Cutting mechanism of straw cutting machine

A technology of cutting mechanism and cutting machine, which is applied in cutting equipment, agricultural machinery and implements, applications, etc., can solve the problems of environmental pollution, large sulfur content, high ash content, etc., and achieve the effect of low operating cost, high applicability, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

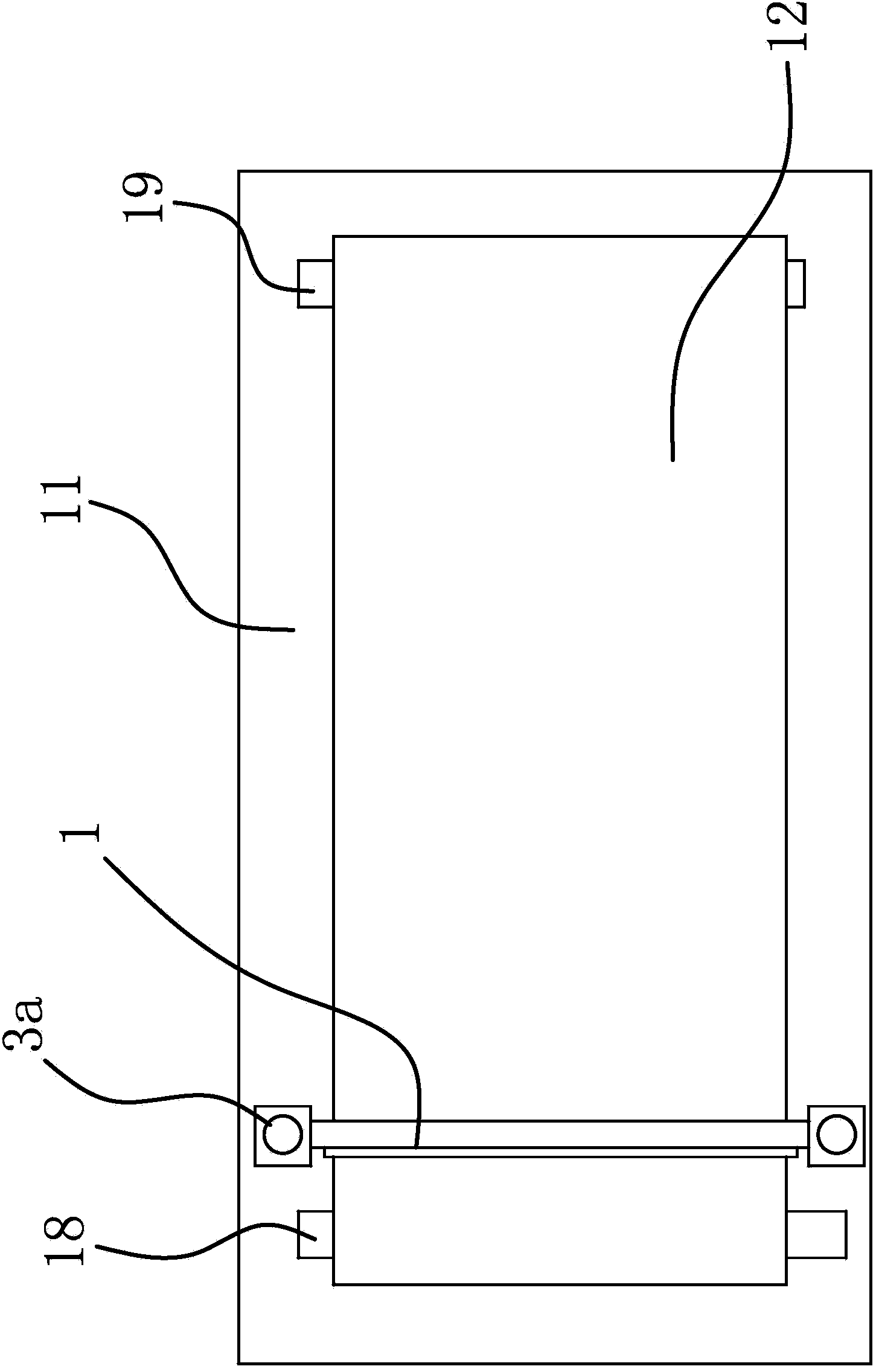

[0059] Such as figure 1 As shown, the straw cutting machine includes a frame 11 with a movable conveyor belt 12 on the frame 11 , and the cutting mechanism of the straw cutting machine is arranged on the frame 11 and close to the conveyor belt 12 .

