Low-energy-consumption method for preparing fiberboards by using bio-enzyme to separate fibers

A fiber separation and biological enzyme technology, which is applied in the field of materials to reduce energy consumption, promote rapid development, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

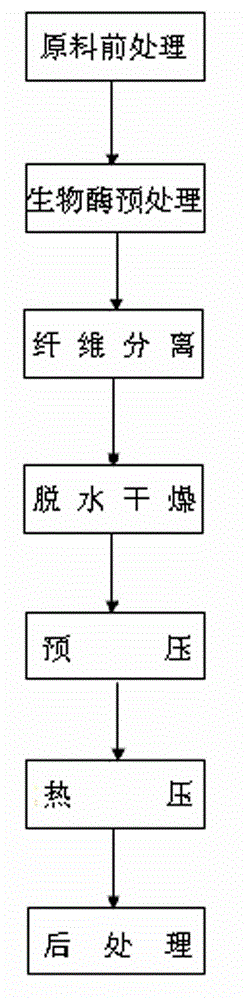

[0016] The fiberboard preparation method of low energy consumption bio-enzyme fiber separation according to the present invention includes raw material pretreatment, bio-enzyme pretreatment, fiber separation, dehydration and drying, pre-pressing, hot pressing, and post-processing steps, specifically including:

[0017] A. Raw material pretreatment: adjust the moisture content of raw wood, crop straw or bamboo to 30-50%, and crush it into wood chips, bamboo chips or crop straw scraps with a length of 1-2cm, a width of 2-3cm, and a thickness of 3-5mm for later use;

[0018] B. Biological enzyme pretreatment: add a biological enzyme solution with a solid-liquid ratio of 10 to 50 times to the pretreated raw materials for 5 to 120 minutes, and then add 10 to 50 times of ligninase for 5 to 120 minutes;

[0019] C. Fiber separation: the wood chips, bamboo chips or crop straw scraps pretreated by biological enzymes are separated by a disc mill;

[0020] D. Dehydration and drying: dehy...

Embodiment 1

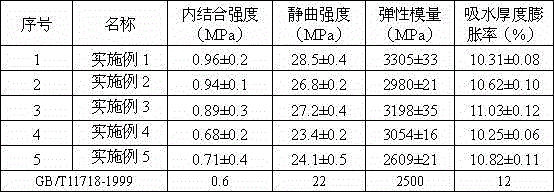

[0035] Example 1 ——Preparation of eucalyptus fiberboard by separating fibers by biological enzyme method

[0036] Eucalyptus is used as the raw material of the board. It has been determined that the moisture content of eucalyptus raw materials is 8 to 10%, and the raw materials are humidified to control their moisture content to 40%. Use a chipper to make raw materials into wood chips with a length of 1-2cm, a width of 2-3cm, and a thickness of 3-5mm. The wood chips are placed in a solution of biological enzymes (pectinase and ligninase) at a temperature of 60°C. The concentration of the enzyme is 10%, the ratio of wood chips to solution is 30%, and the treatment time is 30 minutes; the treated wood chips or scraps are separated into fibers by a disc mill; the separated fibers are dehydrated, and then sizing and sizing The amount is 12% of the weight of the fiber, while adding 1% paraffin emulsion, and then drying the fiber to a moisture content of 8-10%. Lay the fibers afte...

Embodiment 2

[0037] Example 2 ——Biological enzymatic separation of fibers to prepare eucalyptus fiberboard

[0038] Repeat Example 1, with the following differences: first use a temperature of 50°C and a concentration of 20% pectinase solution for 10 minutes, then use a temperature of 60°C and a concentration of 10% ligninase solution for 10 minutes, wood chips and solution The ratio is 50%, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com