Live axle tunneling/turning method and device

A shaft tunneling and turning technology, which is applied in the field of live shaft tunneling and turning methods and devices, can solve the problems of difficulty in creating a non-rotationally symmetric free-form surface, affecting the geometric and physical characteristics of the machined surface, and inability to realize the reciprocating feed motion of the tool, etc. Achieve the effect of improving cutting efficiency, high surface quality and uniform surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

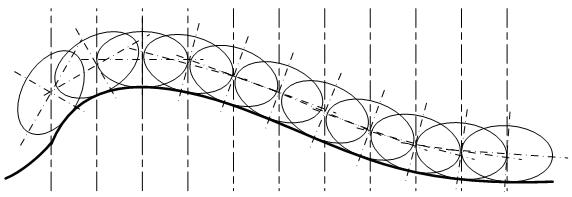

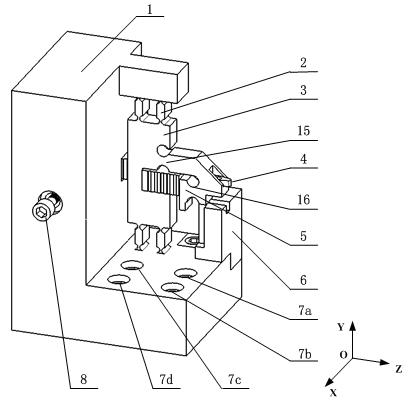

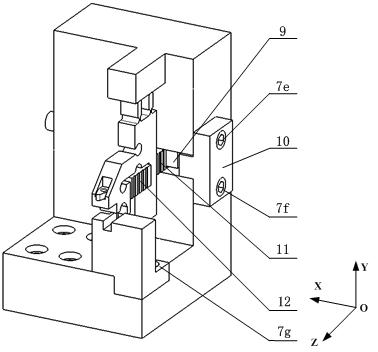

[0041] The present invention is a kind of live shaft excavation turning method, comprises the following steps:

[0042] (1) Clamp a workpiece on the front end of the spindle of an ultra-precision CNC lathe, and use a vacuum suction cup or a special fixture for clamping. The movement of the ultra-precision CNC lathe includes: the rotary motion of the spindle, X Lateral feed movement of the shaft slide and Z Longitudinal feed movement of the shaft slide;

[0043] (2) Install a live shaft driving and turning device on the X shaft slide or Z On the shaft slide, the driving signals of the two living shafts of the living shaft digging and turning device are actively controlled to synchronously form the fast reciprocating motion of the tool required for free-form surface turning and the fast cutting speed of the tool required for cutting difficult-to-machine materials. Excavation cutting movement.

[0044] The living shaft tunneling and turning method of the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com