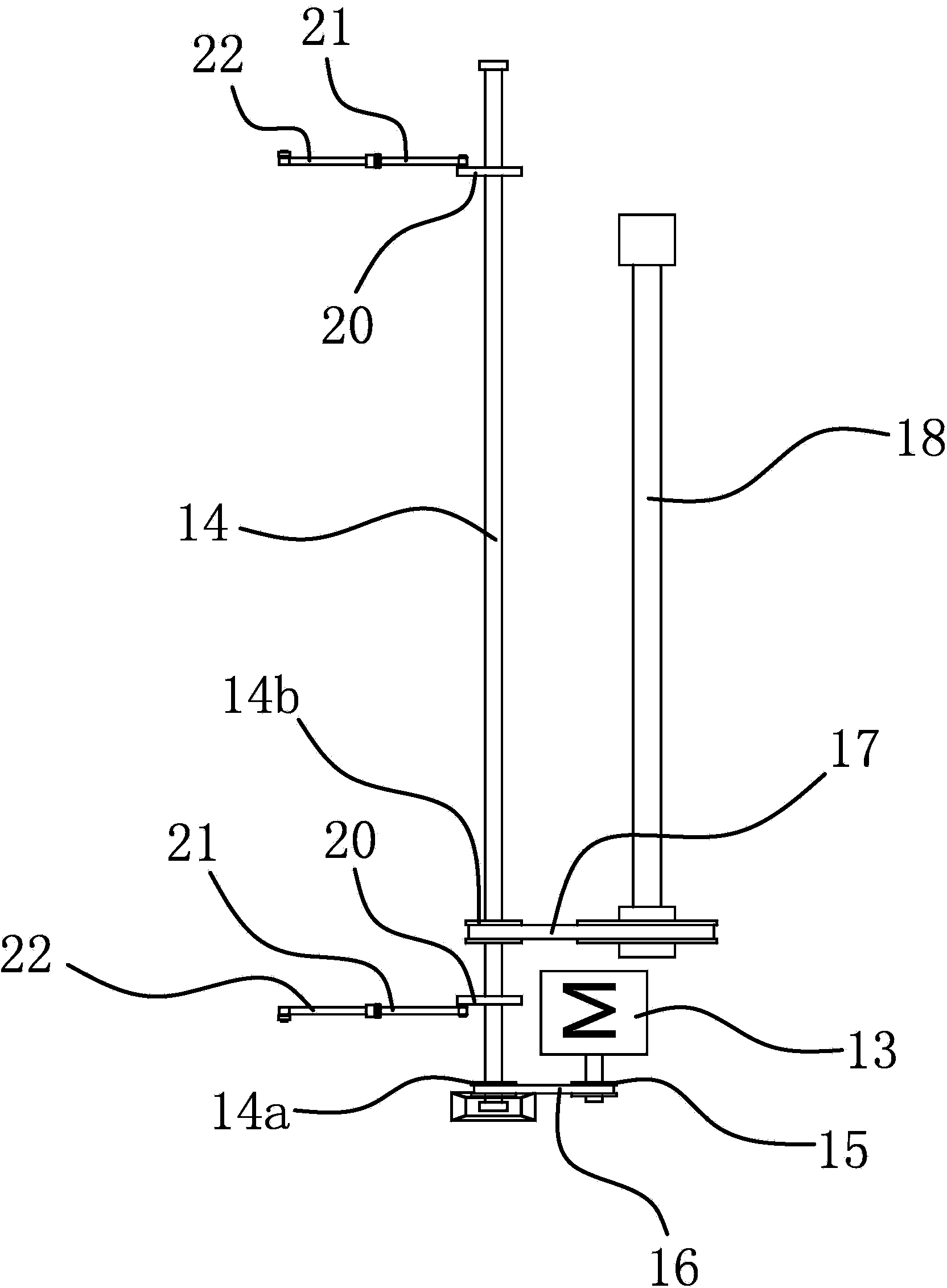

[0060] The cutting mechanism of the straw cutting machine includes a knife rest 3, a cutter 1, a pretensioner 7 and a driving member 13. There is a guide structure between the knife rest 3 and the frame 11, and the guide structure can make the knife rest 3 relative to the frame. 11 Pan up and down.

