Polylactic acid compound preparation method

A compound, polylactic acid technology, applied in the field of polymer synthesis, can solve the problems of low molecular weight modified polymers, unfavorable for cell physiological function, low polymer mechanical properties, etc. The effect of product separation and solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

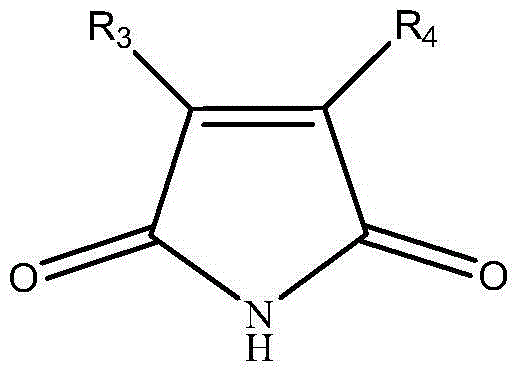

[0028] The preparation of embodiment 1 maleic anhydride modified polylactic acid

[0029] In the autoclave, add 30g of lactide, 3g of maleic anhydride, 9mg of stannous octoate, 3mg of benzoyl peroxide and 50ml of toluene, blow nitrogen gas for 5 minutes to remove oxygen, and store at 200°C under sealed conditions React under water for 20h, then cool with water, open the autoclave, pour the solution into 500ml of anhydrous methanol, stir for 1 hour, remove unreacted substances, then suction filter, and vacuum-dry the powder obtained by suction filtration to obtain the viscosity average molecular weight It is a modified polylactic acid-maleic anhydride of 280,000, without discoloration.

Embodiment 2

[0030] The preparation of embodiment 2 maleic anhydride modified polylactic acid

[0031] In the autoclave, add 30g of lactide, 2g of maleic anhydride, 9mg of stannous octoate and 3mg of benzoyl peroxide and 50ml of toluene, feed nitrogen for 5 minutes to remove oxygen, under sealed conditions at 200 React at ℃ for 20h, then cool with water, open the autoclave, pour the solution into 500ml of anhydrous methanol, stir for 1 hour, remove unreacted substances, then filter with suction, and dry the powder obtained by suction filtration in vacuum to obtain a viscous homogeneous Polylactic acid-maleic anhydride modified product with a molecular weight of 260,000, no discoloration.

Embodiment 3

[0032] The preparation of embodiment 3 maleic anhydride modified polylactic acid

[0033] Add 30g of lactide, 1.5g of maleic anhydride, 9mg of stannous octoate and 3mg of benzoyl peroxide and 50ml of toluene in the autoclave, feed nitrogen for 5 minutes to remove oxygen, under sealed conditions at 200 React at ℃ for 20h, then cool with water, open the autoclave, pour the solution into 500ml of anhydrous methanol, stir for 1 hour, remove unreacted substances, then filter with suction, and dry the powder obtained by suction filtration in vacuum to obtain a viscous homogeneous Polylactic acid-maleic anhydride modified product with a molecular weight of 250,000, no discoloration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com