Water soluble full-alloy metal grinding fluid

A fully synthetic, grinding fluid technology, applied in the field of metal grinding fluid, can solve problems such as poor lubricating performance and anti-rust performance, large surface roughness of the workpiece, rapid surface rust return, etc., to achieve excellent lubrication and no organic residues , The effect of long storage life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

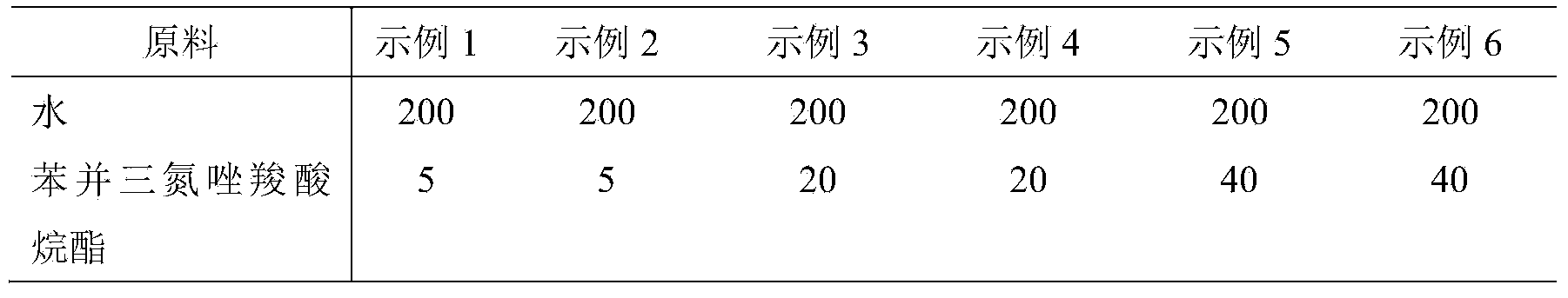

[0040]Example 1 Water-soluble fully synthetic metal grinding fluid concentrated stock solution proportioning example

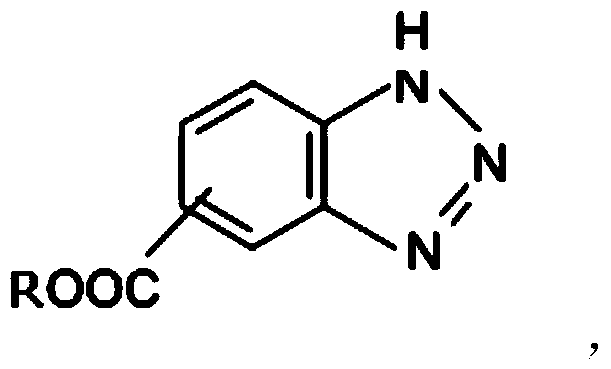

[0041] Preparation method of long-chain nitrogen-containing heterocyclic organic ester (long-chain benzotriazole carboxylic acid alkyl ester) in the present invention:

[0042] (1) Add 0.01~0.2mol benzotriazole carboxylic acid, 10~150mL SOCl 2 and 1-15mL DMF, heated to reflux for 1-5 hours;

[0043] (2) Cool, add 15-250mL petroleum ether, precipitate benzotriazole carboxylic acid chloride, filter;

[0044] (3) Add 2 to 40 g of sodium hydroxide, 15 to 300 mL of water and 0.01 to 0.2 mol of alkyl alcohol into another three-necked flask, place it in ice water, and dissolve the benzotriazole carboxyl Acyl chloride is added to the reaction solution in batches, and reacted for 5 to 10 hours;

[0045] (4) Pour the reaction solution into 25-500mL of water, the precipitated solid is the alkyl benzotriazole carboxylate, and filter it for later use.

[0046] The al...

