Grapheme-organic material layered assembling film and preparation method thereof

A technology of organic material layer and layered assembly, which is applied in the direction of coating, layered products, epoxy resin coating, etc., can solve the problems that have not attracted enough attention of people, and achieve light weight, excellent thermal conductivity and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of graphene

[0025] 5 g of graphite and 3.75 g of sodium nitrate (analytical pure) were added to the flask, and then 375 mL of concentrated sulfuric acid (analytical pure) was added. Then, in an ice-water bath, slowly add 22.5 g of potassium permanganate while stirring, the addition time is controlled at 1 h, and then kept for 2 h to cool down to room temperature. Stir at room temperature for five days. During these five days, the reaction solution first turned green, then dark brown, and finally brick brown, and became viscous. The reaction solution was slowly added into 700mL of 5wt% dilute sulfuric acid, the addition time was controlled at 1h, the stirring was kept, and the temperature was controlled at 98°C. The reaction solution was stirred at this temperature for another 2 h, and then cooled to 60 °C. Add 15 mL of hydrogen peroxide (30% aqueous solution), keep at 60° C. for 2 h, then cool down to room temperature, and stir for ano...

Embodiment 2

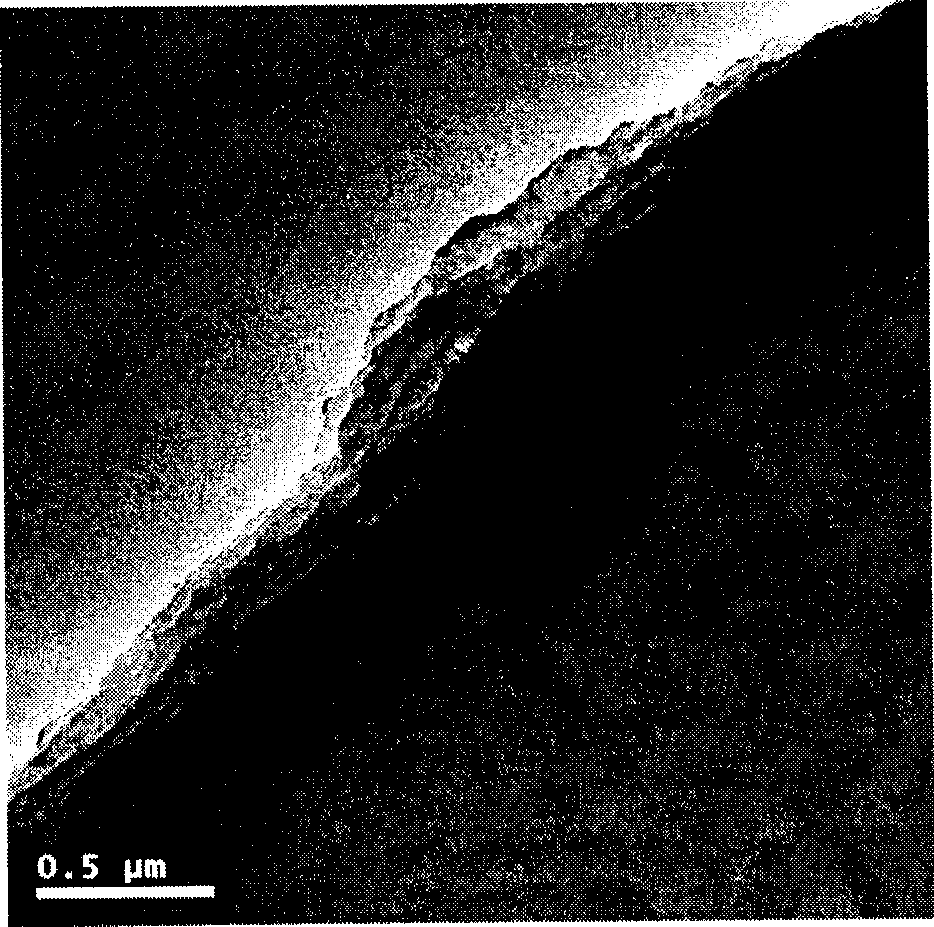

[0027] Preparation of raw material solution: 50mg graphene (prepared by the method in Example 1, average diameter 1-2 μm, thickness is about 0.7-1.4nm) is added in 250ml water, through ultrasonic wave (500W) treatment 30 minutes, make it dissolve completely ; Take 2g of polyethyleneimine (PEI, average molecular weight 10000) and dissolve it in 200ml of deionized water, stir it well and let it stand for use.

[0028] The preparation of graphene / polyethyleneimine layered self-assembled film goes through the following steps:

[0029] 1. Apply a sacrificial layer of polycellulose acetate (1wt.%, acetone solution) on the polytetrafluoroethylene substrate by spin coating, and let it dry naturally;

[0030] 2. Add polyethyleneimine solution dropwise to the substrate rotating at 3000 rpm, spin coating for 15 seconds, wash with water, dry at 60-80°C;

[0031] 3. Add the prepared graphene solution dropwise onto the substrate rotating at 3000 rpm, spin coat for 15 seconds, wash with wat...

Embodiment 3

[0034] Preparation of raw material solution: 200mg graphene (prepared by the method in Example 1, average diameter 5-10 μm, thickness is about 1-2nm) is added in 200ml ethanol, through ultrasonic wave (500W) treatment 40 minutes, make it dissolve completely After standing still for use; Epoxy resin (bisphenol A type, 618), low molecular weight polyamide and ferrocene are dissolved in the acetone solution by mass ratio 55 / 30 / 1, fully stir, and obtaining concentration is 50% solution.

[0035] Preparation of graphene / epoxy resin-ferrocene multilayer film:

[0036] 1. Apply a sacrificial layer of cellulose polyacetate (1wt.%, acetone solution) on the polytetrafluoroethylene substrate by spin coating, and dry it in the air;

[0037] 2. Dip the above substrate into the epoxy resin-ferrocene solution, pull it out after 2 seconds, and dry it at room temperature;

[0038] 3. Add the prepared graphene solution dropwise onto the substrate rotating at 3000 rpm, spin coat for 30 seconds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com