Control method and device for electronic control piston cooling nozzle, vehicle and storage medium

A technology of a piston cooling nozzle and a control method, which is applied in the field of vehicles, can solve the problems of reduced control accuracy of an electronically controlled piston cooling nozzle and inability to accurately evaluate the piston temperature, and achieves the effect of ensuring the control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

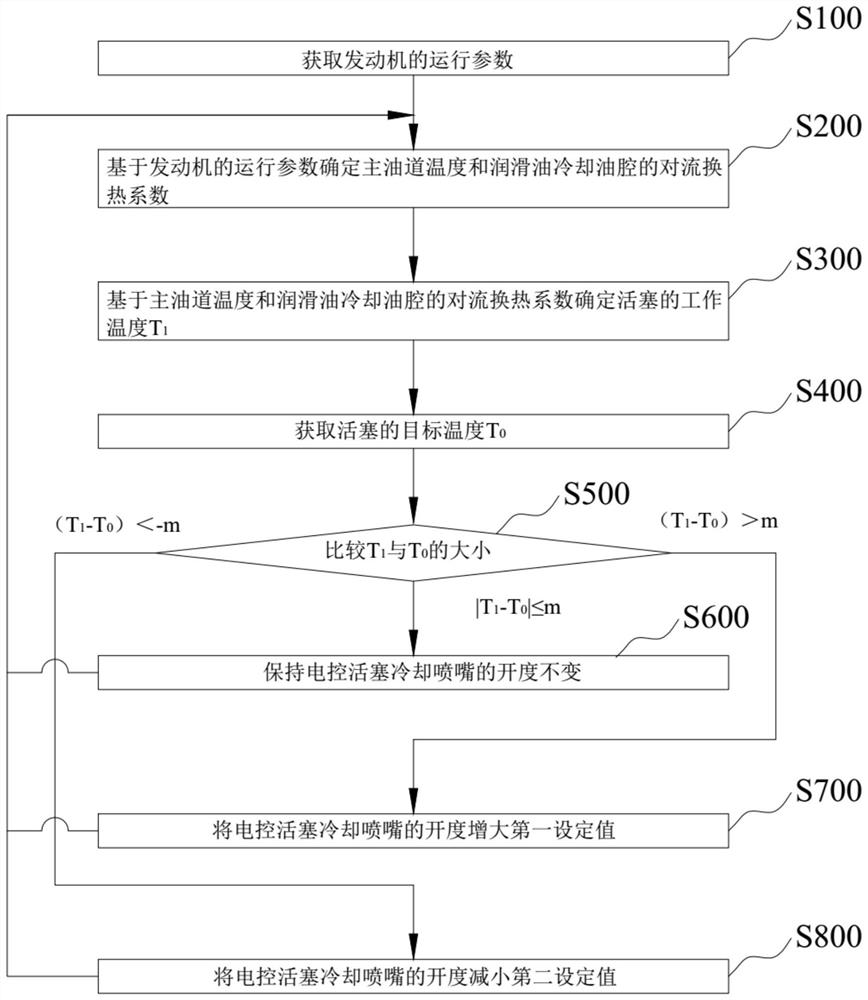

Embodiment 1

[0084] The existing piston cooling nozzle control method comprehensively considers the operating conditions of the engine, the real-time engine speed, the engine load, the oil pressure of the main oil passage, the real-time value of the oil temperature of the main oil passage, and the pre-calibrated data through the bench test. Perform different control steps after the meter, the engine electronic control unit ECU controls the variable oil pump to change its displacement to reach the corresponding target oil pressure of the main oil passage; and controls the pressure limiting valve to achieve the corresponding opening based on the target oil pressure of the main oil passage Piston cooling jets produce different flow rates. However, the influence of lubricating oil on the piston is not only reflected in the temperature, but also the convective heat transfer coefficient of the lubricating oil cooling oil cavity will affect the actual temperature of the piston, so this method is n...

Embodiment 2

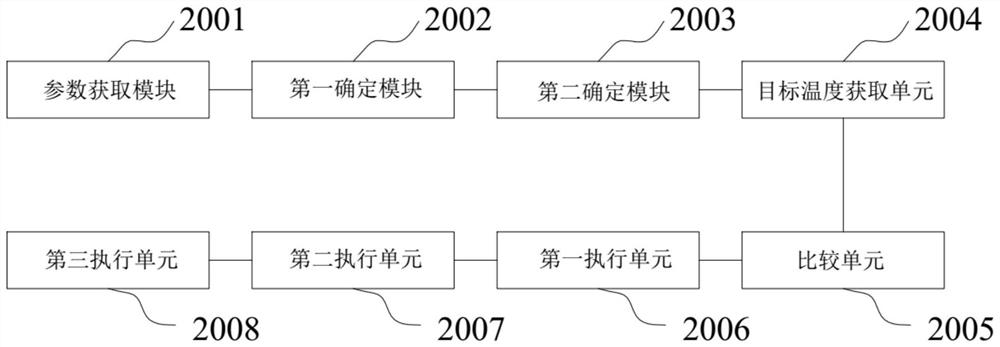

[0138] This embodiment provides a control device for an electronically controlled piston cooling nozzle, and the control device for an electronically controlled piston cooling nozzle is used to implement the above-mentioned control method for an electronically controlled piston cooling nozzle. Specifically, as figure 2 As shown, the control device for the electronically controlled piston cooling nozzle includes a parameter acquisition module 2001 , a first determination module 2002 , a second determination module 2003 , a target temperature acquisition unit 2004 , a comparison unit 2005 and a first execution unit 2006 .

