Scalpel preliminary cleaning box

A scalpel and preliminary technology, applied in the field of cleaning boxes, can solve problems such as time-consuming, cumbersome and complicated cleaning process, etc., and achieve the effect of good cleaning effect and improving cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

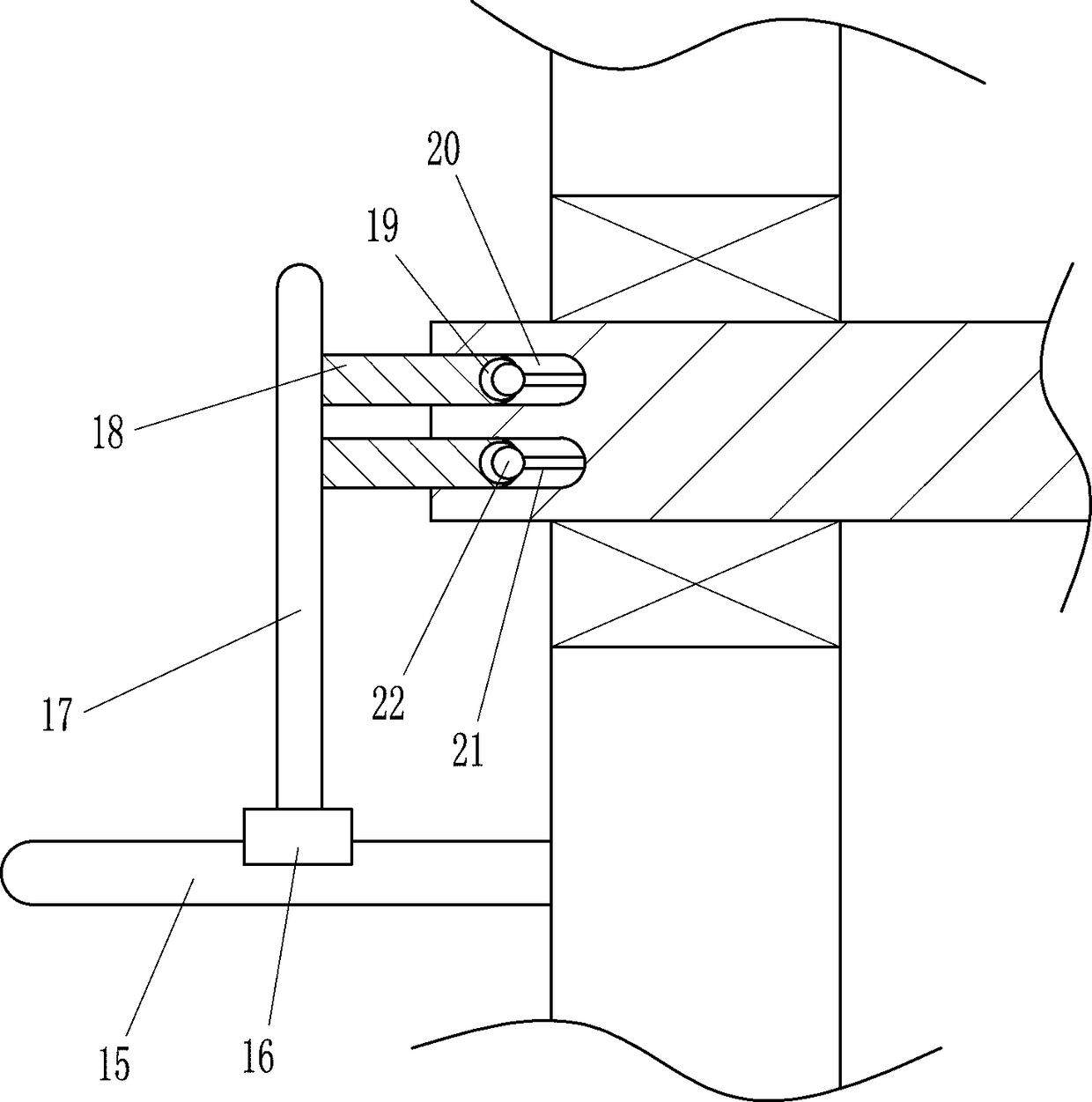

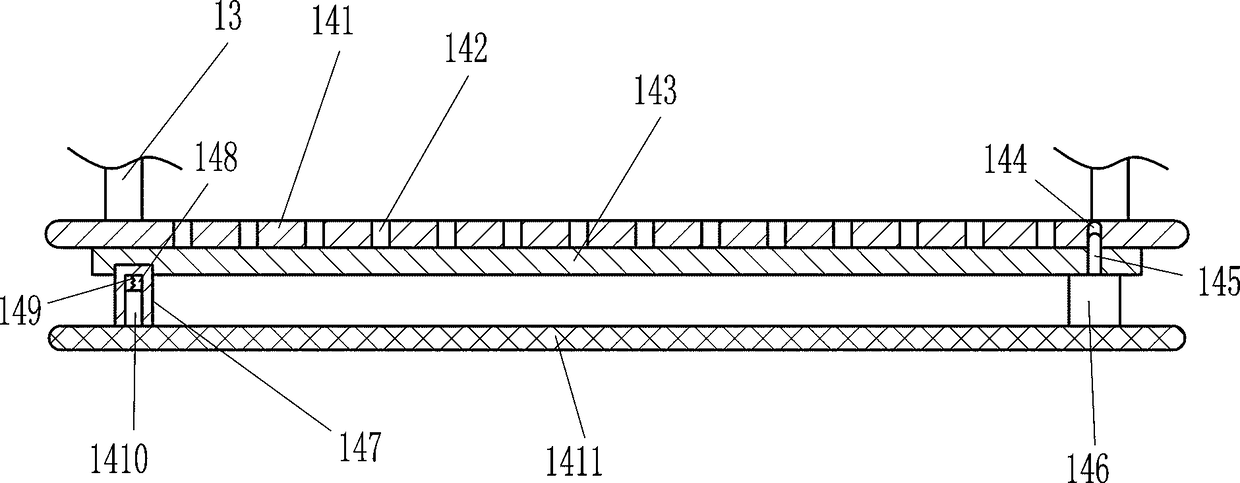

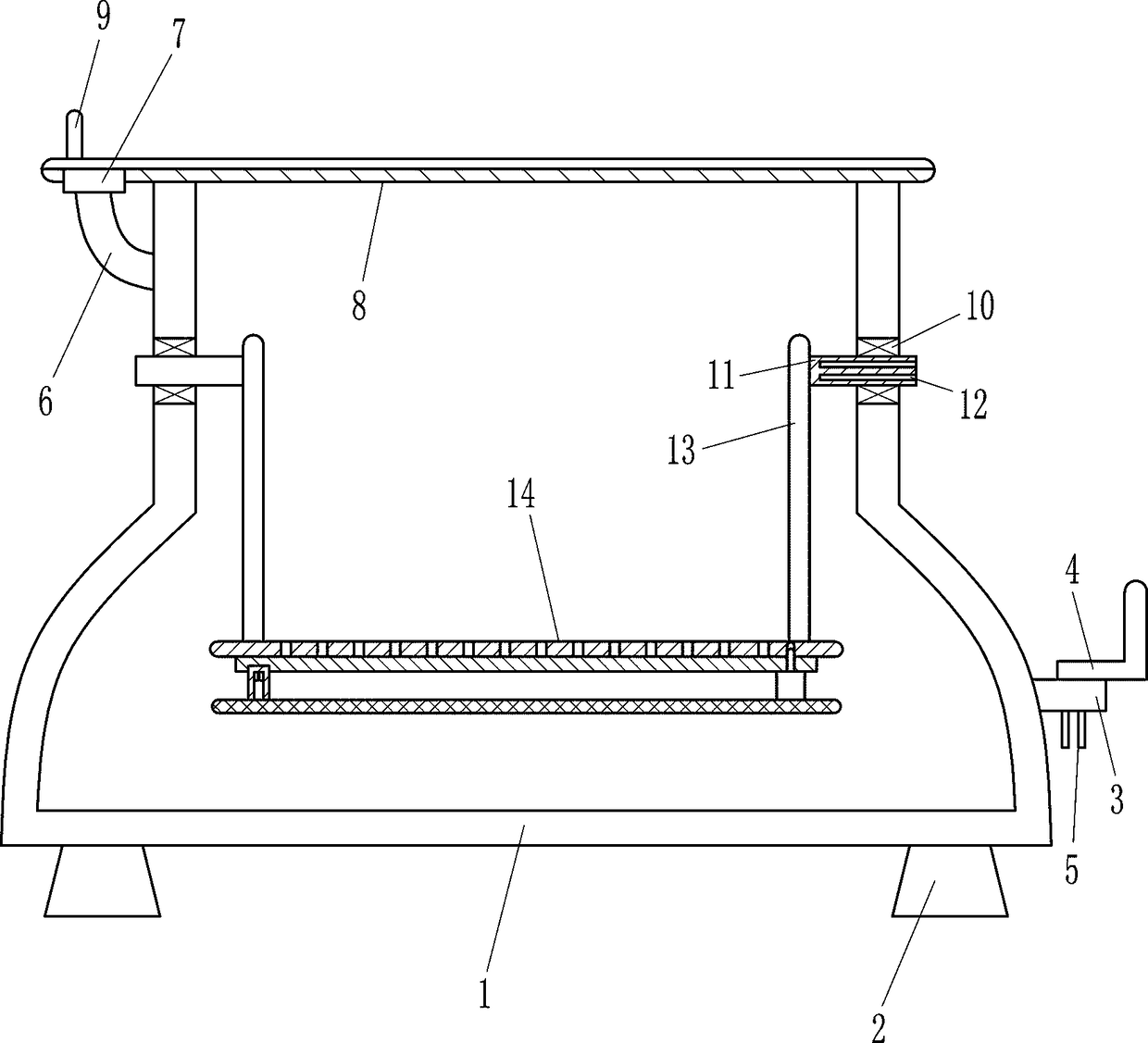

[0016] A scalpel preliminary cleaning box, such as Figure 1-4 As shown, it includes a frame body 1, a foot pad 2, a ring 3, a grip 4, a plunger 5, a first connecting rod 6, a first sliding block 7, a first sliding rail 8, a cover plate 9, and a bearing seat 10. , Rotating shaft 11, swing rod 13 and placing device 14, placing device 14 includes placing plate 141, second slide rail 