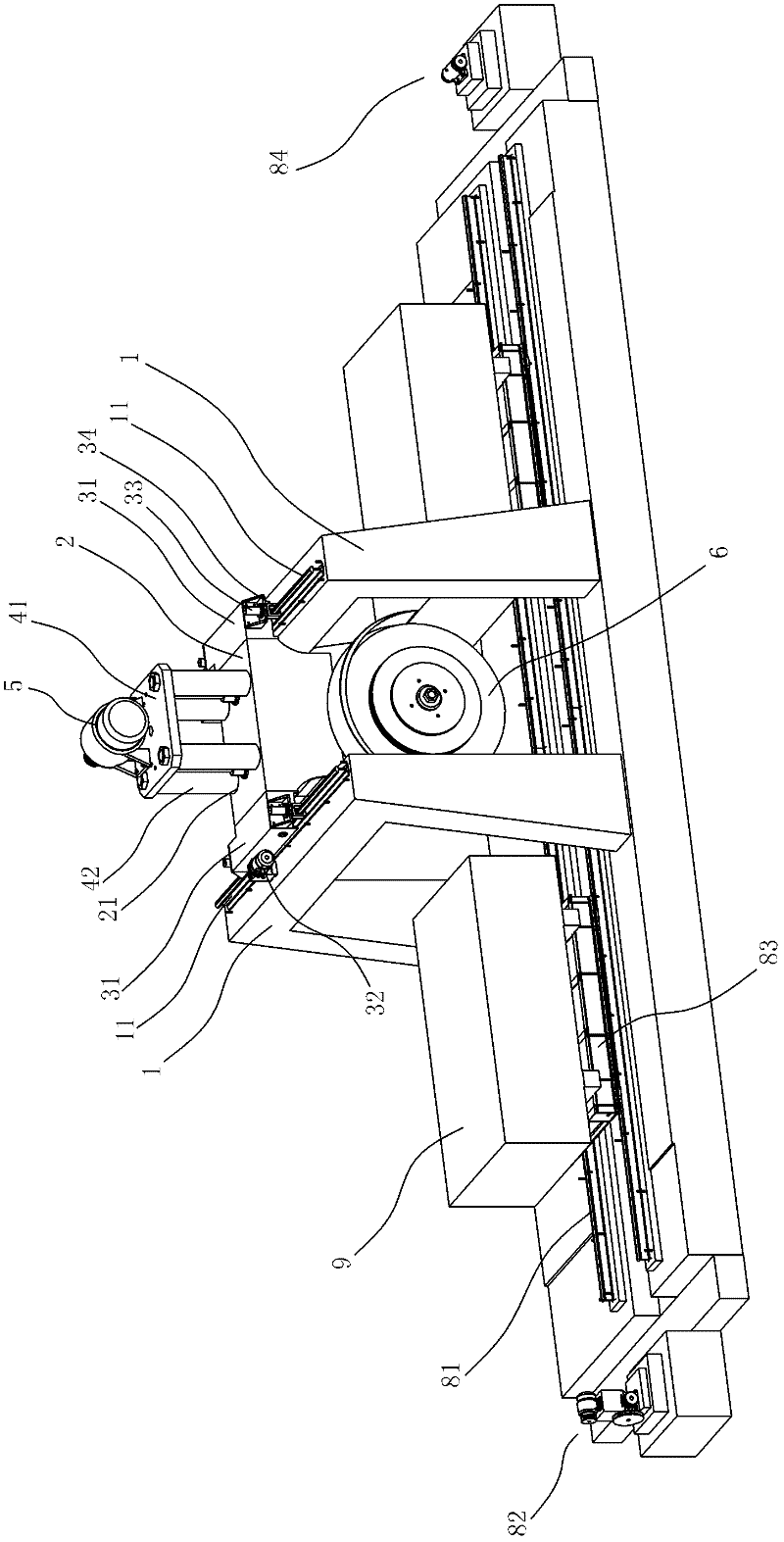

Large frame type gantry cutting machine

A large cutting machine and frame-type technology, applied in the field of stone processing, can solve the problems of large vibration, affecting the cutting accuracy and stability of the stone cutter, and low rigidity, and achieve the effect of reducing vibration, improving cutting accuracy and stability, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

