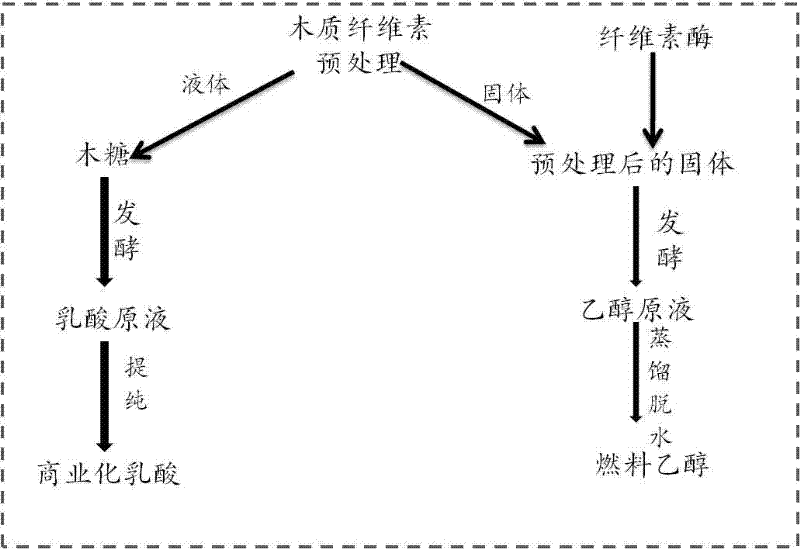

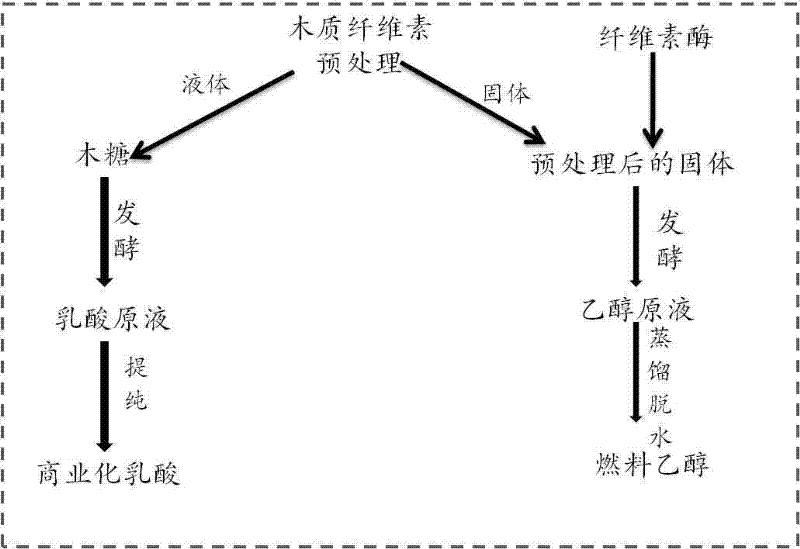

Method for co-production of lactic acid and alcohol by lignocellulose

A technology for lignocellulose and ethanol production, which is applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., and can solve the problems of high cost per unit of ethanol production and low utilization value added.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1: 3 kilograms of straw were placed in a 50-liter pretreatment reactor, 3 kilograms of water were added, 1.6Mpa saturated steam was introduced for 10 minutes, and 6.5 liters of pretreated liquid obtained after the straw was squeezed, in the liquid Add 13 milliliters of 98% concentrated sulfuric acid, transfer the liquid into another reaction kettle and heat it to 160 degrees Celsius with steam for 30 minutes; use lime to neutralize to pH 5.0, leave standstill for 3 hours, and filter out the crystalline sulfuric acid by centrifugal filtration. Calcium; the neutralized xylose-containing liquid obtained from pretreatment is concentrated 10 times under reduced pressure at 80 degrees Celsius; at this time, the concentration of xylose is about 450 g / l, and the mass of the pretreated straw after pressing is 5.5 kg , the water content accounts for 60% (mass percentage); add 5.5 kg of pretreated straw into a 20-liter fermenter, add culture medium for disinfection, add...

Embodiment 2

[0036] Embodiment 2: place 3 kilograms of straws in the pretreatment reactor of 50 liters, add 20 kilograms of water and 300 grams of calcium hydroxide, directly feed 200 degrees Celsius of saturated steam to make the temperature of reaction reach 150 degrees Celsius, and keep for 1 hour; After passing through plate-and-frame pressure filtration, the liquid part was neutralized to pH 6 by adding sulfuric acid, left standing for 3 hours, and the crystallized calcium sulfate was filtered off by centrifugation. A unit of xylanase was reacted for 2 hours, and the final xylose concentration was 85 g / l. After fermentation by Rhizopus oryzae as in Example 1, the final lactic acid concentration was 50.5 g / l, and the lactic acid liquid was obtained by separation and purification. 99% lactic acid solution; after the solid part is added to the 20-liter fermentor, the medium is added for disinfection, the volume is 15 liters, and hydrolysis and fermentation are carried out as in Example 1,...

Embodiment 3

[0037] Embodiment 3: place 3 kilograms of straws in 50 liters of pretreatment reactors, start to feed the steam of 1.2Mpa for 5 minutes, reduce the temperature to 50-60 degrees Celsius, and use a plate and frame filter press to filter and wash to obtain liquid 8 liter, the remaining grass is still placed in the pretreatment reactor of 50 liters, and the steam of 2.0Mpa is passed into for 5 minutes, and the temperature is reduced to 50-60 degrees Celsius, and the plate and frame filter press is used to filter and wash to obtain 9 liters of liquid; The two liquids were mixed, transferred to another reactor and heated to 160 degrees Celsius with steam, and kept for 60 minutes; the treated liquid was concentrated to 2 liters, and the obtained xylose concentration was 150 g / l, as shown in Example 1. After the fermentation of Rhizopus oryzae, the final concentration of lactic acid was 90 g / l, and the lactic acid liquid was separated and purified to obtain a 99% lactic acid solution; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com