143, bolt 145, spacer 146, second sliding block 147, spring 149 and guide rod 1410, frame body 1 There are foot pads 2 on the left and right sides of the bottom, the lower right part of the frame 1 is provided with a ring 3, the top of the ring 3 is placed with a grip 4, and the bottom left of the grip 4 is provided with two insertion rods 5 for insertion The lower part of the rod 5 passes through the ring 3, the upper left part of the frame body 1 is provided with a first connecting rod 6, the top of the first connecting rod 6 is provided with a first sliding block 7, and the first sliding block 7 is...

Embodiment 2

[0018] A scalpel preliminary cleaning box, such as Figure 1-4 As shown, it includes a frame body 1, a foot pad 2, a ring 3, a grip 4, a plunger 5, a first connecting rod 6, a first sliding block 7, a first sliding rail 8, a cover plate 9, and a bearing seat 10. , Rotating shaft 11, swing rod 13 and placing device 14, placing device 14 includes placing plate 141, second slide rail 143, bolt 145, spacer 146, second sliding block 147, spring 149 and guide rod 1410, frame body 1 There are foot pads 2 on the left and right sides of the bottom, the lower right part of the frame 1 is provided with a ring 3, the top of the ring 3 is placed with a grip 4, and the bottom left of the grip 4 is provided with two insertion rods 5 for insertion The lower part of the rod 5 passes through the ring 3, the upper left part of the frame body 1 is provided with a first connecting rod 6, the top of the first connecting rod 6 is provided with a first sliding block 7, and the first sliding block 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com