Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "Improve cutting stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

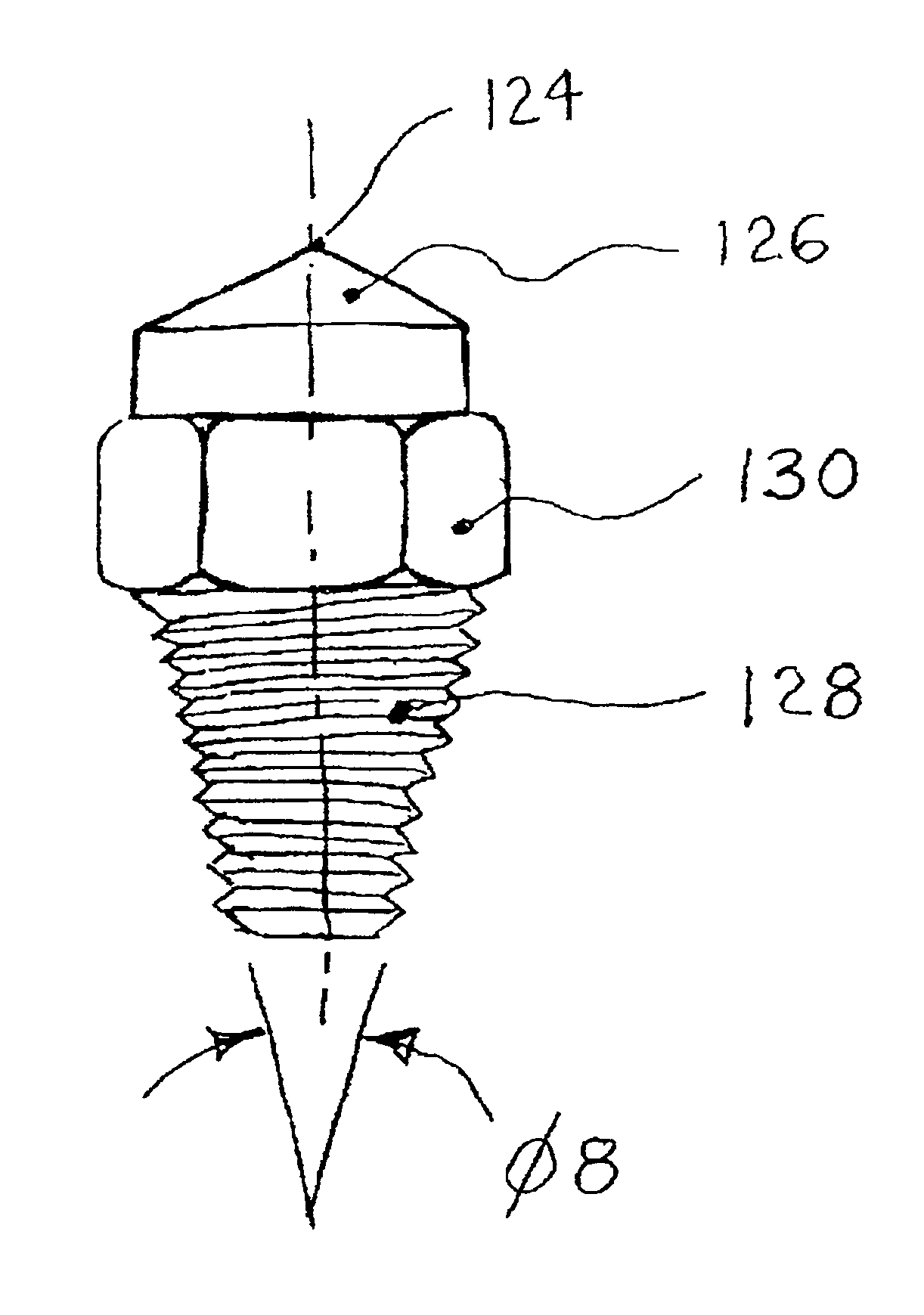

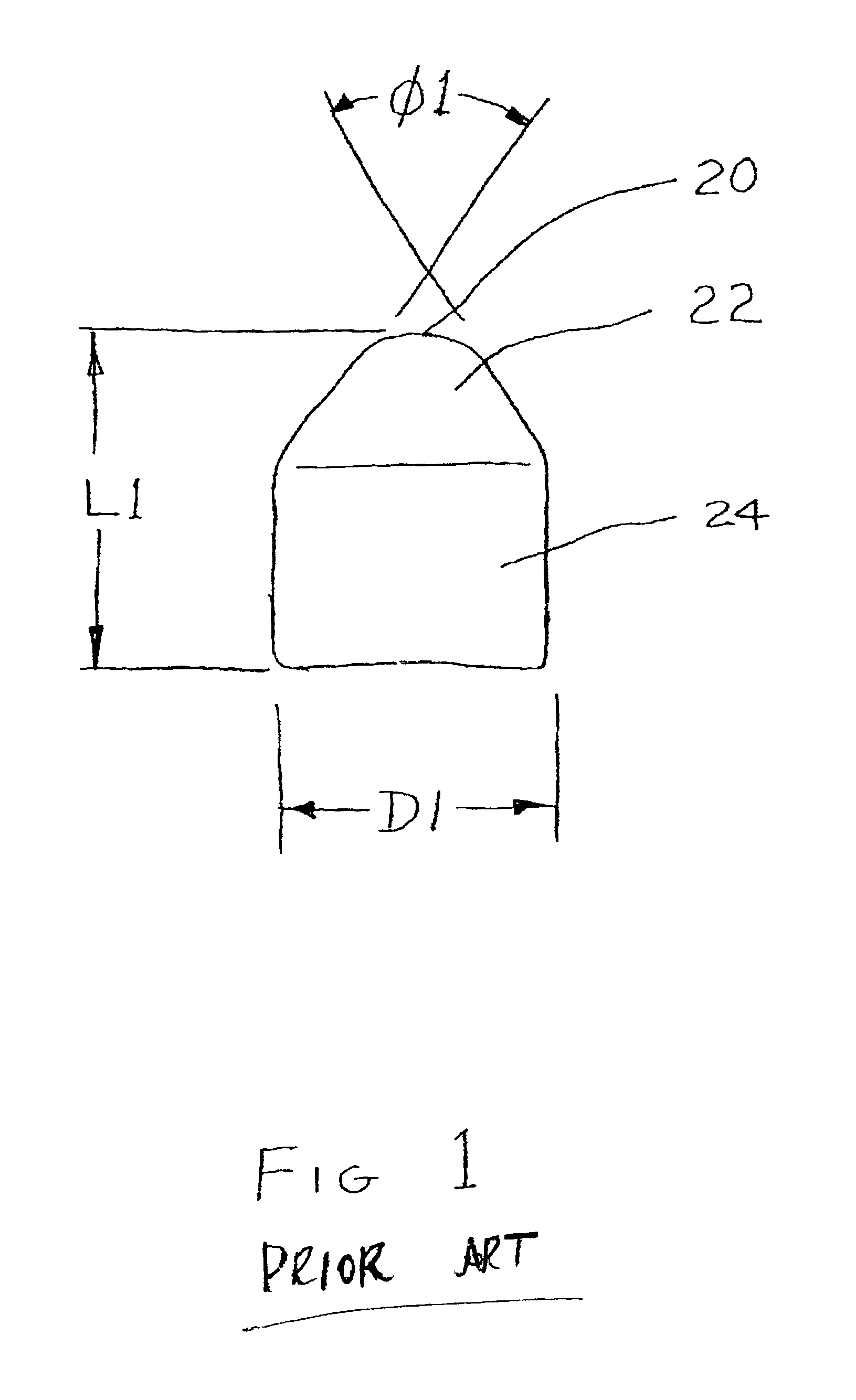

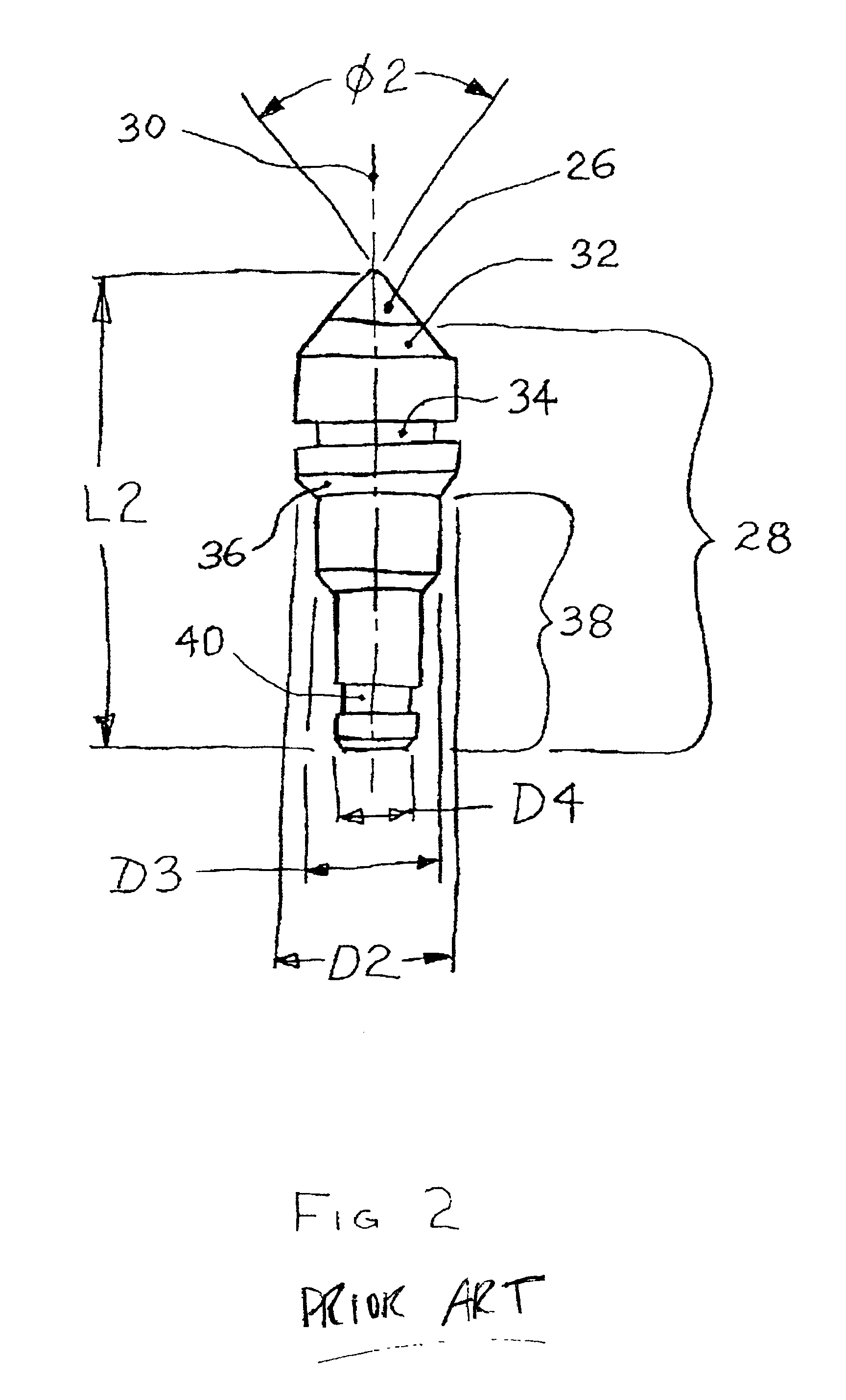

Rotary contact structures and cutting elements

Owner:DVORACHEK HAROLD A

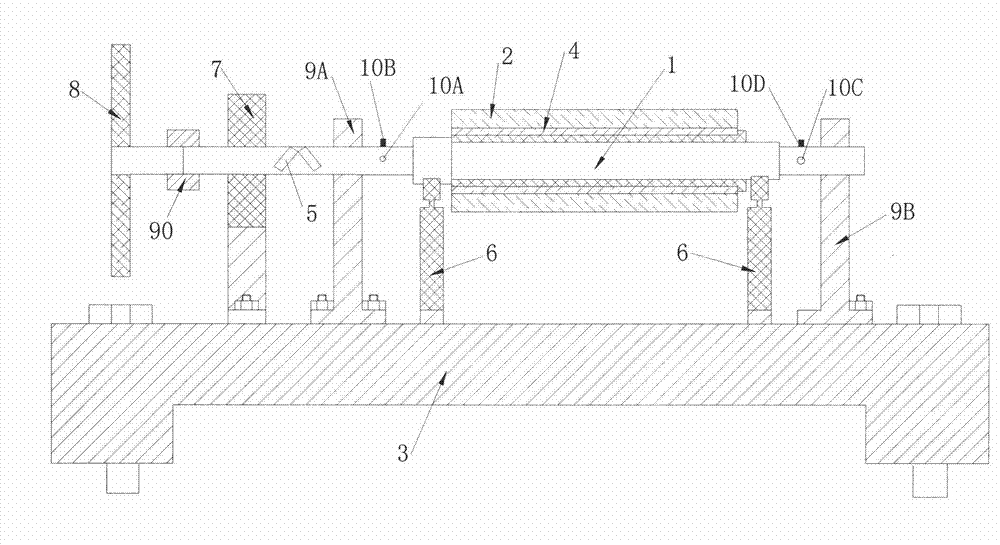

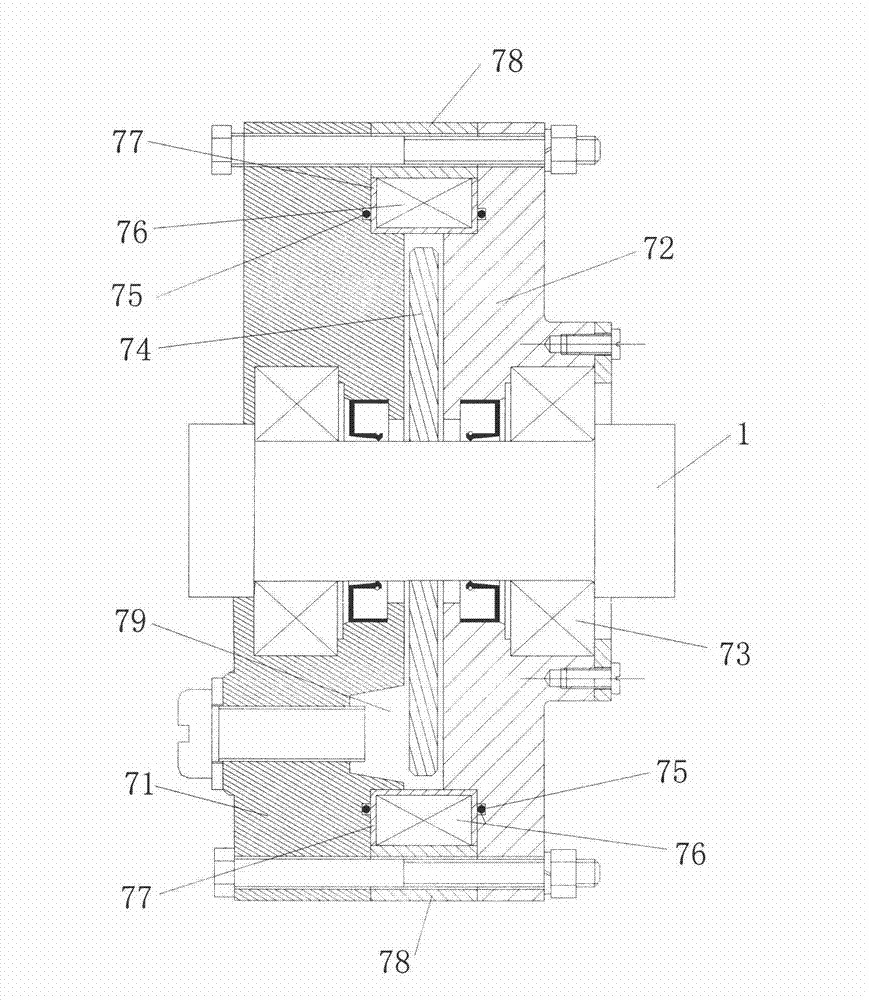

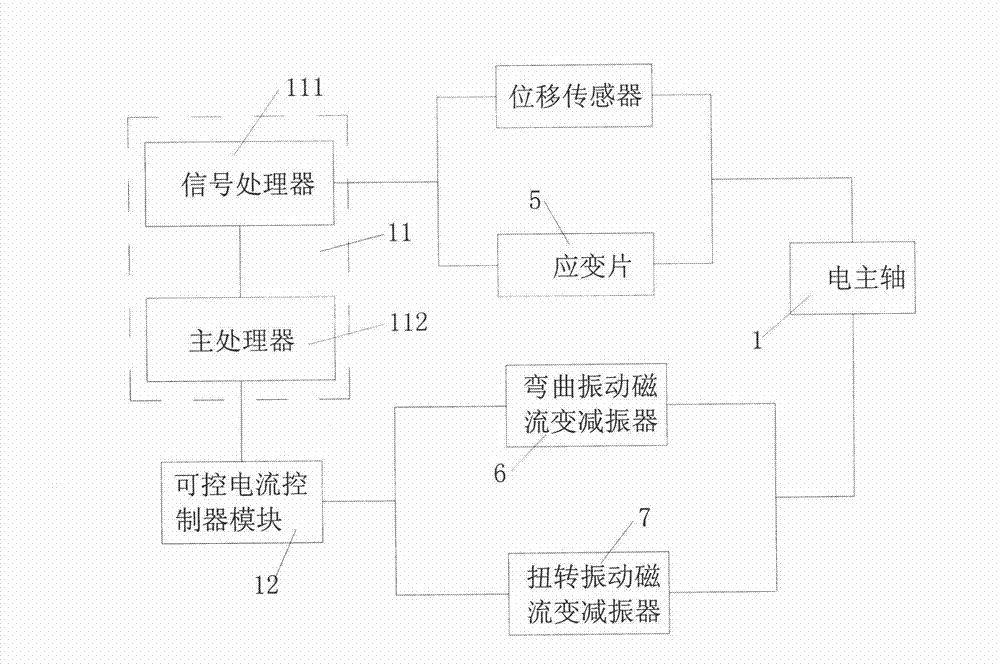

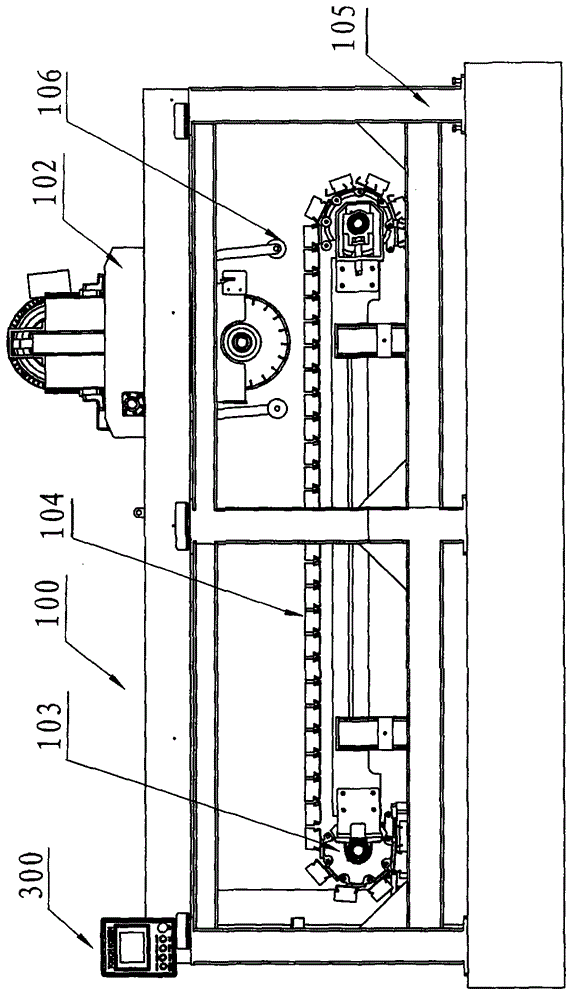

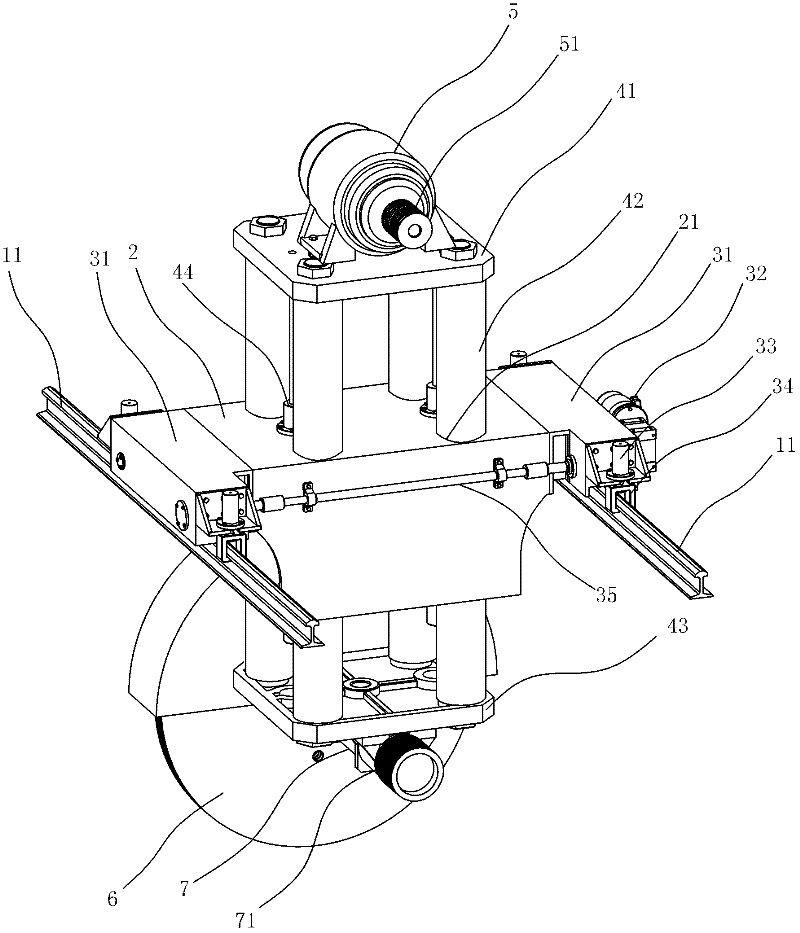

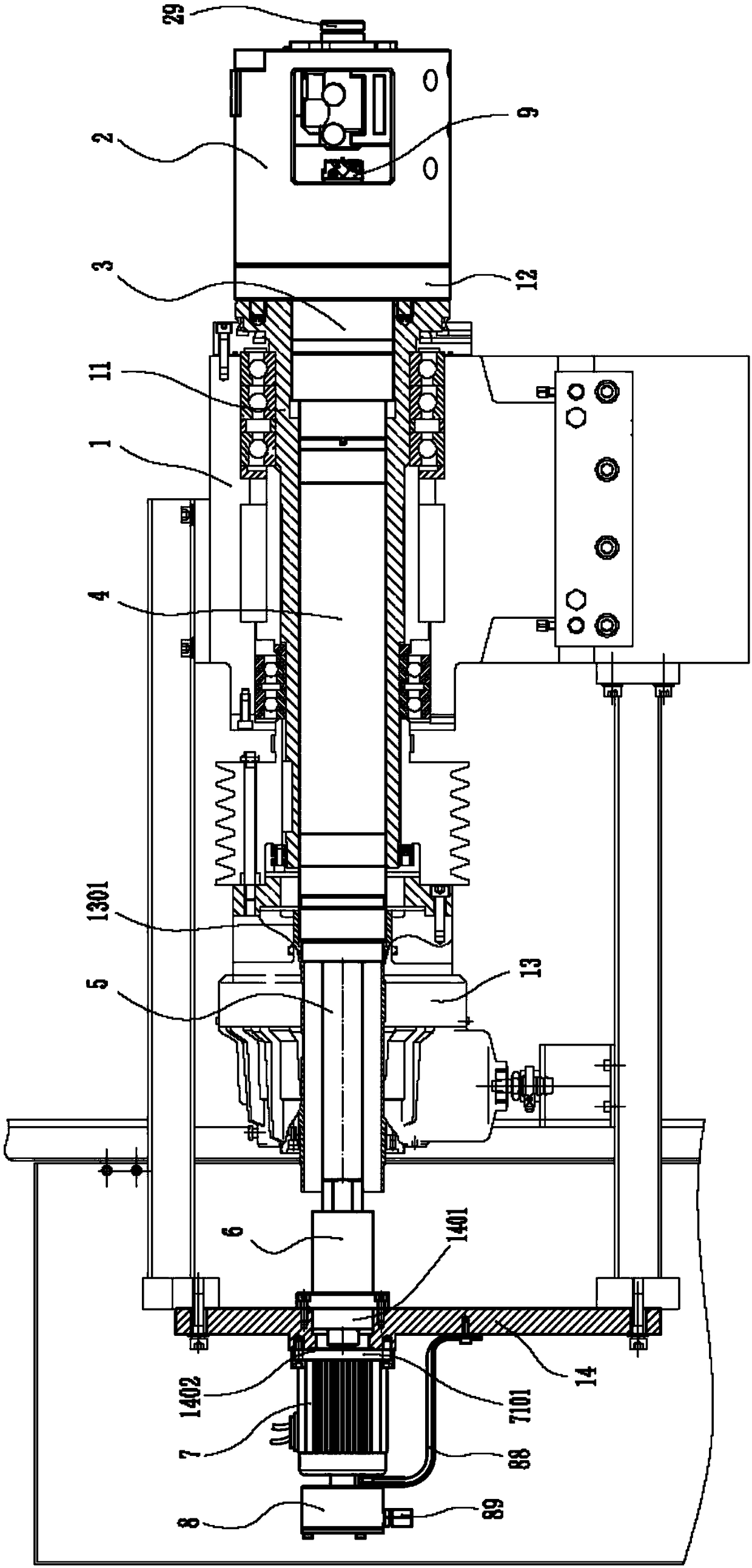

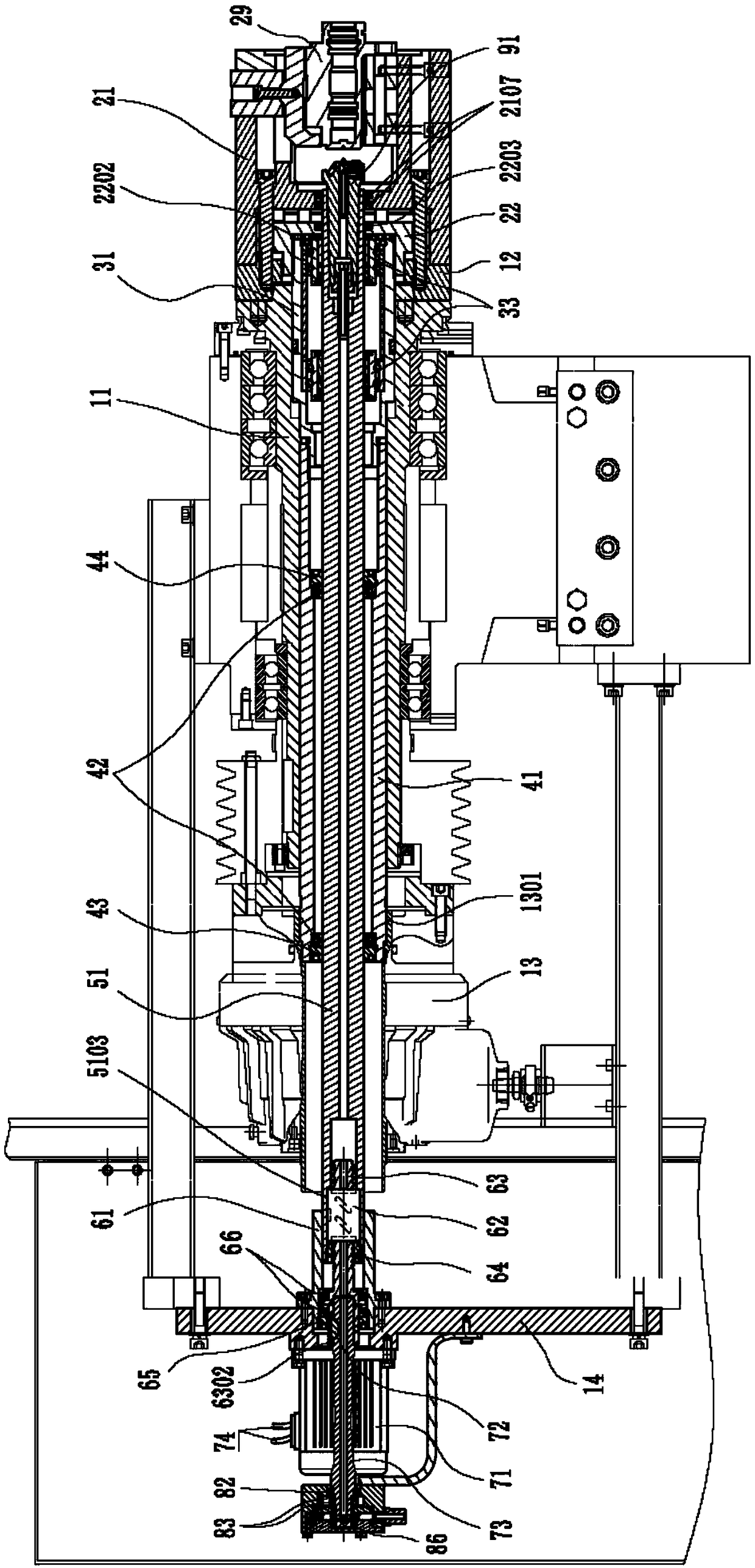

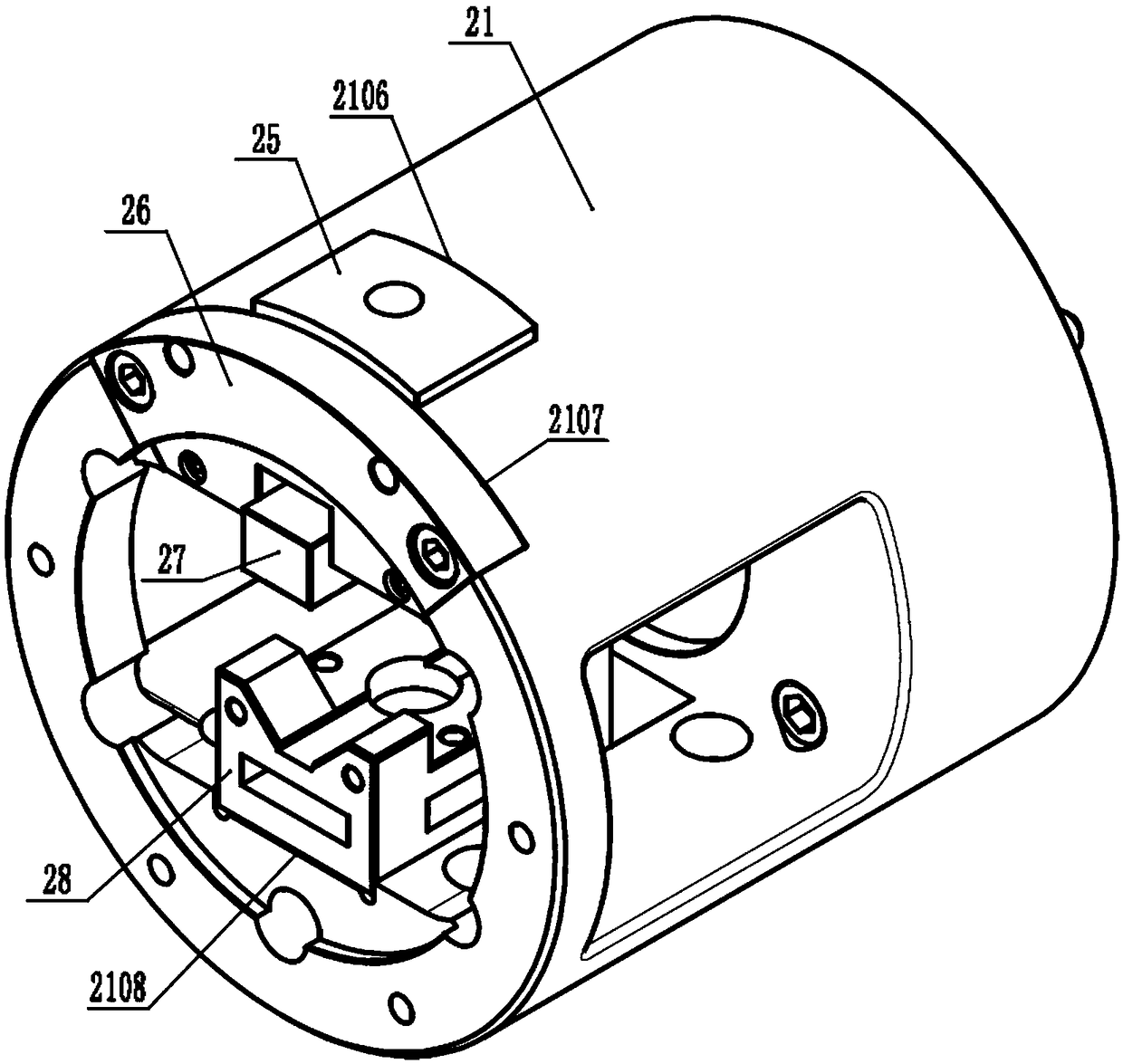

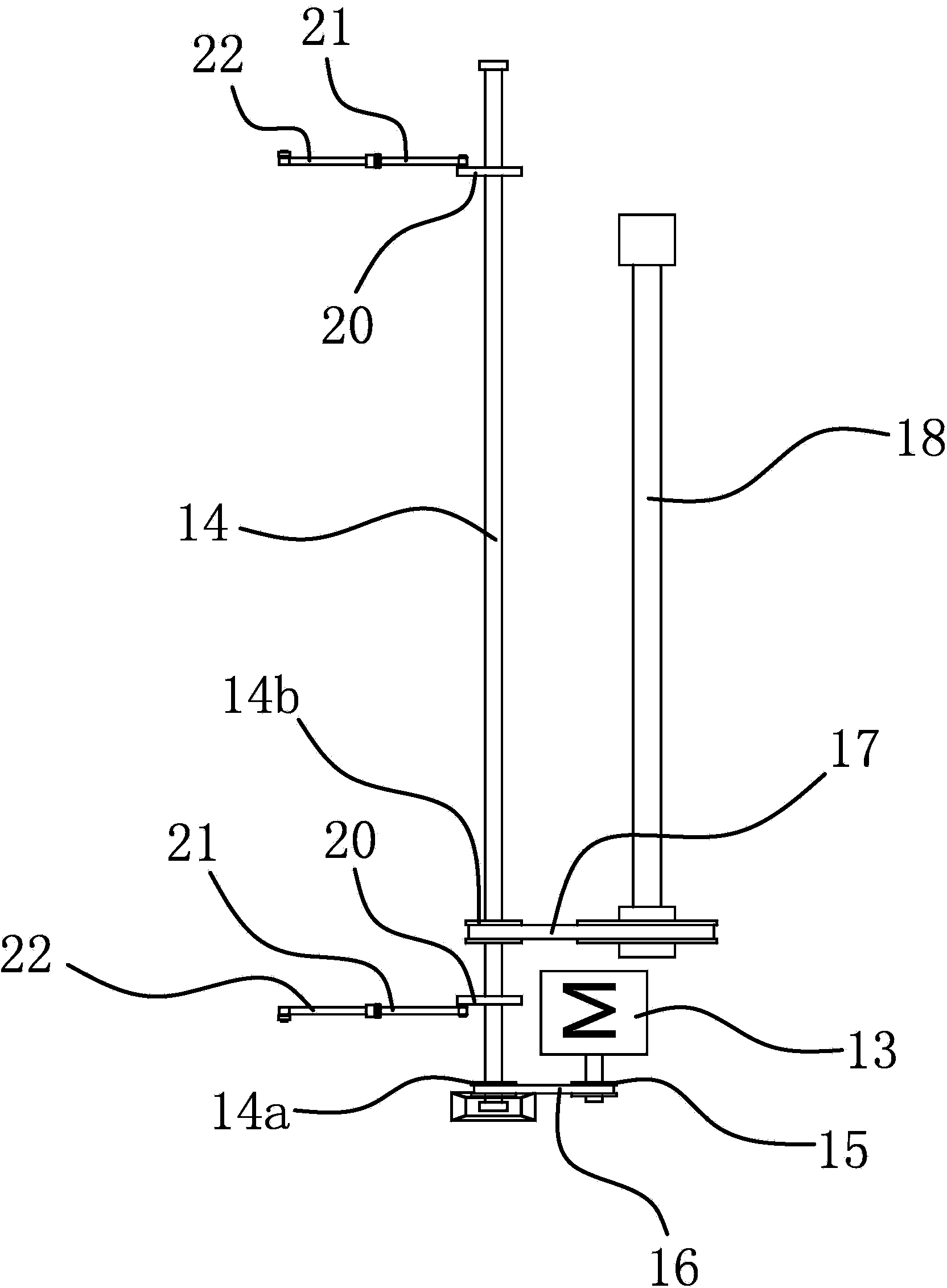

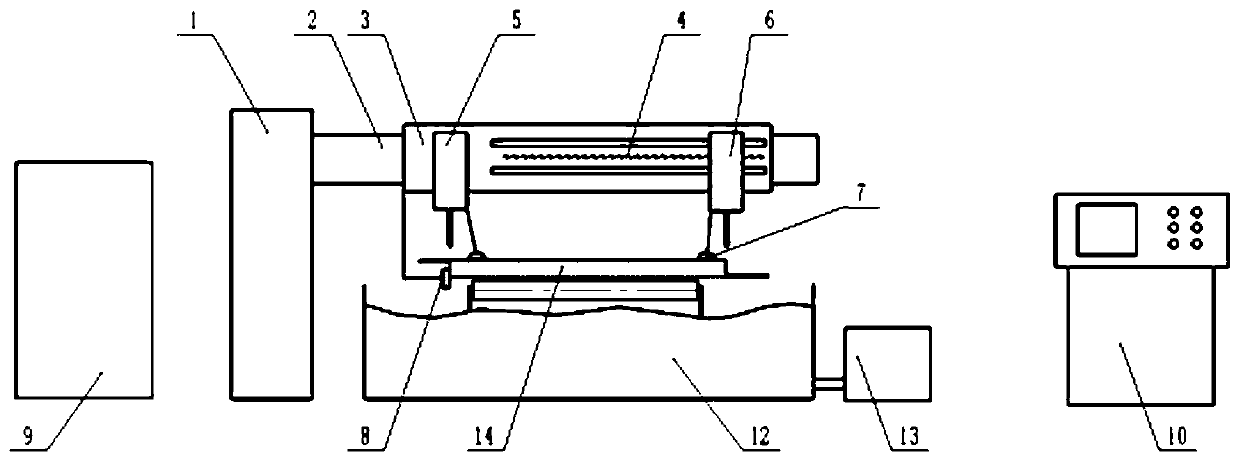

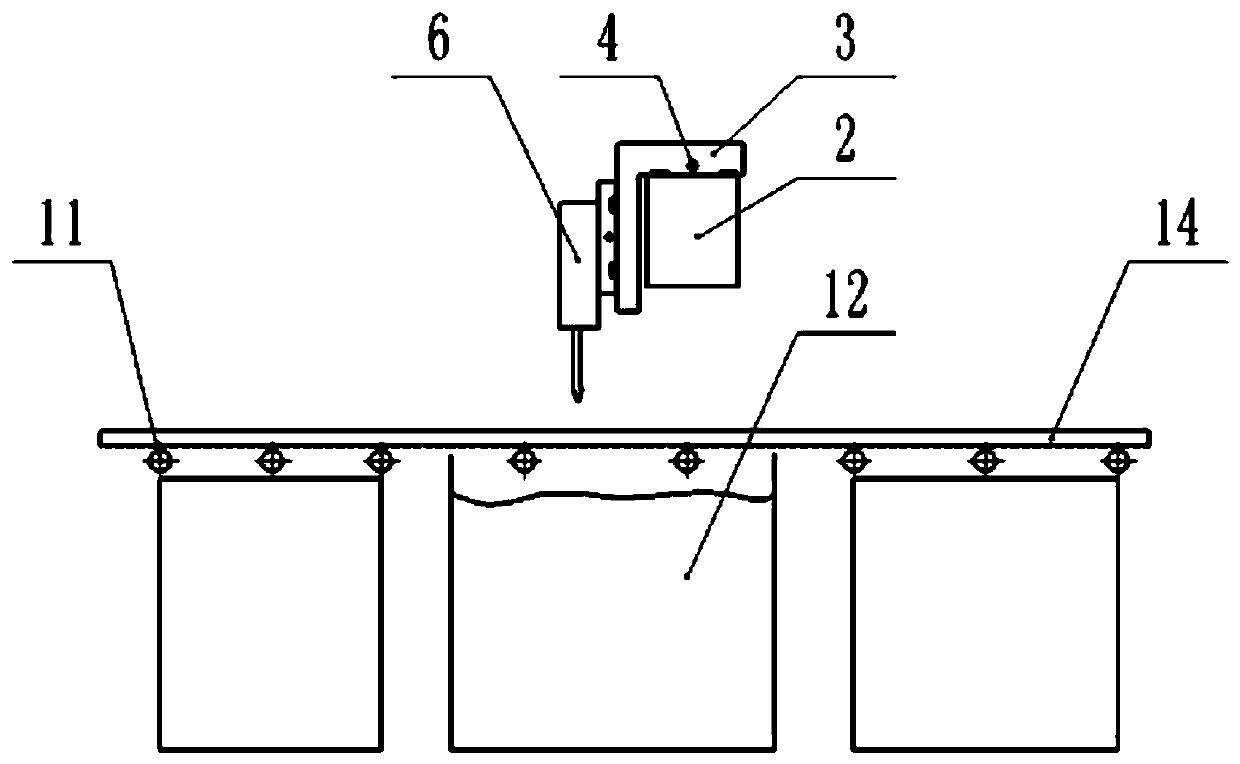

Electric spindle semi-active vibration control test stand, system and electric spindle control method

InactiveCN102853979AImprove vibrationVibrate in real timeMachine part testingVibration testingSemi activeMechanical models

The invention discloses an electric spindle semi-active vibration control test stand, a system and an electric spindle control method, wherein the electric spindle semi-active vibration control method comprises the following steps: through a processor, an electric spindle torsional coupled vibration signal is separated by using an experience modal decomposition and Hilbert transformation