Pressure stabilizing method and its device for beating of disc mill

A voltage stabilizing device and disc refiner technology, applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of easily disturbed stability, weakened shearing effect, and affecting beating quality, etc. Achieve the effect of being conducive to large-scale promotion and application, low production cost and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

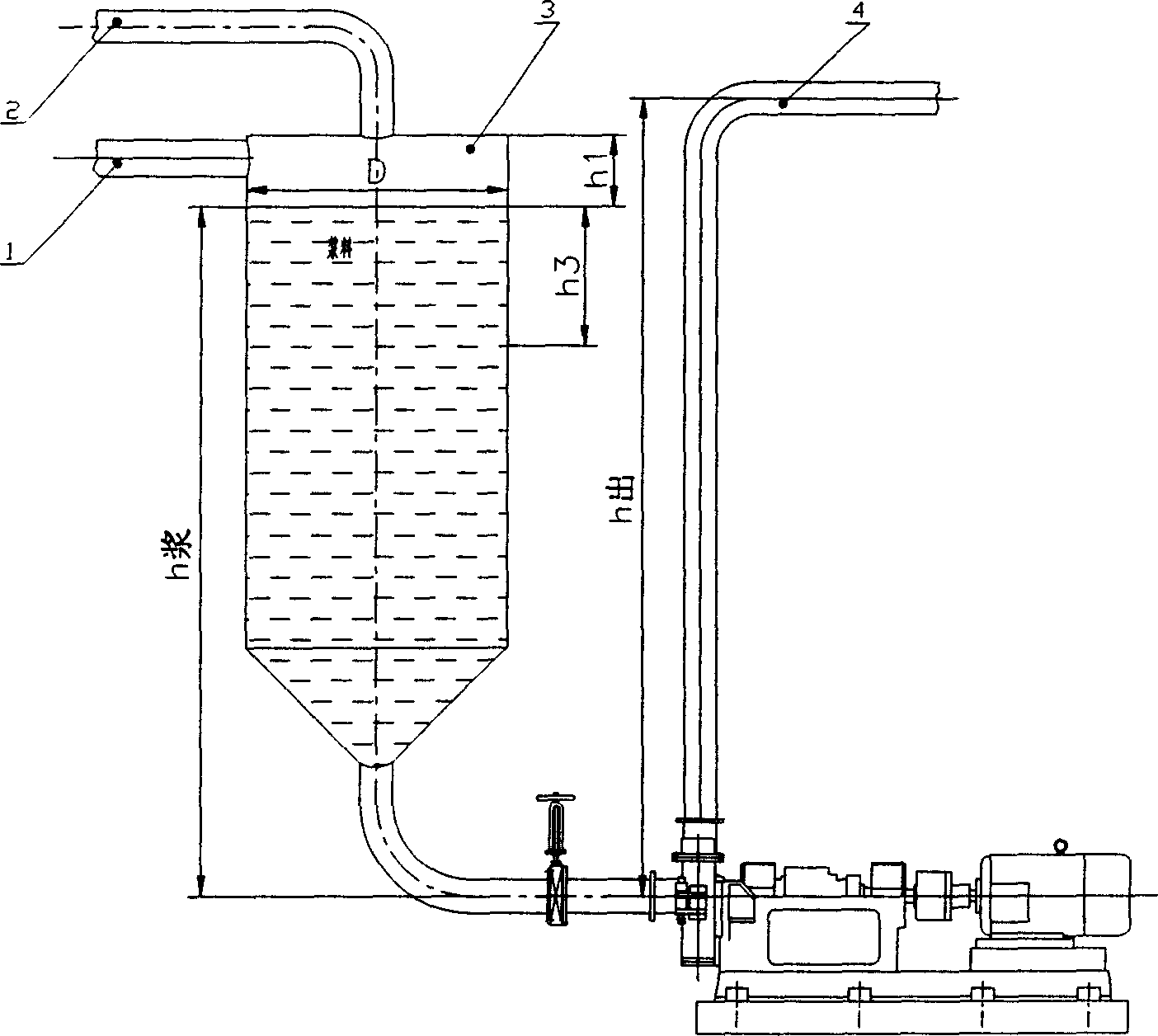

[0019] figure 1 A specific embodiment of the present invention is shown, by figure 1 It can be seen that the beating and pressure stabilizing device of the disc refiner of the present invention comprises a pulp inlet pipe 1, an overflow pipe 2, a pressure stabilizing tower 3, and a pulp outlet pipe 4, and one end of the pulp inlet pipe 1 is connected with the outlet of the slurry pump or the previous process, and the other end is connected with the outlet of the previous process. The pressure stabilizing tower 3 is connected near the top opening, and the overflow pipe 2 is connected to the top of the stabilizing tower 3, and its diameter is larger than that of the slurry inlet pipe 1. The height and diameter of the stabilizing tower 3 are determined by the beating pressure to be maintained by the system It is determined by the allowable change value of the pressure. The bottom of the pressure stabilizing tower 3 is designed as an inverted cone, and the outlet of the bottom is...

