Sawtooth-shaped cutting steel wire with flat section

A technology for cutting steel wire and zigzag, which is applied in the field of flat cross-section zigzag cutting steel wire, which can solve problems such as low tensile strength, slippage, and reduced photoelectric conversion efficiency of silicon wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

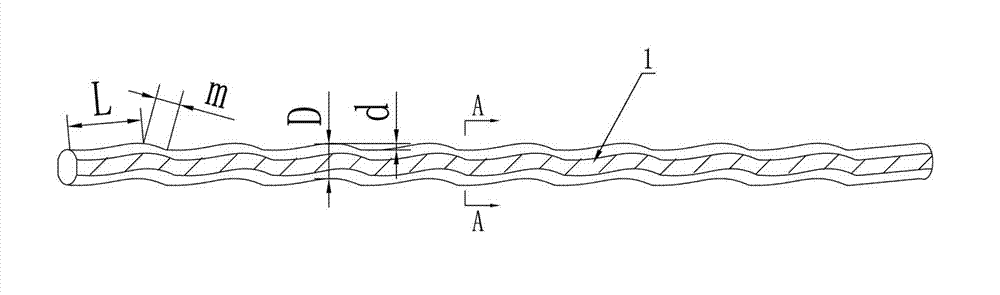

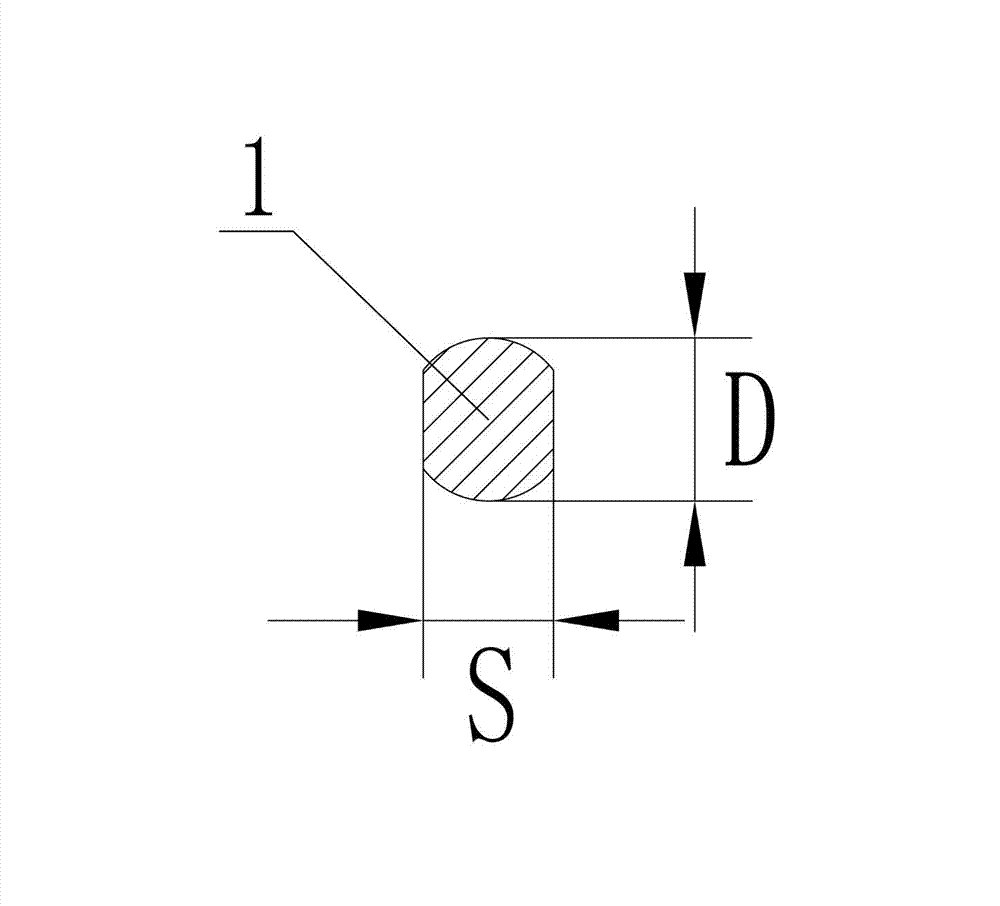

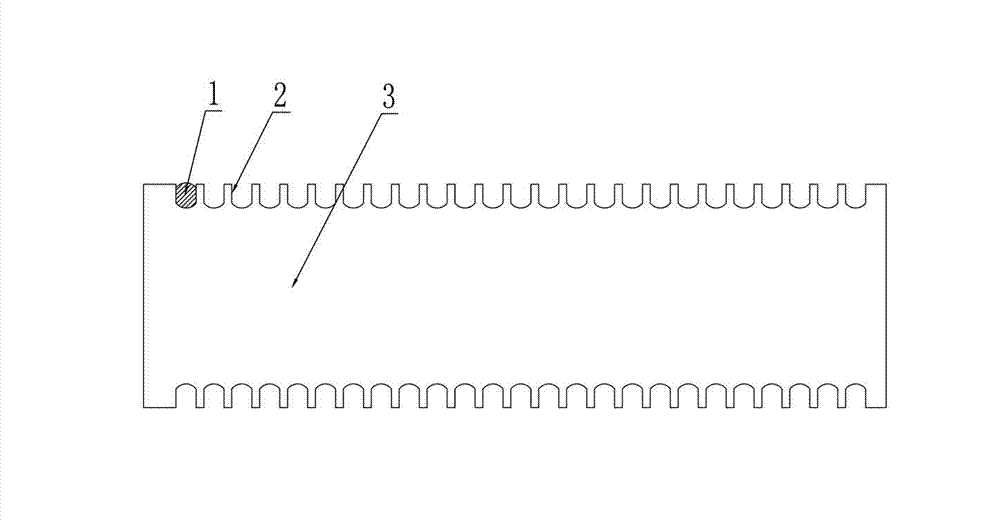

[0014] Such as figure 1 , figure 2 , image 3 As shown, the flat section zigzag cutting steel wire includes: cutting steel wire 1, the cross section of the cutting steel wire 1 is set in a flat shape, the cutting steel wire 1 is continuously zigzag distributed along its axial direction, and the sawtooth in the cutting steel wire 1 The length of the short side m of the sawtooth is 1 / 3 to 1 / 2 times the length of the long side L of the sawtooth, and the height d of the sawtooth is 0.15 to 0.3 times the height D of the flat cross-section of the cutting steel wire 1. The setting of the sawtooth It can effectively increase the feeding speed of the silicon rod when the cutting steel wire 1 cuts silicon crystals, and further improves the cutting efficiency of the cutting steel wire 1 for silicon crystals; the ratio of the width S to the height D of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com