method so as to obtain a test frequency and a test phase; through an electric spindle intensive parameter equivalent mechanical model and the design parameter of the electric spindle system, the theory frequency and theory phase of the bending vibration and the torsional vibration of the electric spindle are obtained; through a force synchronizing vibration control model, the testing frequencies of the bending vibration and the torsional vibration of the electric spindle are combined, the test phase, the theory frequency and the theory phase are combined, so that a first pulse-width modulation (PWM) signal of a magneto-rheological absorber used for controlling the bending vibration and a second PWM signal of the magneto-rheological absorber used for controlling the torsional vibration are generated respectively. Therefore the bending vibration and the torsional vibration of the electric spindle can be synchronously controlled.

Owner:JIAXING UNIV

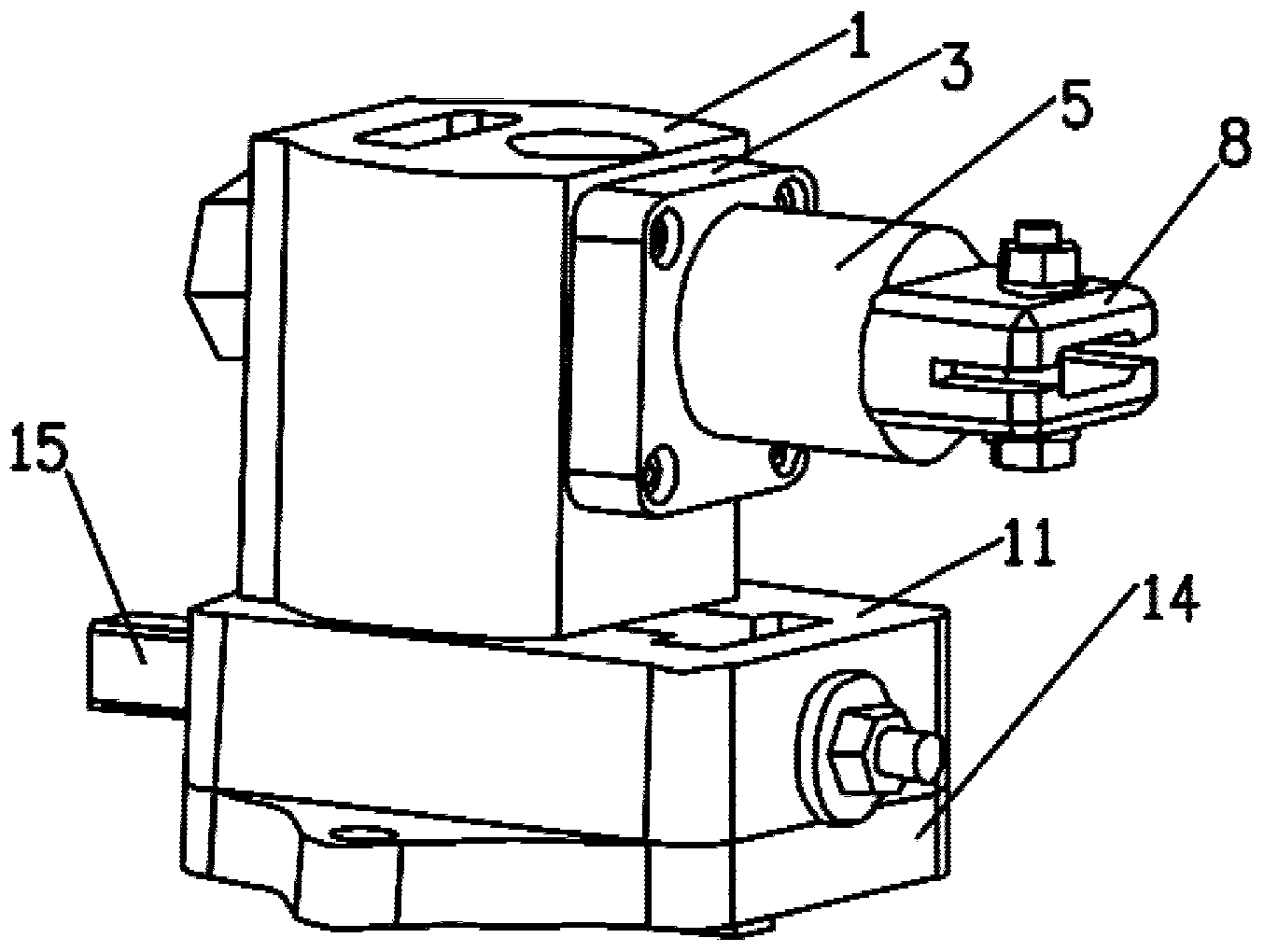

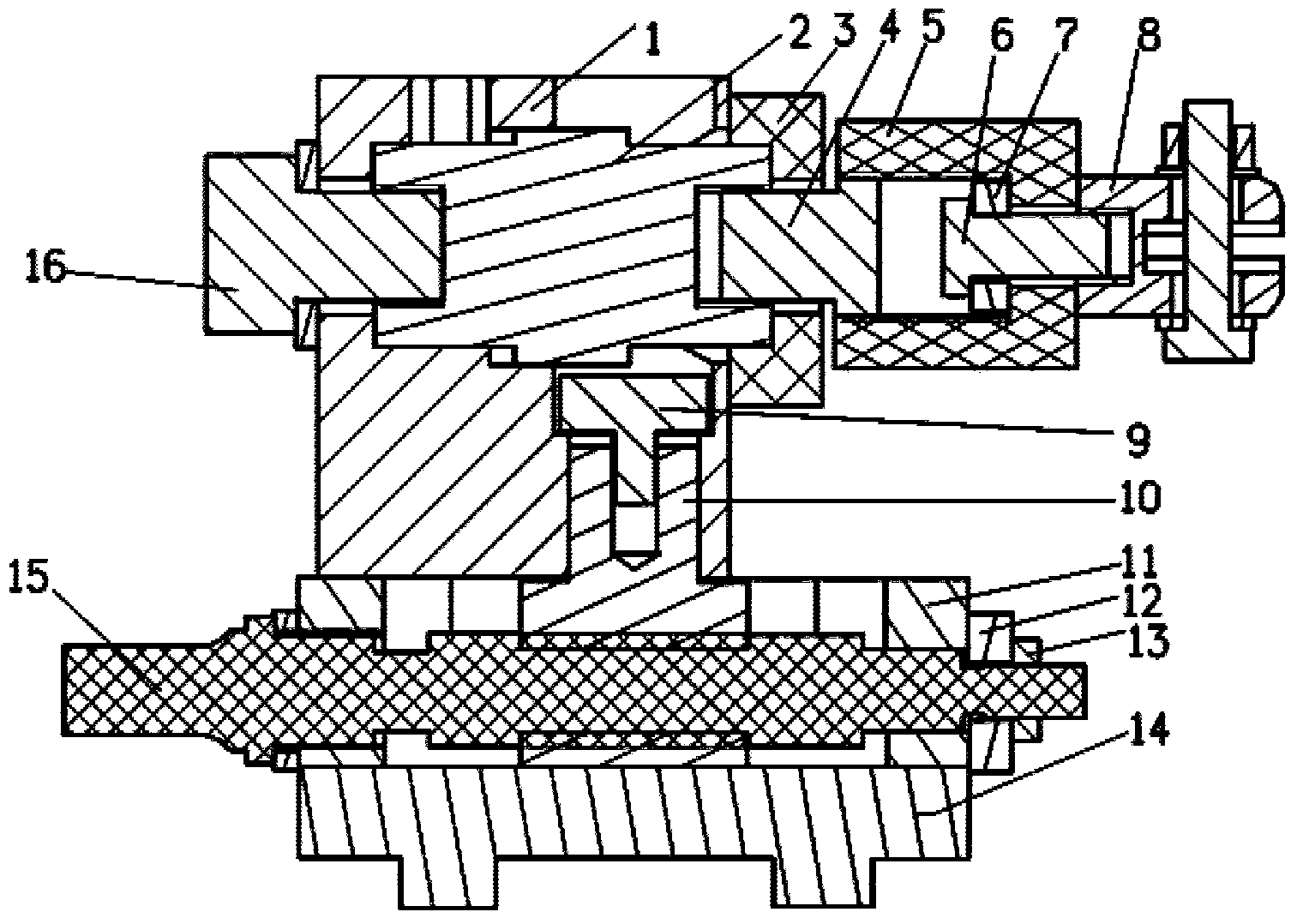

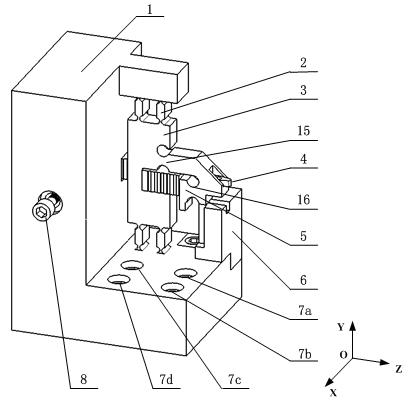

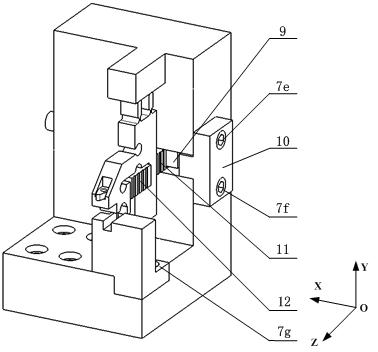

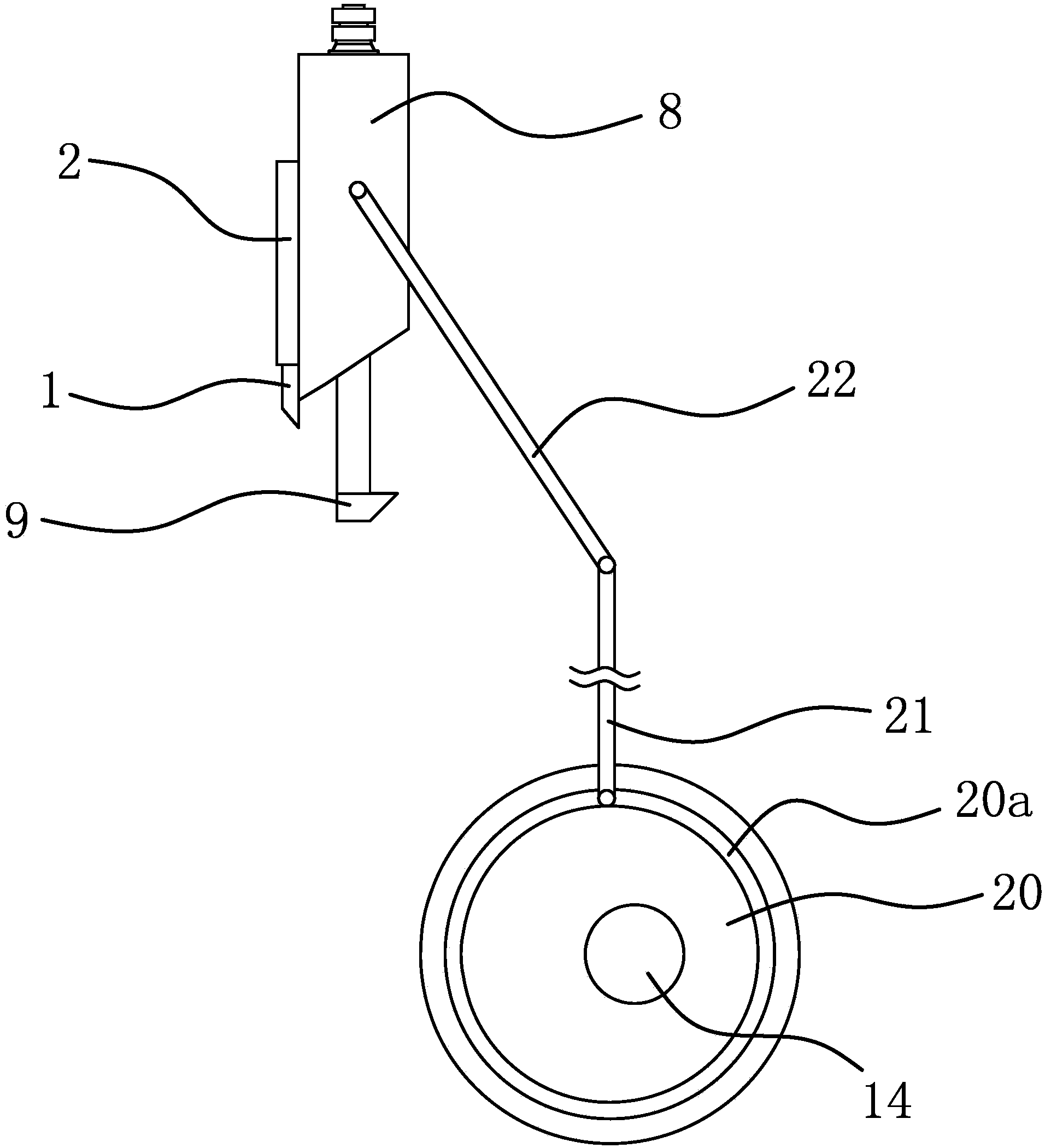

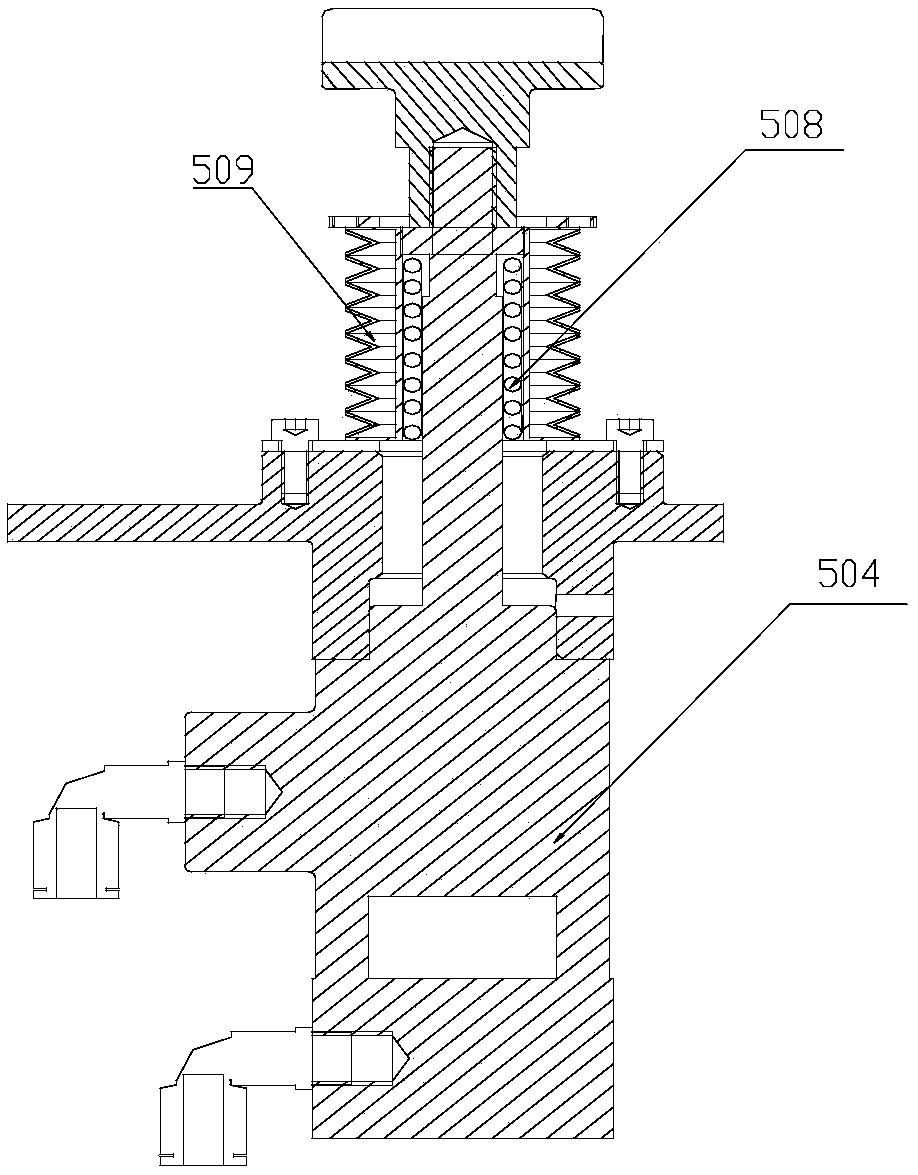

Special tension clamp for milling of blade type parts

InactiveCN103846706AReasonable structureReliable actionWork clamping meansMeasurement/indication equipmentsEngineeringMachine tool

