of microorganism-based methods, biochemical equipment and methods, separation/purification of carboxylic acid compounds, etc., can solve high energy consumption, complex selectivity and system composition, and difficult to guarantee purity and other problems, to achieve the effect of overcoming calcium sulfate waste residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

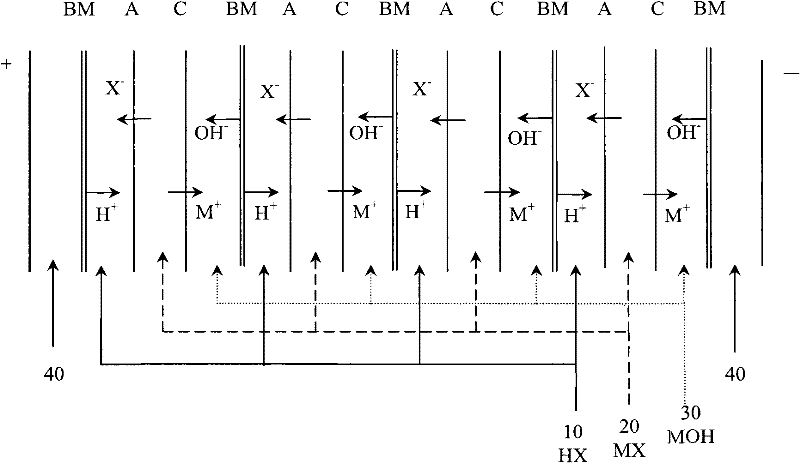

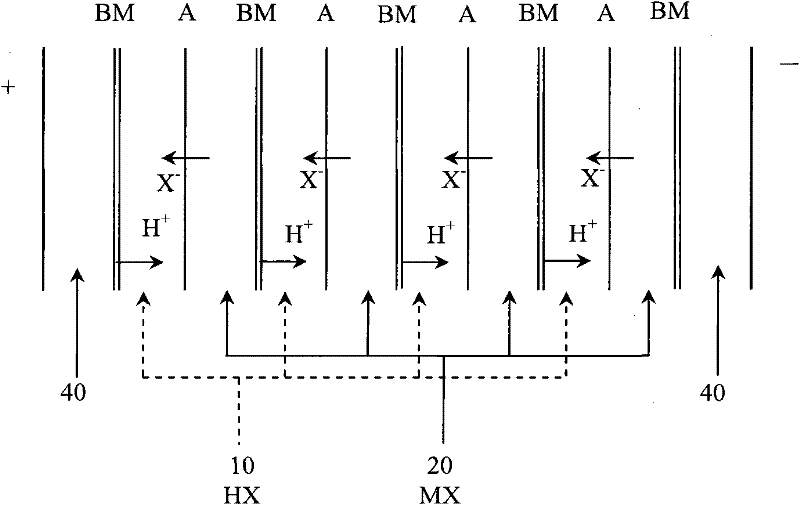

Method used

Image

Examples

Embodiment 1

[0090] Step 1) prepare lactic acid fermentation liquid:

[0091] The microbial strain used was Lactobacillus paracasei (Lactobacillus paracasei, NERCB0401 (Industrial Microbiology, 2007, Vol. 37, Issue 4, 1-5)), and fed-batch fermentation was carried out with the above strain. There are two types of media used:

[0092] (1) Seed medium: glucose 40g / L, peptone 10g / L, beef extract 10g / L, yeast powder 5g / L, diammonium hydrogen citrate 2g / L, sodium acetate 5g / L, dipotassium hydrogen phosphate 2g / L L, Tween 801mL / L, magnesium sulfate 0.6g / L, manganese sulfate 0.25g / L.

[0093] (2) Fermentation medium: glucose 60g / L, peptone 10g / L, beef extract 6g / L, yeast powder 10g / L, sodium chloride 0.03g / L, ferrous sulfate 0.01g / L, sodium acetate 4g / L , diamine citrate 2g / L, potassium dihydrogen phosphate 2g / L, Tween-801mL / L, magnesium sulfate 0.2g / L, manganese sulfate 0.2g / L.

[0094] Two kinds of media were prepared according to the above formula and sterilized at 121°C for 15 minutes, in w...

Embodiment 2

[0104] Step 1) Preparation of lactic acid fermented liquid: same as step 1) of Example 1, to obtain about 3.4 liters of fermented liquid containing calcium lactate with a lactic acid concentration of 160 g / L.

[0105] Sterilization: Pass the fermented liquid obtained in step 1) through a 0.2 μm microfiltration membrane of Tianjin Motianmo Engineering Technology Co., Ltd. to obtain 3 liters of fermented clear liquid with a lactic acid concentration of about 160 g / L.

[0106] Step 2) Precipitation replacement: Add 5.1mol / L sodium carbonate solution in the above-mentioned sterilized fermented liquid, the volume ratio is about 5: 1, fully stir and mix, make it react completely; Filter to obtain calcium carbonate solid and lactic acid concentration 134g / L L of fermentation broth containing sodium lactate is about 3.5L.

[0107] Step 3) Ion-exchange column adsorption of lactic acid: 3.15 liters of fermented liquid containing sodium lactate obtained in step 2) is passed through an io...

Embodiment 3

[0113] Step 1) Preparation of lactic acid fermented liquid: same as step 1) of Example 1, obtain about 3.5 liters of fermented liquid containing calcium lactate with a lactic acid concentration of 160 g / L.

[0114] Sterilization: pass the fermented liquid obtained in step 1) through the 0.2 μm microfiltration membrane of Tianjin Motianmo Engineering Technology Co., Ltd. to obtain about 3.1 liters of fermented clear liquid with a lactic acid concentration of about 160 g / L.

[0115] Step 2) Precipitation replacement: Add 5.0mol / L potassium carbonate solution in the above-mentioned sterilized fermentation broth, the volume ratio is about 5.1: 1, fully stir and mix, make it react completely; filter to obtain calcium carbonate solid and lactic acid concentration 134g / L L of fermentation broth containing potassium lactate is about 3.5L.

[0116] Step 3) Ion-exchange column adsorption of lactic acid: pass 3.45 liters of fermented liquid containing potassium lactate obtained in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com