Full-biodegradable lamination composite paper material and preparation method thereof

An all-biological and composite paper technology, applied in paper coatings, special paper, chemical instruments and methods, etc., can solve the problems of poor barrier properties of materials, low production efficiency of sticky rolls, etc., and achieve excellent barrier properties, strong Brownian motion, good The effect of melt fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

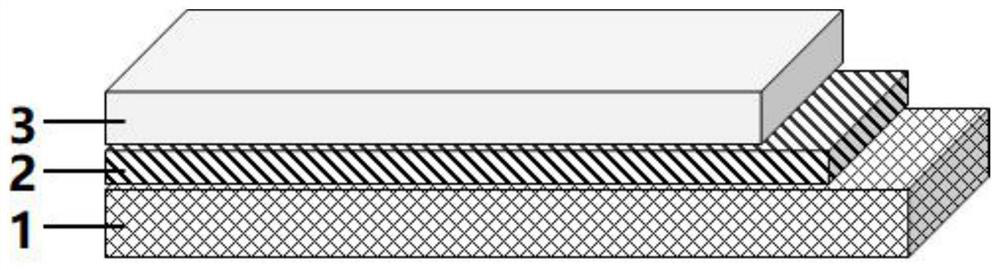

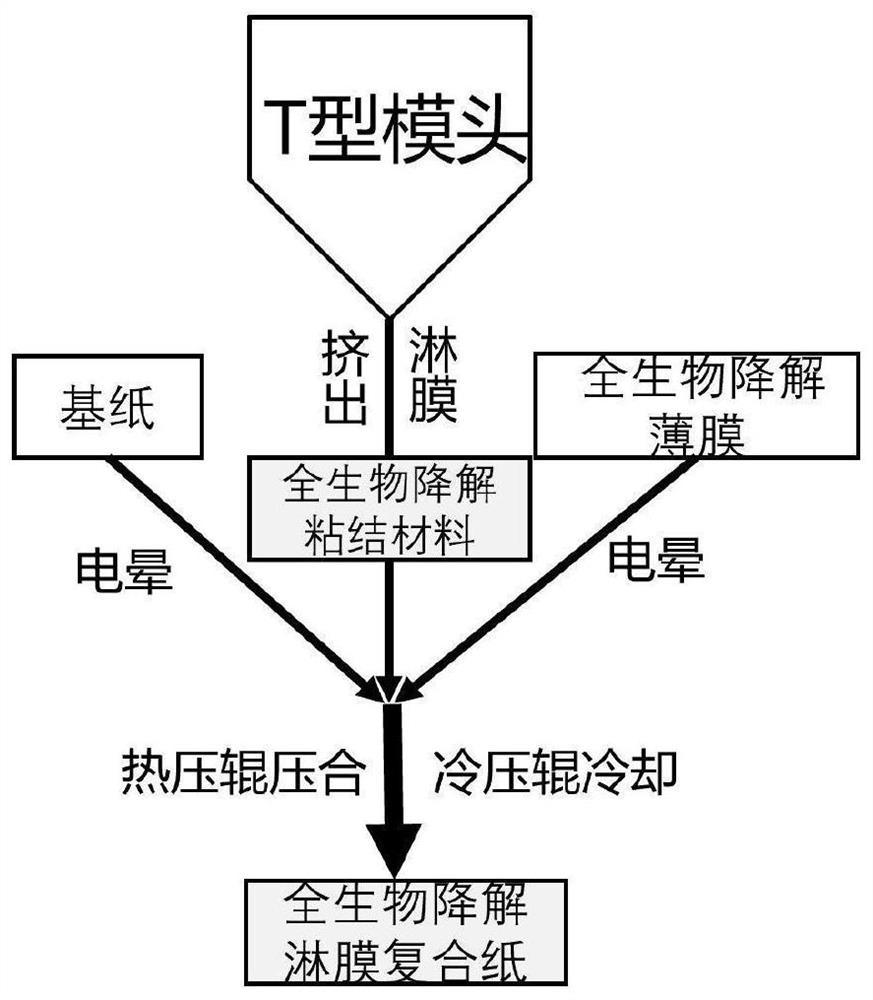

[0061] A fully biodegradable film-coated composite paper comprises: a base paper layer 1, an adhesive layer 2, and a film layer 3.

[0062] The base paper layer is kraft paper with a grammage of 80g / m 2 .

[0063] The film layer is a fully biodegradable film made of fully biodegradable material A by blown film. The fully biodegradable material A has the following composition: PBAT-1, 60%, in the polymer, the molar ratio of the repeating unit x comprising A units accounts for 48% of the sum of the repeating units x and y, and the melt index 3g / 10min (2.16kg, 190°C), melting temperature T m The temperature is 120°C, the number average molecular weight Mn is 60000-65000, the weight average molecular weight Mw is 130000-140000, the Tg is -33°C, and the Tc is 42°C; mixed resin-1 is PLA: 10%; mineral powder is calcium carbonate: 29.8 %, 3000 mesh; the compatibilizer is Joncryl ADR 4468: 0.2%.

[0064] The above-mentioned fully biodegradable film is prepared by the following meth...

Embodiment 2

[0077] A fully biodegradable coated composite paper, the structure and process flow are the same as in Example 1

[0078] The base paper layer is white cardboard with a grammage of 250g / m 2 .

[0079] The fully biodegradable material A has the following composition: PBAT-1, 80%, in this polymer, the molar proportion of the repeating unit x comprising A units accounts for 50% of the sum of the repeating units x and y, and the melt index is 4.6 g / 10min (2.16kg, 190℃), melting temperature T m The temperature is 125°C, the number average molecular weight Mn is 60000-65000, the weight average molecular weight Mw is 130000-140000, the Tg is -30°C and the Tc is 45°C; the mixed resin-1 is a combination of PLA: 10% and PBS: 5%; ore The powder is calcium carbonate: 4.7%, 2500 mesh; the compatibilizer is KL-E4370: 0.3%.

[0080] The film is blown by a film blowing machine to obtain a fully biodegradable film with a thickness of 30 μm and a width of 1000 mm.

[0081] The temperatures ...

Embodiment 3

[0088] A fully biodegradable coated composite paper, the structure and process flow are the same as in Example 1

[0089] The base paper layer is white cardboard with a grammage of 120g / m 2 .

[0090] Fully biodegradable material A is composed of the following: PBAT-1, 60%, in this polymer, the molar ratio of the repeating unit x including the A unit accounts for 51% of the sum of the repeating units x and y, and the melt index is 3.9 g / 10min (2.16kg, 190℃), melting temperature T m The temperature is 123°C, the number-average molecular weight Mn is 70,000-75,000, the weight-average molecular weight Mw is 140,000-150,000, the Tg is -28°C, and the Tc is 52°C; the mixed resin-1 is a combination of PHA: 10% and PGA: 4.5%; Mineral powder is kaolin: a combination of 15% and 10% silica, both of 4000 mesh; compatibilizer is Joncryl ADR 4370F: 0.5%.

[0091] The film is blown by a film blowing machine to obtain a fully biodegradable film with a thickness of 50 μm and a width of 1200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com