Cropping device

A cutting and cutting technology, applied in the field of cutting equipment, can solve the problems of large number of cylinders, occupation, and many parts, and achieve the effect of expanding the scope of use, reducing the use, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

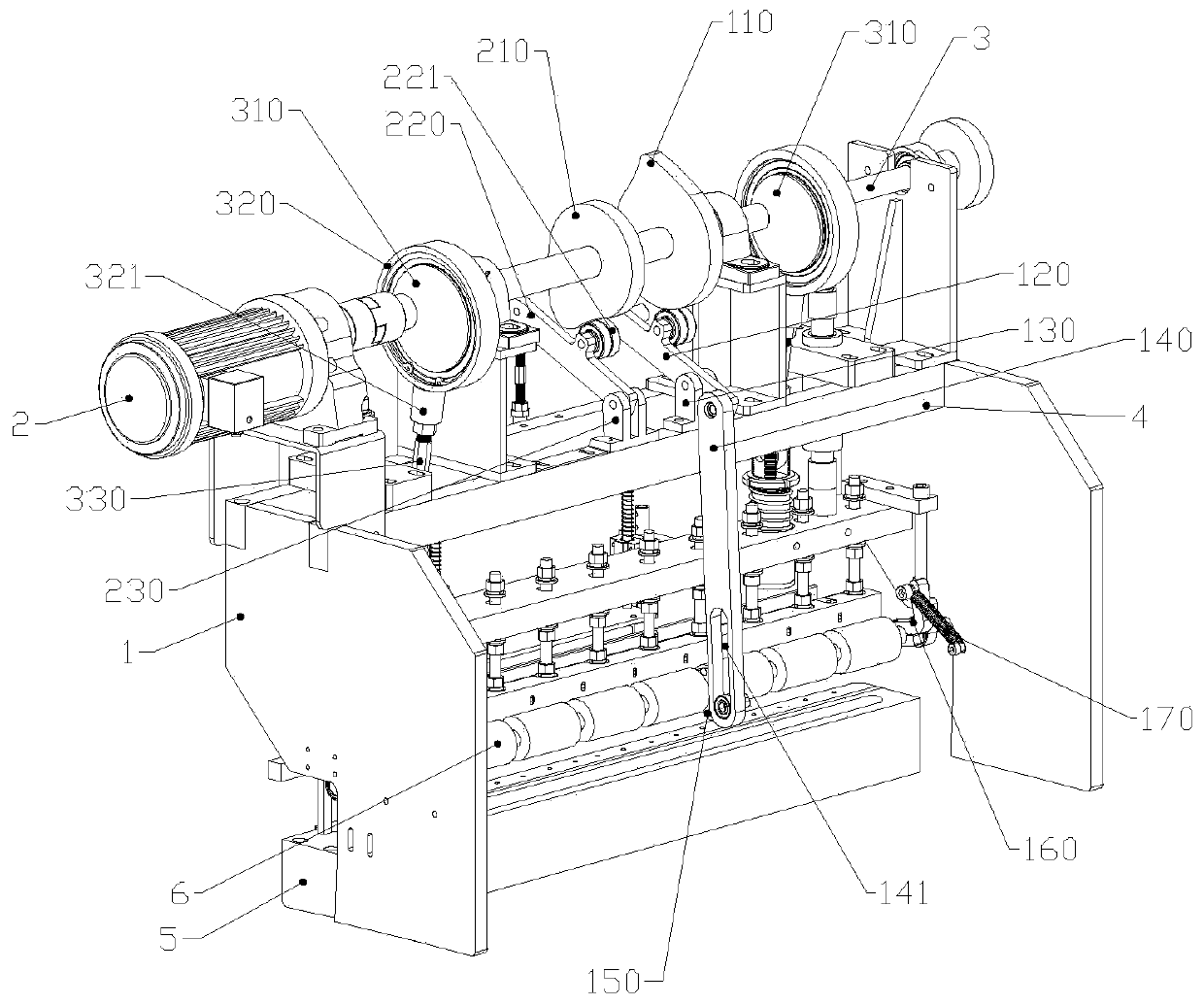

Embodiment 1

[0054] Example 1 combined figure 1 , figure 2 , image 3 As shown, a cutting device includes a cutting unit, and the linkage unit includes a bag rubbing unit, a bag pressing unit, and a cutting unit. The first transmission structure, the second transmission structure and the third transmission structure. In this embodiment, the cutting unit, bag rubbing unit, and bag pressing unit all use the combination of cam and transmission to realize specific actions. The cams and connecting rods in the cutting unit are respectively named as the first eccentric wheel 310 and the second Eccentric wheel 310, cam sleeve connecting rod 330, the cam and connecting rod in the rubbing bag unit are named as the first cam 110, the first connecting rod 140, and the cam and connecting rod in the bag pressing unit are named as the second cam 210, The second connecting rod 240 . Such as figure 1 As shown, the first eccentric wheel 310, the second eccentric wheel 310, the first cam 110, and the s...