The invention discloses a special tension clamp for milling of blade type parts. A tension sensor is arranged in a blade clamp and is used for accurately measuring the prestress on a blade, and the prestress on the blade is adjusted by a screw rod transmission mechanism, so the prestress can be accurately controlled during blade processing, the cutting stability is effectively improved, and the mechanical vibration of the cutting processing is reduced. A fixing clamp is arranged on a base, a movable measuring adjusting device is fixedly arranged on the fixing clamp, a clamping mechanism is arranged at the side surface of the movable measuring adjusting device, and a base is fixedly arranged on a worktable. A clamp head rotates around the center of a rotary indexing table of a machine tool, the tension sensor is connected with the clamp head through a connecting sleeve tube, and when a workpiece is clamped, the influence on the tension sensor by the rotation of the clamp head is avoided, and the measuring is convenient. The clamp has the advantages that the clamp is suitable for clamping and processing the blade type parts on a four-axis milling machine, the processing quality of the part surface is obviously improved, and the production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

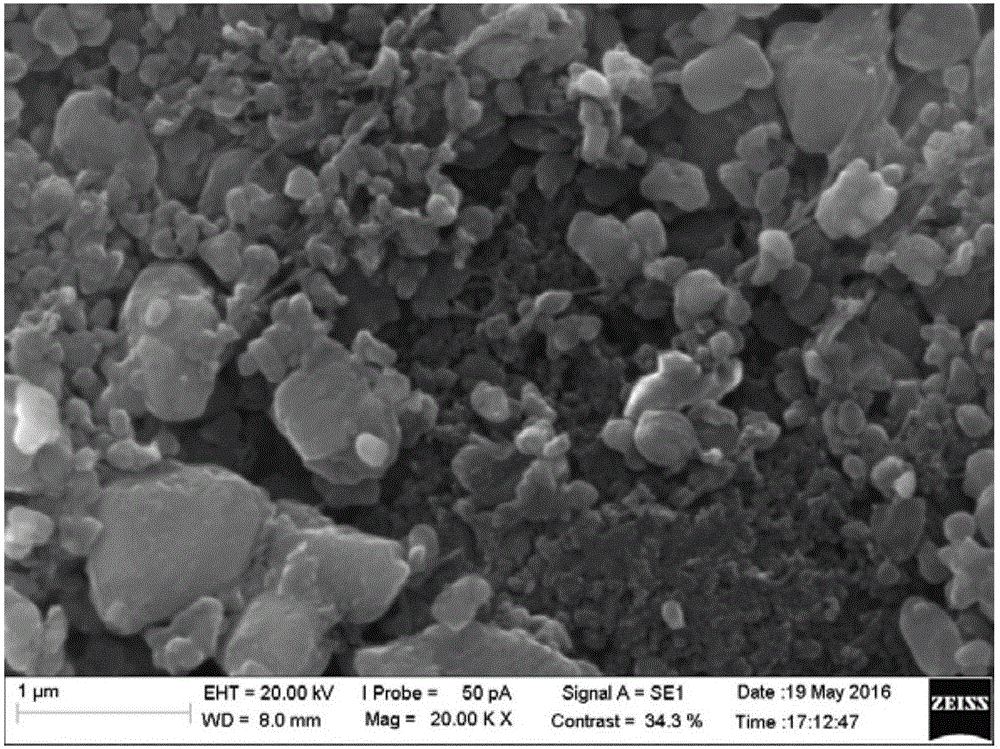

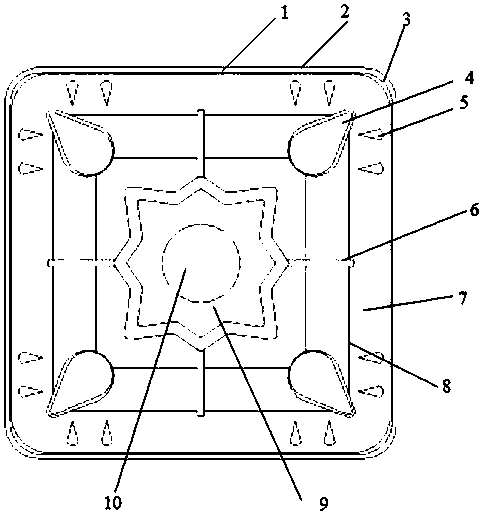

Ultra-thin resin dicing blade for QFN high-quality cutting and preparing method of ultra-thin resin dicing blade

ActiveCN106378714AHigh strengthExtend your lifeBonded abrasive wheelsGrinding devicesGraphiteUltimate tensile strength

The invention discloses an ultra-thin resin dicing blade for QFN high-quality cutting. Burdening of the ultra-thin resin dicing blade comprises a resin bond, diamond and inorganic filler, wherein the volume fraction of the diamond ranges from 12.5% to 30%, the grain size of the diamond ranges from 38 microns to 104 microns, and the volume fraction of the resin bond ranges from 35% to 55%. The inorganic filler is composed of silicon carbide, graphite and chromic oxide, the silicon carbide accounts for 6%-25% of the volume fraction of the total burdening, the graphite accounts for 3%-8% of the volume fraction of the total burdening, and the chromic oxide accounts for 5%-15% of the volume fraction of the total burdening. In the formula, the strength of the dicing blade can be greatly improved through the silicon carbide and the chromic oxide in the formula, meanwhile, the service life of the dicing blade is prolonged, a small amount of graphite is used for assistance, the self-sharpening capability of the blade can be improved, and good cutting quality and stability of the blade are kept. The invention further discloses a preparing method of the above dicing blade. The preparing method comprises the steps that raw materials are mixed through a wetting agent, and hot pressing, secondary curing and machining are conducted. The process is simple, the characters of the raw materials can be brought into full play, and the efficient, high-quality and ultra-thin resin dicing blade suitable for QFN cutting is prepared.

Owner:苏州赛尔科技有限公司

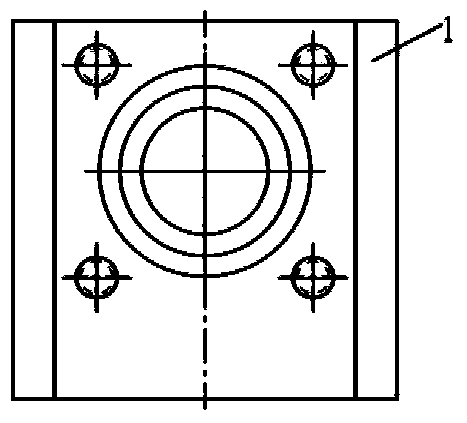

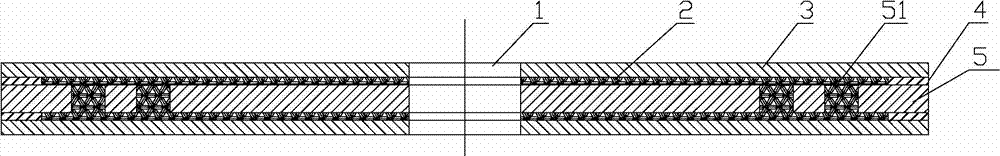

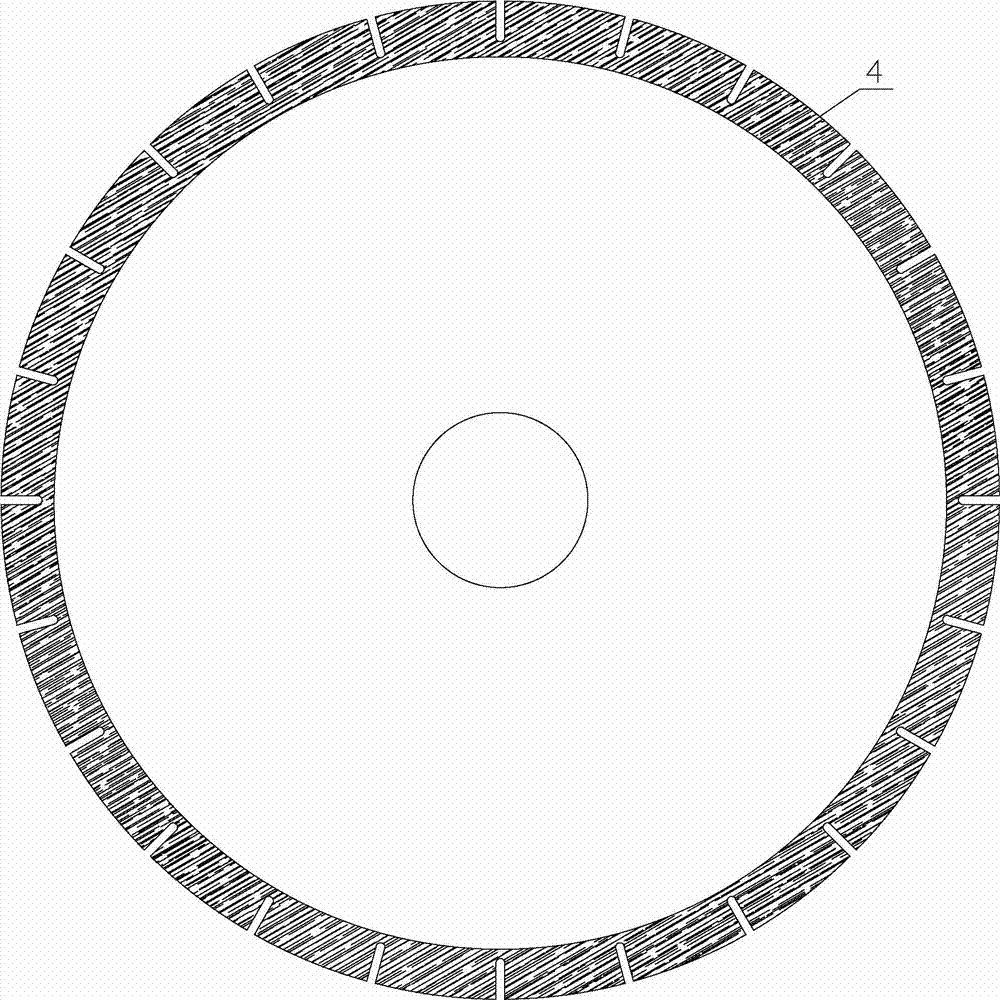

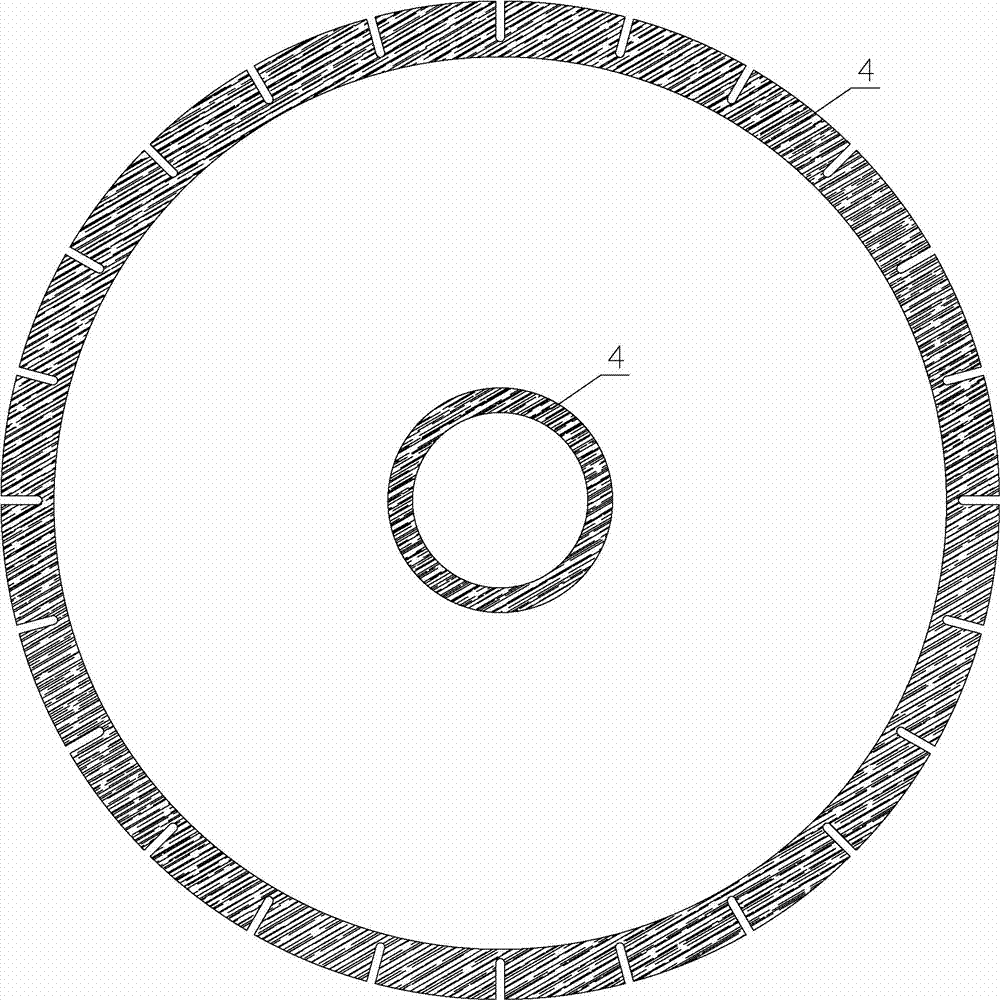

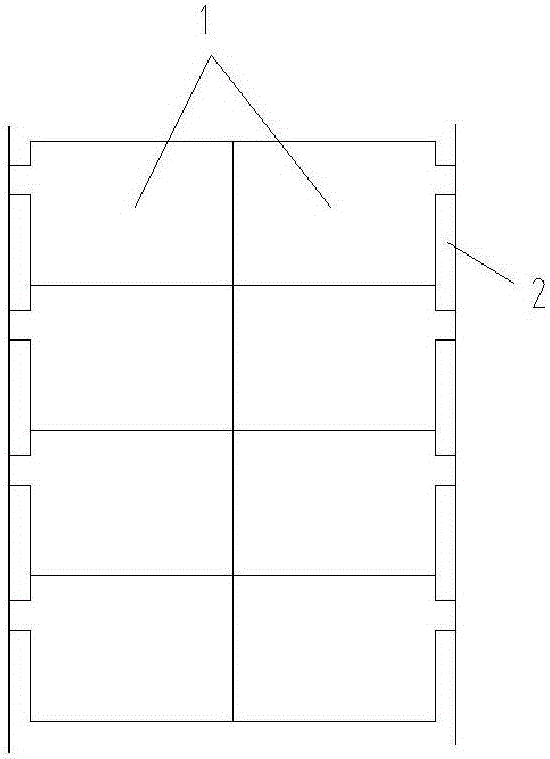

Adhesive composite silencing saw blade primary structure

An adhesive composite silencing saw blade primary structure comprises a saw blade primary structure body, wherein a center hole is formed in the center of the saw blade primary structure body, and the saw blade primary structure body is formed by bonding a plurality of layers of metal plates through adhesive layers. There are three layers of metal plates, and the thickness of the middle layer of metal plate is larger than the thickness of the outer layer primary structure body. A welding layer is further arranged in the adhesive layers. According to the adhesive composite silencing saw blade primary structure, the composite structure formed by bonding the multiple layers of metal plates is adopted for making the saw blade primary structure body have good strength, rigidity and plasticity, and therefore on the one hand, cutting deflection can be effectively reduced, and on the other hand, self-absorbing and buffer performance of cutting vibration can be improved. The arranged adhesive layers serve as damping medium layers to effectively reduce vibration generated in the saw cutting process and lower noise generated in the saw cutting process.

Owner:HEIXUANFENG SAW IND

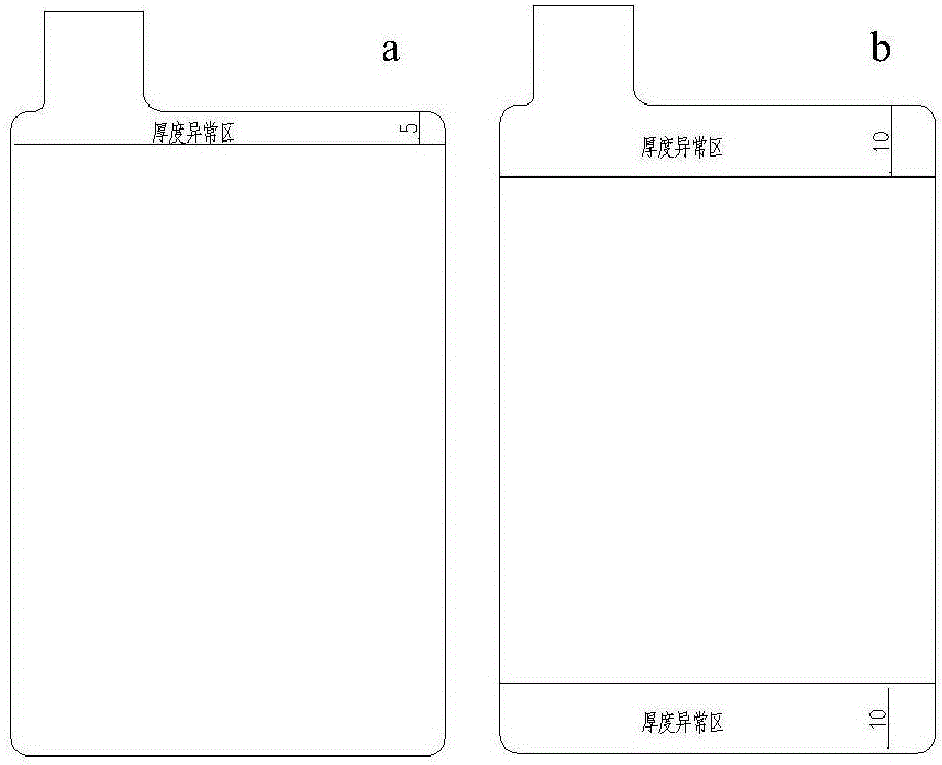

Preparation method of water system laminated type lithium-ion battery pole piece

ActiveCN106129326AQuality assuranceConsistent densityElectrode rolling/calenderingElectrode collector coatingMeasuring instrumentEngineering

The invention discloses a preparation method of a water system laminated type lithium-ion battery pole piece and belongs to the technical field of production of lithium-ion batteries. The method has the following advantages that (1) continuous coating is realized, the coating efficiency is improved, the range of a coating thickness abnormal region is reduced and the coating thickness is monitored online; (2) continuous roll pressing is realized, the roll pressing efficiency is improved, a roll pressing thickness is monitored online and frequent vibration loss of a roll pressing machine is alleviated; (3) the thicknesses of cut regions are the same in a cutting process, the cutting defects are small and the stability is good; (4) the slicing efficiency can be improved by utilizing high-speed slicing equipment, surface defects of the pole piece can be monitored online by utilizing a CCD (Charge Coupled Device) image measuring instrument and NG pole pieces are eliminated; and (5) the waste of raw material left overs is reduced and the utilization rate of positive and negative electrode foils and positive and negative electrode materials is improved.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

Live axle tunneling/turning method and device

InactiveCN102179530ARealize high-precision trackingLarge asymmetryAutomatic control devicesFeeding apparatusReciprocating motionEngineering

The invention provides a live axle tunneling / turning method and device, which belong to the field of ultraprecise cutting and complicated curved surface cutting. The method comprises the following steps: clamping a workpiece at the front end of a main shaft of an ultraprecise numerically-controlled lathe; arranging a live axle tunneling / turning device on an X-axis slide carriage or Z-axis slide carriage; and carrying out active control on the drive signals of two live axles of the live axle tunneling / turning device, thus synchronously forming a rapid tool reciprocating motion required for theturning generation of free curved surfaces and a rapid tool tunneling / turning motion required for realizing the cutting of materials difficult to machine. Because of having multi-element varying-parameter cutting characteristics, the invention can efficiently realize the high-quality generation of complicated curved surfaces of materials difficult to machine.

