Treatment method for improving performance of producing methane through anaerobic fermentation of straw and application thereof

A technology of anaerobic fermentation and treatment method, applied in fermentation, waste fuel, etc., can solve the problems of refractory degradation and high pretreatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

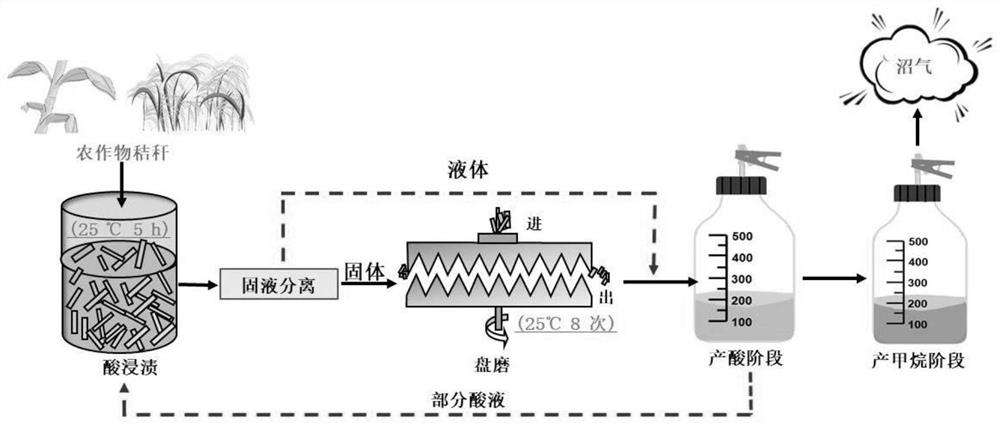

Method used

Image

Examples

Embodiment 1

[0041] (1) Raw material handling

[0042] The air-dried corn stalks are first cut into 3-4 cm, then pulverized with a pulverizer, passed through a 20-mesh sieve, and dried and stored for later use.

[0043] The biogas slurry is obtained from the mesophilic anaerobic fermentation of corn stalks and cow dung (the TS ratio of corn stalks and cow dung is 1:1, the TS ratio of fermented material and inoculated sludge is 1:1, and the total TS of the fermenter is 8%) after 40 days. part.

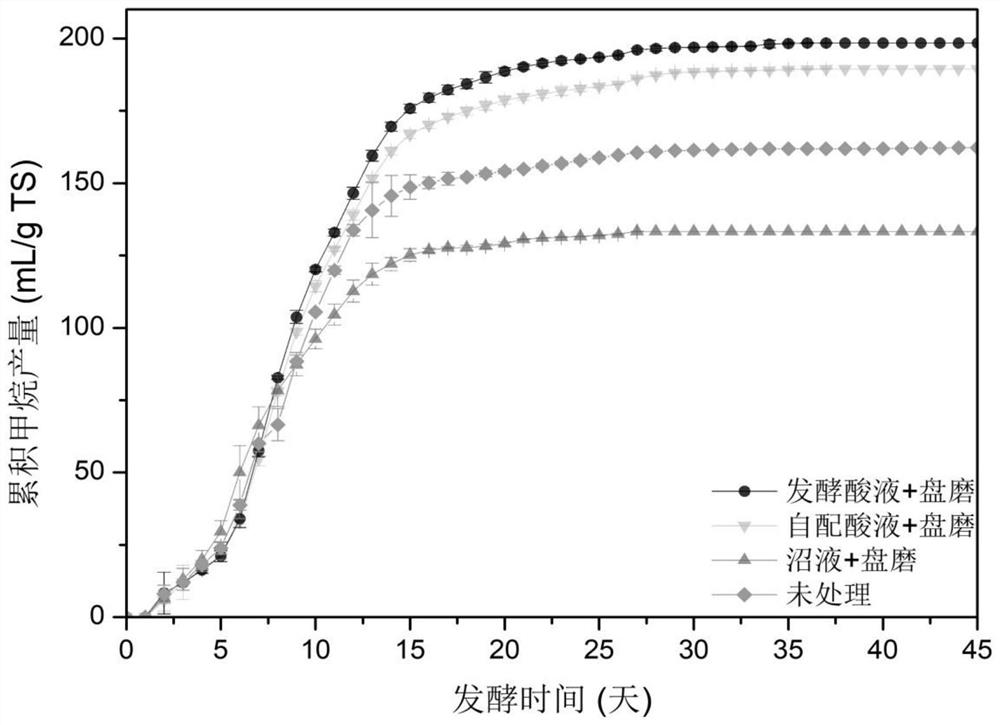

[0044] Preparation method of fermented acid solution: corn stalks and inoculated sludge passed through a 20-mesh sieve were subjected to mesophilic anaerobic fermentation with a TS ratio of 3:2, the total TS of the fermenter was 16%, and the concentration of VFAs was monitored once a day to select At the peak time of acid production, the fermentation broth was taken out on the 7th day.