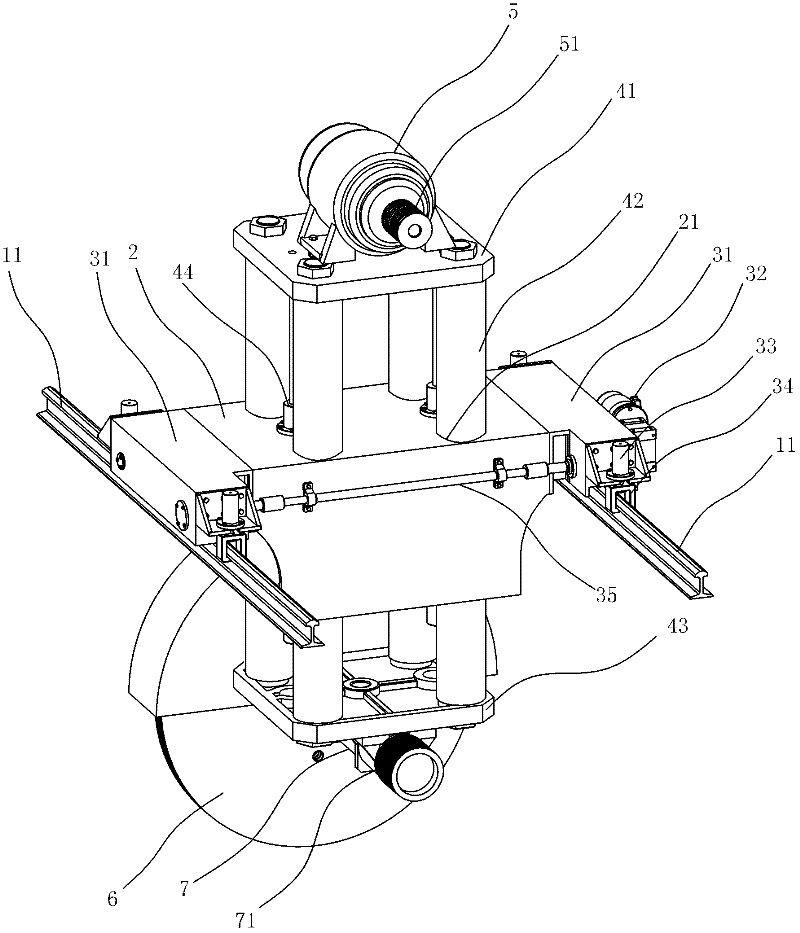

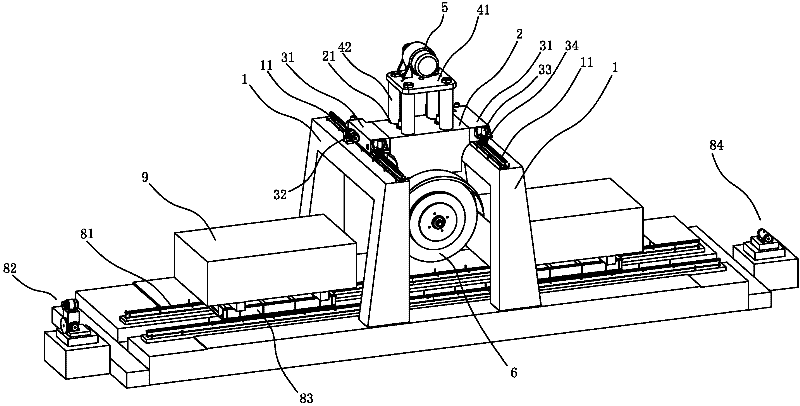

[0018] refer to figure 1 and figure 2 As shown, a frame-type gantry large cutting machine includes two gantry-type supports 1 arranged at intervals in the transverse direction, two longitudinal rails 11 that are arranged on the crossbeams of the two gantry-type supports 1 and extend horizontally along the longitudinal direction, and are movable between the two longitudinal rails 11. The main base body 2, the walking device that is arranged on the two sides of the main base body 2 and cooperates with the two longitudinal rails 11, the lifting frame that can be vertically lifted and moved to be arranged on the main base body 2, and the lifting frame that is arranged on the main base body 2 and the lifting frame Between the lifting oil cylinder 44 used to drive the lifting frame to move up and down, the main shaft 7 arranged longitudinally and horizontally at the lower end of the lifting frame, the saw blade 6 arranged on the main shaft 7, and the main shaft 7 that is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com