Automatic trimming equipment for wind turbine blade girder

A wind power blade, automatic cutting technology, applied in the direction of automatic control devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of unfavorable health of employees, low work efficiency, poor manual cutting accuracy, etc., to improve cutting stability High performance and cutting accuracy, avoid manual cutting, reduce the effect of environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the purpose, structure and function of the present invention, a wind power blade girder automatic trimming device of the present invention will be further described in detail in conjunction with the accompanying drawings.

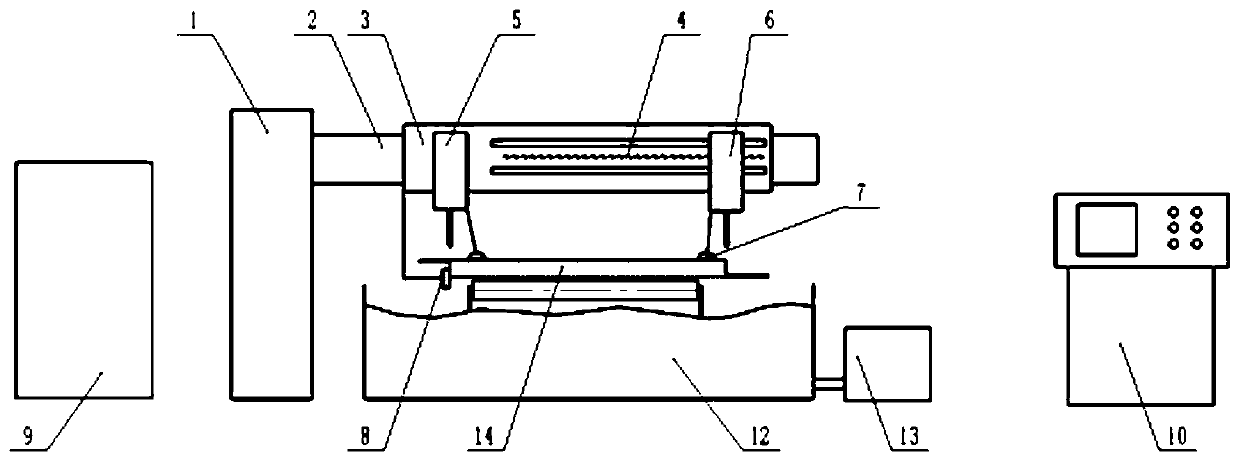

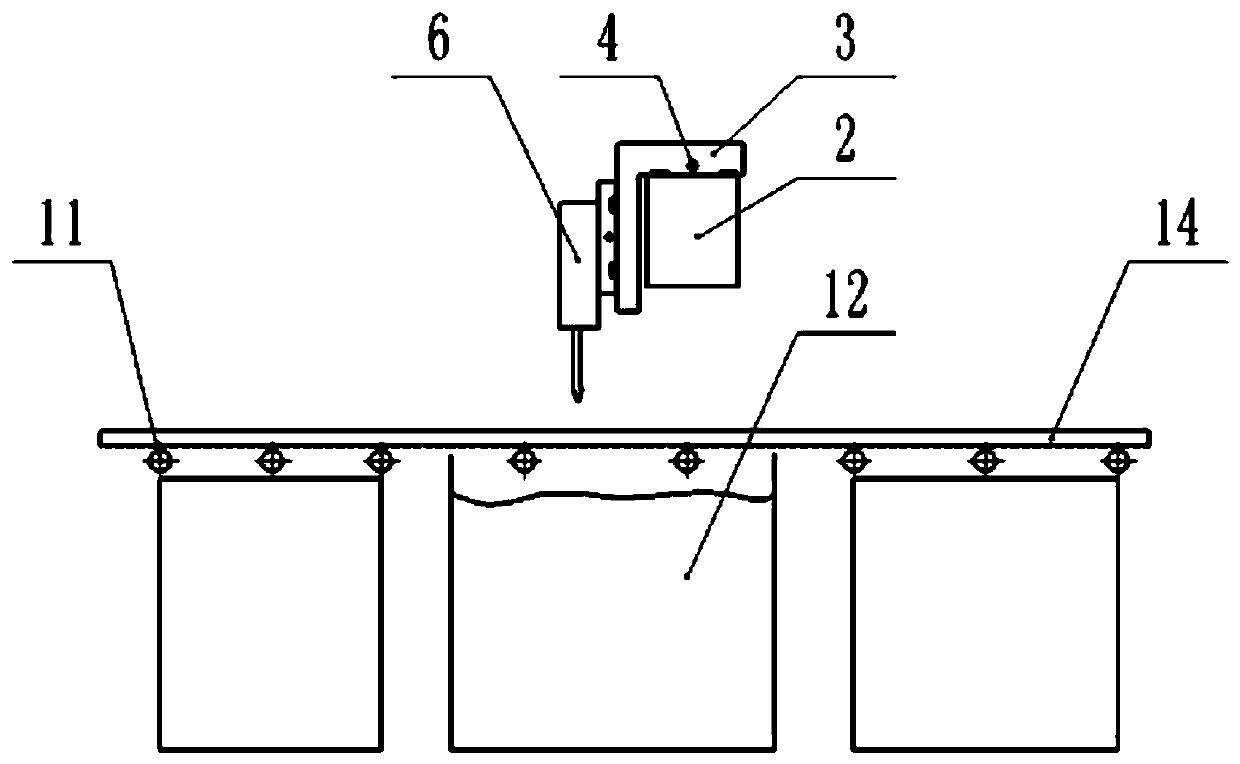

[0016] Such as Figure 1 to Figure 2 As shown, it is shown as a wind power blade girder automatic edge trimming device of the present invention, comprising a transverse guide rail 2, suspended above the girder 14 to be cut on the conveying platform 11, and fixed to the ground through the frame 1 connected by the side, and The length direction of guide rail 2 is provided with slide table 3 that can move left and right, slide table 3 is provided with fixed cutter head 5, movable cutter head guide rail 4, fixed cutter head 5 is positioned at the left side of slide table 3, and the right The side is provided with a movable cutter head 6, and the fixed cutter head 5 and the movable cutter head 6 can move up and down, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com