Owner:JILIN UNIV

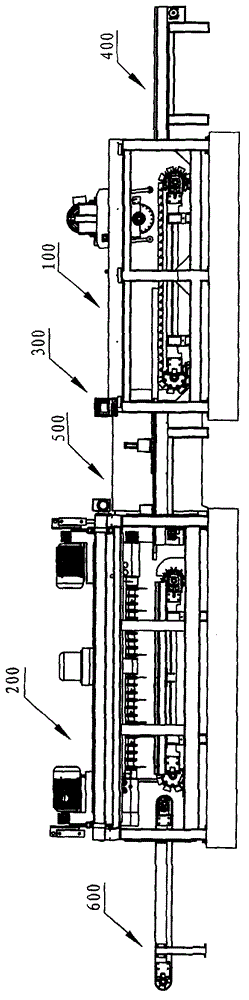

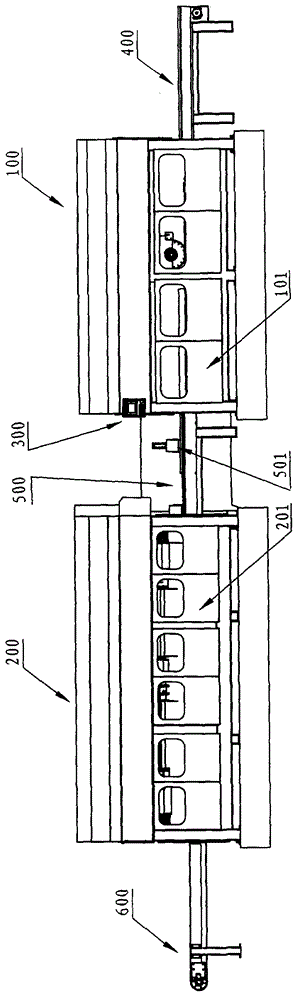

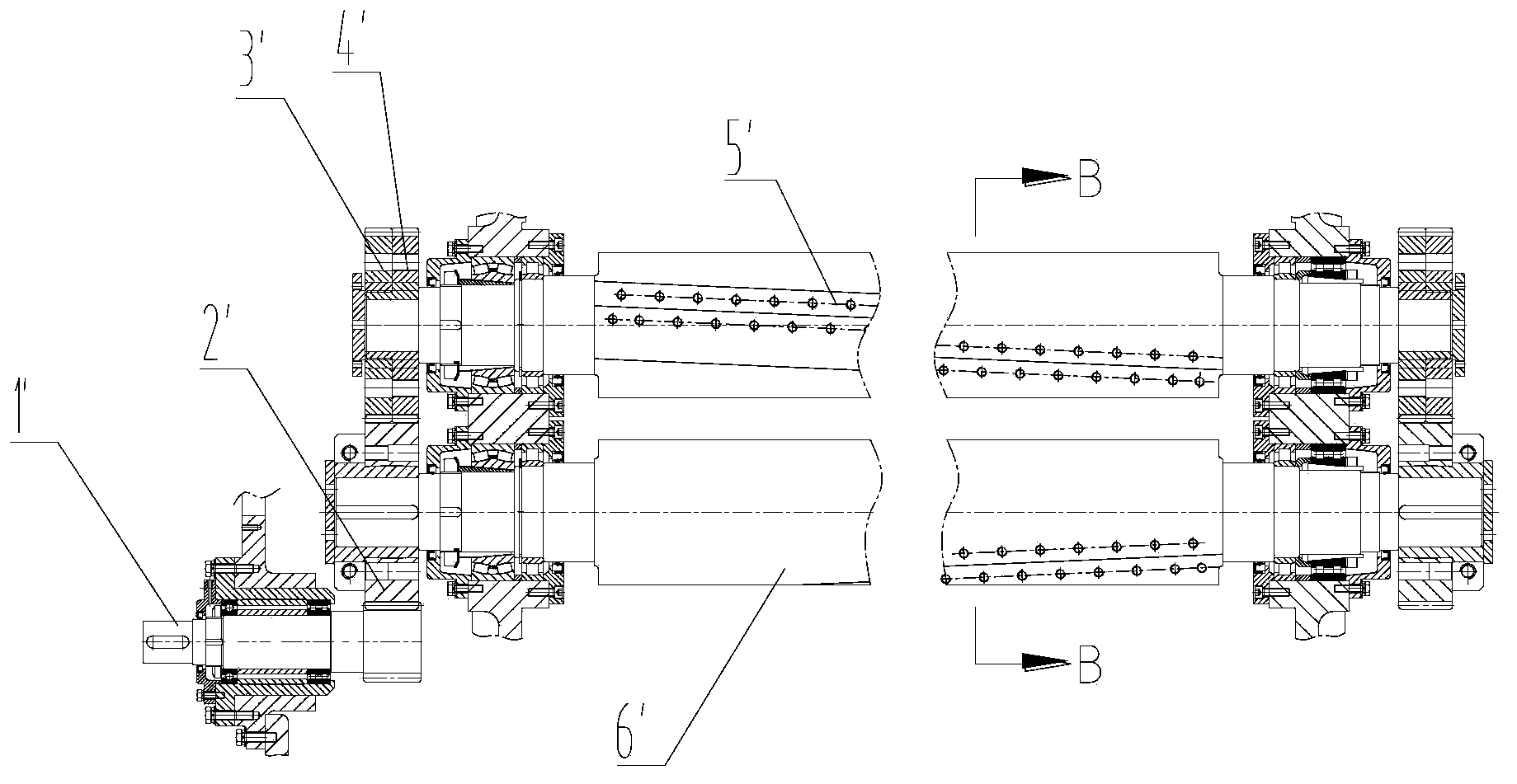

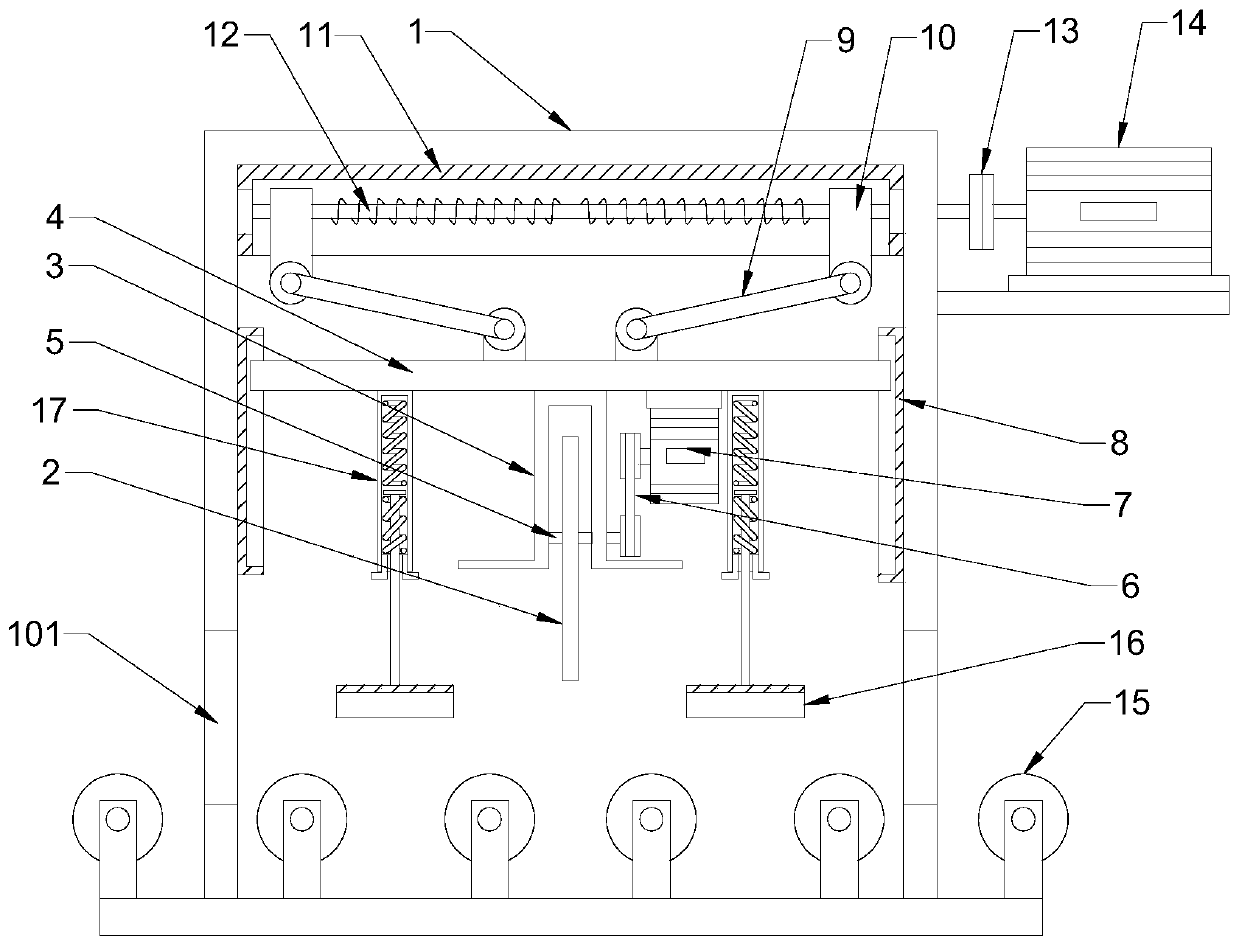

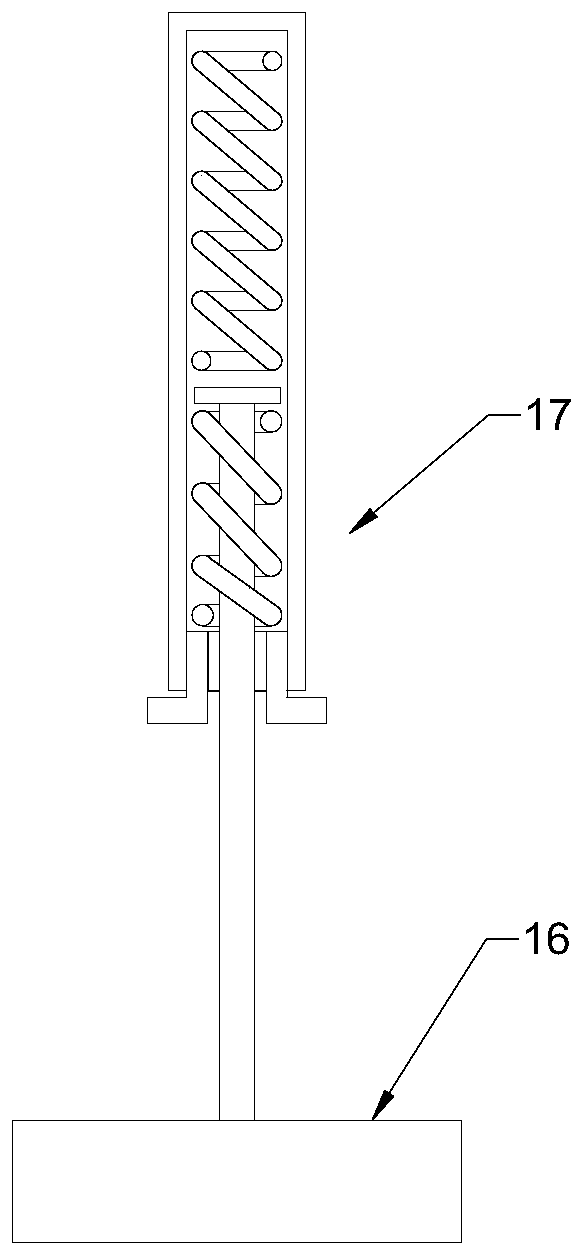

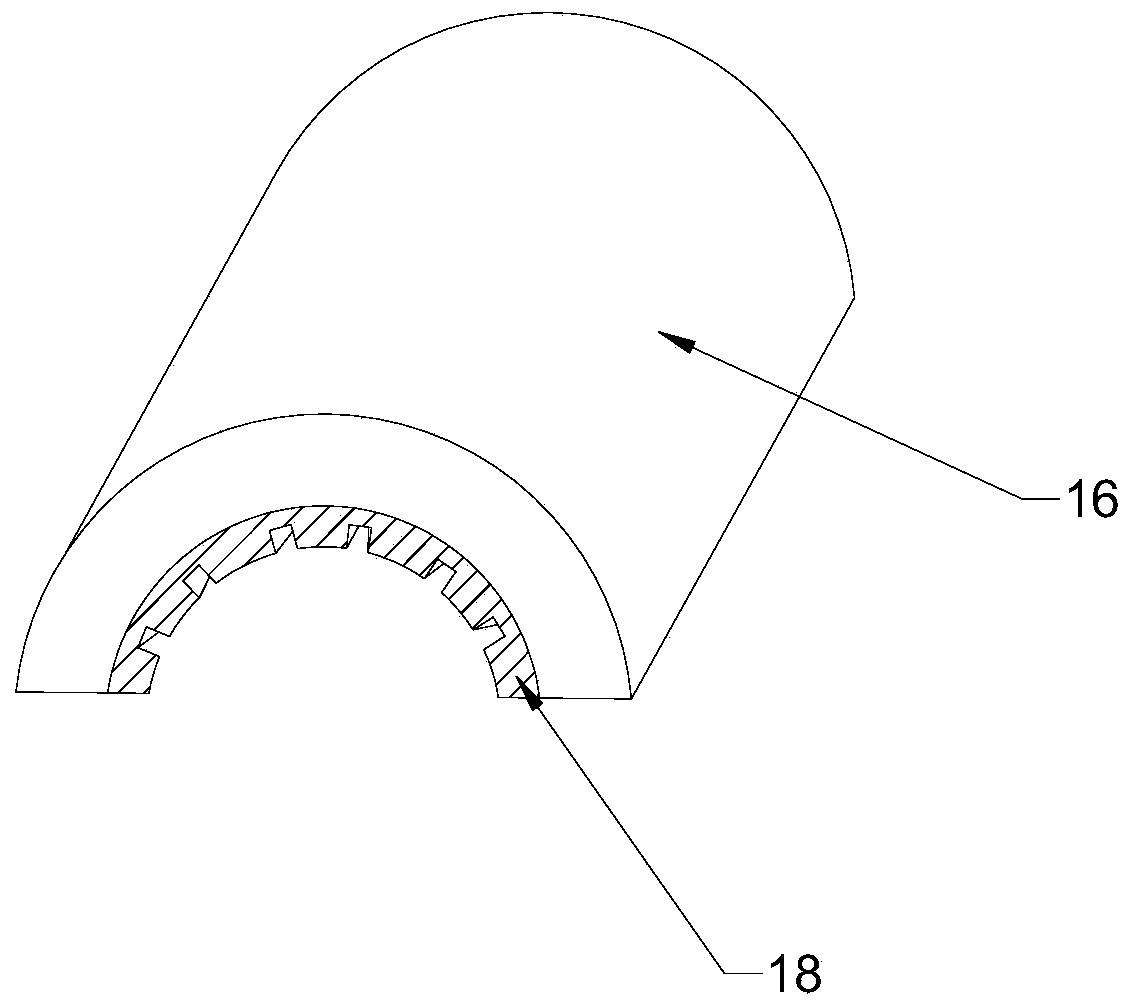

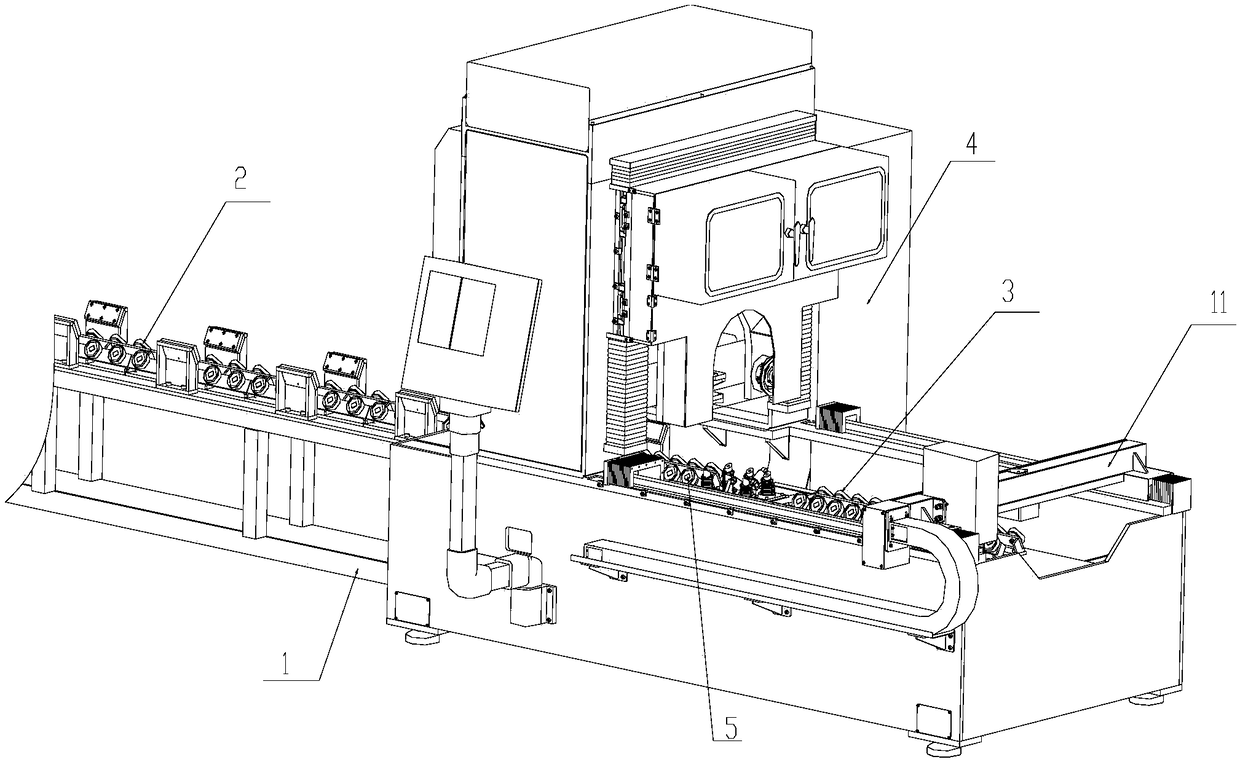

Numerical control stone multi-plate continuous cutting assembly line

ActiveCN102717442ASave human effortHigh degree of automationWorking accessoriesStone-like material working toolsElectric machineReciprocating motion

The invention discloses a numerical control stone multi-plate continuous cutting assembly line, which comprises a numerical control system, and a feeding workbench, a longitudinal cutter I, a transition workbench, a transverse cutter II and a discharging workbench which are arranged in movement direction of a stone plate in sequence, wherein the transverse cutter II comprises a transverse multi-blade saw set II, a machine workbench II, a hydraulic lifting system, a cross beam transverse reciprocating motion driving mechanism and a positioning device; machine saw blade shafts II in the II transverse multi-blade saw set are two saw blade shafts which are arranged along the same axis and are driven by a motor respectively; a connection structure is arranged between the inner ends of the two saw blade shafts; and the outer ends of the two saw blade shafts are provided with a locking structure respectively. According to the numerical control stone multi-plate continuous cutting assembly line, an entire piece of stone plate which meets the thickness requirement can be automatically and continuously cut into a plurality of rectangular plates of a required size, so that the numerical control stone multi-plate continuous cutting assembly line has the advantages of high automation degree, low labor intensity, high cutting efficiency, long service life, low production cost and the like.

Owner:LAIZHOU FULIN MACHINERY

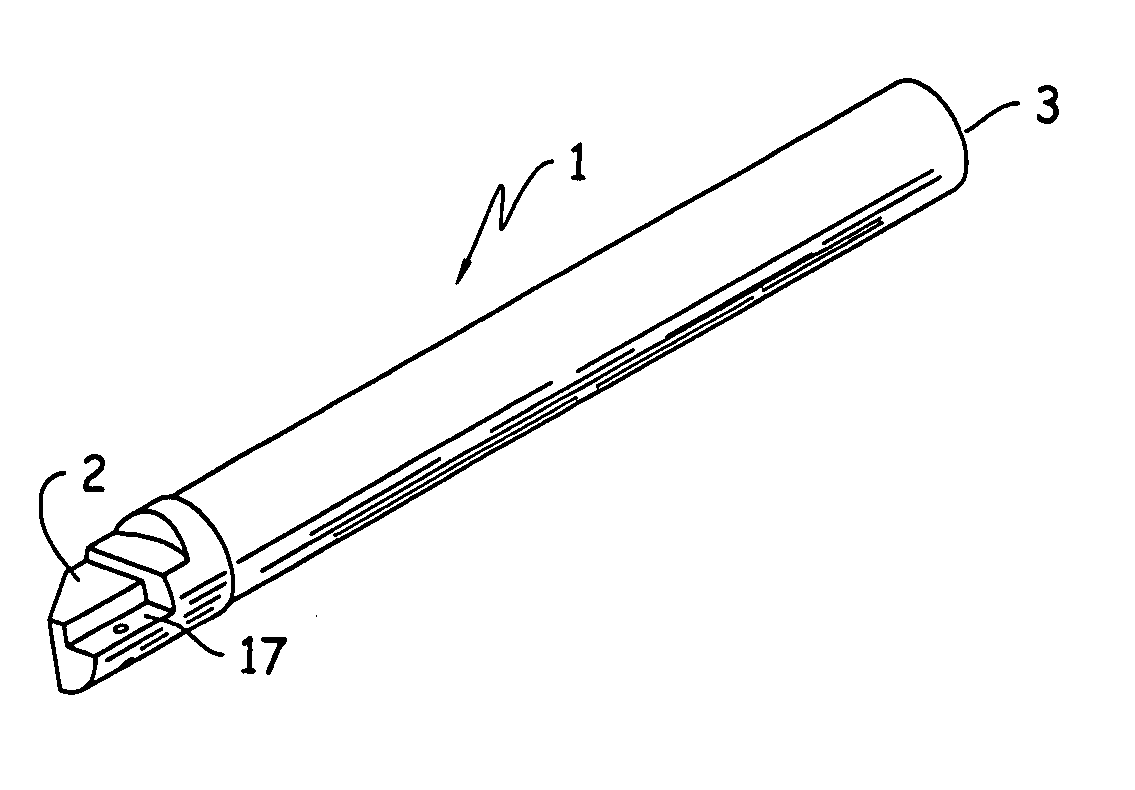

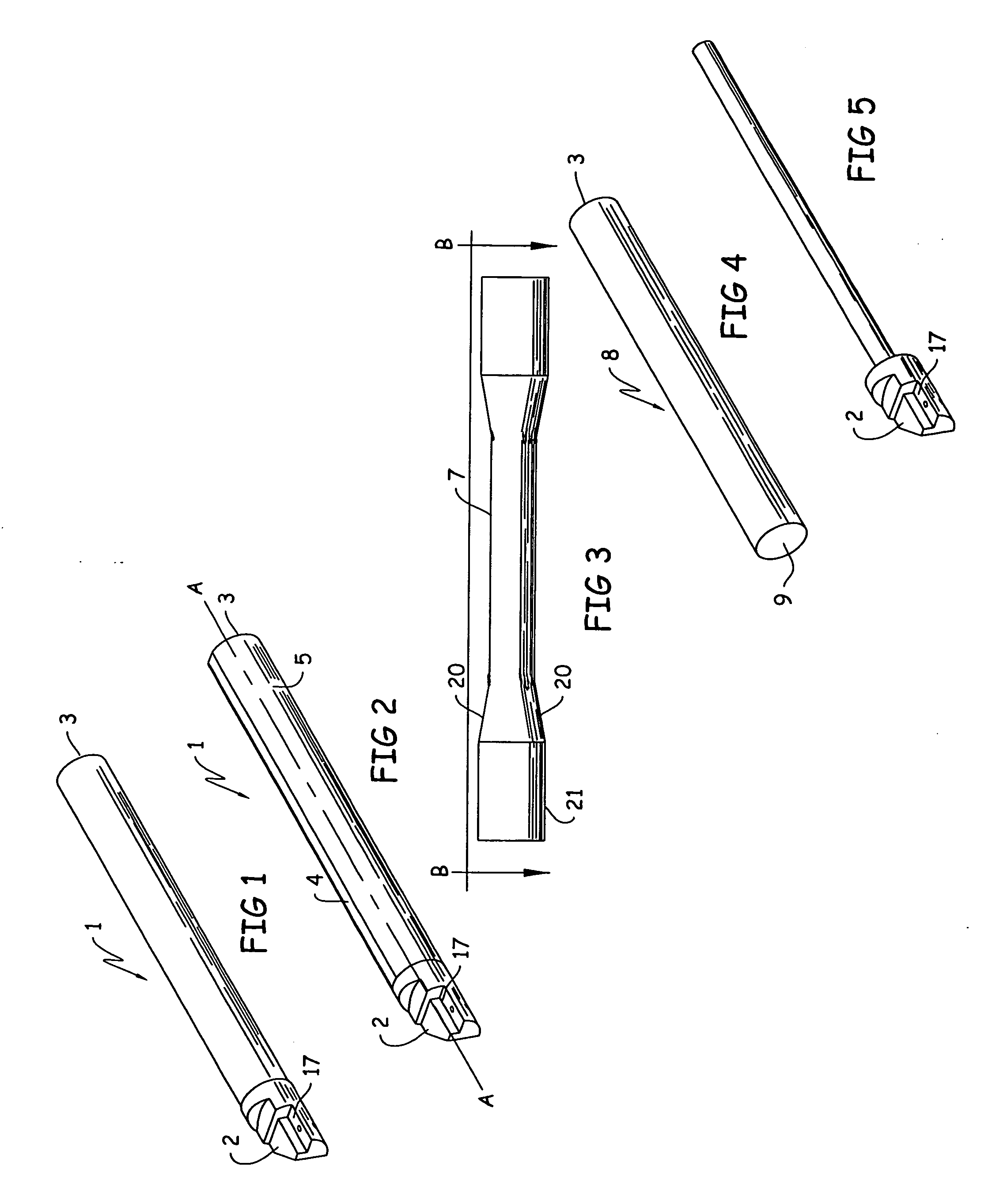

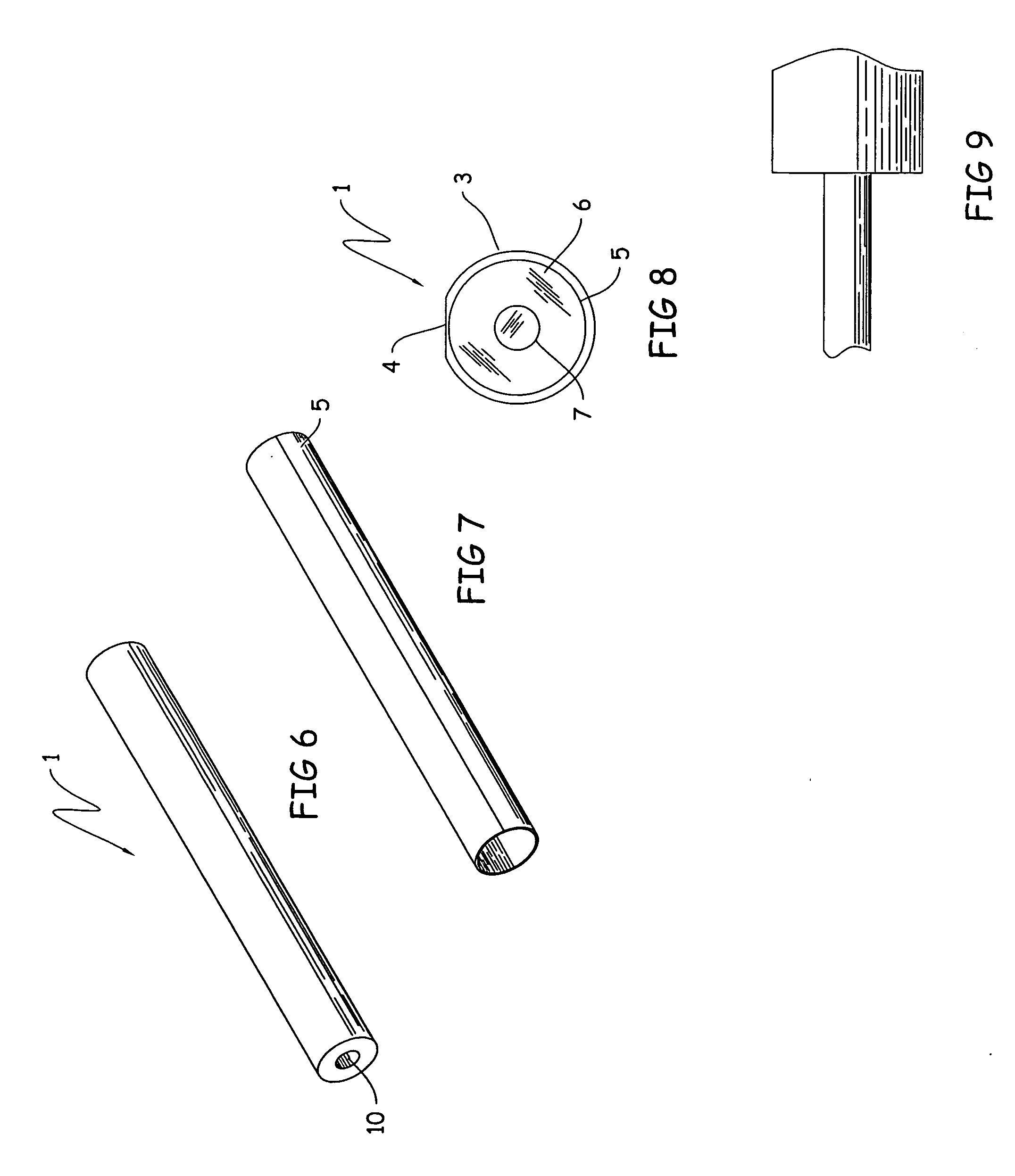

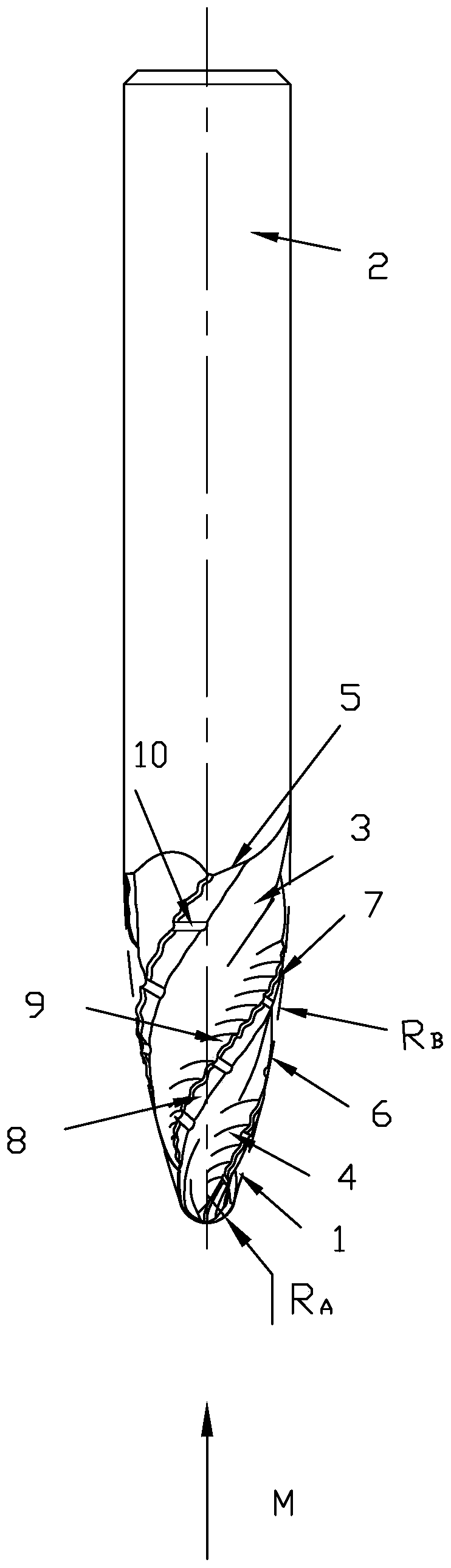

Novel composite tool holders and boring tools

InactiveUS20080292418A1Eliminate the effects ofIncrease the angleThread cutting machinesSynthetic resin layered productsSurface finishHigh density

Tool bars that are manufactured as a composite, that is, layered devices. The tool bars can have a solid core, covered with a wrapped composite material, and then optionally covered with a metal sleeve. The tool bars are provided with high strength, improved stiffness over prior art tool bars, high density, low coefficient of thermal expansion, high damping capacity, improved rigidity, improved damping, less chatter and vibration, improved work piece tolerance, improved surface finish, increased speed / fee rates, and low production cost.

