Thyristor rectifier bridge parallel operation full digital current homogenizing control device

An all-digital rectifier bridge technology, applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc., to achieve the effect of large current sharing coefficient, easy fault judgment and convenient parameter adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

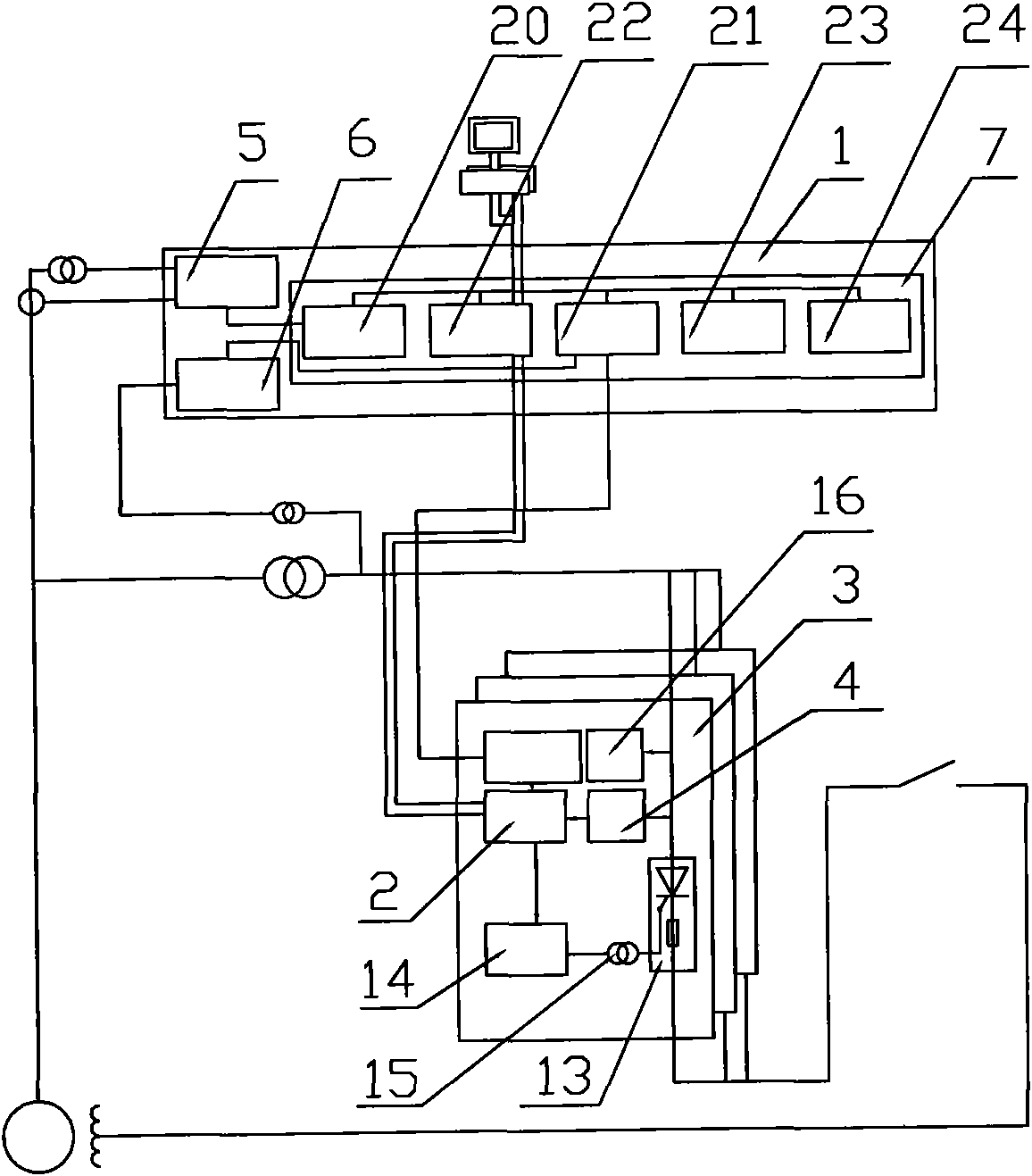

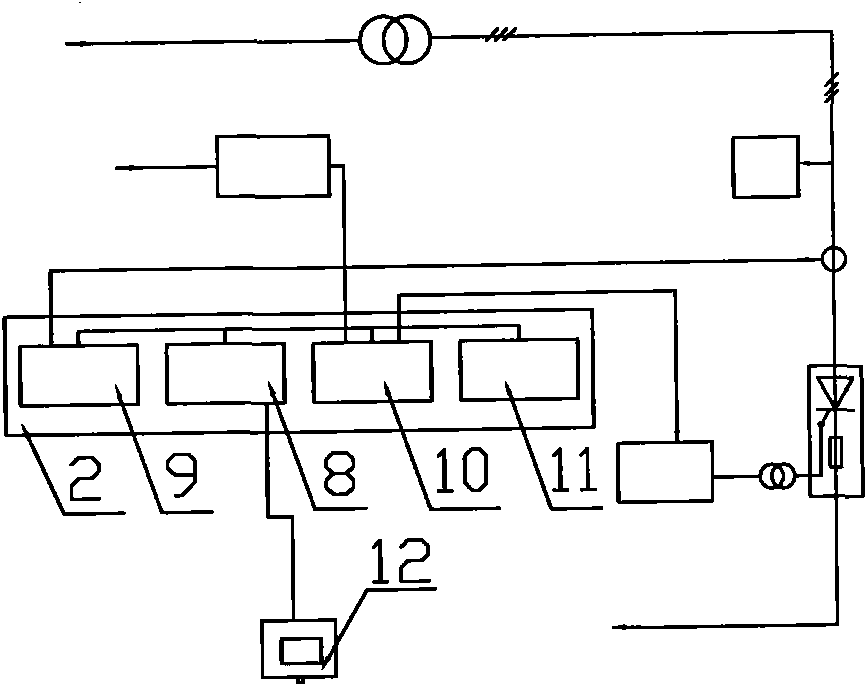

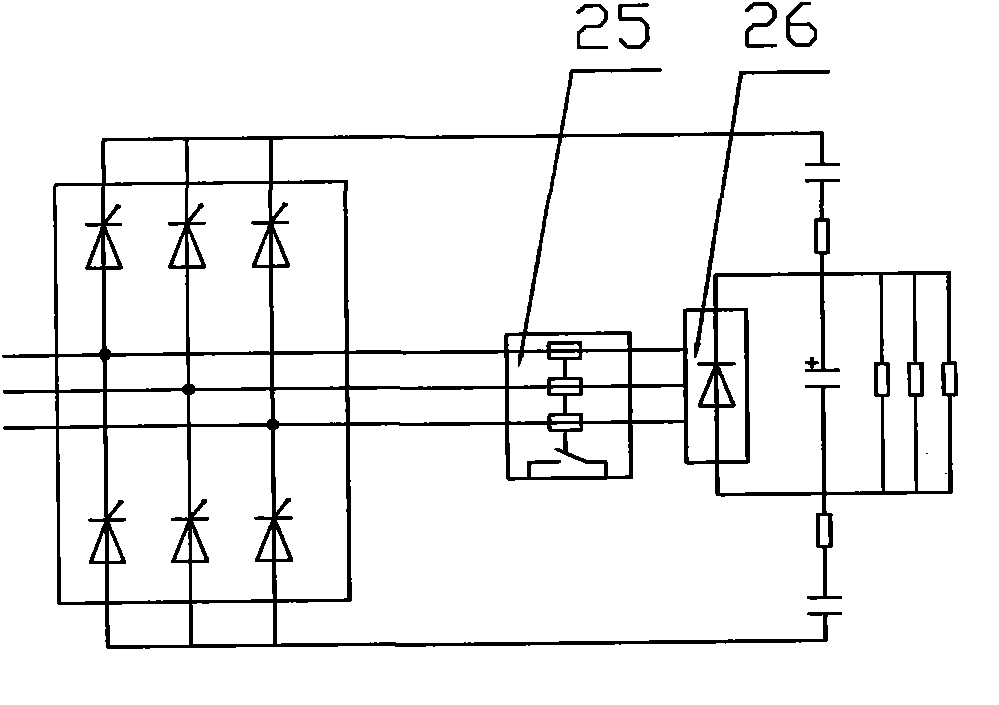

[0023]Thyristor rectifier bridges operate in parallel with a fully digital intelligent current sharing control device, including a regulator 1, a rectifier cabinet controller 2, a thyristor rectifier bridge 3 and a detection device 4. The regulator 1 is the main controller, and the machine-side signal processing module 5 , a synchronous signal processing module 6 and a regulator controller 7; the rectifier cabinet controller 2 is a slave controller, which is composed of a rectifier cabinet controller control module 8, a rectifier cabinet controller analog-to-digital conversion module 9, and a rectifier cabinet controller pulse Forming module 10, rectifier cabinet controller switching value input and output module 11 and rectifier bridge display controller 12; thyristor rectifier bridge 3 is composed of thyristor fully controlled rectifier bridge 13, pulse amplification module 14, pulse transformer isolation trigger module 15 and centralized reverse The blocking peak absorption ...

Embodiment 2

[0027] Thyristor rectifier bridges operate in parallel with a fully digital intelligent current sharing control device, including a regulator 1, a rectifier cabinet controller 2, a thyristor rectifier bridge 3 and a detection device 4. The regulator 1 is the main controller, and the machine-side signal processing module 5 , a synchronous signal processing module 6 and a regulator controller 7; the rectifier cabinet controller 2 is a slave controller, which is composed of a rectifier cabinet controller control module 8, a rectifier cabinet controller analog-to-digital conversion module 9, and a rectifier cabinet controller pulse Forming module 10, rectifier cabinet controller switching value input and output module 11 and rectifier bridge display controller 12; thyristor rectifier bridge 3 is composed of thyristor fully controlled rectifier bridge 13, pulse amplification module 14, pulse transformer isolation trigger module 15 and centralized reverse The blocking peak absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com