Embodiment 2

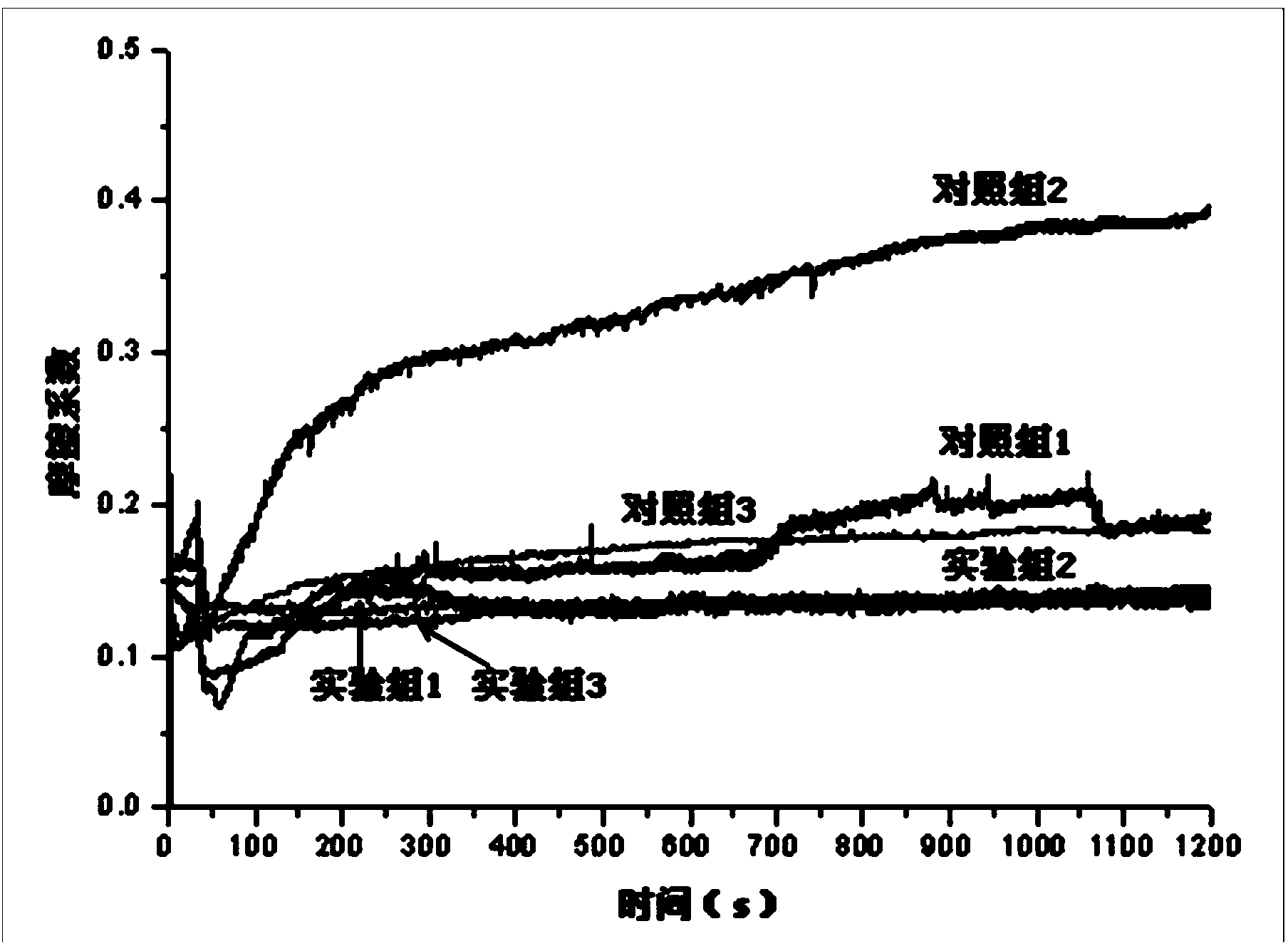

[0053] Example 2 Effect of Chain Length on the Lubrication Performance of Alkyl Benzotriazole Carboxylate and Comparison with the Lubrication Performance of Commercial Grinding Fluid

[0054] One of the proportions in Examples 1-6 is used to prepare a stock solution of water-soluble fully synthetic metal grinding fluid, in which benzotriazole carboxylate alkyl esters prepared by alkyl alcohols with different chain lengths are added; the stock solution is diluted 20 times to form a working solution , the lubricating performance of the working fluid was tested on the friction and wear test machine, and the lubricating performance was compared with the 20-fold diluted working fluid of commercial emulsified lubricant and fully synthetic grinding fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com