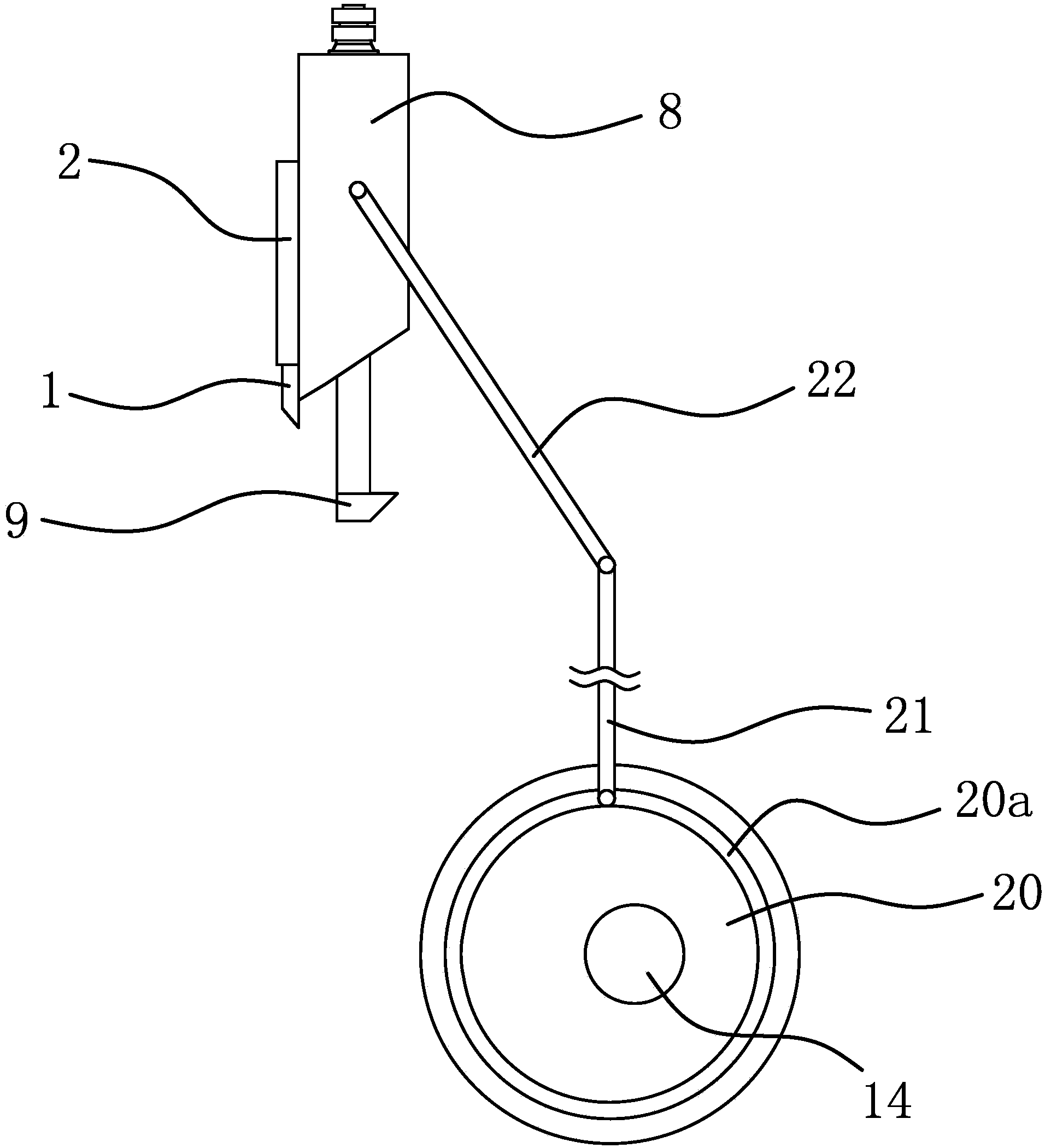

[0061] The cutter 1 is fixedly connected to the knife holder 3, the pretensioning part is connected to the knife holder 3 and after the pretensioning part is in contact with the straw material, the pretensioning part can move up, so that the pretensioning part moves from the lower part of the cutter 1 to the Cutter 1 is flush with each other.

[0062] There is a transmission mechanism one between the driver 13 and the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com