Owner:KAY DONALD ELWOOD

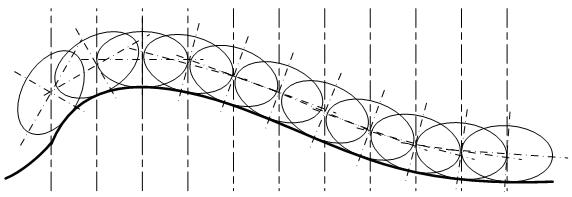

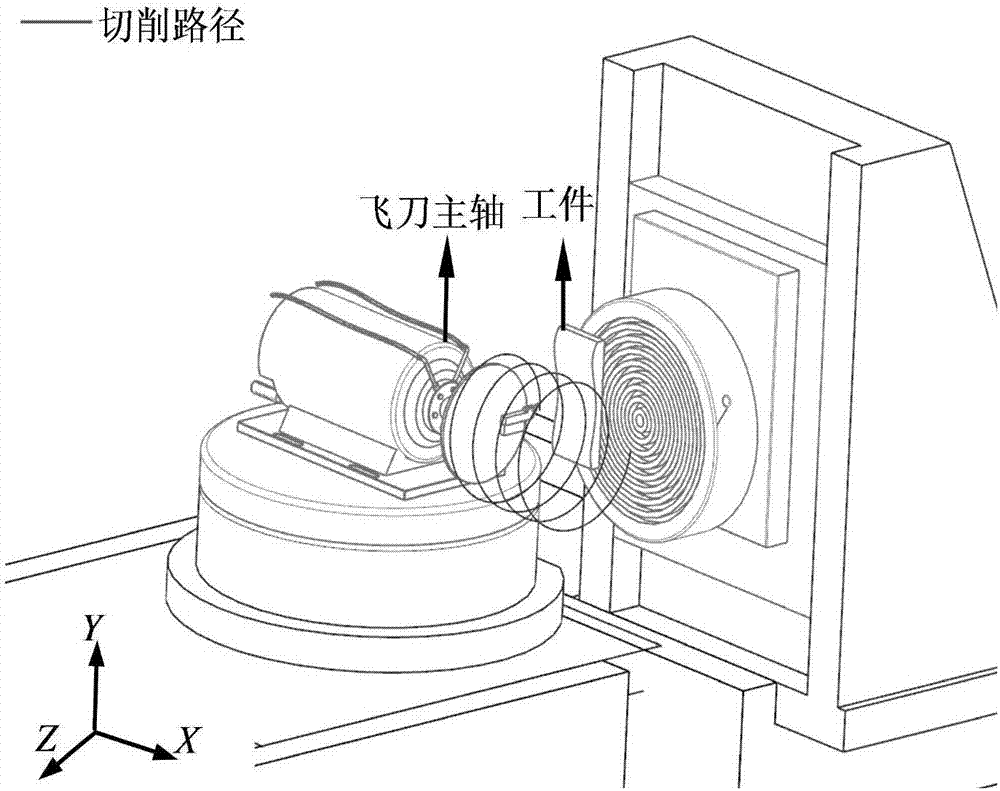

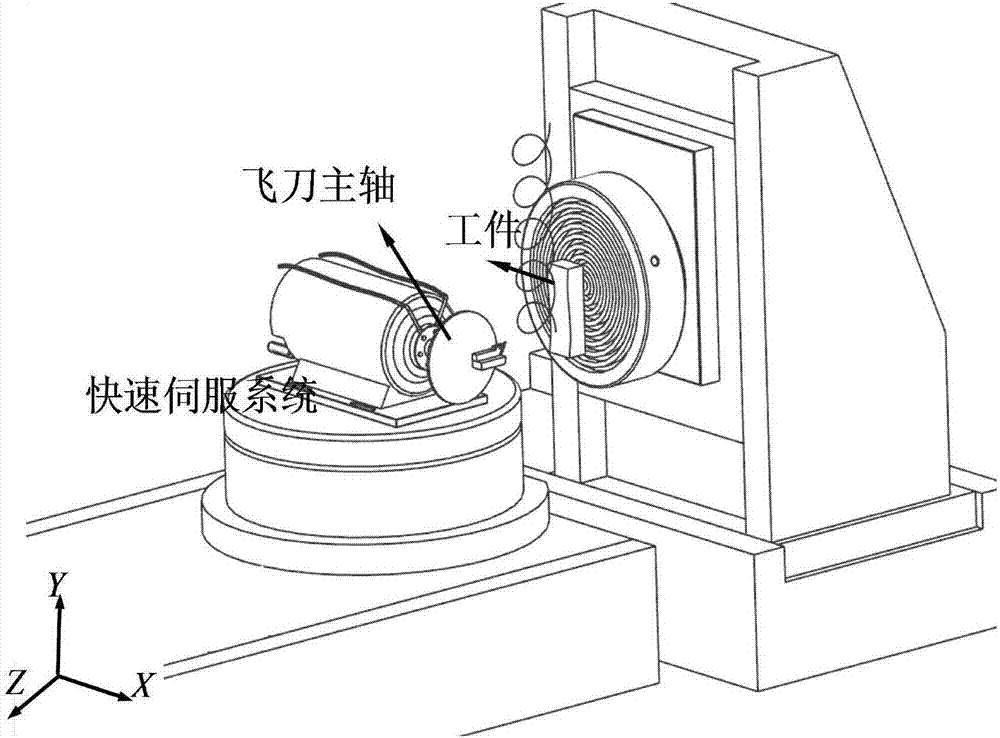

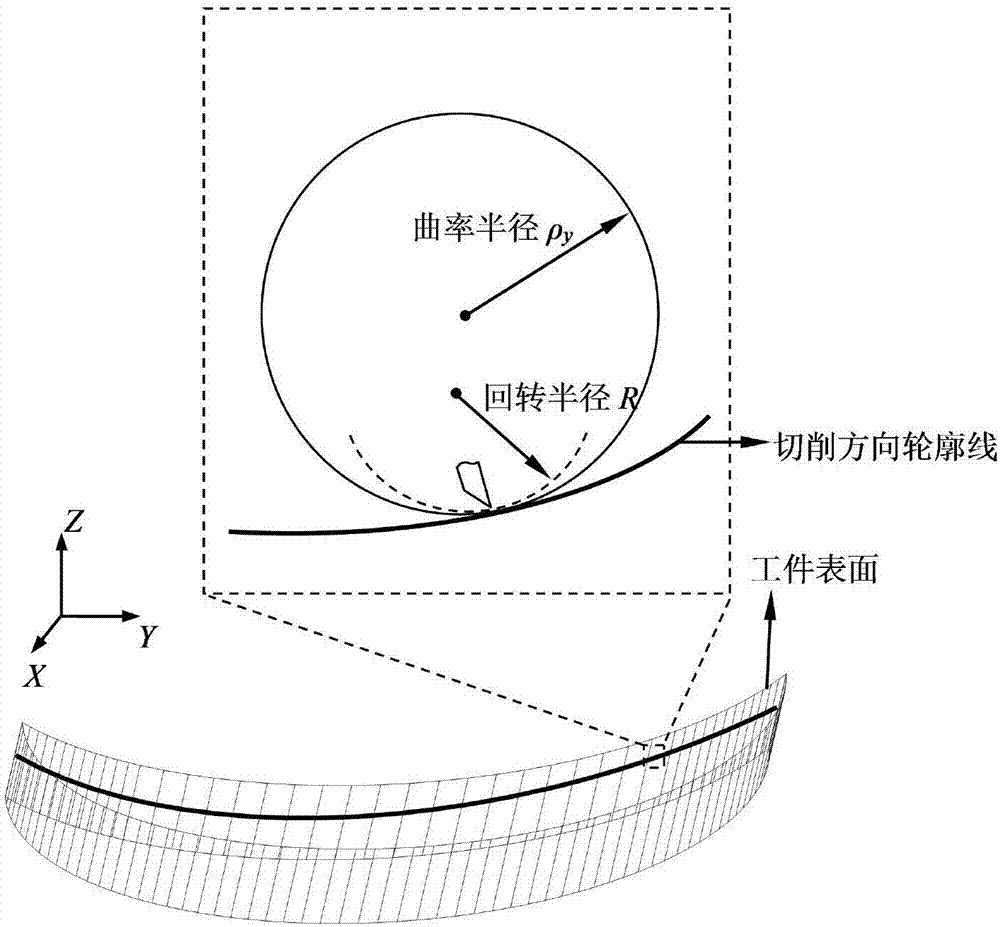

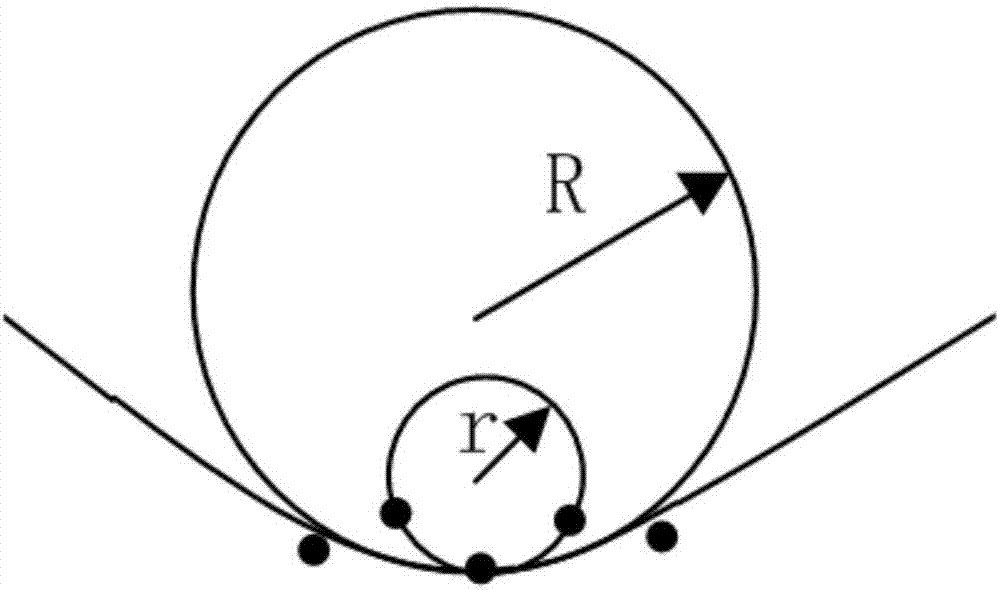

Processing method of complicated curve surface of fragile material

ActiveCN107116707AIncrease the frequency of intermittent cuttingReduced single-cut removalWorking accessoriesFine working devicesEngineeringMachining process

The invention relates to a processing method of a complicated curve surface of a fragile material. The processing method comprises the steps that according to the shape of a surface to be processed, an appropriate fly cutter spindle turning radius and an appropriate milling feeding direction, and a fly cuter turning spindle can be selected to be parallel to the milling feeding direction or perpendicular to the milling feeding direction; according to the processing process characteristics and the cutting characteristics of a material, appropriate cutting parameters and appropriate cutting tool geometric parameters are design so as to guarantee that the removal amount of the material in single-pass cutting is controlled within a plastic removal rang; based on the cutting parameters and the cutting tool geometric parameters, a processing path of fly cutter cutting and milling feeding is generated, and path compensation is conducted before processing, and after compensation, the contour of a cutting tool traverses the path to form a processed surface; a workpiece to be processed is mounted on a spindle of an ultra-precision machine tool, and a fly cutter is perpendicularly mounted on an ultra-precision milling shaft; and the workpiece is processed.

Owner:TIANJIN UNIV

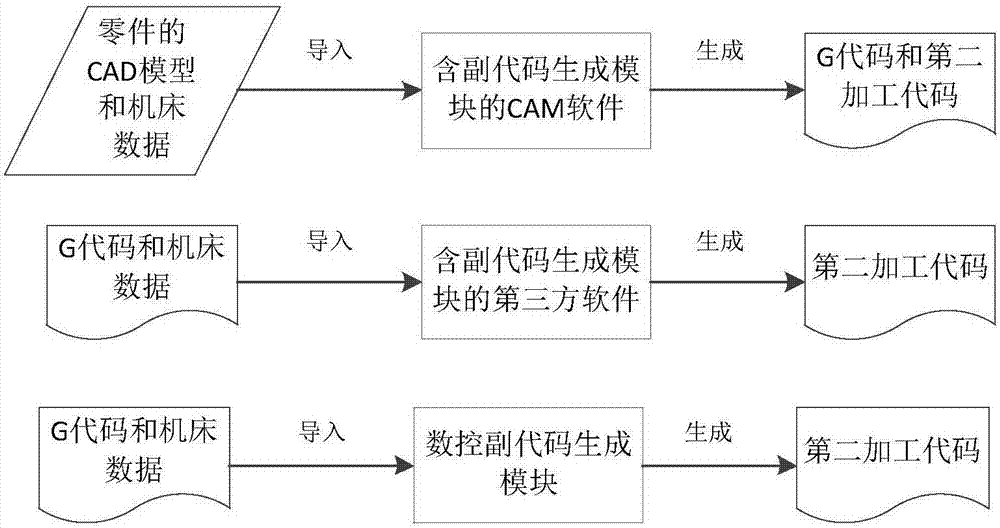

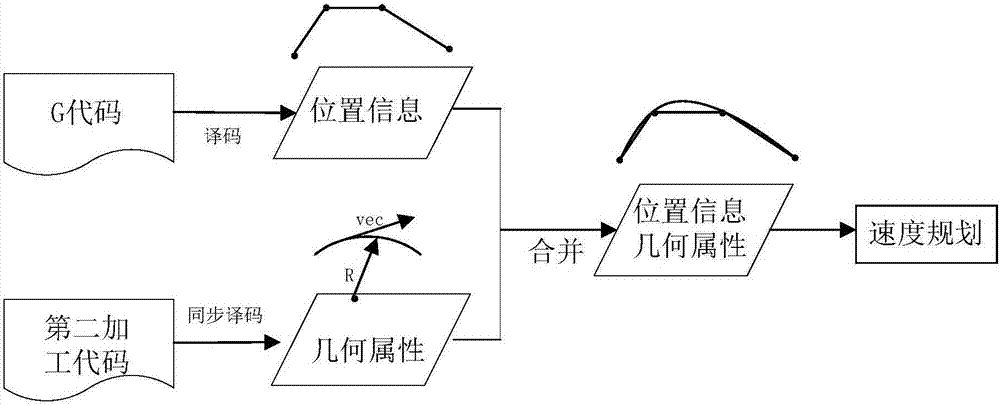

Double-code joint effect-based numerical control machining method

The invention belongs to the numerical control machining technical field and discloses a double-code joint effect-based numerical control machining method. The method includes the following steps that: (1) the geometric feature information of tool paths is calculated according to G codes in a numerical control machining preparation stage or offline process, so that second machining codes can be generated; (2) in a pre-machining code loading stage, a numerical control system loads the G codes and the second machining codes simultaneously; and (3) in a machining operation stage, the numerical control system synchronously analyzes the location information of the G codes and the geometric feature information of a tool path matched with the location information of the G codes in the second machining codes, and merges the geometric feature information of the tool path into a procedure data structure which is generated through analyzing the G codes, so that the speed and acceleration control of a machining process can be optimized. With the double-code joint effect-based numerical control machining method adopted, the motion control performance of the numerical control system can be improved without increasing costs, and quality and efficiency can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

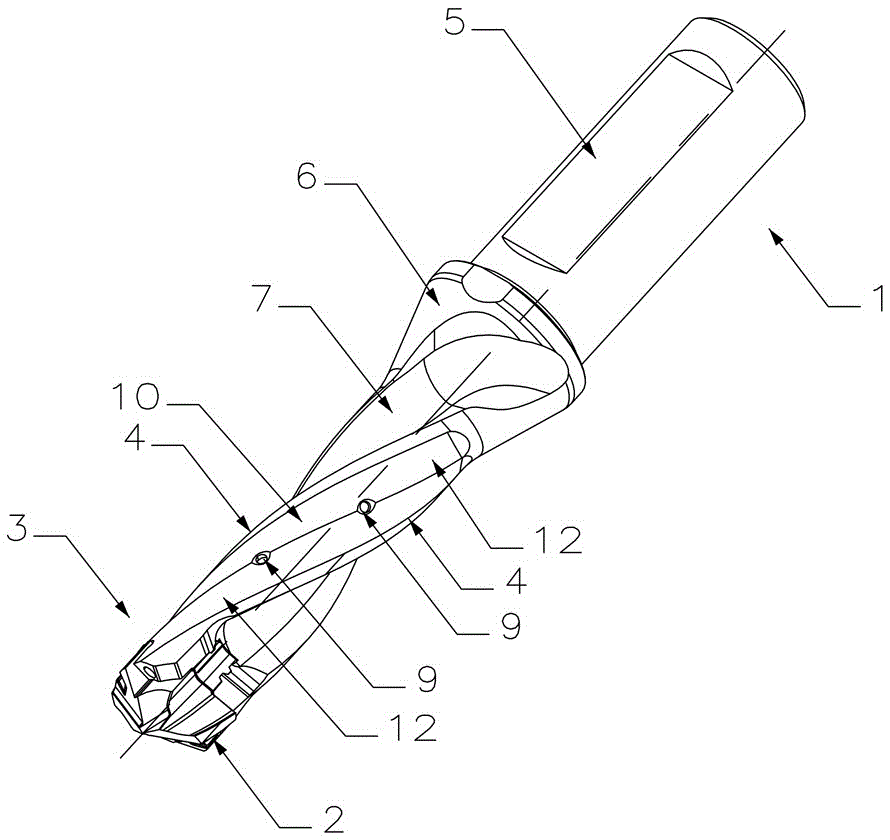

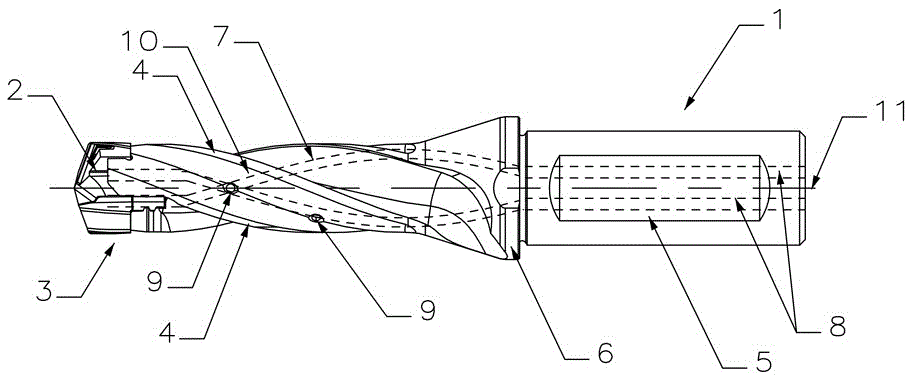

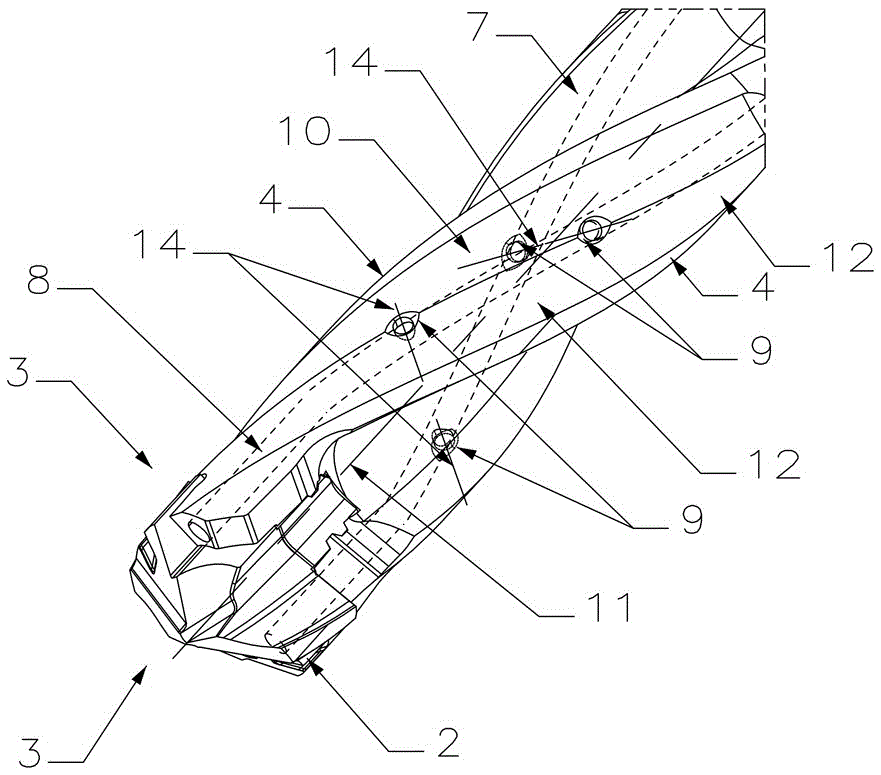

High-precision drill bit

ActiveCN105522200AImprove processing efficiencyImprove surface finish qualityTransportation and packagingTwist drillsMachined surfaceKnife blades

The invention discloses a high-precision drill bit, comprising a tool body and cutting blades; the tool body is composed of a shank portion, a cutting end portion and a peripheral surface located between the shank portion and the cutting end portion; the cutting blades are located on the cutting end portion; a cooling channel penetrating from the shank portion to the cutting end portion is formed in the tool body; a chip pocket for removing chips is formed in the peripheral surface; shaft guiding bar groups are arranged at positions, corresponding to every cutting blades, on the peripheral surfaces; each shaft guiding bar group comprises at least two shaft guiding bars; every two adjacent shaft guiding bars in each shaft guiding bar group, the peripheral surface and a surface machined define a sealing region; at least one communicating hole is formed in each part, between every two adjacent shaft guiding bars in each shaft guiding bar group, of the peripheral surface; and each communicating hole communicates with the cooling channel. The high-precision drill bit has the characteristics of low circumferential stress on each shaft guiding bar, high precision and long service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

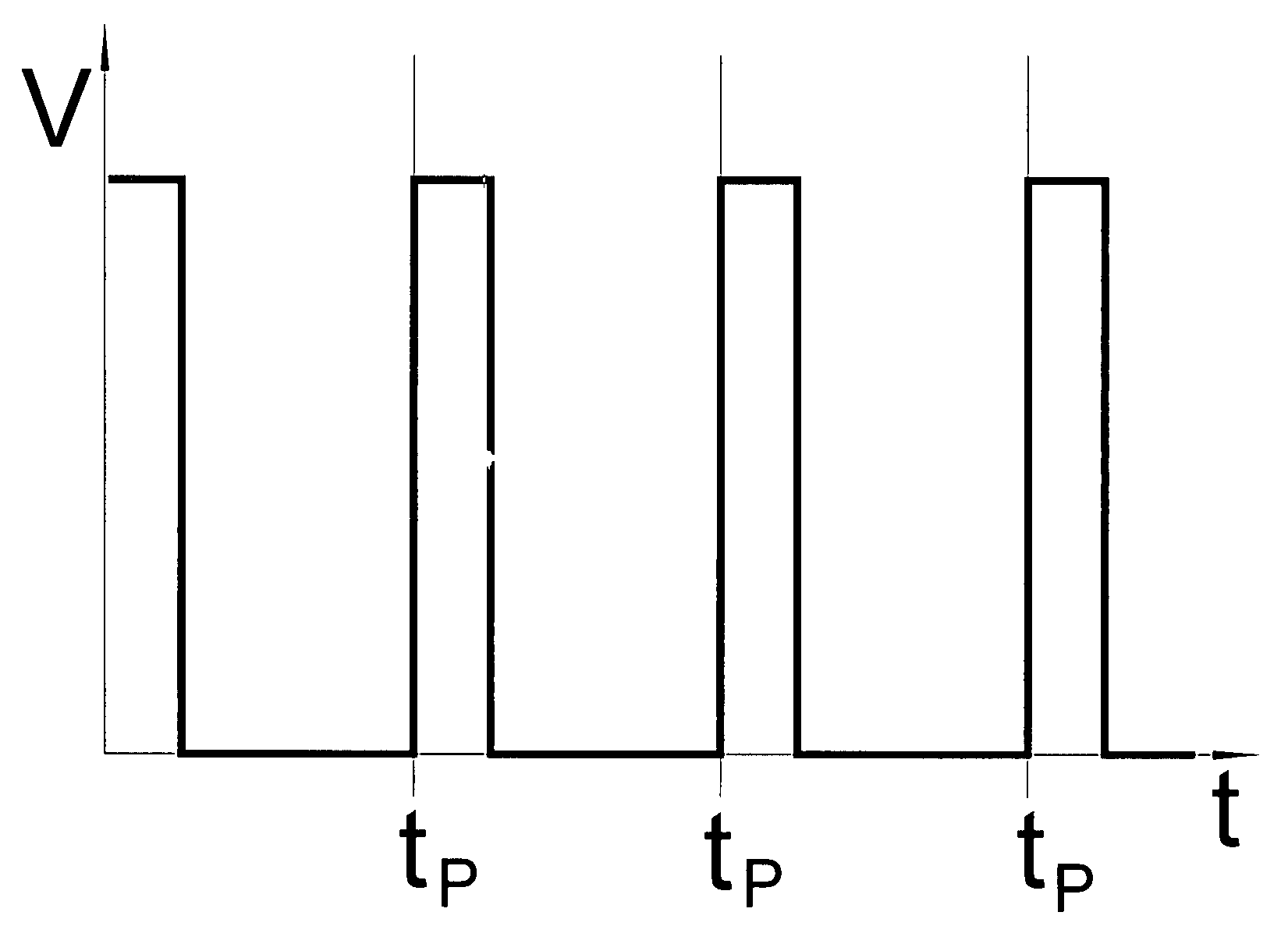

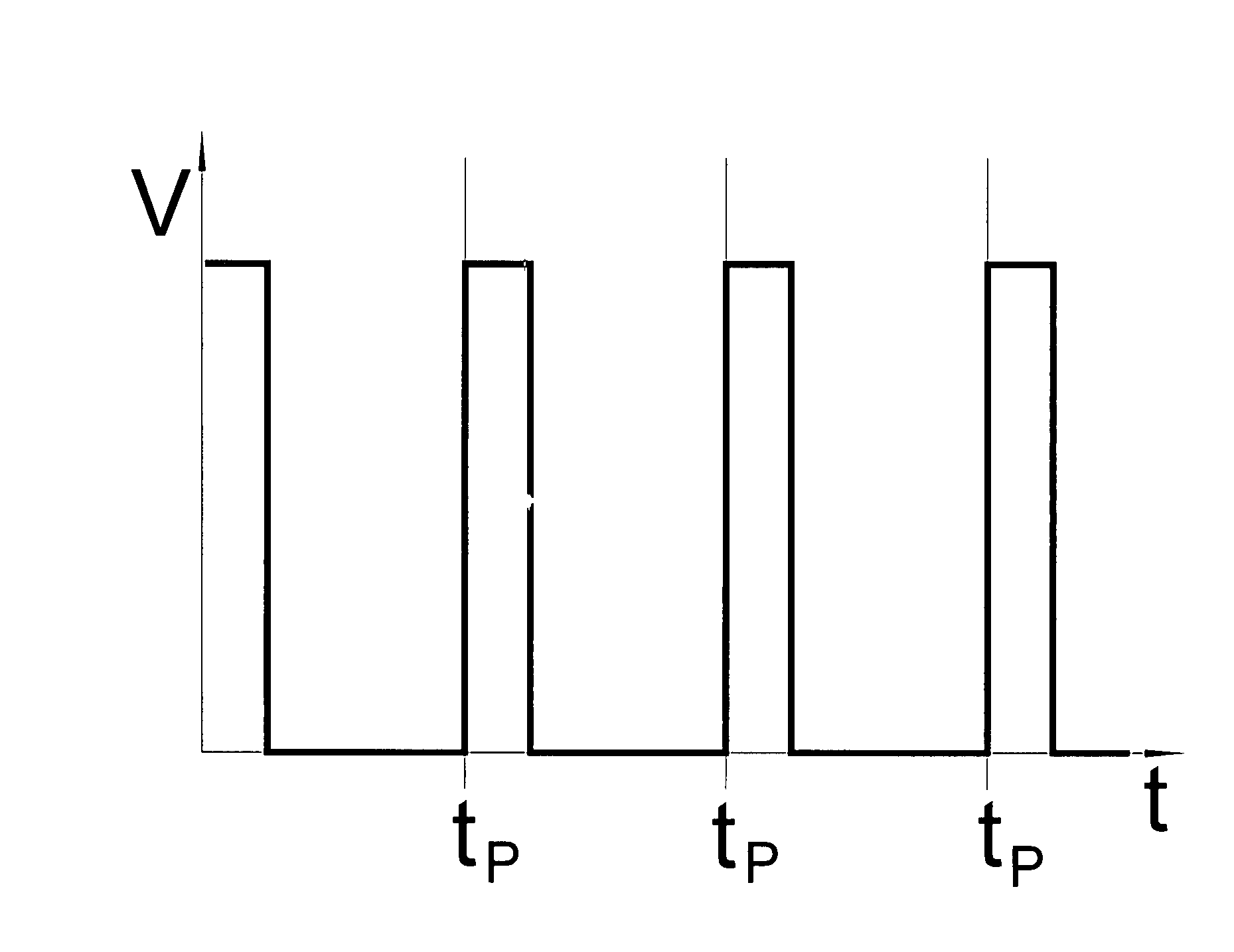

Method for thermal cutting

InactiveUS20080115862A1Quality improvementNeat cutArc welding apparatusPlasma welding apparatusEngineeringNozzle

The invention relates to a method for thermal cutting, wherein a cutting gas is piped into a cutting nozzle and guided on to a work piece to be processed by means of the cutting nozzle. According to the invention the cutting gas is at least reduced in a periodically repetitive manner wherein the time in which the cutting gas is guided onto the work piece in an undiminished manner is shorter than half of a period. In addition the invention relates to a corresponding device with a valve.

