Production method of black facial mask paper

A production method and technology of facial mask paper, applied in paper, papermaking, papermaking and other directions, can solve the problems of poor strength and softness of facial masks, poor penetration and hydration performance of facial masks, poor air permeability of facial masks, etc., and achieve a unique black appearance, continuous and efficient production, The effect of good binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

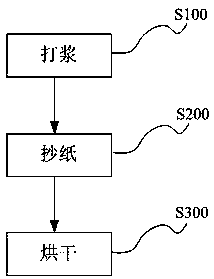

Method used

Image

Examples

Embodiment 1

[0074] 1. Main raw materials:

[0075] The particle size of nano-scale carbon black is 100-150nm, and softwood pulp fiber and hardwood pulp fiber are bleached pulp series or natural color pulp series.

[0076] 2. Main equipment:

[0077] Hydraulic pulper, conifer line double disc mill, broadleaf line double disc mill, Fourdrinier paper machine, front drying cylinder, surface application machine, back drying cylinder.

[0078] 3. Method steps:

[0079] (1) Pulping section: Use a hydraulic pulper to disintegrate softwood pulp fibers according to a mass percentage concentration of 3.2%. During the disintegration process, nano-grade carbon black is added to form a softwood pulp fiber-carbon black mixed pulp to make softwood pulp In the fiber-carbon black mixed pulp, the weight percentage of softwood pulp is 73%, and the weight percentage of nano-scale carbon black is 27%.

[0080] At the same time, the hardwood pulp fibers are broken down by a mass percentage concentration of 4.2% by using ...

Embodiment 2

[0093] 1. Main raw materials:

[0094] The particle size of nano-scale carbon black is 100-150nm, and softwood pulp fiber and hardwood pulp fiber are bleached pulp series or natural color pulp series.

[0095] 2. Main equipment:

[0096] Hydraulic pulper, conifer line double disc mill, broadleaf line double disc mill, Fourdrinier paper machine, front drying cylinder, surface application machine, back drying cylinder.

[0097] 3. Method steps:

[0098] (1) Beating section: use a hydraulic pulper to disintegrate softwood pulp fibers according to a mass percentage concentration of 3.4%. During the disintegration process, nano-grade carbon black is added to form a softwood pulp fiber-carbon black mixed pulp to make softwood pulp In the fiber-carbon black mixed pulp, the weight percentage of softwood pulp is 68%, and the weight percentage of nano-scale carbon black is 32%.

[0099] At the same time, the hardwood pulp fibers are broken down by a mass percentage concentration of 4.2% by using ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wet strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com