Embodiment 2

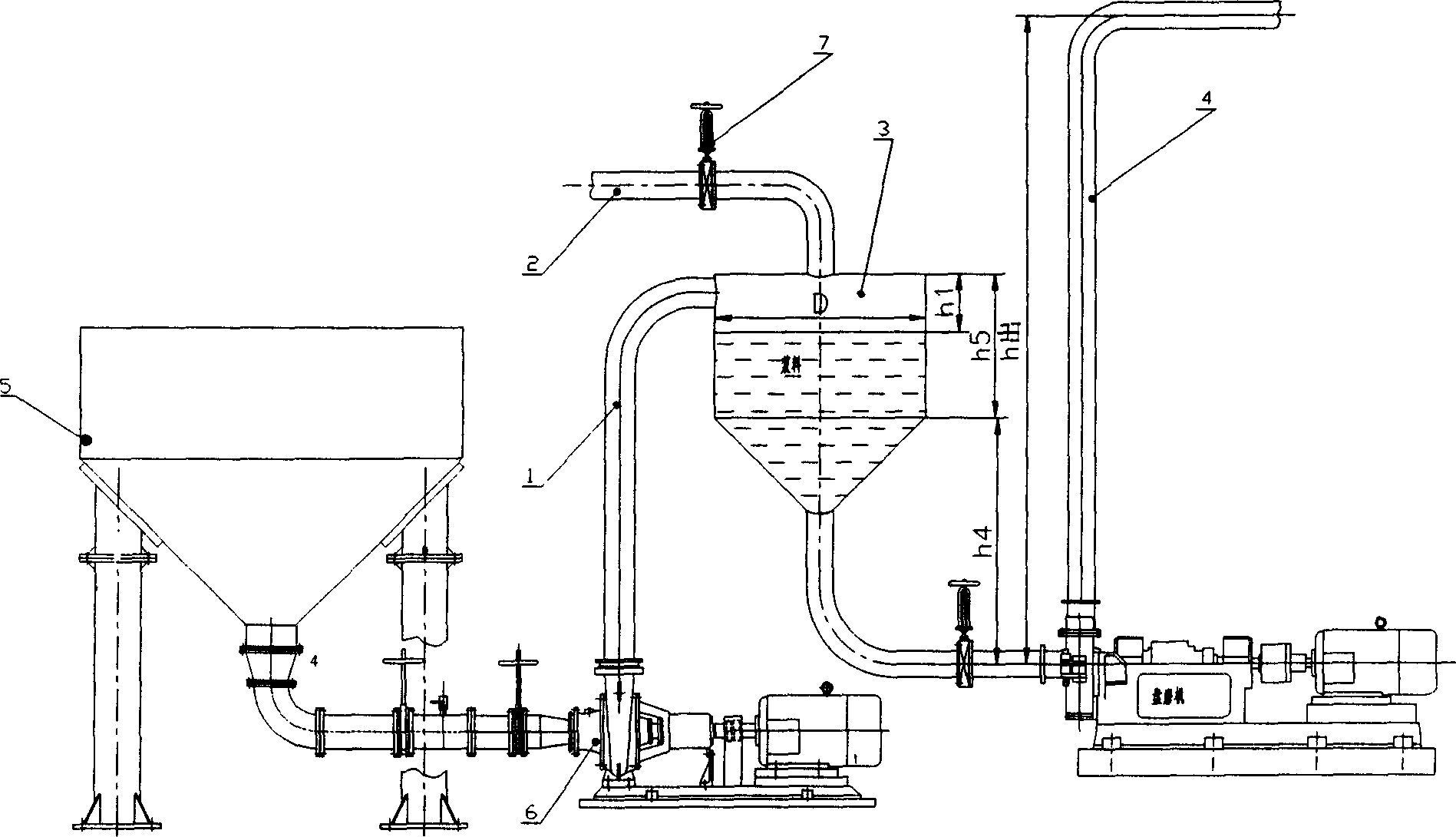

[0021] figure 2 Another specific embodiment of the present invention is shown, by figure 2It can be seen that the pulping and stabilizing device of the disc refiner of the present invention comprises a pulp storage tower 5, a pulp pump 6, a pulp inlet pipe 1, an overflow pipe 2, a control valve 7, a pressure stabilizing tower 3, a pulp outlet pipe 4, and one end of the pulp inlet pipe 1 It is connected to the slurry pump 6, and the other end is connected to the top opening of the pressure stabilizing tower 3. The overflow pipe 2 is connected to the top of the stabilizing tower 3 and is equipped with a control valve 7. The height and diameter of the stabilizing tower 3 are maintained by the system. It is determined by the beating pressure and the allowable change value of the pressure, the maximum and minimum value of the return flow controlled by the control valve, and the fluctuation amount of the pulp pump. The bottom of the pressure stabilizing tower 3 is designed as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com