Owner:LINDE AG

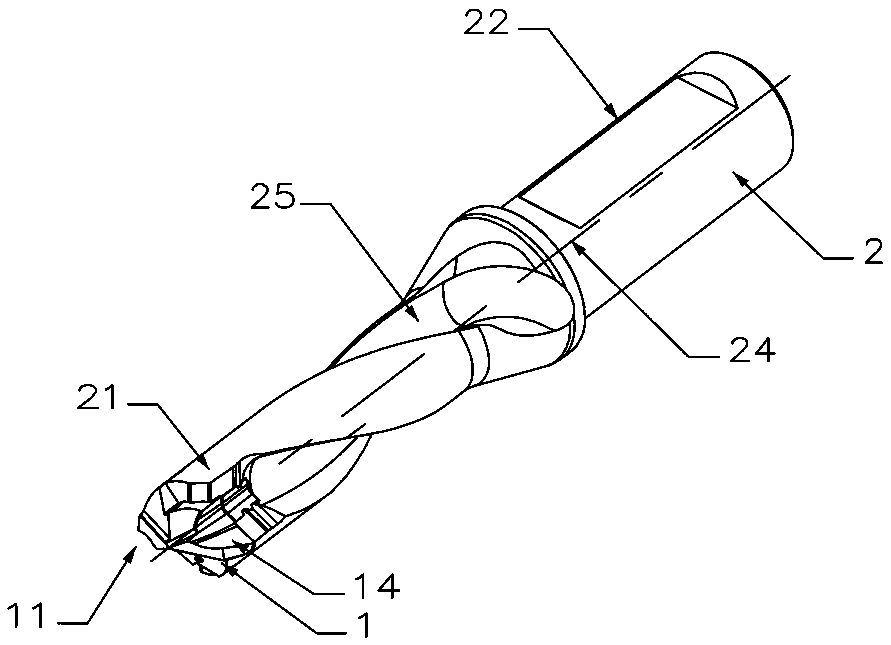

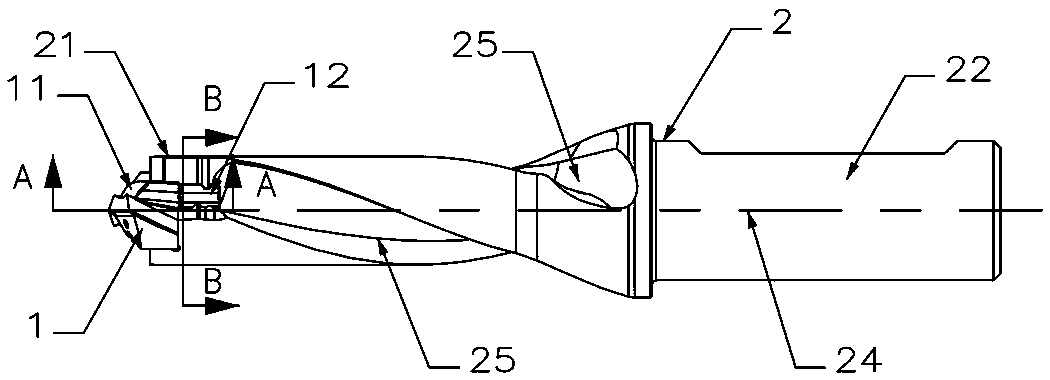

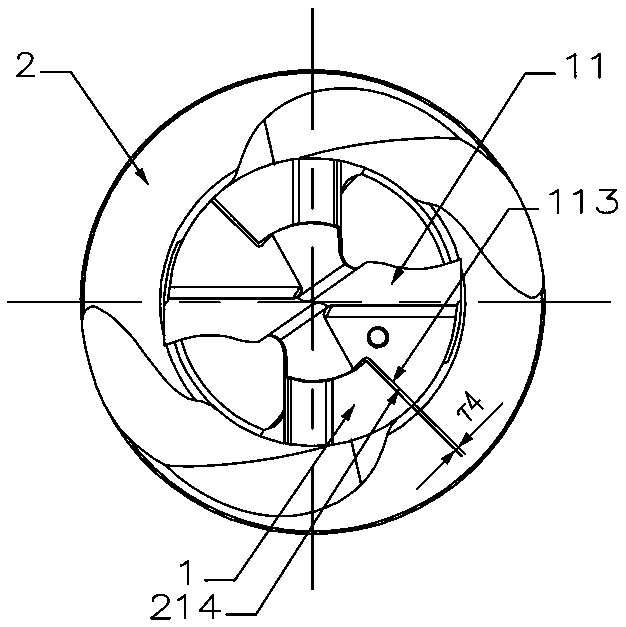

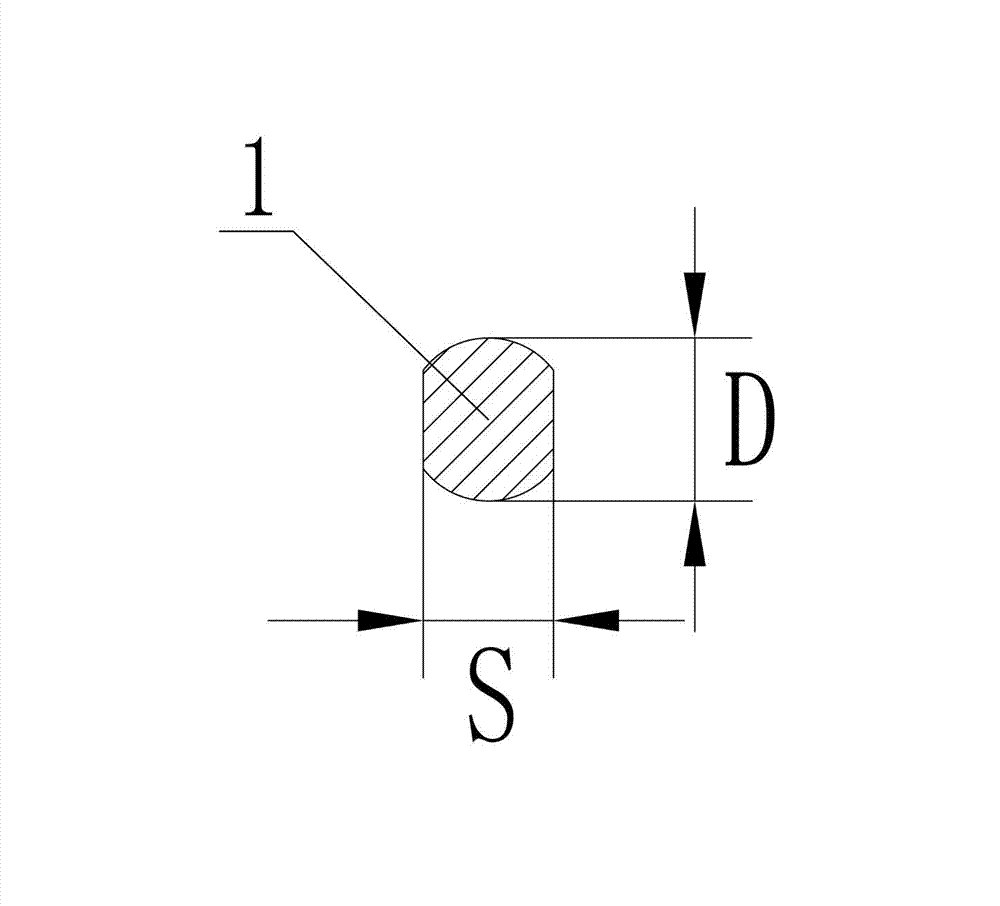

Stably clamping drilling tool

ActiveCN109262027AEasy clampingReduce manufacturing difficultyTransportation and packagingChucksBiomedical engineeringLambda

The invention discloses a stably clamping drilling tool. A projection is spirally twisted into a recess along the direction of a center shaft, an outer circumferential surface is matched with an innercircumferential surface to achieve changing interference magnitude lambda in the cutting part clamping process of a clamping component, and -0.1mm<=lambda<=0.05mm. The drilling tool has the advantages of rapidness in assembly and disassembly, no axial looseness, high positioning precision, simplicity in manufacture, good interchangeability and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

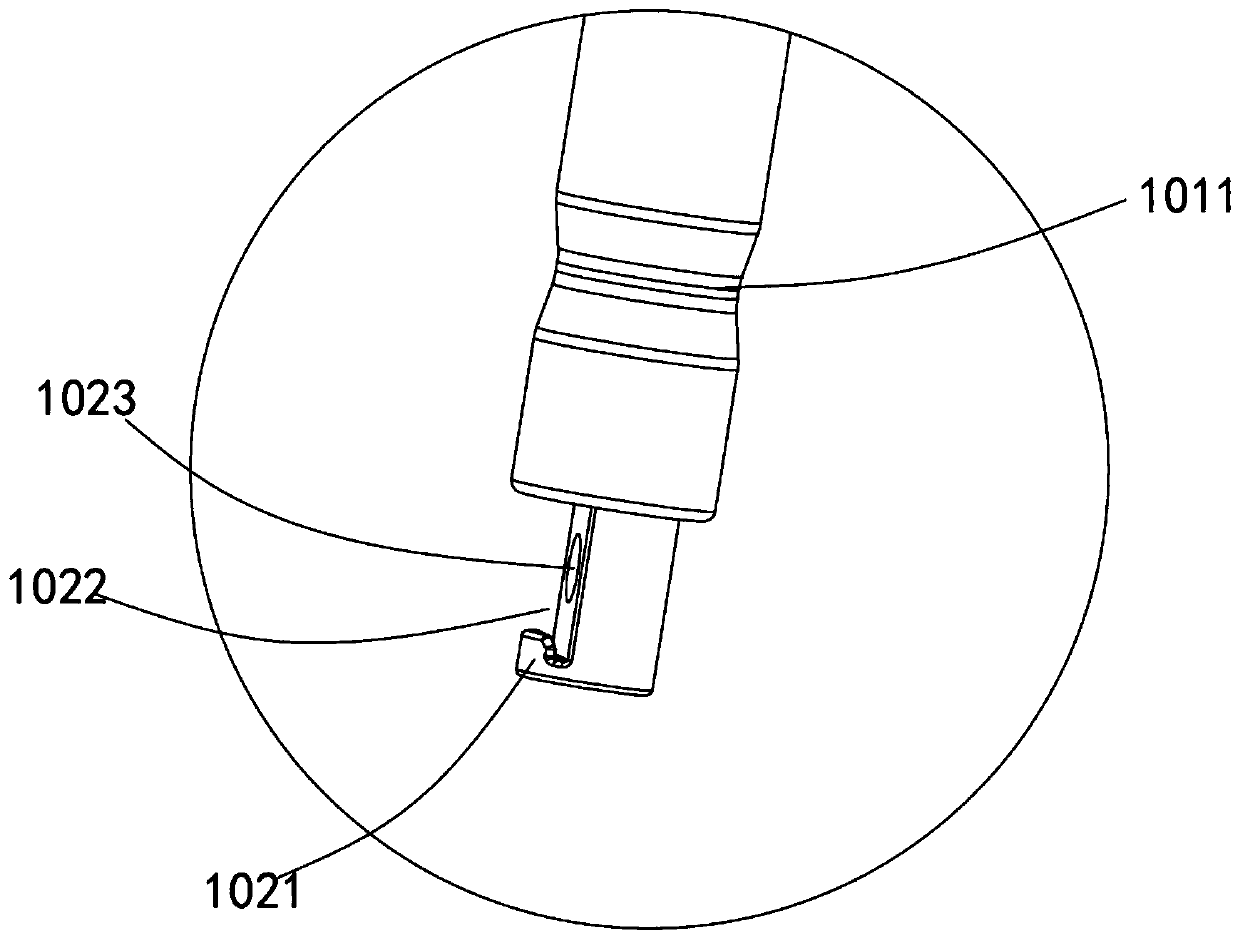

Wire end tightening humanoid robot and using method thereof

ActiveCN110625624AGuaranteed reliabilityMeet cutting requirementsGripping headsHeight differenceEngineering

The invention discloses a wire end tightening humanoid robot and a using method thereof. The humanoid robot comprises a wire end gripping device, a moving device for driving the wire end gripping device and a guide fusing device, wherein the guide fusing device comprises an upper partition column, a lower partition column and a fusing device body, and a height difference is generated between the upper partition column and the lower partition column. In a first state, the upper partition column and the lower partition column can cooperate with at least one side plate to limit a wire from movingoutwards from the inside of the guide fusing device; in a second state, notches at same positions are formed in the upper partition column and the lower partition column so as to allow the wire to pass through; and the fusing device body can fuse the wire between the upper partition column and the lower partition column when the upper partition column and the lower partition column are in the first state. According to the scheme, manual work can be simulated to tighten wire ends, therefore, the wire end fixing firmness can be ensured, packaging tape is not required in use, and the cost is low. The wire is cut off by combining with a hot fusing way, the cutting requirements of various materials, such as metal, can be effectively met, the cutting stability is high, and the application rangeis wide.

Owner:SUZHOU JIANGJIN AUTOMATION TECH

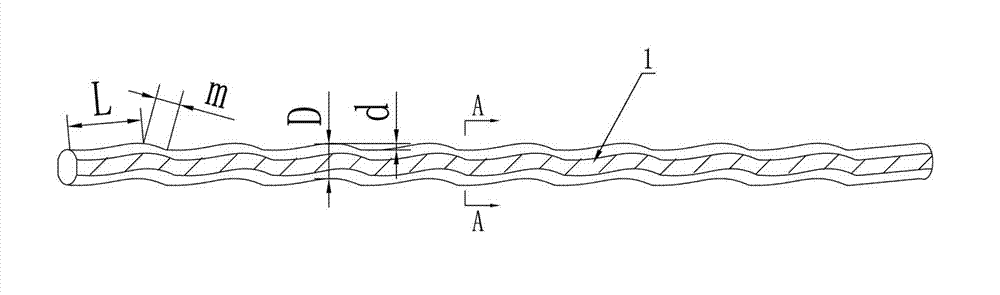

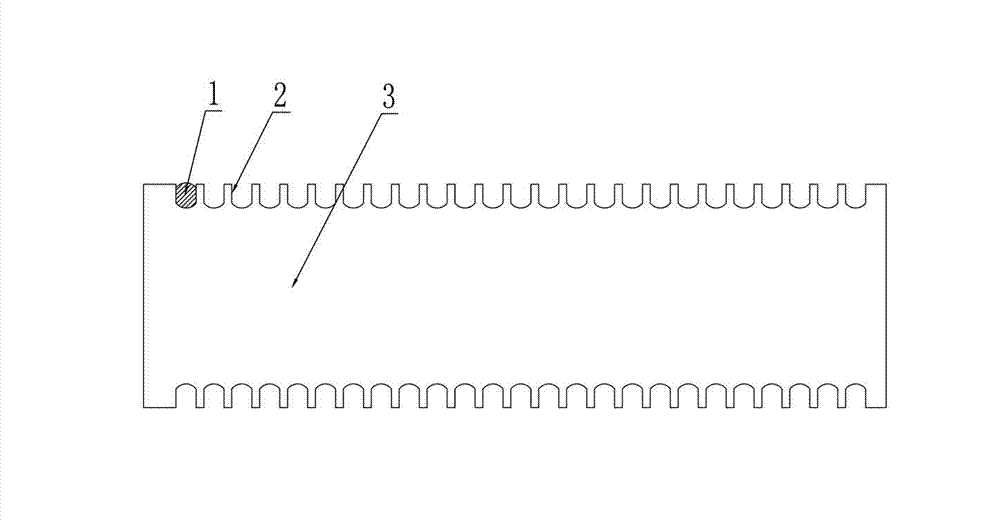

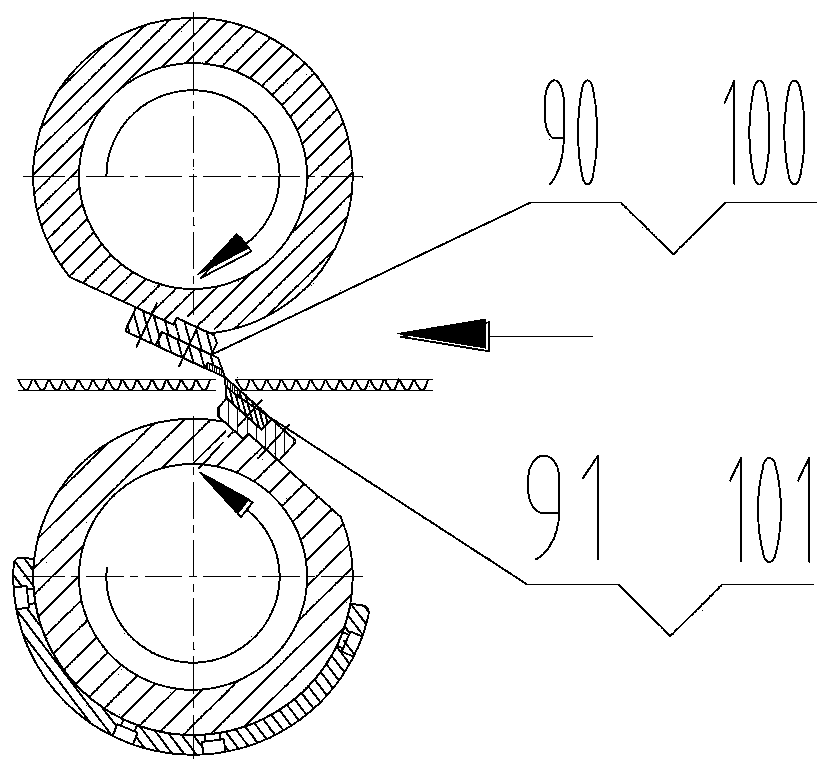

Sawtooth-shaped cutting steel wire with flat section

ActiveCN103692567APrevent self-rotationImprove cutting stabilityFine working devicesSurface finishSilicon

The invention discloses a sawtooth-shaped cutting steel wire with a flat section. The sawtooth-shaped cutting steel wire comprises a cutting steel wire body, wherein the cross section of the cutting steel wire body is flat; the cutting steel wire body is in continuous sawtooth-shaped distribution along the axial direction; the length of a short sawtooth edge of each sawtooth in the cutting steel wire body is 1 / 3-1 / 2 time of the length of a long sawtooth edge of each sawtooth; the height of each sawtooth is 0.15-0.3 time of the height of the flat cross section of the cutting steel wire body; a ratio of the width to the height of the flat cross section of the cutting steel wire body is 0.7-0.9. The sawtooth-shaped cutting steel wire with the flat section has the advantages that due to the flat arrangement of the cross section of the cutting steel wire, the phenomenon of self-rotation of the cutting steel wire in a main roller guide slot in a cutting process is avoided; line marks on the tail part of a silicon crystal cutting surface are reduced, the surface smoothness of the silicon crystal cutting surface is improved, and the cutting stability of the cutting steel wire is further improved; furthermore, due to the continuous and uniform sawtooth-shaped arrangement of the cutting steel wire along the axial direction, the silicon stick feeding speed of the cutting steel wire is increased, and the cutting efficiency is improved.