[0045] Table 2 shows the measurement results of basic indicators of biogas slurry and fermented acid solution. ...

Embodiment 2

[0056] (1) Raw material handling

[0057] The air-dried corn stalks are first cut into 3-4 cm, then pulverized with a pulverizer, passed through a 20-mesh sieve, and dried and stored for later use.

[0058] (2) Pretreatment method

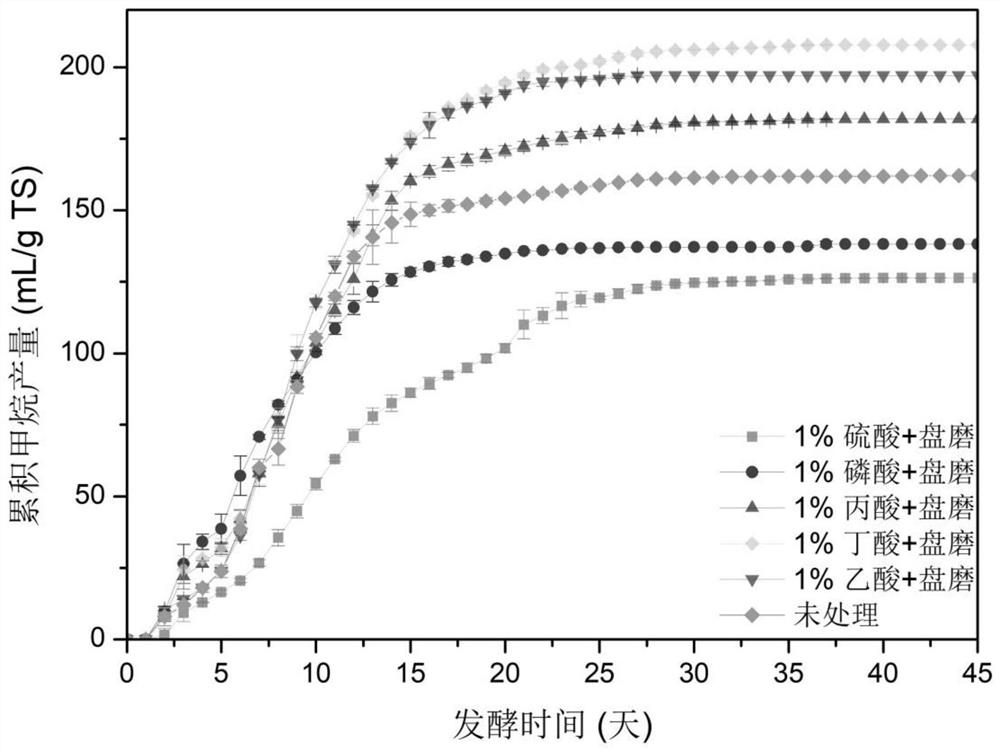

[0059] The crushed corn stalks were immersed in 1% sulfuric acid, 1% phosphoric acid, 1% acetic acid, 1% propionic acid, 1% butyric acid (both volume ratio) at room temperature (25°C) for 5 hours, and the solid-to-liquid ratio was 1: 10. The impregnated corn stalks were filtered, and the resulting liquid was continued to be used as an impregnating liquid, and the solid was disc-grinded 8 times with a disc mill at a rotational speed of 2800 r / min.

[0060] (3) Anaerobic fermentation

[0061] The pretreated solids and inoculated sludge were fed into fermentors at a ratio of 1:2 (based on TS), and distilled water was added to each fermenter to adjust the total TS to 6%. The initial pH of each fermentor was adjusted to 7.0 ± 0.1 with NaOH solution....

Embodiment 3

[0065] (1) Raw material handling

[0066] The air-dried corn stalks are first cut into 3-4 cm, then pulverized with a pulverizer, passed through a 20-mesh sieve, and dried and stored for later use.

[0067] (2) Pretreatment method

[0068] The crushed corn stover was immersed in 0.5% acetic acid, 2% acetic acid and 4% acetic acid at room temperature (25 °C) for 5 hours, with a solid-to-liquid ratio of 1:10. The impregnated corn stalks were filtered, and the resulting liquid was continued to be used as an impregnating liquid, and the solid was disc-grinded 8 times with a disc mill at a rotational speed of 2800 r / min. A control group of disc grinding only and 1% acetic acid immersion only was set up.

[0069] (3) Anaerobic fermentation

[0070] The pretreated solids and inoculated sludge were fed into fermentors at a ratio of 1:2 (based on TS), and distilled water was added to each fermenter to adjust the total TS to 6%. The initial pH of each fermentor was adjusted to 7.0 ±...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com