Embodiment 2

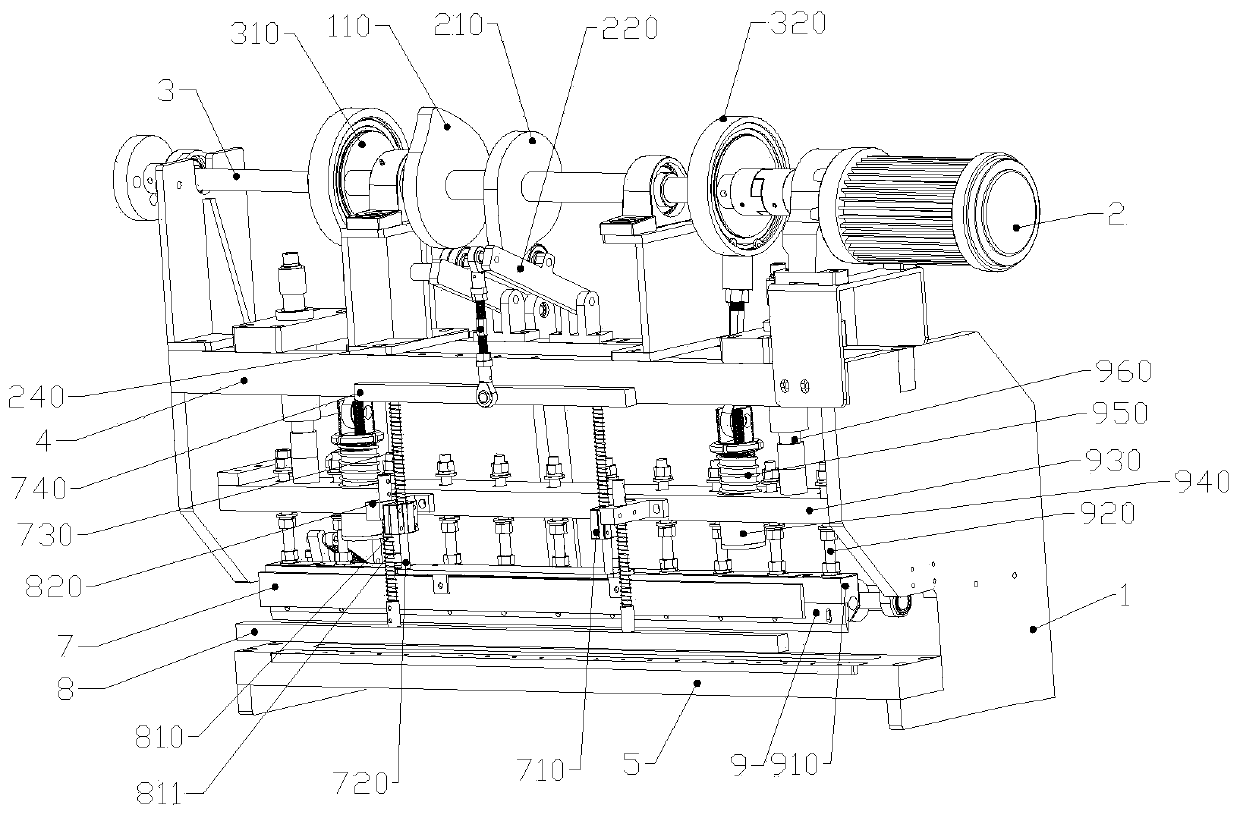

[0085] Embodiment 2 In this embodiment, on the basis of Embodiment 1, an auxiliary flattening unit (also a kind of bag pressing unit) is added to cooperate with the cutting mechanism by adopting a mechanical structure. The auxiliary flattening unit includes an auxiliary rod 8 (that is, the auxiliary flattening member described in the summary of the invention), the two ends of the auxiliary rod 8 are fixedly connected with the second connecting rod 810, and the two ends of the connecting rod two 810 are respectively fixed to the fixing seat of the bag pressing unit through the second fixing seat 820 On -710, in this way, the auxiliary flattening unit, the bag pressing unit, and the cutter 9 unit can act synchronously, and before the cutter 9 performs cutting or synchronously with the cutter 9, the material is compressed for cutting.

[0086] The second fixed seat 820 is provided with a vertical through hole, the top of the connecting rod two 810 passes through the through hole f...

Embodiment 3

[0089] Embodiment 3 This embodiment provides a cutting device, which differs from Embodiments 1 and 2 in that a heat insulation unit is added to the linkage unit, and the heat insulation board 7 is a strip plate, which adopts heat insulation Made of material such as heat-insulating bakelite, the heat-shielding board 7 is usually arranged parallel to the cutter 9 . The heat insulation unit has its own independent fourth transmission structure and fourth cam. The fourth cam is also sleeved on the main shaft 3. The most protruding part of the fourth cam rotates to the bottom of the main shaft 3 no later than the first eccentric wheel 310. The second eccentric wheel 310.

[0090] In particular, the connection between the heat shield 7 and the fourth transmission structure can also be divided into two connection relationships: first, direct connection: the heat shield 7 is symmetrically arranged, and its center is connected to the fourth transmission structure of the fourth transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com