Owner:苏闽(张家港)新型金属材料科技有限公司

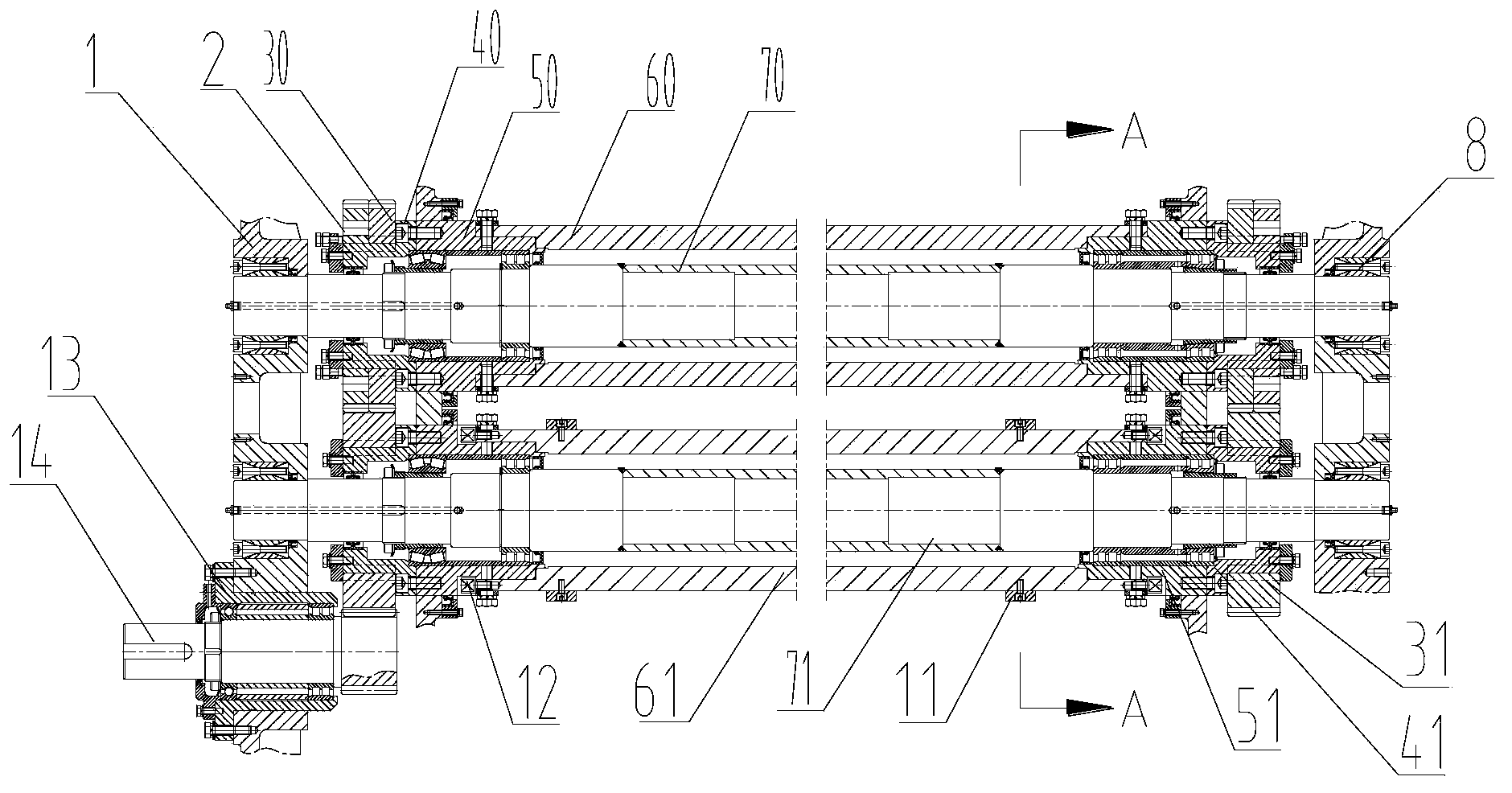

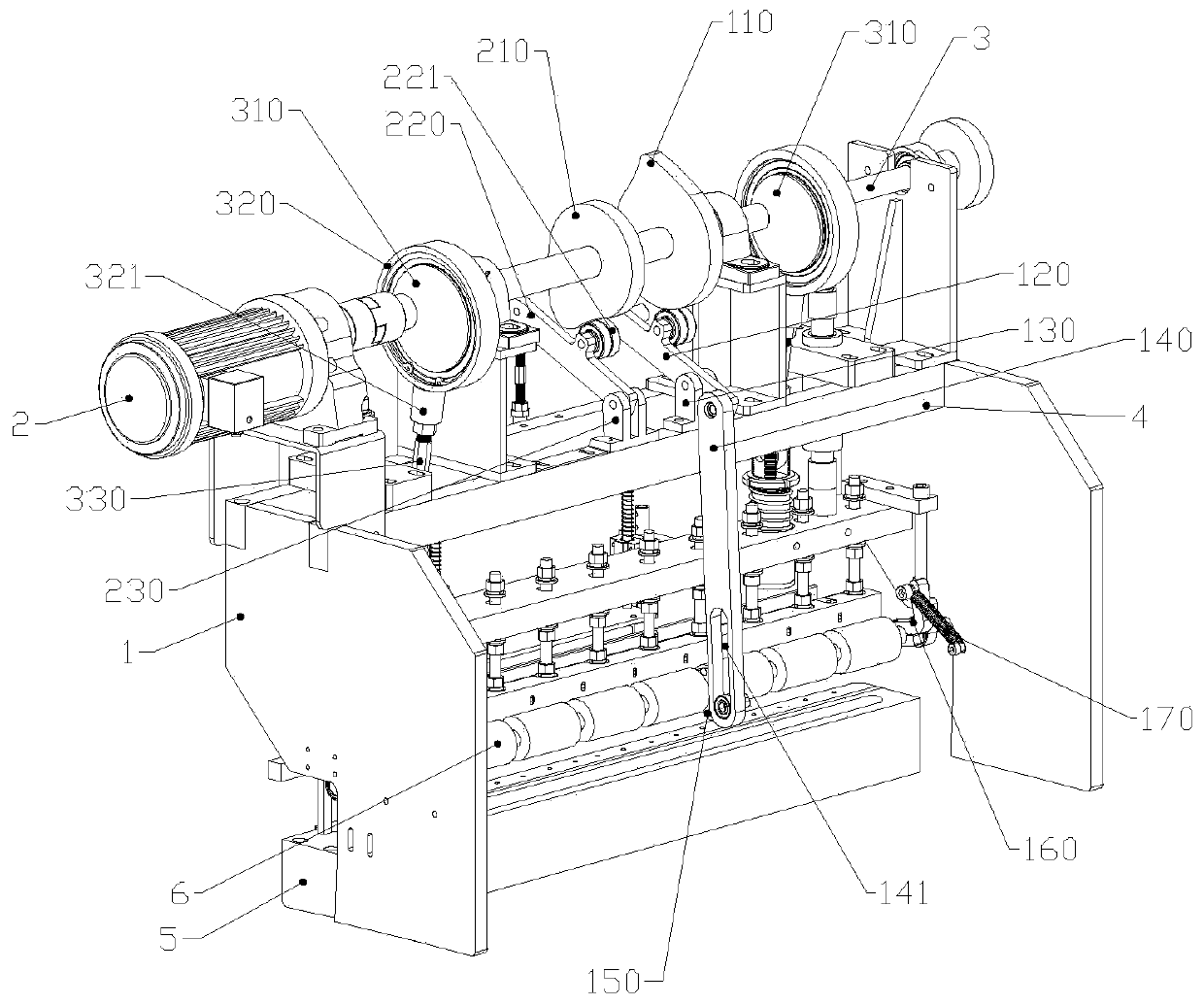

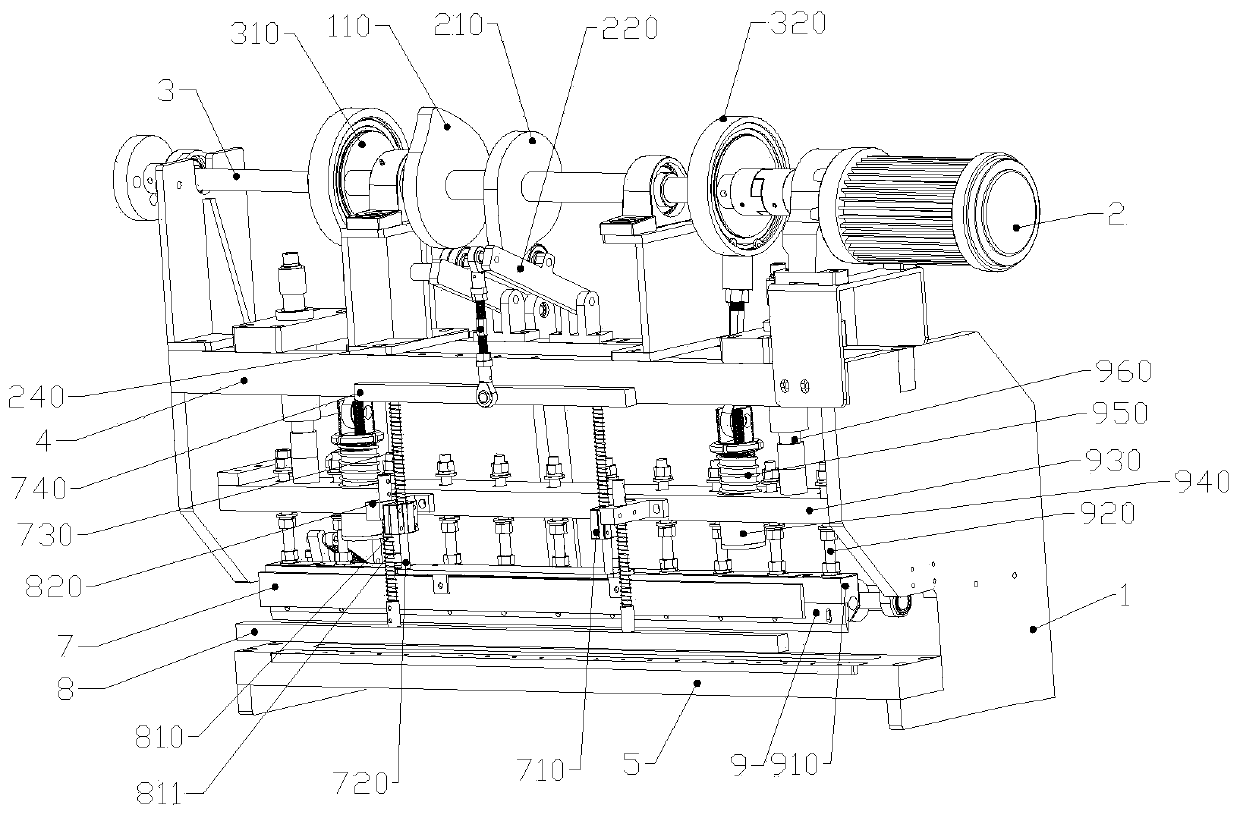

Cutter shaft structure of transverse cutting machine

A cutter shaft structure of a transverse cutting machine is characterized in that the ends of core shafts (70 and 71) are fixedly mounted on a box body (1) through expansion sleeves (8); self-aligning roller bearings are mounted on the core shafts (70 and 71); roller bearing supports (50 and 51) are fixedly mounted on the self-aligning roller bearings and fixedly assembled with rollers (60 and 61); roller rotation driving structures are mounted on the roller bearing supports (50 and 51) and at the ends of the rollers (60 and 61); cutter holders and cutters (100 and 101) are mounted on the outer sides of the rollers (60 and 61); the core shafts (70 and 71) are fixed; the roller rotation driving structures drive the rollers (60 and 61) to rotate around the core shafts. According to the structure, the core shafts are fixed while the rollers are rotated, which reduces inertia of rotation and the weight of cutter shafts so as to achieve an energy saving effect and reduce the bearing interval; the cutter shaft structure has good cutting stability and remarkable energy saving effect when used for cross cutting of wide paper boards (W is greater than or equal to 2,200).

Owner:湖南益晟机械科技有限公司

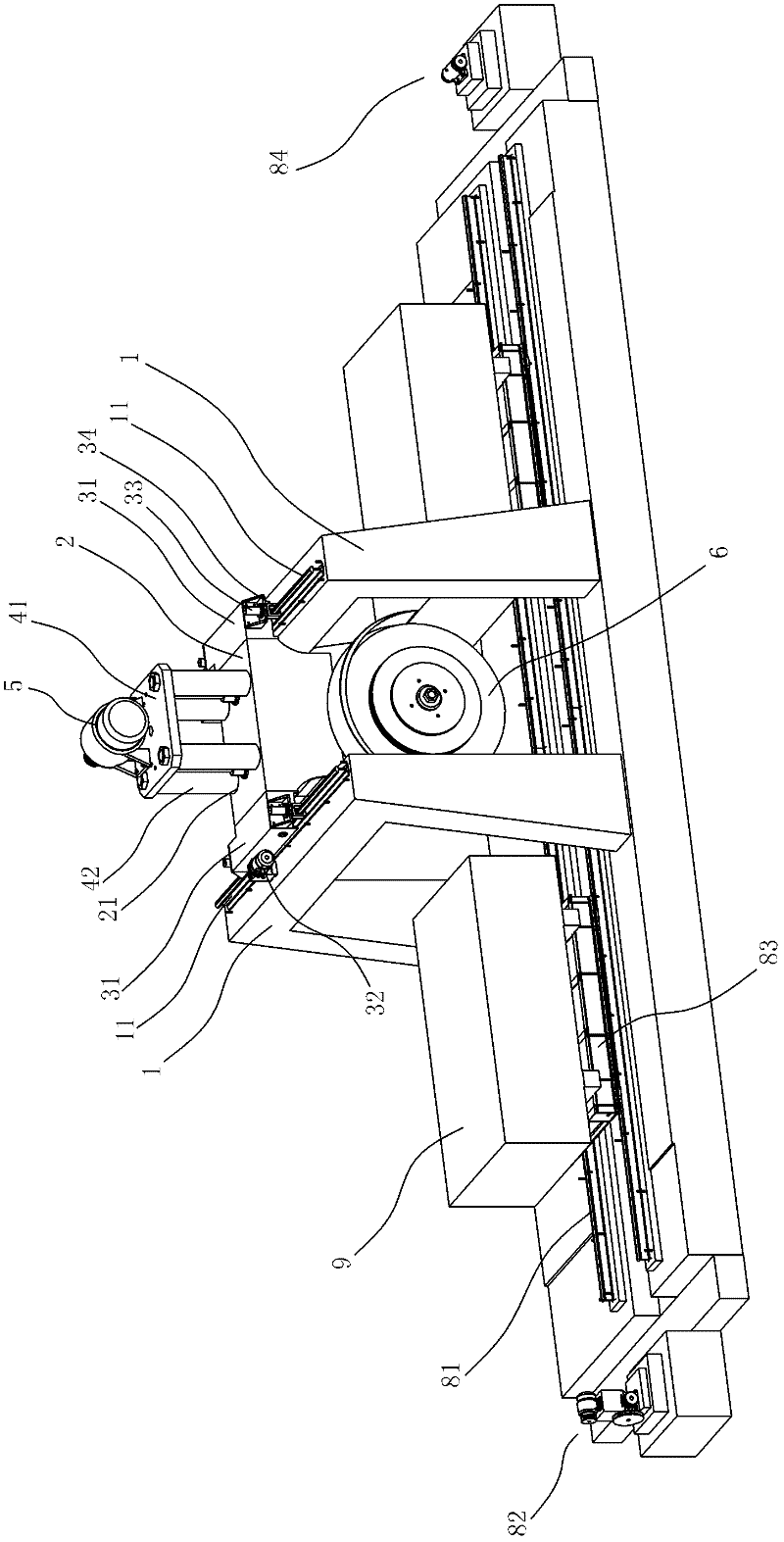

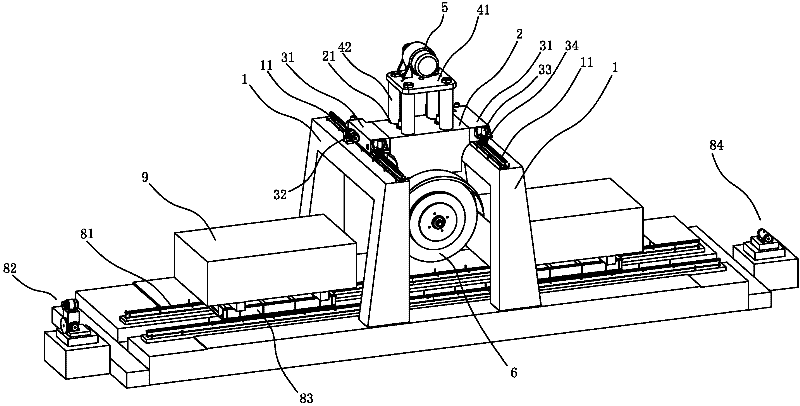

Large frame type gantry cutting machine

InactiveCN102514102AImprove rigidityReduce vibrationStone-like material working toolsStructural engineeringEngineering

The invention provides a large frame type gantry cutting machine, comprising two gantry type brackets, two longitudinal rails, a main base body, walking devices, a hoisting frame, a driving device, a main shaft, a saw bit and a main motor, wherein the two gantry type brackets are transversely arrayed at intervals; the two longitudinal rails are arranged on cross beams of the two gantry type brackets and horizontally extend in a longitudinal direction; the main base body is arranged between the two longitudinal rails through a movable frame; the walking devices are arranged at two sides of the main base body and are matched with the two longitudinal rails; the hoisting frame is movably arranged on the main base body in a vertically hoisting manner; the driving device is arranged between the main base body and the hoisting frame and is used for driving the hoisting frame to hoist and move; the main shaft is horizontally arranged at the lower end of the hoisting frame in the longitudinal direction; the saw bit is arranged on the main shaft; and the main motor is arranged at the upper end of the hoisting frame and is connected through a transmission mechanism to drive the main shaft to rotate. The large frame type gantry cutting machine, provided by the invention, has the advantages of simple structure, accuracy in action, stability and the like.

Owner:晋江市凯达石材机械有限公司

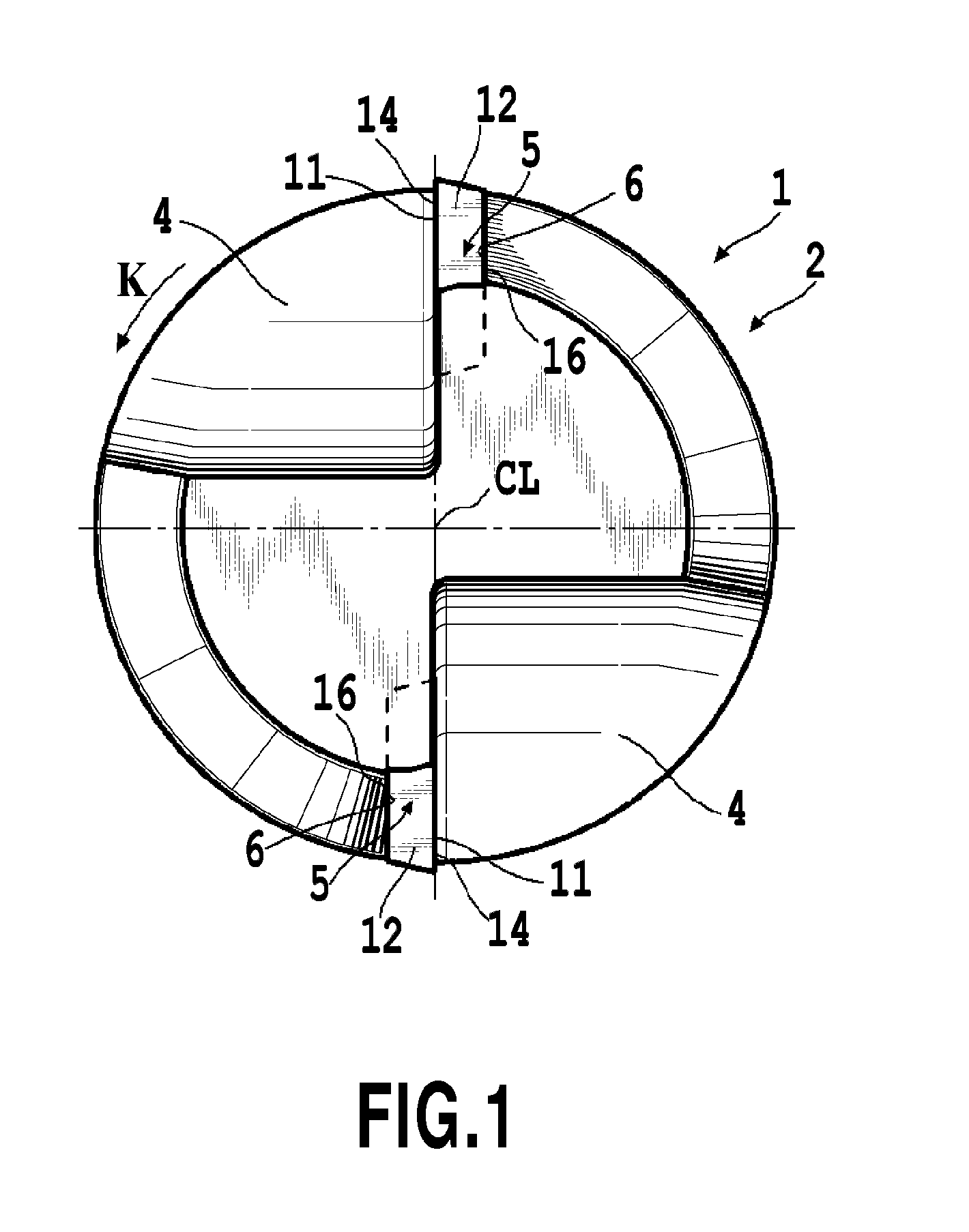

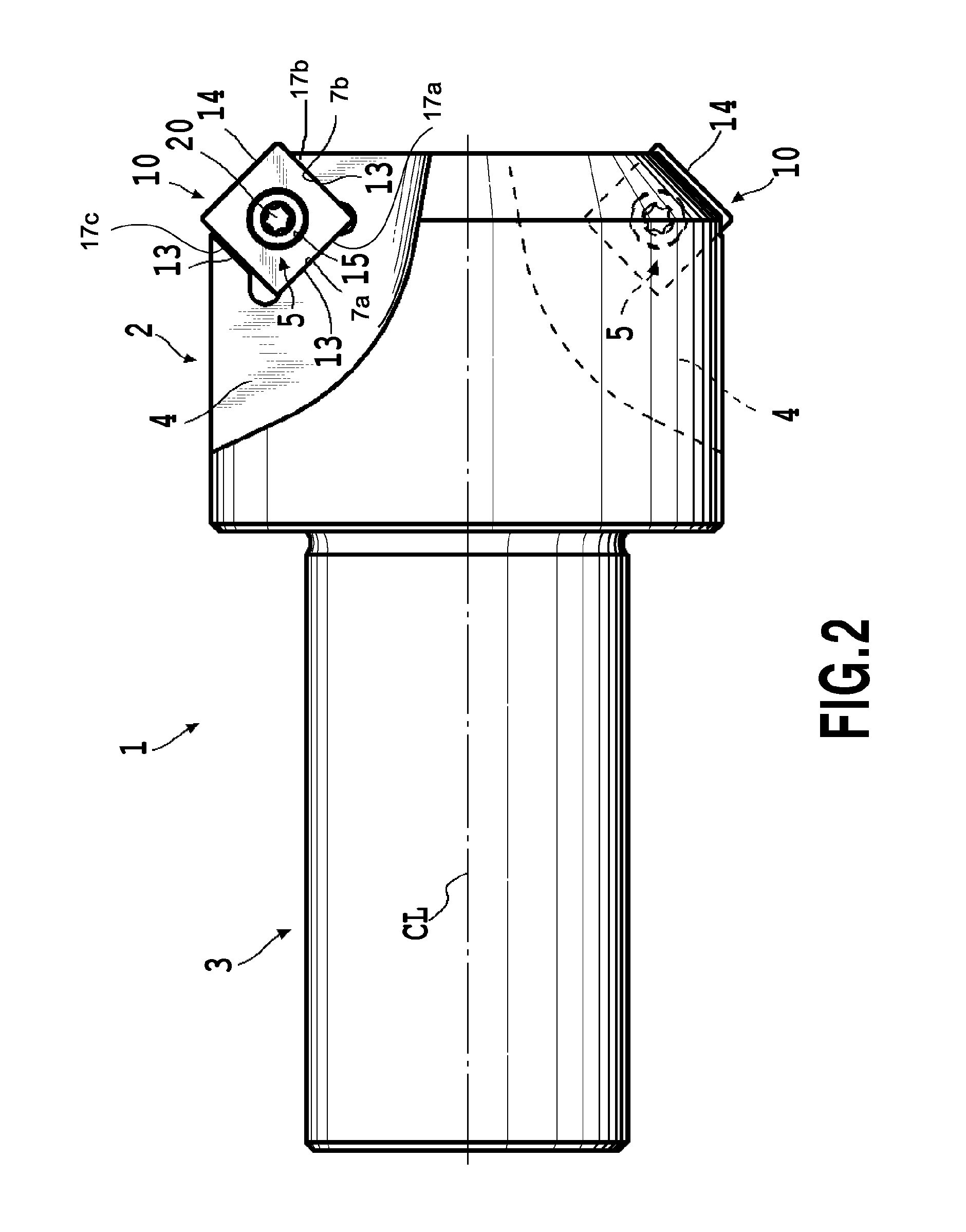

Cutting Tool with a Replaceable Blade Edge

ActiveUS20120230790A1Attachment precisionCut partWood turning toolsTransportation and packagingKnife bladesEngineering

As viewed from a side opposing a bottom face (6) of an insert attachment seat, an angle (α) between first and second restraint wall faces (7a) and (7b) rising from the bottom face (6) is smaller than an angle (β) between two peripheral faces of a cutting insert contacting them respectively. A first peripheral face of the cutting insert contacts the first restraint wall face (7a) in a substantially parallel posture with the extending direction of the first restraint wall face (7a), while the second peripheral face contacts the second restraint wall face (7b) in an end portion of the second restraint wall face (7b).

Owner:TUNGALOY CORP

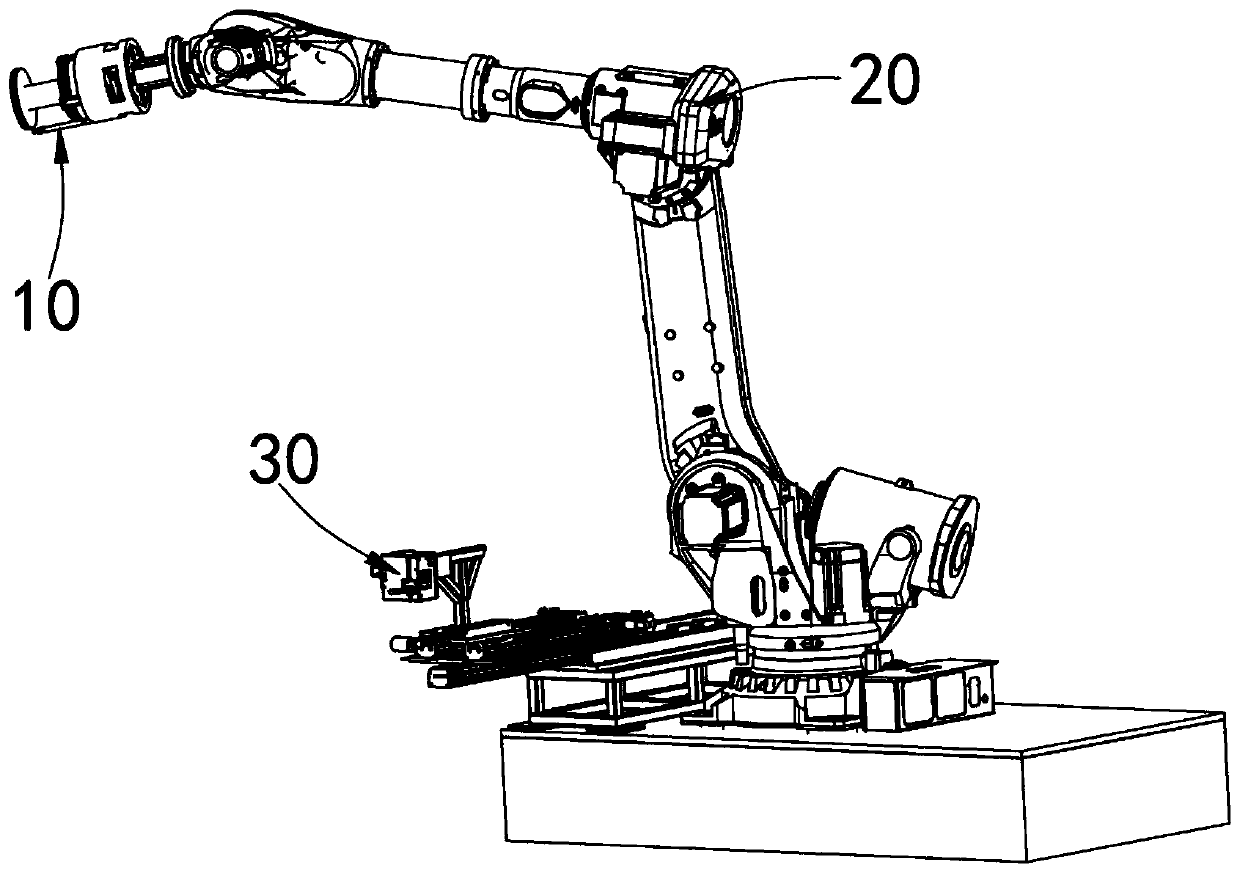

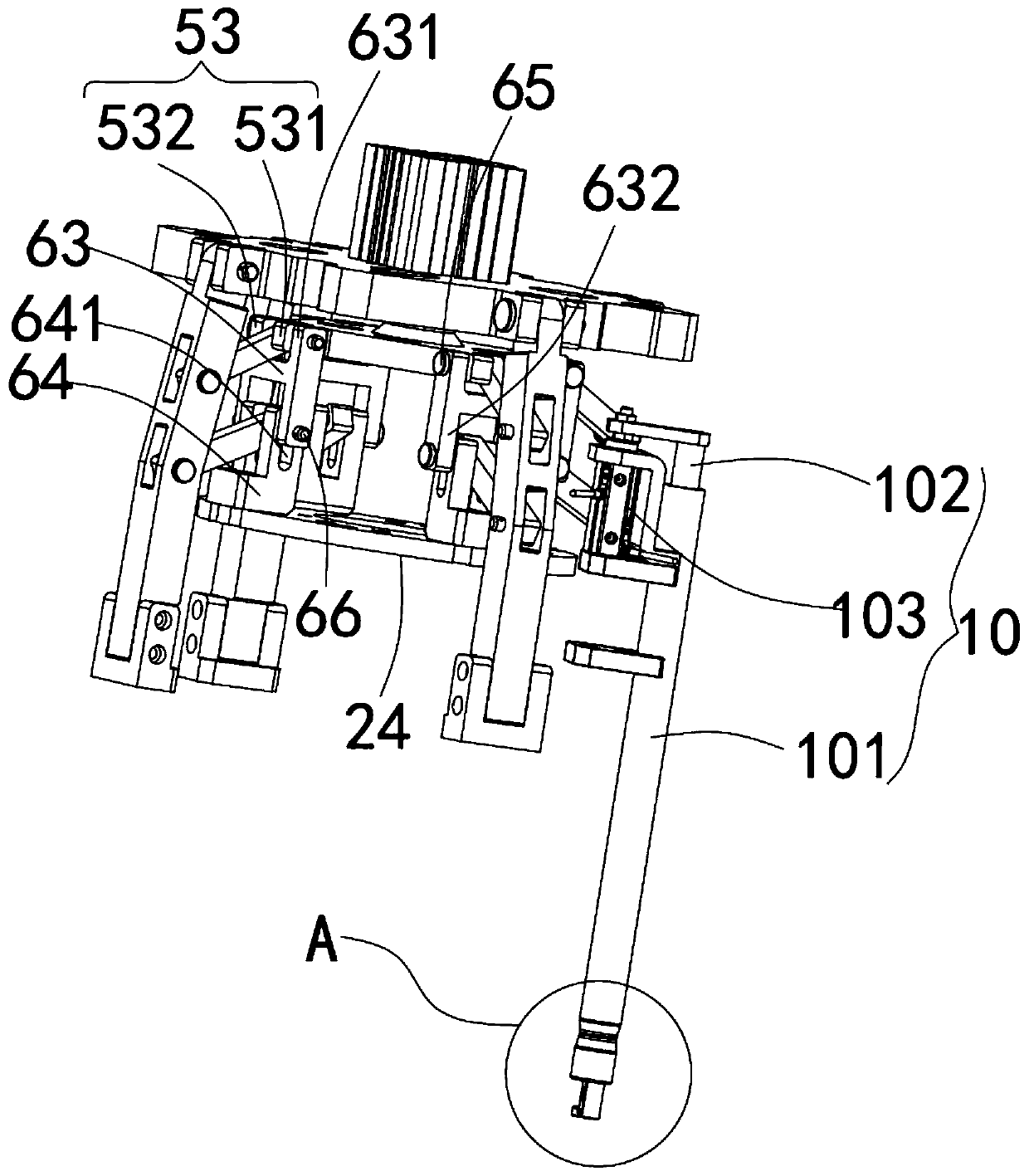

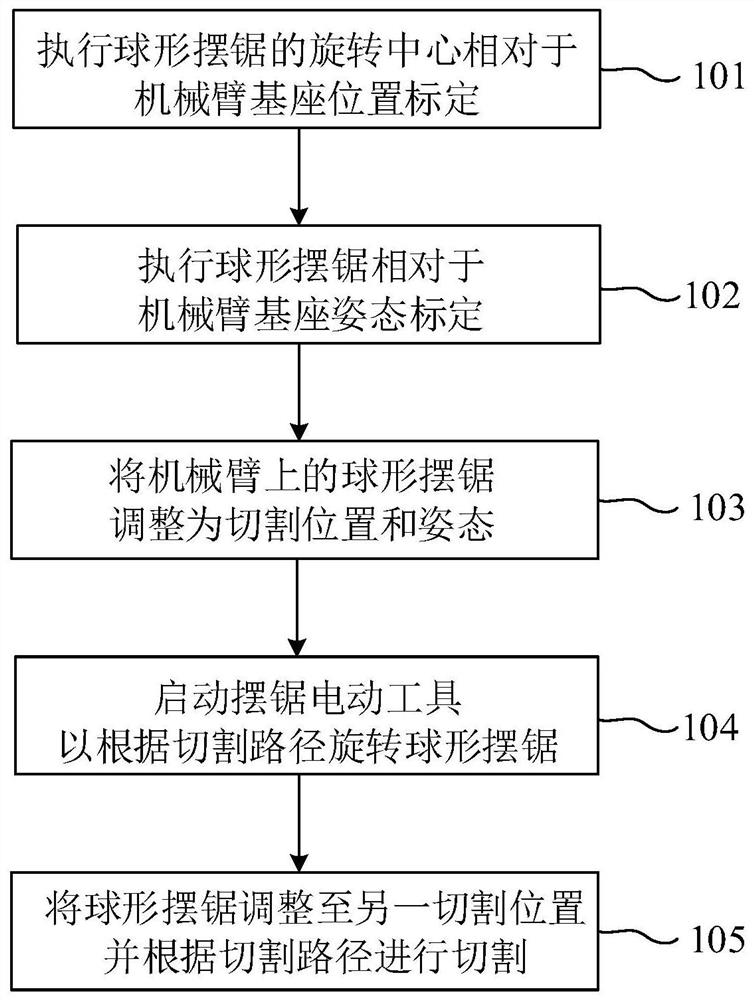

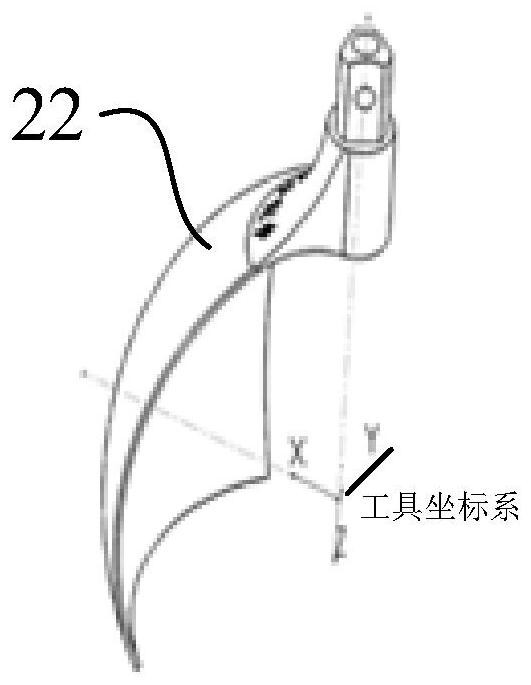

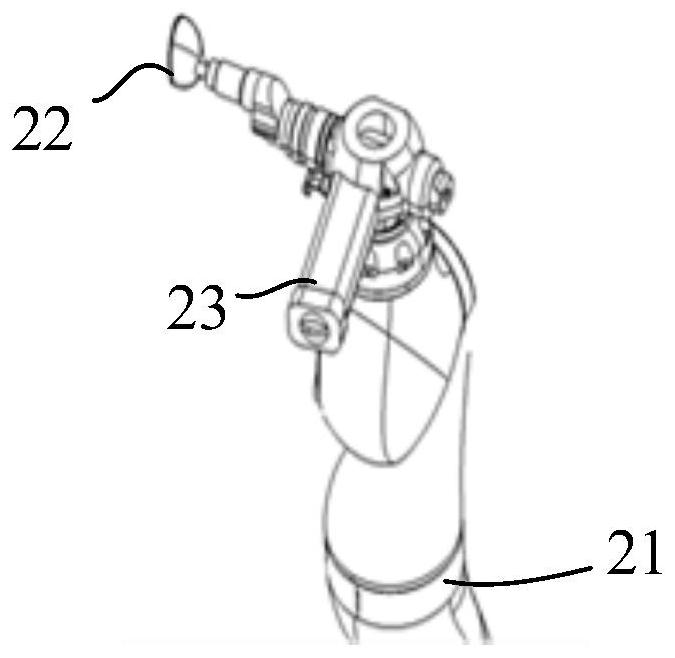

Method and system for cutting acetabular cup based on mechanical arm

ActiveCN112790867ARule out displacement instability factorsImprove cutting efficiencySurgical navigation systemsSurgical manipulatorsSimulationCentre of rotation

The invention discloses a method and system for cutting an acetabular cup based on a mechanical arm. The method comprises the steps that position calibration of the rotating center of a spherical swing saw relative to a mechanical arm base used for installing the spherical swing saw and posture calibration of the spherical swing saw relative to the mechanical arm base are executed; the current position and posture of the spherical swing saw on the mechanical arm are determined, and the current position and posture are adjusted to be the cutting position and posture; and the spherical swing saw is rotated according to a pre-planned cutting path to cut the spherical acetabular cup. The mechanical arm is used for automatically cutting the spherical acetabular cup, human hands are effectively replaced, unstable factors of swing saw displacement caused by oscillation and the like are effectively eliminated, and therefore the cutting efficiency and stability are improved; the position and posture of the swing saw face relative to the end of the mechanical arm can be calibrated through a special calibration tool, so that the cutting precision is improved.

