Numerically controlled lathe spindle drilling device

A CNC lathe and drilling technology, which is applied to the positioning device, clamping device, boring machine/drilling machine parts, etc., can solve the problem that the tool cannot be cut and processed, so as to improve production efficiency, shorten the process flow, and reduce the labor intensity of employees. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

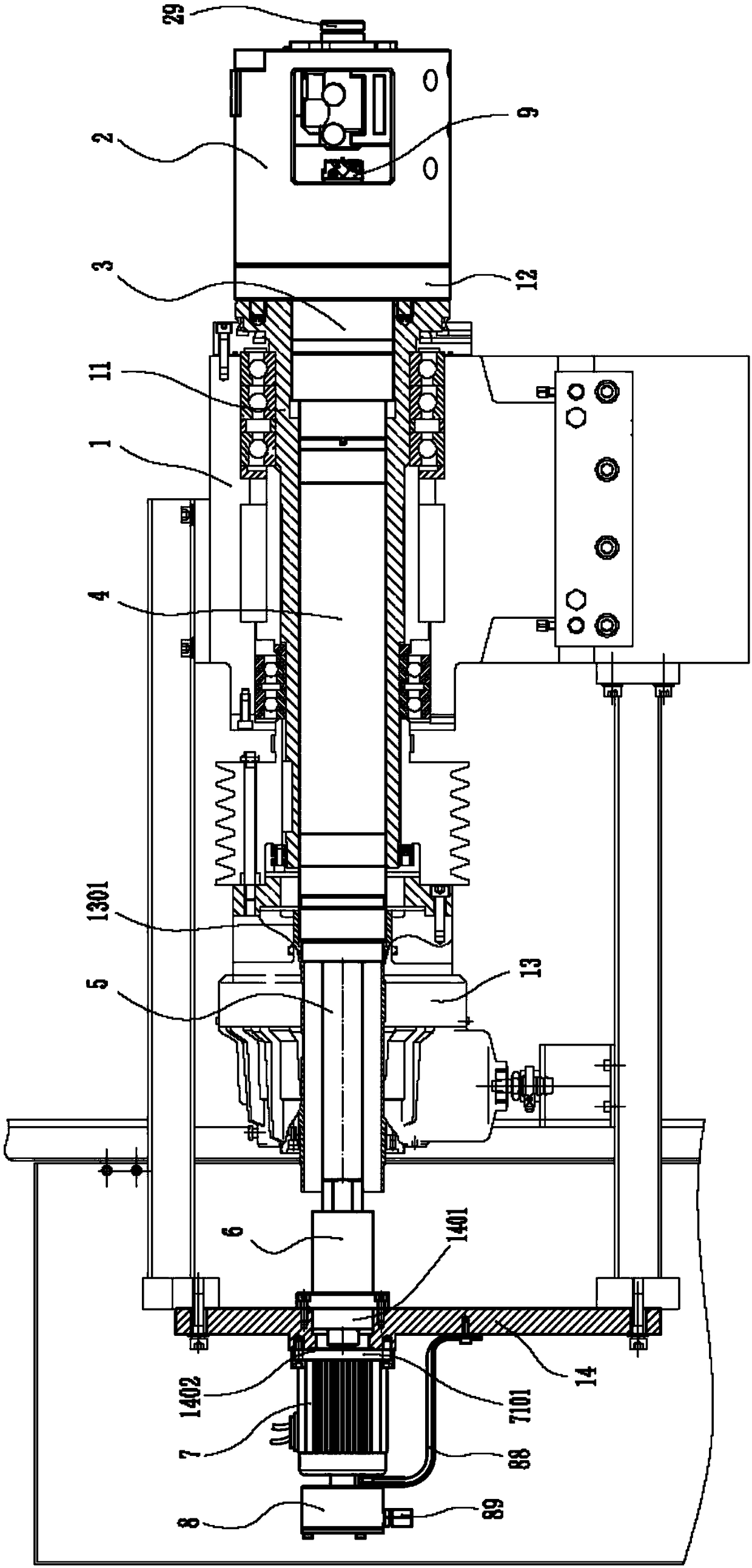

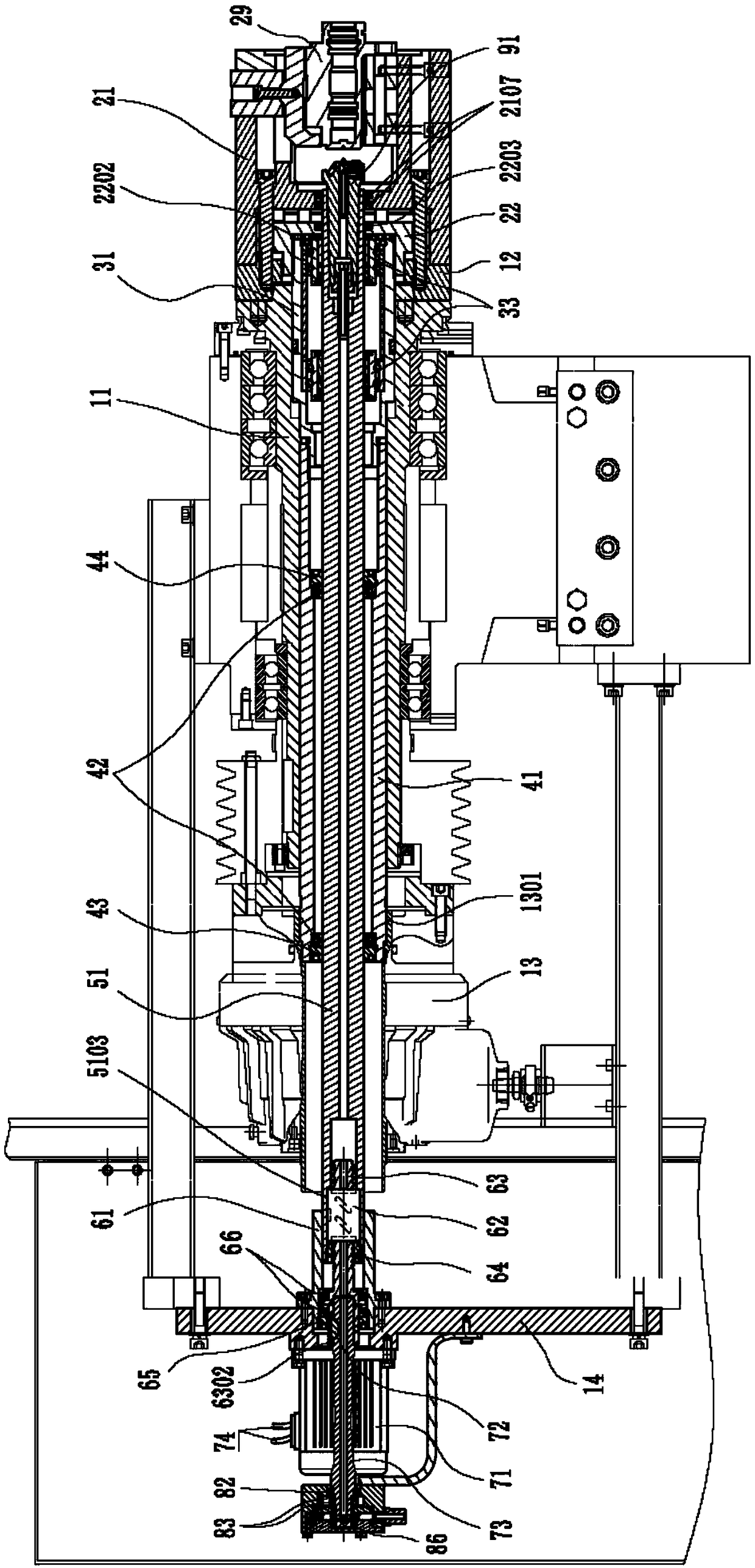

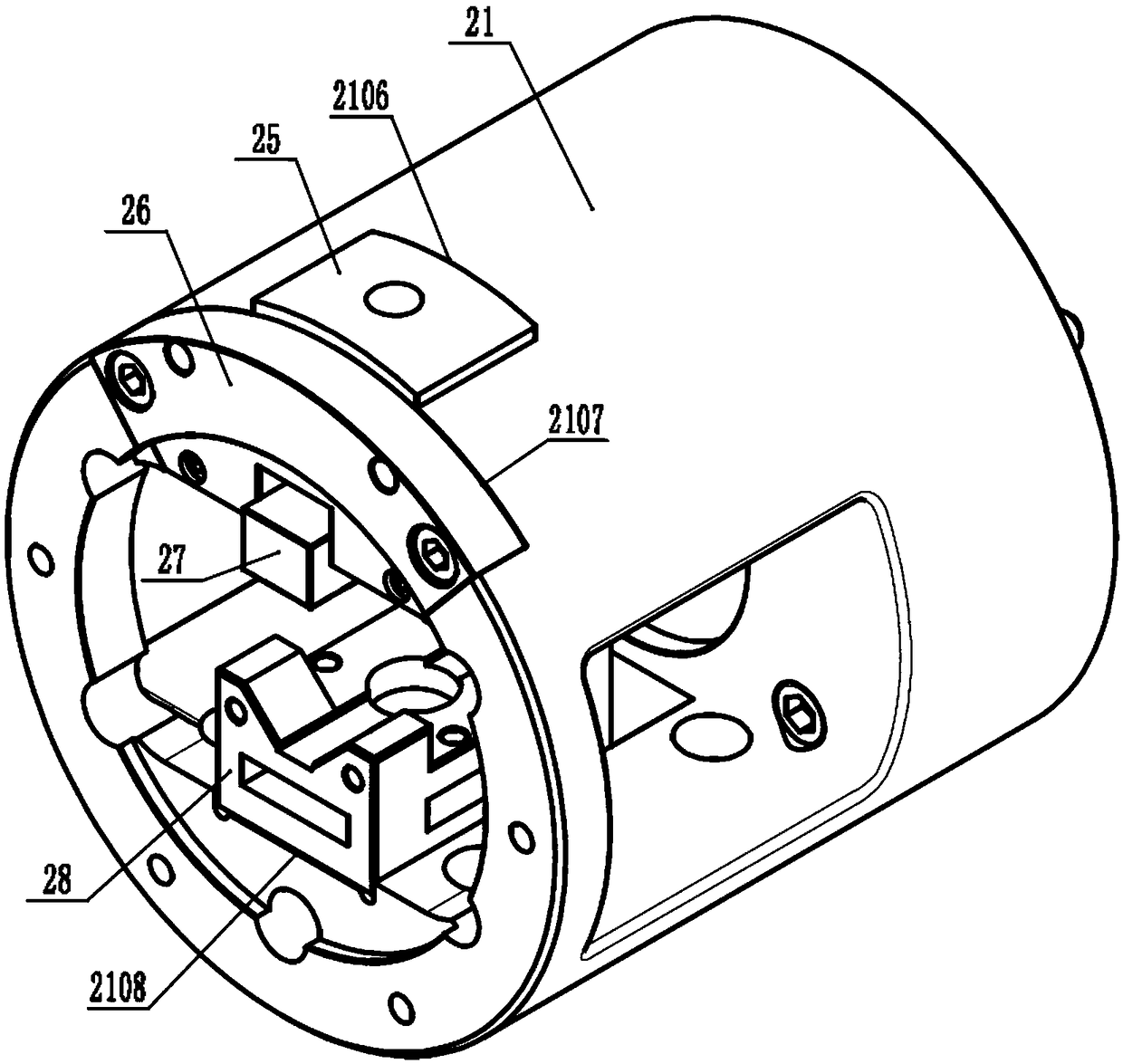

[0053] refer to figure 1 and Picture 1-1 Shown: including CNC lathe 1, fixture 2, support sleeve 3, pull tube 4, mandrel 5, ball screw pair 6, improved servo motor 7, liquid flow device 8, drilling taper shank combination tool 9, of which: method The blue plate 12 is fixedly connected with the machine tool spindle 11, the spigot at the left end of the rotary body 21 of the fixture 2 is fixedly connected with the step circle at the right end of the flange plate 12, the external thread at the right end of the step sleeve 31 of the support sleeve 3 is connected with the left end of the cap piston 22 in the inner cavity of the fixture The inner hole is threadedly connected, the external thread at the left end of the step sleeve 31 is connected with the internal thread at the right end of the hollow pipe 41 of the drawing tube 4, the external thread at the left end of the hollow pipe 41 is connected with the internal thread 1301 at the right end of the machine tool spindle hydraul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com