[0139] The parameter acquisition module 2001 is used to acquire engine operating parameters, including engine speed, engine load rate, lubricating oil flow, wind speed flowing through the radiator, coolant flow and atmospheric temperature. The first determination module 2002 is configured to determine the temperature of the main oil passage and the convectiv...

Embodiment 3

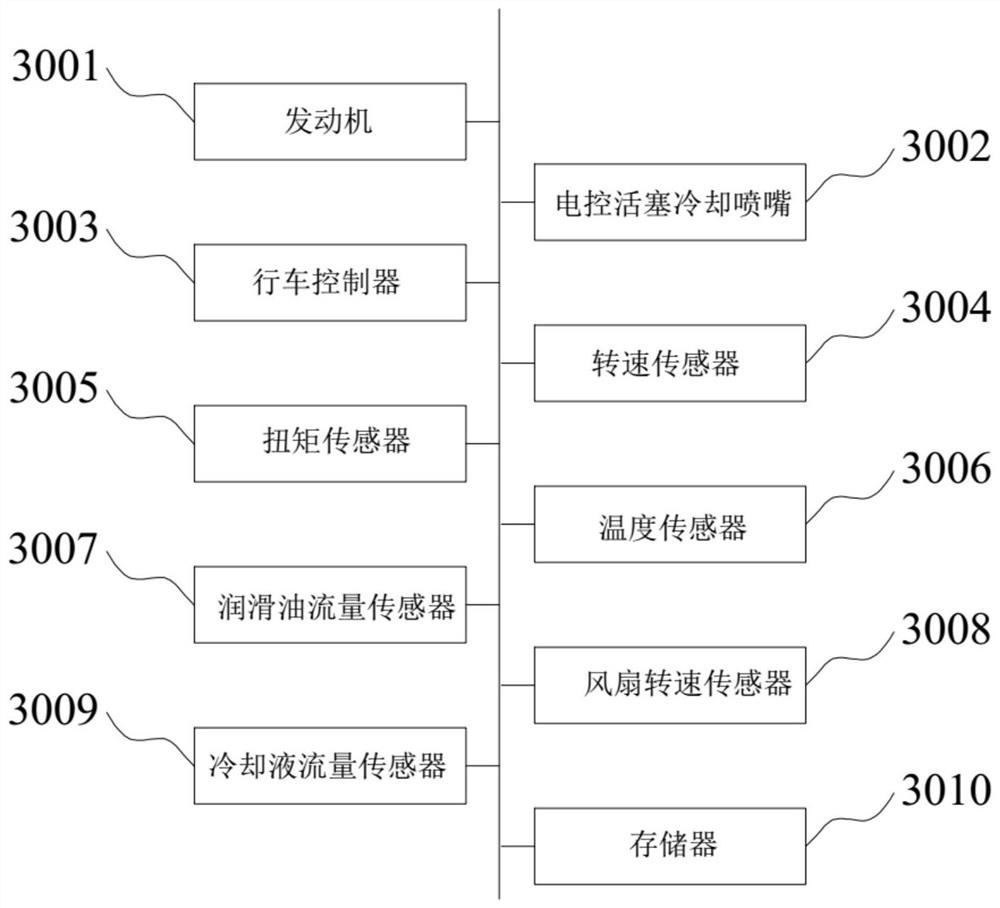

[0143] This embodiment provides a vehicle such as image 3As shown, the vehicle includes an engine 3001, an electronically controlled piston cooling nozzle 3002, a driving controller 3003, a rotational speed sensor 3004, a torque sensor 3005, a temperature sensor 3006, a lubricating oil flow sensor 3007, a fan rotational speed sensor 3008, a coolant flow sensor 3009 and memory 3010. Among them, the engine 3001, the electronically controlled piston cooling nozzle 3002, the driving controller 3003, the rotational speed sensor 3004, the torque sensor 3005, the temperature sensor 3006, the lubricating oil flow sensor 3007, the fan rotational speed sensor 3008, the coolant flow sensor 3009 and the memory 3010 pass through the bus connect. The rotational speed sensor 3004 is used to detect the engine rotational speed of the engine and send the detected engine rotational speed to the driving controller 3003; the torque sensor 3005 is used to detect the torque of the engine and send ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com