Owner:SHANGHAI ELECTRICGROUP CORP

Heavy type cutting rotary turning and milling composite blade

InactiveCN108655427AImprove impact resistanceStable cutting processMilling cuttersCutting insertsSet screwEdge strength

A blade is mainly applied to the field of heavy type cutting, and the problems that during heavy type machining of large special-shaped pieces, since the cutting parameters are large and the machinedcomponent surface state is complex, the blade is likely to vibrate, and failures happen need to be solved. For the large special-shaped piece machining complex work condition, a heavy type cutting rotary turning and milling composite blade is developed and designed. The blade is provided with a linear cutting edge and an arc cutting edge; and meanwhile, the large parameters during heavy type cutting are considered, so that negative chamfer is designed, and the cutting edge strength of the blade can be improved. Streamline protrusions and conical abrasion reducing protrusions are designed on the upper cutter face, and during machining, the functions that the cutting temperature is reduced and scrap rolling and discharging are assisted can be achieved, and meanwhile the anti-vibration capability of the blade is improved. An octangle groove and a set screw hole are designed in the geometric center of the blade, an annular heat dissipation groove is designed in the bottom, the blade and air contact area can be increased while cutting fluid is stored, the heat dissipation function is achieved during blade cutting, and meanwhile the blade strength is improved. The whole blade structure is complete, the production cost is low, and the heavy type cutting rotary turning and milling composite blade is suitable for being used for heavy type turning and milling machining.

Owner:HARBIN UNIV OF SCI & TECH

Cropping device

PendingCN111360893AImprove cutting stabilitySimple structural designBag making operationsPaper-makingLinear motionDrive by wire

The invention belongs to the field of cropping equipment, and discloses a cropping device. At least two components of a cutter, a bag pressing piece, a bag twisting piece and a heat isolation piece are included. A rotary main shaft is arranged. A transmission structure for converting the rotation movement of the main shaft into the linear movement or for transmitting the rotation movement of the main shaft is arranged between the main shaft and at least two components. A rotary power source is adopted in the cropping device, a traditional air cylinder linear driving manner is replaced, the structure design can be optimized, the equipment size is reduced, and assembling and maintaining are convenient; and under the coaxial situation, the two ends of the cutter can act more easily, stress iskept consistent, and the cropping equipment has better action stability and can adapt to the occasion where the action speed is high.

Owner:WENZHOU KEWANG MACHINERY

Numerically controlled lathe spindle drilling device

ActiveCN108941627AReduce labor intensitySimple processTransportation and packagingWork clamping meansFriction reductionBall bearing

The invention relates to a numerically controlled lathe spindle drilling device, and belongs to drilling devices. The numerically controlled lathe spindle drilling device comprises a numerically controlled lathe, a clamp, a supporting sleeve, a pull pipe, a mandrel, a ball screw pair, an improved servo motor, a liquid flow device and a drilling taper shank combined cutter. According to the numerically controlled lathe spindle drilling device, a deep groove oilless combined ball bearing is arranged, so that the assembling precision and strength of the mandrel are improved, moreover, the mandrelis not limited by high-speed rotation of a machine tool spindle in a bearing hole, the axial reciprocating motion is free, the friction is reduced, the cutting stability of the cutter is improved, acutting fluid of the drilling device enters a cutting area through a liquid conveying hole inside the drilling device, so that the cutter and a workpiece are cooled, the cutting deformation is reduced, a built-up edge is prevented from being generated, the service life of the cutter is prolonged, and the product quality is improved; the drilling device has the advantages that the workpiece is clamped once, the two ends of the workpiece can be machined at the same time, multiple passes of working procedures are completed, the process can be optimized, the process flow can be shortened, the production efficiency can be improved, and the labor intensity of workers can be reduced.

Owner:长春科技学院

Cutting mechanism of straw cutting machine

The invention provides a cutting mechanism of a straw cutting machine and belongs to the technical field of machines. The problem that an existing straw cutting machine is complex in structure is solved. According to the cutting mechanism of the straw cutting machine, a movable conveying belt is arranged on a machine frame of the cutting machine, the cutting mechanism is arranged on the machine frame and located on the upper portion of the conveying belt and comprises a knife rest, a cutting knife, a pretensioning piece and a driving piece, a guide structure enabling the knife rest to horizontally move up and down relative to the machine frame is arranged between the knife rest and the machine frame, the cutting knife is fixedly connected to the knife rest, the pretensioning piece is connected to the knife rest and can move from the lower portion of the cutting knife to be flush with the cutting knife after making contact with straw materials, a first driving mechanism is arranged between the driving piece and the conveying belt and can drive the conveying belt to move, and a second driving mechanism is arranged between the driving piece and the cutting knife and can drive the cutting knife to move relative to the machine frame. The cutting mechanism of the straw cutting machine is compact in structure.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Resin based diamond dicing blade for LED segmentation and preparation method thereof

The invention discloses a resin based diamond dicing blade for LED segmentation and a preparation method thereof. The preparation method includes: subjecting a mixture of diamond, resin powder, zinc oxide, alumina, carbon fiber and 4-methylbenzyl alcohol to ball milling, and then performing hot-pressing to obtain a hot-pressed green body; conducting curing treatment on the hot-pressed green body at 130-160DEG C for 12-16h to obtain a molded body; and processing the molded body to obtain the resin based diamond dicing blade for LED segmentation. The product provided by the invention can meet LED precision machining process, the blade precision can reach 4microm, the cutting speed can be raised to 40mm / s, and the life span can reach 8000m, therefore the working efficiency and processing costare greatly improved.

Owner:苏州赛尔科技有限公司

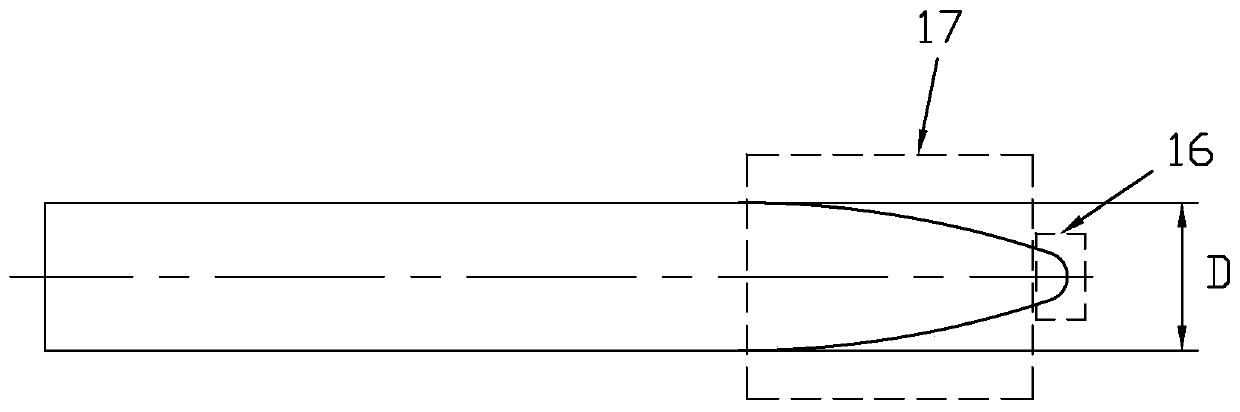

Efficient drum-shaped profiling end mill

PendingCN110695426AHigh cutting lengthImprove processing efficiencyMilling cuttersStructural engineeringEnd mill

The invention discloses an efficient drum-shaped profiling end mill. The efficient drum-shaped profiling end mill comprises a cutting part and a handle part, wherein the cutting part is provided witha plurality of chip grooves which spirally extend from the bottom end to the handle part; the surface, facing the cutting rotation direction, of each chip groove is a front cutter surface; the front cutter surfaces and the peripheral surface of the cutting part are intersected to form cutting edges; the cutting edges are wave-shaped cutting edges by machining the front cutter surfaces, and are divided into circumferential cutting edges and ball head cutting edges; the outlines of the circumferential cutting edges are two sections of symmetrical arcs; the bottom end cutting edges are the ball head cutting edges; included angles of the edges are unequal; the surface, connected with the cutting edges, in the peripheral surface of the cutting part is a first rear cutter surface; the first rearcutter surface extends from the bottom end of the cutting part to the handle part; chip breaking grooves are spirally distributed in the first rear cutter surface. The efficient drum-shaped profilingend mill has the advantages that the semi-finish machining and finish machining efficiency of a workpiece can be greatly improved, a narrow workpiece can be machined, the strength is high, and the service life is long.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

Vertical cutting device for tubular workpiece

InactiveCN110170696AImprove cutting efficiencyImprove cutting stabilityTube shearing machinesShearing machine accessoriesCouplingEngineering

The invention discloses a vertical cutting device for a tubular workpiece. The vertical cutting device comprises a cutting box, a cutting wheel and a conveying roller; the cutting wheel is rotatably connected with a protective cover through a rotating shaft, and the upper end of the protective cover is fixedly connected with a lifting plate; a group of connecting rods arranged symmetrically is hinged with the upper side of the lifting plate through hinge seats, and movable blocks are hinged with the upper ends of the connecting rods through hinge seats; each movable block is provided with a horizontal chute plate in a nesting mode, and each horizontal chute plate is internally provided with a two-way screw rod; and each two-way screw rod extends to the outer side of the cutting box, and isconnected with a screw rod motor through a coupling. According to the vertical cutting device, through arrangement of the lifting plate, the vertical chute plates, the connecting rods, the movable blocks moved face to face or oppositely, and the two-way screw rods, the cutting wheel can be used for automatic vertical cutting, and the cutting efficiency is improved; the incision quality is guaranteed; through arrangement of an extrusion fixing plate, a spring telescopic rod and a rubber pad, the extrusion fixing plate is moved with the lifting plate for extruding and fixing the cut tubular workpiece; and the cutting stability is improved, and the cutting quality is guaranteed.

Owner:赵言

Crystalline silicon single-knife guillotine

PendingCN108748749AAdapt to layout needsIncrease flexibilityWorking accessoriesFine working devicesEngineeringCrystalline silicon

The invention relates to a crystalline silicon single-knife guillotine, and belongs to the technical field of crystalline silicon processing equipment. The crystalline silicon single-knife guillotineincludes a base, a conveying mechanism and a cutting mechanism, wherein the conveying mechanism and the cutting mechanism are located above the base; the conveying mechanism is divided into two levelsin the axial direction of the crystalline silicon, the two levels are the feeding conveying assembly and the discharging conveying assembly respectively, a moving supporting mechanism is arranged between the feeding conveying assembly and the discharging conveying assembly, and the cutting mechanism is arranged above the moving supporting mechanism in a cross mode; and a clamping claw assembly isarranged on the discharging conveying assembly. According to the crystalline silicon single-knife guillotine, the conveying mechanism is combined with the moving supporting mechanism so as to fix thecrystalline silicon with different cutting lengths, and the flexibility is high; and meanwhile, the integration of winding, rewinding and cutting functions is achieved, the structure is compact, theequipment manufacturing cost is reduced, the crystalline silicon single-knife guillotine is also adapt to factory layout needs, the structure is compact, the economy and durability are achieved, and the application prospects are wide.

Owner:QINGDAO GAOCE TECH CO LTD

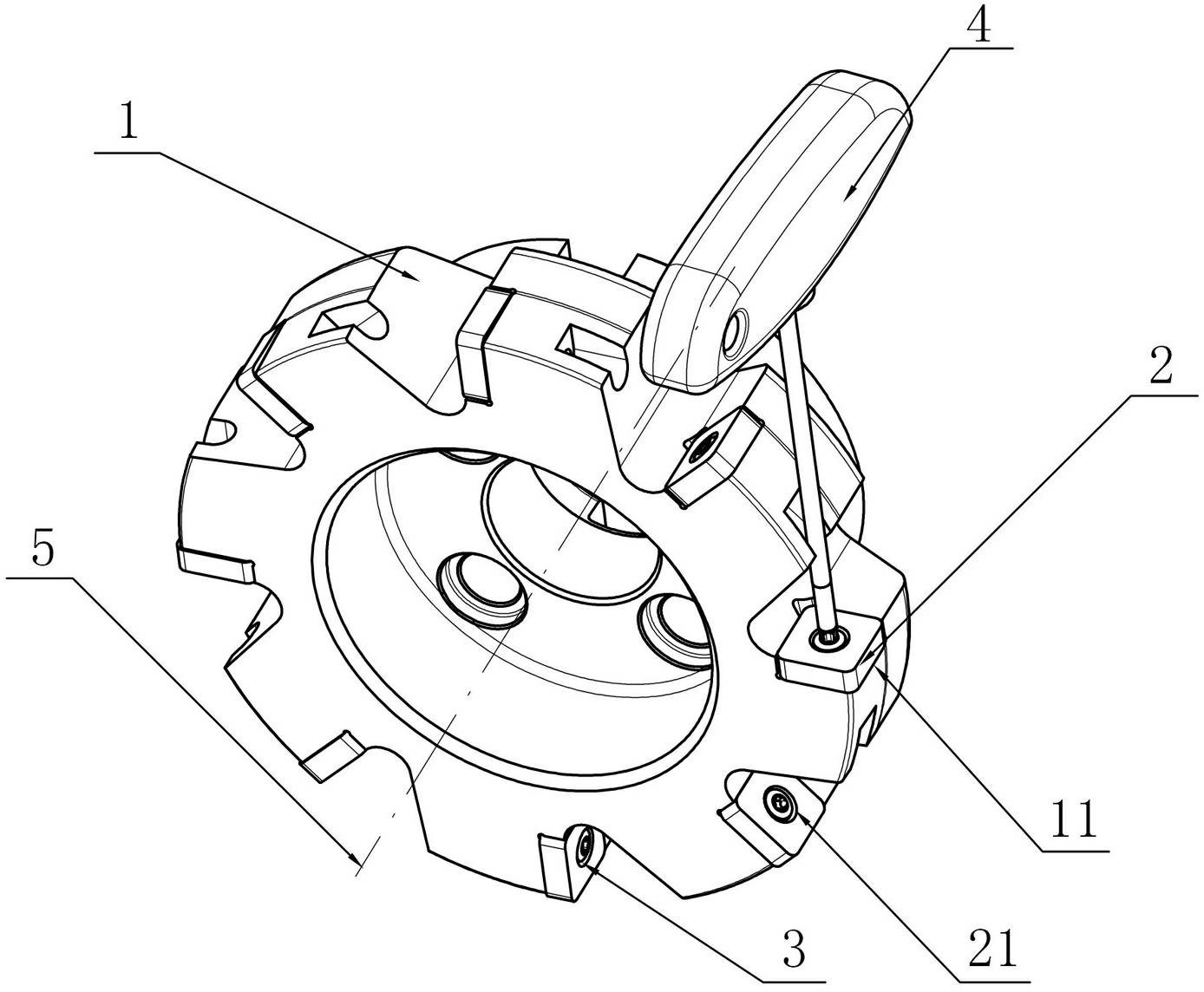

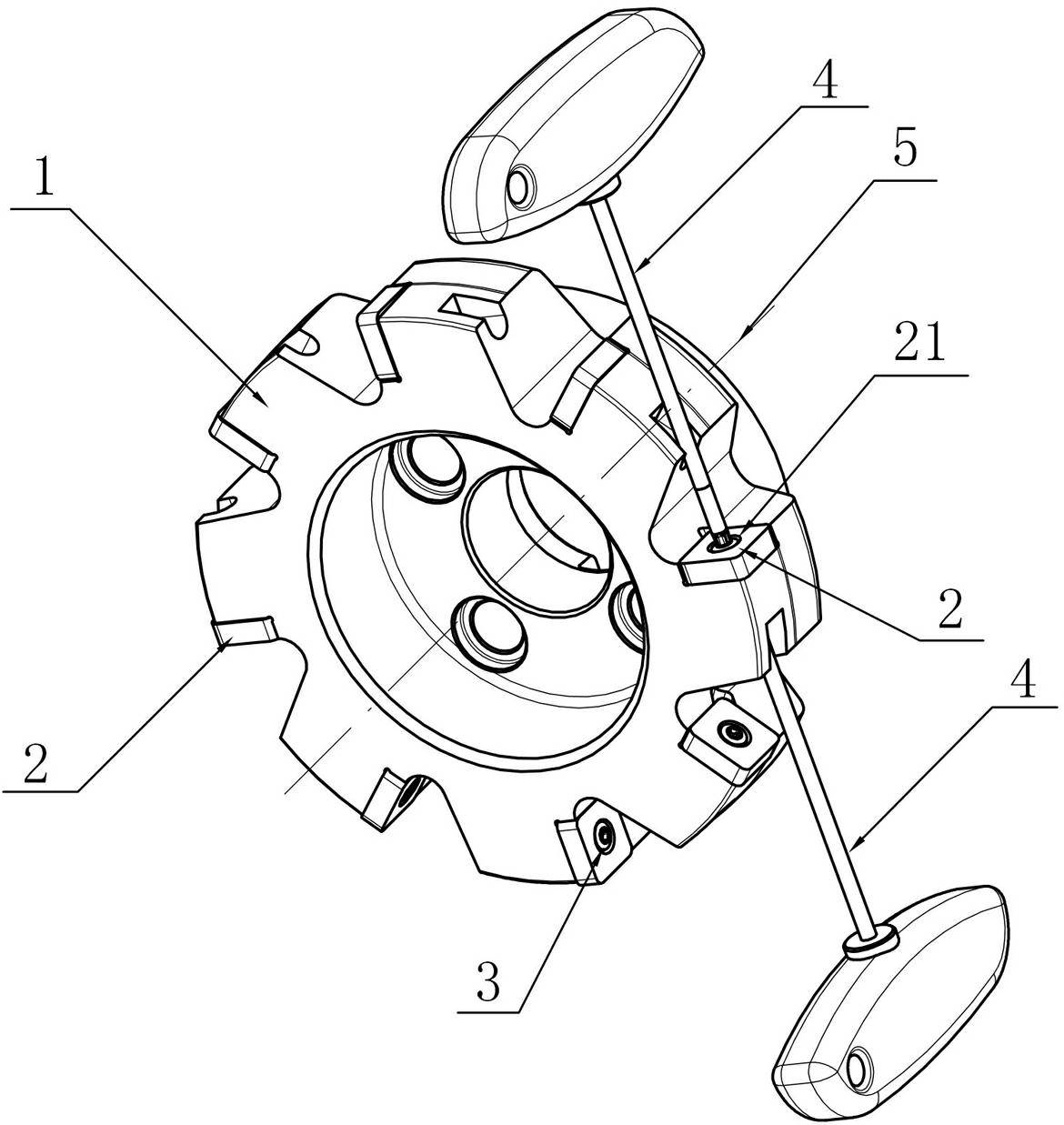

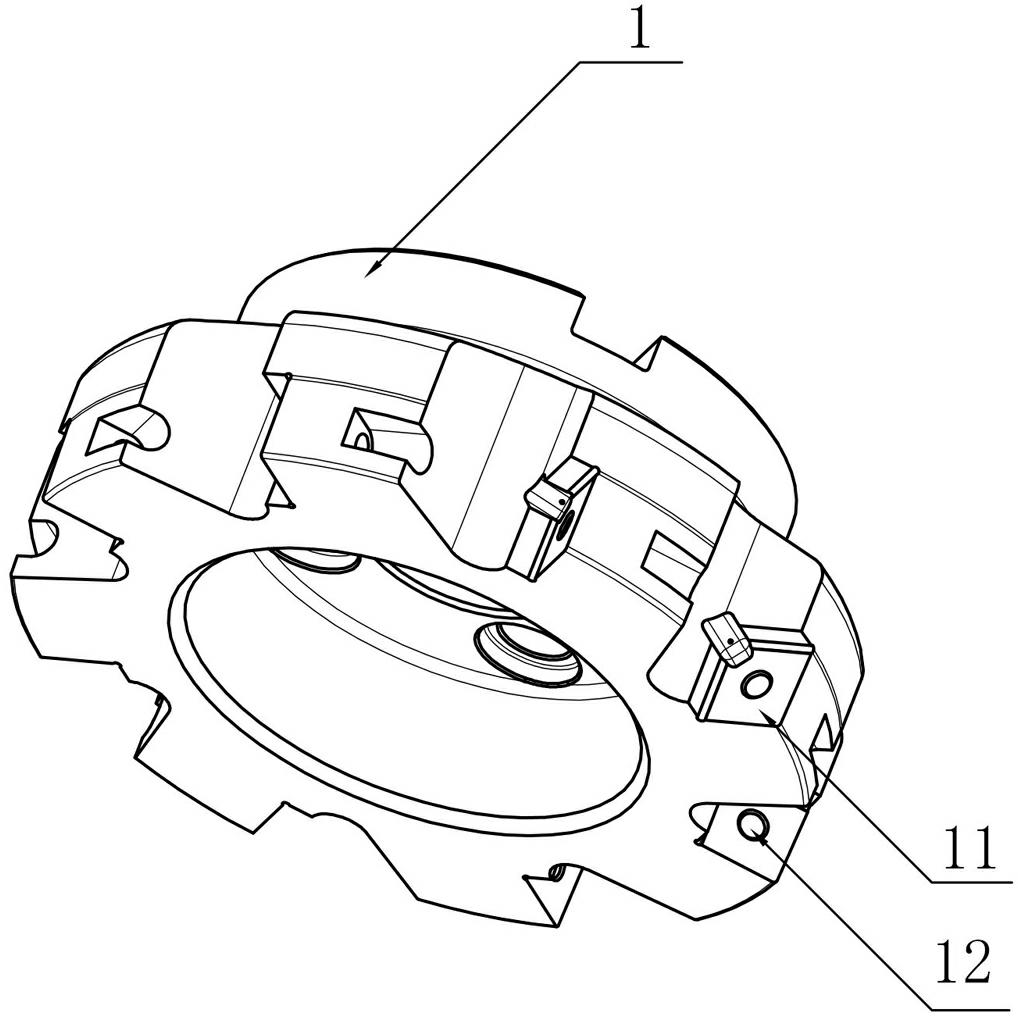

Milling cutter

InactiveCN102601439AImprove cutting stabilityReduce cutting vibrationMilling cuttersMilling cutterCutting force

The invention discloses a milling cutter, comprising a cutter body, cutting blades and a fastening piece, wherein the cutter body is at least provided with a group of cutter grooves; each cutter groove is internally provided with one cutting blade; each cutting blade is provided with a central hole and fastening piece connecting holes are arranged in the bottom surfaces of the cutter grooves; the head part of the fastening piece is pressed into the central hole and the tail part of the fastening piece passes through the central hole to be connected with the fastening piece connecting holes; the tail end of the fastening piece is provided with a first concave hole which is connected with a wrench in an inserting manner; and the fastening piece connecting holes pass through the cutter body. The milling cutter disclosed by the invention has the advantages of simple structure, convenience for attaching and detaching, relatively-increased blade number, high cutting efficiency, small cutting force and small vibration.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Automatic trimming equipment for wind turbine blade girder

PendingCN111571290AImprove cutting accuracyReduce pressure on environmental protectionAutomatic control devicesFeeding apparatusTurbine bladeTool bit

The invention discloses automatic trimming equipment for a wind turbine blade girder. The automatic trimming equipment comprises a transverse guide rail, a sliding table, a fixed cutter head, a movable cutter head and a sensing detection system, wherein the transverse guide rail is located on a to-be-cut girder; the sliding table is arranged in the length direction of the transverse guide rail, the fixed cutter head and a movable cutter head guide rail are arranged on the sliding table; the fixed cutter head and the movable cutter head can move up and down, the fixed cutter head is arranged onthe left side of the sliding table, and the movable cutter head is arranged on the movable cutter head guide rail and can move left and right relative to the fixed cutter head; and the sensing detection system is connected with the sliding table, the fixed cutter head and the movable cuter head and used for detecting the position of the girder, and the sliding table, the fixed cutter head and themovable cutter head are correspondingly controlled to move according to the detected signals, so that the to-be-cut girder is cut freely. The automatic trimming equipment can operate automatically, produces no dust and is high in cutting accuracy; two sides of front and back edges of the girder are cut simultaneously, and the working efficiency is high; the automatic trimming equipment senses andcontrols the cutting width, cuts the girders with different widths and has a wide applicable range; and quality accidents and safety accidents such as cut wounds of workers are avoided.

Owner:国能联合动力技术(保定)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com